enraf 854 ATG Series User manual

Instruction manual 854 ATG Page 1

Instruction manual

series 854 ATG

level gauge

December 2005

Part no. 4416.220

Rev. 3

Enraf B.V.

P.O. Box 812

2600 AV Delft

Netherlands

Tel. : +31 15 2701 100

Fax : +31 15 2701 111

Website : http://www.enraf.com

Page 2

Copyright 1999 - 2005 Enraf B.V. All rights reserved.

Reproduction in any form without the prior consent of Enraf B.V. is not allowed. This manual is for information

only. The contents, descriptions and specifications are subject to change without notice. Enraf B.V. accepts no

responsibility for any errors that may appear in this manual.

The warranty terms and conditions applicable in the country of purchase in respect to Enraf B.V. products are

available from your supplier. Please retain them with your proof of purchase.

Preface

Instruction manual 854 ATG Page 3

Preface

This manual is intended for technicians involved with the commissioning and service of the Enraf series

854 Advanced Technology Gauge.

A description preceding the technical procedures gives the technical information necessary to understand its

functioning. It is recommended to read this description prior to performing any of the procedures.

For mechanical and electrical installation of the 854 ATG, refer to the Installation guide 854 Advanced

Technology Gauge. This manual describes the commissioning, maintenance and trouble shooting of the basic

854 ATG level measurement. Other features such as: level alarm outputs, analog level output, temperature

measurement, pressure measurement, etc. are describes in separate manuals. For an overview, refer to the list

of related documents in Appendix F.

Legal aspects

The information in this manual is copyright property of Enraf B.V., Netherlands.

Enraf B.V. disclaims any responsibility for personal injury or damage to equipment caused by:

Deviation from any of the prescribed procedures;

Execution of activities that are not prescribed;

Negligence of the general safety precautions for handling tools, use of electricity and microwave radiation.

EC declaration of conformity

This instrument is in conformity with the protection requirements of EC Council Directive 89/336/EEC.

The CE conformity marking fulfills the provisions of

EN 50081-2 Generic Emission Standard

EN 50082-2 Generic Immunity Standard

73/23EEC Low Voltage Directive

when installed, maintained and applied according to requirements as specified in this manual.

Additional information

Please do not hesitate to contact Enraf or its representative if you require additional information.

Table of contents

Page 4

Table of contents

Preface............................................................................. 3

1 Introduction ......................................................................... 6

1.1 Principleofmeasurement ........................................................ 6

1.1.1 Levelmeasurement...................................................... 7

1.1.2 Interfacebetweentwoproducts ............................................ 7

1.1.3 Relativedensity ......................................................... 7

1.2 Optionalfunctions .............................................................. 7

1.3 Remotemonitoring.............................................................. 8

1.4 Approvals(FM,CENELEC) ....................................................... 8

2 Safety .............................................................................. 9

2.1 Safety aspects of the 854 Advanced Technology Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Personalsafety ............................................................... 10

2.3 Safetyconventions............................................................. 10

3 Commissioning...................................................................... 11

3.1 Checks before starting the commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Installation of measuring drum and displacer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.1 Tools ................................................................ 12

3.2.2 Installationofmeasuringdrum ............................................ 12

3.2.3 Installationofdisplacer .................................................. 13

3.2.4 Unlocking (locking) the motor block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Programming(configuring)thegauge .............................................. 14

3.3.1 Introductionintoprogramming............................................. 14

3.3.2 Applypowertothe854ATG .............................................. 16

3.3.3 Selecting dimension and decimal separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.4 Tankandgaugedata.................................................... 18

3.3.5 Alarmsettings ......................................................... 20

3.3.6 Ullagereadout ......................................................... 21

3.3.7 Display control and password protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4 Levelcalibration............................................................... 23

3.4.1 Standardlevelcalibration ................................................ 23

3.4.2 Level calibration with a tank top reference stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4.3 Level calibration using the top of ball valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.4 Interfacemeasurement .................................................. 25

