USER MANUAL

STM 550 / EMSI –ENOCEAN MULTISENSOR FOR IOT APPLICATIONS

© 2023 EnOcean | www.enocean.com F-710-017, V1.0 STM 550 User Manual | v1.7 | March 2023 | Page 5/112

9.8.12 STANDARD_TX_INTERVAL .................................................................... 51

9.8.13 THRESHOLD_CFG1............................................................................... 52

9.8.14 THRESHOLD_CFG2............................................................................... 54

9.8.15 LIGHT_SENSOR_CFG ........................................................................... 55

9.8.16 ACC_SENSOR_CFG .............................................................................. 56

9.8.17 SOLAR_THRESHOLD............................................................................. 57

9.8.18 SOLAR_TX_INTERVAL .......................................................................... 58

9.8.19 LIGHT_THRESHOLD ............................................................................. 59

9.8.20 LIGHT_TX_INTERVAL ........................................................................... 60

9.8.21 ACCELERATION_THRESHOLD ................................................................ 61

9.8.22 ACCELERATION_TX_INTERVAL .............................................................. 62

9.8.23 TEMPERATURE_THRESHOLD ................................................................. 63

9.8.24 TEMPERATURE_TX_INTERVAL ............................................................... 64

9.8.25 HUMIDITY_THRESHOLD........................................................................ 65

9.8.26 HUMIDITY_TX_INTERVAL...................................................................... 66

9.8.27 MAGNET_CONTACT_TX_INTERVAL......................................................... 67

9.8.28 ILLUMINATION_TEST_RESULT............................................................... 68

9.9 USER DATA ................................................................................................ 68

10 Mechanical interface .................................................................................... 69

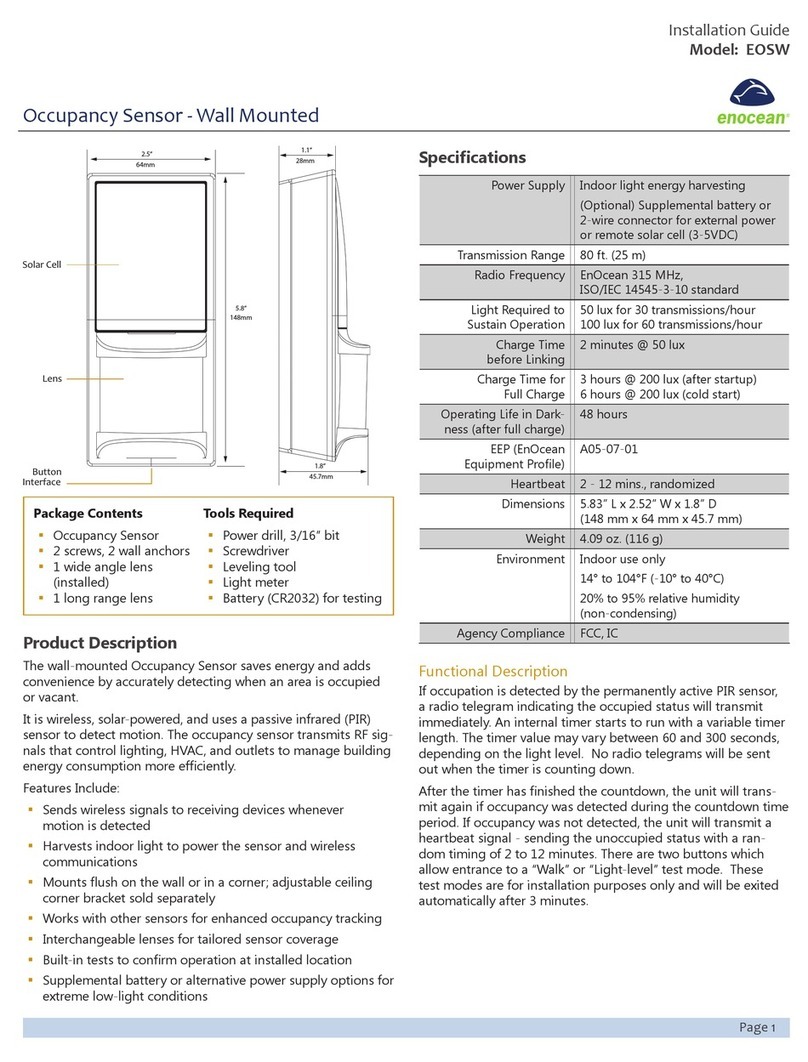

10.1 STM 550 .................................................................................................... 69

10.1.1 Top view............................................................................................. 69

10.1.2 Bottom view........................................................................................ 70

10.1.3 Cut view (A-A) .................................................................................... 71