4 Operation .......................................................................... 26

4.1 Display ...................................................................... 26

4.1.1 XPUdisplay ........................................................... 27

4.1.2 XPU-2display ......................................................... 27

4.2 Repeatabilitytest .............................................................. 29

4.3 Locktest..................................................................... 29

4.4 Freezeandblockcommands..................................................... 30

4.5 Unlock ...................................................................... 30

4.6 Interfacemeasurement ......................................................... 31

4.7 Dipmode .................................................................... 31

4.8 Verifylevelcalibration .......................................................... 32

4.8.1 Verify level calibration against a tank top reference stop . . . . . . . . . . . . . . . . . . . . . . . . 32

4.8.2 Verify level calibration on top of ball valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.9 Dataitemsandoperationalcommands ............................................. 33

Table of contents

Instruction manual 854 ATG Page 5

5 Maintenance........................................................................ 34

5.1 Preventivemaintenance ........................................................ 34

5.2 Instrumentcovers ............................................................. 35

5.3 Drumcompartment ............................................................ 36

5.3.1 Detaileddescription..................................................... 36

5.3.2 Removingthemeasuringdrum ............................................ 37

5.3.3 Replacingthedrumbearings.............................................. 38

5.4 Theelectroniccompartment ..................................................... 39

5.4.1 Detaileddescription..................................................... 39

5.4.2 Dismantling the electronic compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.4.3 Replacingsoftware ..................................................... 41

5.4.4 InitializingNOVRAM .................................................... 41

5.5 Calibratingforcetransducer...................................................... 42

5.6 Synchronizingthereferenceencoder .............................................. 43

6 Troubleshooting .................................................................... 44

6.1 Problemswithdisplacermovement ................................................ 44

6.2 XPUerrorcode(itemEP) ....................................................... 45

6.3 SPUerrorcode(itemES) ....................................................... 45

6.4 SPUstatusrequest(itemQS) .................................................... 46

AppendixA Articleandpartnumbers ................................................. 47

Appendix B Additional information on displacers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

AppendixC ASCIItable ........................................................... 52

AppendixD Displayformats ........................................................ 53

AppendixE PCBlayout............................................................ 58

AppendixF Relateddocuments ..................................................... 59

Index ............................................................................. 60

Introduction

Page 6

Figure 1.1 Principle of measurement

1 Introduction

The Enraf 854 ATG (Advanced Technology Gauge) measures the liquid level and can be programmed to

measure two additional interface levels.

The 854 ATG has four programmable level alarms, and also provides diagnostic information. This information

can be displayed on the internal display, the Portable Enraf Terminal (PET) as well as on remote systems.

Optionally, the instrument can be provided with software for density measurement of the stored product.

The optional MPU board provides a 4 - 20 mA analog level output and can be used to adapt the 854 series level

gauge for control applications or analog recorders.

Spot temperature can be measured when the 854 ATG is equipped with an optional TPU-2 board (Temperature

Processor Unit), or HSU board (HART and Spot temperature processor Unit).

Average product temperature as well as average gas temperature measurement can be performed when the

854 ATG is equipped with the optional MPU, HPU or OPU board and a 862 MIR or 862 MIT unit.

Honeywell ST3000 series pressure transmitter can be connected via the optional OPU board.

®

Via the optional HPU or HSU board, HART pressure transmitter and/or a HART compatible external water

TM

bottom probe can be connected.

1.1 Principle of measurement

Introduction

Instruction manual 854 ATG Page 7

Refer to figure 1.1.

The principle is based on detection of variations in the buoyancy of a displacer. The displacer is suspended from

a strong, flexible measuring wire which is stored on a precisely grooved measuring drum.

The shaft of the drum is connected to the stepper motor via a magnetic coupling.

The apparent weight of the displacer is measured by a force transducer. The actual output of the force

transducer is compared with a desired value for the apparent weight of the displacer. If a discrepancy exists

between measured and desired value, an advanced software control module adjusts the position of the stepper

motor.

1.1.1 Level measurement

A level variation of product, in which the displacer is partially immersed, causes a change in buoyancy, which will

be detected by the force transducer. The resulting difference between measured and desired value will cause a

variation in the position of the stepper motor and consequently raise or lower the position of the displacer until

the measured value equals the desired value.

To avoid oscillations, a certain hysteresis and integration time is software adjustable. This results in a stable and

accurate averaged level measurement.

The stepper motor turns one revolution for every 10 mm of vertical movement of the displacer.

One revolution is divided into 200 steps, therefore one step is equivalent to 0.05 mm. This resolution is direct

consequence of the stepper motor principle. The correct functioning of the stepper motor is continuously

checked. This is achieved by decoding the unique pattern of an encoder disk mounted on the motor shaft.

1.1.2 Interface between two products

Measurement of the interface between two products is achieved by sending an interface command to the gauge.

This causes the stepper motor processor to move the displacer to a position where the apparent weight of the

displacer matches a pre-programmed set point.

1.1.3 Relative density

To measure the relative density, the displacer is positioned at specific heights and the apparent weight of the

displacer at each height is measured. Knowing the volume of the displacer, its weight in air, and the measured

apparent weight, the relative density of the product at each position of the displacer can be calculated.

The software for the density measurement is available as an option.

1.2 Optional functions

Optional functions can be added in the 854 ATG when using one of the following optional boards form the

854 family: TPU-2, MPU, HPU, OPU or HSU board.

Alarm relays are optionally available on the SPU II board. Density measurement is an optional module of the

SPU software. An XPU-2 board (in stead of the standard XPU board) is required with the following options:

external HART water bottom probe (e.g. Enraf 964 WaterScout), RS-232C/RS-485 communication, and

connection for a 977 Tank Side Indicator.

The table on next page gives an overview of all options and related manuals.

Introduction

Page 8

Option Board Refer to

Level alarm output relays SPU II Instruction manual SPU II Hard alarm output contacts

(or digital outputs)

Density measurement SPU II Instruction manual 854 density option

Analog level output (4 - 20 mA) MPU Instruction manual MPU analog 4 - 20 mA

Spot temperature measurement TPU-2 or Instruction manual TPU-2 / HSU option board

HSU

Average temperature measurement MPU or Instruction manual 862 MIT

via 864 MTT and 862 MIT HPU or

OPU

Average temperature measurement MPU or Instruction manual 862 MIR

via 863 MRT and 862 MIR HPU or

OPU

Pressure measurement for mass, HPU or Instruction manual HIMS

density and/or vapour pressure HSU

via HART protocol

Pressure measurement for mass, OPU Instruction manual HIMS

density and/or vapour pressure

via Honeywell DE protocol

Water bottom measurement via HPU or Instruction manual Water bottom measurement

external probe HSU and via capacitive probe

XPU-2

Connection for 977 TSI Tank Side XPU-2 Instruction manual 977 TSI Tank Side Indicator

Indicator

RS-232C / RS-485 communication XPU-2 Instruction manual XPU-2 option RS-232C / RS-485

1.3 Remote monitoring

Central monitoring of the 854 ATG is possible via tank inventory systems such as ENTIS+ and Entis Pro.

Remote display can be achieved by using the 877 FDI field indicator, the 977 TSI tank side indicator or the 878

CPI panel indicator.

1.4 Approvals (FM, CENELEC)

The Enraf 854 Advanced Technology Gauges are certified by official testing institutes as Factory Mutual and

PTB (CENELEC) to be explosion proof (suitable for zone 0). The gauges are also approved and certified by

Weights and Measures (W&M) or Custom and Excise authorities for legal use and custody transfer.

Safety

Instruction manual 854 ATG Page 9

Warning

The 854 ATG is designed to measure the liquid level in storage tanks. The instrument is

suitable for flammable liquids (refer to the explosion proof certification data below).

For other applications contact Enraf.

Caution

The 854 ATG is an explosion proof instrument with intrinsically safe output/input circuits.

Modification to the instrument may only be carried out by trained personnel which is authorized by Enraf.

Failure to adhere to this will invalidate the approval certificate.

The safety approval can become invalid when the instrument housing is damaged.

Directly inform Enraf in this case to verify if the instrument still can be used.

2 Safety

2.1 Safety aspects of the 854 Advanced Technology Gauge

For the medium pressure versions (till 6 bar), the 854 ATG drum compartment housing is of aluminium, and for

the chemical version the drum housing is of stainless steel.

For the high pressure version (max 40 bar), the 854 ATG housing is of stainless steel.

The housing of the 854 ATG is explosion proof:

EEx de IIB T6 acc. to CENELEC and in addition zone 0, certified by PTB Germany

(PTB no.: Ex-89.C.1035)

Class I, Division 1, Groups B, C, & D acc. to ANSI/NFPA no. 70, certified by Factory Mutual Research

USA (FM no.: 3Q2A9.AX).