10.1.4 Front view .......................................................................................... 71

10.1.5 Side view............................................................................................ 72

10.2 Housing ..................................................................................................... 73

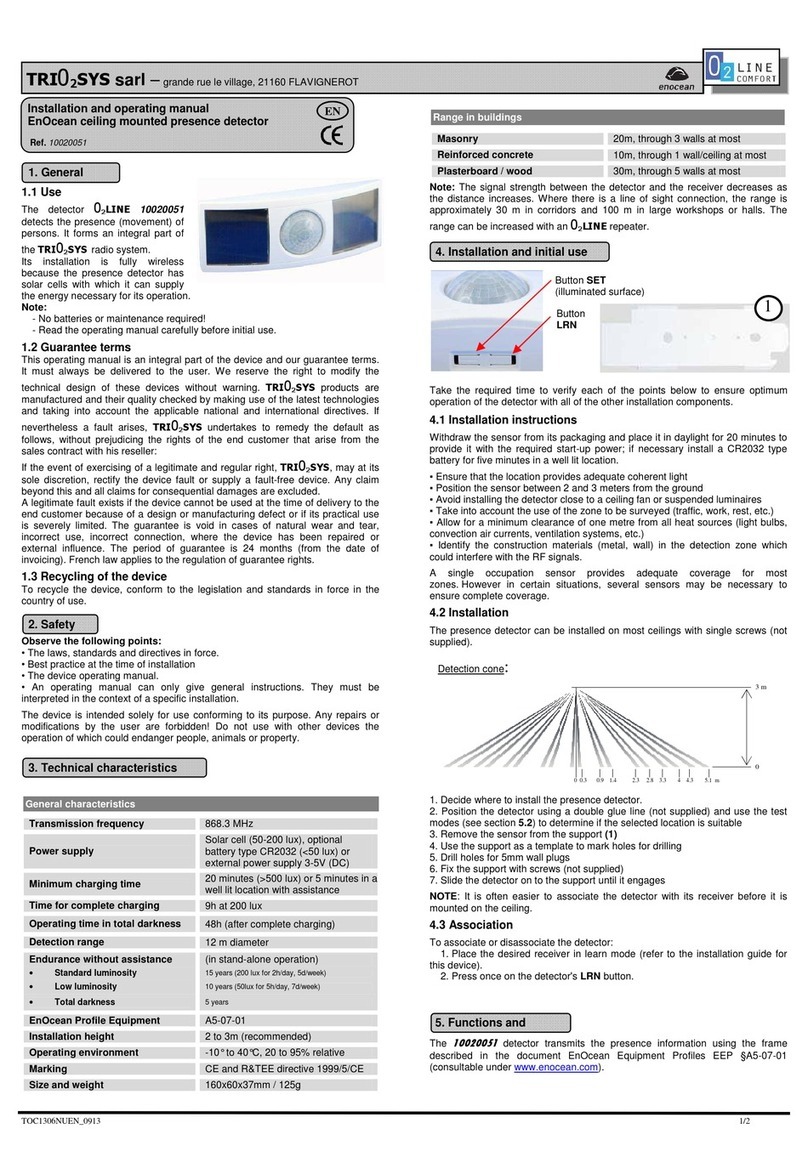

11 Installation recommendations ....................................................................... 74

11.1 Setup instructions ....................................................................................... 74

11.2 Installation location ..................................................................................... 75

11.3 Mounting options (Housing only) ................................................................... 75

11.4 Temperature and humidity sensor ................................................................. 76

11.5 Acceleration sensor...................................................................................... 77

11.5.1 Device orientation use cases ................................................................. 77

11.5.1.1 Temperature effects on acceleration vector .......................................... 78

11.5.2 Device acceleration use cases................................................................ 79

11.5.3 Installation suggestions ........................................................................ 79

11.6 Illumination measurement ............................................................................ 80

11.6.1 Ambient light sensor ............................................................................ 80

11.6.2 Solar cell ............................................................................................ 80

11.7 Magnet contact sensing................................................................................ 81

11.8 Energy harvesting ....................................................................................... 81

11.9 NFC configuration ........................................................................................ 82

12 Regulatory notes ......................................................................................... 83

12.1 European Union........................................................................................... 83

12.1.1 Declaration of conformity...................................................................... 83

12.1.2 Waste treatment.................................................................................. 83

12.2FCC (United States) ..................................................................................... 84