Ex d IIB T6, IP54, Class I Zone 1, according to SAA.

The environmental conditions for the 854 ATG are:

ambient temperature : -40 to +85 °C (-40 to +185 °F)

operating pressure : max. 6 bar for medium pressure and chemical version

max. 40 bar for high pressure version

relative humidity : 0 - 100 %

ingress protection : IP65 (NEMA 4), suitable for outdoor installation

over voltage category : II

pollution degree : I

The drum compartment, which is in contact with the tank atmosphere, is separated from the electronic

compartment. A magnet coupling transfers the measuring drum movement (and thus the displacer movement) to

the electronic compartment.

The wiring for intrinsically safe options, such as temperature or pressure measurement, is fed via two separate

cable entries.

Optionally, the covers of the drum compartment, electronic compartment and terminal compartment can be

provided with blocking facilities which prevents unauthorised opening.

Programming (configuration) of the 854 ATG can be done by the 847 PET (Portable Enraf Terminal), which is an

intrinsically safe device and is connected to the 854 ATG via an infra-red coupling.

Safety

Page 10

Warning

In hazardous areas it is compulsory to use personal protection and safety gear such as:

hard hat, fire resistive overall, safety shoes, safety glasses and working gloves.

Avoid possible generation of static electricity. Use non-sparking tools and explosion proof testers.

Do not open any of the instrument covers while power is still connected.

Never start working before the work permit is signed by all parties.

Pay attention to the kind of product in the tank. If any danger for health, wear a gas mask

and take all necessary precautions.

2.2 Personal safety

Safe execution of the procedures in this manual requires technical experience in handling tools, and knowledge

of safety regulations in handling electrical installation in hazardous environments.

The sequence of steps in a procedure may also be important from the point of view of personal safety and

prevention of damage; it is therefore advised not to change the sequence of procedure steps or modify any

procedure in any other way.

2.3 Safety conventions

"Warnings", "Cautions", and "Notes" have been used throughout this manual to bring special matters to the

immediate attention of the reader.

A Warning concerns danger to the safety of the technician or user;

A Caution draws attention to an action which may damage the equipment;

A Note points out a statement deserving more emphasis than the general text, but does not deserve a

"Warning" or a "Caution".

Commissioning

Instruction manual 854 ATG Page 11

Caution

Keep screw thread from the compartment covers free from dirt.

Grease them lightly with an acid-free grease before closing the instrument.

When closing, turn the covers counter-clockwise until the thread clicks into place, then turn clockwise.

3 Commissioning

3.1 Checks before starting the commissioning

Examine the mechanical and electrical installation after the 854 ATG is installed on the tank.

Refer to the installation guide 854 Advanced Technology Gauge.

Check the correct orientation of the gauge with respect to the tank.

Check that the gauge is leveled within 2°.

Check that the O-ring and gaskets are supplied.

Check that the mains voltage selector of the 854 ATG indicates the local mains supply.

Check the connections of all electrical cabling.

Check the ground connection of the 854 ATG to the tank.

Check that non-used cable inlets are sealed with appropriate stopping plugs.

Close carefully all covers (mind the O-rings) before any electrical power is applied.

335

335

10

8

2

9

11

41

7

35

6

Commissioning

Page 12

Figure 3.1 Tool set for 854 ATG (part no.1854.062)

Figure 3.2 Installing the drum

3.2 Installation of measuring drum and displacer

3.2.1 Tools

It is recommended to use an 847 PET (Portable Enraf Terminal) to load the different parameters.

A tool set for commissioning and maintenance is available from Enraf (refer to figure 3.1).

Item Description

1 Allen key 2 mm

2 Allen key 3 mm

3 Allen key 4 mm

4 Allen key 5 mm

5 Allen key 8 mm

6 Drum bearing puller

7 Test magnet

8 Screwdriver for Allen key screws M4

9 Screwdriver for Allen key screws M6

10 Pipe wrench 27 mm

11 Tommy bar

3.2.2 Installation of measuring drum

Remove the drum compartment cover (rear cover).

Check whether the drum shaft is properly positioned in the drum.

Attach the smallest of the four test weights (or another small

weight) to the measuring wire, remove the rubber band securing

the measuring wire and feed the wire and test weight through the

neck of the gauge (refer to figure 3.2).

Insert the measuring drum onto its bearings.

Check the axial free-play of the drum as follows:

Push the drum towards the magnet cap in such a way that the

drum shaft meets the magnet cap. Release the drum.

Bring the drum in a slight vibration. The drum and drum shaft

should now move towards you with a axial movement of

minimum 1 mm and maximum 2.5 mm.

Note the engraved drum circumference value on a piece of paper for later use. There are several numbers

engraved on the measuring drum. The number you are looking for has a value of approximately 338 mm

(for example: 338.028).

Motor locked

Motor unlocked

span

wire

Commissioning

Instruction manual 854 ATG Page 13

Figure 3.3 Mounting displacer

Figure 3.4 Motor block (un)locked

3.2.3 Installation of displacer

If a density displacer is used, note the engraved displacer weight

and displacer volume on a piece of paper for later use.

Remove the test weight and attach the displacer to the wire

through a mounting hatch.

Note:

If there is no mounting hatch available, the displacer can be

installed by temporarily removing the gauge from the nozzle.

To provide electrical contact between the measuring wire and

displacer, thus permitting the discharge of static electricity and

preventing loss of the displacer, the displacer must be secured

to the measuring wire.

Take an extra piece of wire and fasten one end to the measuring

wire, pass the other end through the hole in the end of the

displacer hook. Secure this end several times around the hook

(refer to figure 3.3).

Close the drum compartment cover.

3.2.4 Unlocking (locking) the motor block

The motor block is locked during transport to protect the force transducer.

After installing the measuring drum and displacer, the motor block locking device must be unlocked.

Open the electronic compartment cover (front cover).

Locate the transport bracket (refer to figures 3.4).

Loosen (do not remove) the Allen key screw and turn the

transport bracket the opposite way.

Use screwdriver for Allen key screws M4

(item 8 of the Enraf tool set).

Fix the Allen key screw of the transport bracket.

Check the span wire. It should always be under tension while

both ends are correctly positioned in the levers of the motor

block and force transducer.

Close the electronic compartment cover.

Note:

Use the same procedure for locking the motor block if the 854 ATG needs to be removed.

Commissioning

Page 14

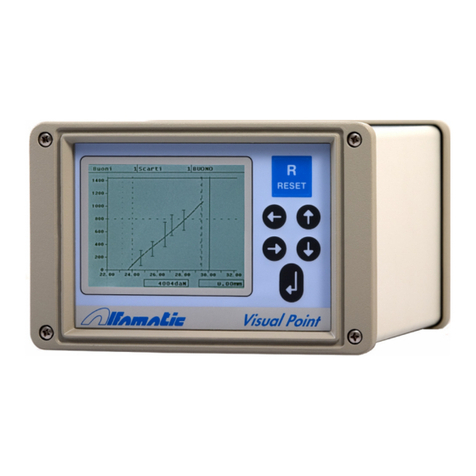

Figure 3.5 Programming the 854 ATG by using the

847 PET

3.3 Programming (configuring) the gauge

3.3.1 Introduction into programming

The 854 ATG is a field-configurable multi-processor

instrument. The instrument can be totally programmed out

in the field, or remotely, without opening the gauge.

It is recommended to use an 847 PET (Portable Enraf

Terminal) to load the different parameters.

It is coupled to the 854 ATG via an infra-red coupling.

The 847 PET is intrinsically safe and waterproof (IP65)

and consists of a full ASCII membrane keyboard and an

LCD display (refer to figure 3.5).

Alternatively, the Enraf service tool Ensite can be used to

configure the instrument.

The Ensite program runs under MS- or PC-DOS 3.0 or

higher. It is recommended to use the service tool to make

a log file of the instrument.

A log file contains all important settings and the

information is stored on the hard disk (or diskette).

For more information, refer to the Instruction manual

Ensite service tool.

The item concept

All parameters, settings, etc, are accessible via so-called items. These items all have unique 2-letter

abbreviations which allow easy access and programming. In this manual, items are printed bold.

There are three different type of items:

Type of item Description

Commands For example: EX (exit). After the EX command the instrument start initialising and

These will force the gauge to execute a special task or function.

modified NOVRAM settings become active.

Data requests For example: JS (jumper setting). Item JS returns the jumper setting on the XPU(-2)

Items for request of setup or measuring data from the gauge.

board. Some of the data items are read-only.

NOVRAM settings down, are stored in NOVRAM. The NOVRAM is a non-volatile RAM memory which

All parameters which can be programmed and should not be lost after power break

does not require battery back up.

Data stored in NOVRAM can be protected by a password and by the Weights & Measures (W&M) jumper on the

XPU(-2) board (refer to figure 3.6).

Protection levels are provided for all NOVRAM items, depending on the importance of an item. Protection level 1

is protected by password 1 (W1) and protection level 2 is protected by password 2 (W2).

If the NOVRAM is protected by the W&M jumper J(A)3 level 2 NOVRAM items cannot be changed without

opening the gauge, thereby breaking off the sealing.

Most data requests and commands are not password protected.

NOVRAM

EPROM

PROCESSOR

CN 1

X.P.U.

VIEW

ANGLE

P1

ST7

ST6

ST4

ST5

ST2

ST3

ST1

CN2

JA1

JA2

JA3

JA4

JA5

JA6

JA7

10EPROM

NOVRAM

J6

J5

J4

J3

J2

J1

10

XPU XPU-2

Contrast

Commissioning

Instruction manual 854 ATG Page 15

Figure 3.6 Jumpers on XPU and XPU-2 board

Protection level 1

Access to items which are not directly measurement related, such as high level alarm (HA), tank identifier (TI),

etc. is protected by password 1 (W1). It is possible to modify these data only after entering the correct level 1

password W1=XXXXXX, where XXXXXX is the level 1 password.

Password W1 itself can be read protected by means of jumper J(A)1 on the XPU(-2) board.

Protection level 2

All NOVRAM items which affect the (remote) level reading, such as reference level (RL), transmission address

(TA), etc. are protected by password 2 (W2). It is possible to modify these data only after entering the correct

level 2 password W2=XXXXXX, where XXXXXX is the level 2 password. Additional measurement related items,

such as temperature items, can also be protected by password 2.

Password W2 itself can be read protected by means of jumper J(A)2 on the XPU(-2) board.

In protection level 2, the items which resides under protection level 1 can also be modified.

W&M protection

Items under protection level 2 can also be protected by jumper J(A)3 on the XPU(-2) board. If this jumper is

placed in position 1, the write access is completely disabled. Also issuing the correct level 2 password will not

work.

The table below gives an overview of the XPU(-2) jumper functions (refer also to figure 3.6).

Jumper (XPU / XPU-2) Function Position “0” Position “1”

JA1 / J1 read password 1 not protected protected

JA2 / J2 read password 2 not protected protected

JA3 / J3 W&M protection not protected protected

JA4 NOVRAM initialising active not active

JA5 - JA7 / J4 - J6 spare

Commissioning

Page 16

How to program?

When the 847 PET is plugged into the 854 ATG and the instrument is powered, the PET can be switched on.

By operating the keyboard, items can be requested and settings can be changed.

For example:

Item (+ setting) Description

(typing in on PET keyboard)

RL <enter> Request for the current value of item RL (reference level).

The reply on the PET display will be: RL+000.0000

This means: the reference level is: 0 metres.

W2=ENRAF2 <enter> Enter protection level 2 (default level 2 password is: ENRAF2).

RL=+012.3400 <enter> Give the required setting for the reference level

(here, as an example: 12.34 metres).

EX <enter> Exit protection level 2.

The 854 ATG will now initialise and the new entered value of the

reference level will become active after the re-start.

Recommended programming sequence

The 854 ATG is already pre-programmed at the factory. However, several parameters, application depended,

must be programmed at commissioning.

Step 1 Start with programming / checking of the format depended items (refer to section 3.3.3)

Step 2 Proceed with programming / checking of the items for the standard level measurement without optional

functions (refer to sections 3.3.4 to 3.3.7).

Step 3 Check with the identification code on the label of your 854 ATG whether the gauge is equipped with

one or more optional functions, and program the items for that options (refer to the appropriate option

manuals).

3.3.2 Apply power to the 854 ATG

To program the gauge, power must be switched on. That should be done in this stage.

Note:

After the initialisation of the gauge, the displacer is moving down, because the default level setting is at 26

metres.

If the displacer movement is unwanted in this stage, issue the FR command by the PET. This action freezes the

displacer position. This command must be repeated after each EX (exit) or RS (reset) command.

The freeze command can be cancelled by the UN (unlock) command.

Commissioning

Instruction manual 854 ATG Page 17

3.3.3 Selecting dimension and decimal separator

When one of the dimension items are changed, all items with related formats have to be changed and the values

must be converted to the new dimension. The same applies for the decimal separator.

Note:

When the 854 ATG is equipped with an XPU-2 board (can be recognised by requesting the software version

item SV reads: XPU ... Hx.x), then all dimension depended items will be automatically changed and the

values will be automatically converted.

Item Name Description

W2= Protection level 2 Enter protection level 2 (default password: ENRAF2)

LD= Level dimension Selects and converts the level dimension.

This item contains one character, which can be:

M : metres; format: sign X X X separator X X X X

F : feet; format: sign X X X X separator X X X

I : inches; format: sign X X X X X separator X X

P : fractions; format: sign X X ’ X X ” X X

DP= Decimal separator The item DP (decimal separator) can be:

.: point or

,: comma

..= format depended items Not required with XPU-2 board.

Program all level dimension and/or decimal separator depended items

to the new dimension and/or separator. Refer to the table below for an

overview of these items.

EX Exit Exit protection level

Items from which the format depends on the level Additional items from which the format

dimension and decimal separator depends on the decimal separator

AH HL LP *) MP *) 28 *) M1 *)

AM *) IL *) LS *) MZ 29 *) M2 *)

AN *) L2 MG *) RL DL *) M3 *)

DB L3 MH RP *) DU *) O1 *)

DH LA MI *) TT H1 *) O2 *)

DZ LL MK *) UR H2 *) O3 *)

HA LM *) ML H3 *) PH *)

HH LN *) MO *) HD *) RO *)

*) The presence of these items depends on the installed option board

Standard floating point format

Some items are expressed in a floating point format. The floating point format is a fixed format;

Standard floating point format: sign point M M M M M M M M E sign P P

where: M = Mantissa

P = Exponent

Gauge tank top TT

Motor limit switch MH

High-high alarm level HH

High alarm level HA

Liquid level RL (used at

calibration procedure)

Low alarm level LA

Low-low alarm level LL

Dipping datum point

Motor limit switch low ML

Lock-test limit switch level MZ

Commissioning

Page 18

Figure 3.7 Tank related level items

3.3.4 Tank and gauge data

Refer to figure 3.7 for the tank related data.

Commissioning

Instruction manual 854 ATG Page 19

Item Name Description

W2= Protection level 2 Enter protection level 2 (default password: ENRAF2)

TT= Tank top Format according to item LD. The tank top level must be set for

correct wire weight compensation. The value you enter now, is

overwritten when the level calibration with displacer stop is used.

MH= Motor limit switch high Format according to item LD. This is the highest allowed position for

the displacer during normal operation.

MZ= Lock test limit switch level Format according to item LD. Item MZ sets the highest displacer

position during a lock test.

ML= Motor limit switch low Format according to item LD. This is the lowest allowed position for

the displacer during normal operation.

DC Drum circumference Standard floating point format; units: metres.

Check whether the pre-programmed drum circumference is in

accordance with the engraved value of the installed measuring drum.

If that is not correct, enter the engraved drum circumference.

DW Displacer weight Standard floating point format; unit: grams. The standard displacers

have a weight of 223 g. If a density displacer is used, check whether

the engraved weight is programmed correctly in this item. If not, then

enter the engraved displacer weight.

DA Displacer area Standard floating point format; units: cm .

2

Check whether the pre-programmed displacer area is in accordance

with the used type of displacer. Refer to Appendix B for information on

the displacer area values. If not correct, program the correct displacer

area.

S1 Set point Standard floating point format; units: grams. With the standard

displacers, the interface 1 set point (level surface) is set to 208 g.

If a density displacer is used, program S1 as: (DW - 15).

TA= Transmission address Two digits. The transmission address identifies the gauge on the Enraf

2-wire field bus. Each gauge must have a unique address, and hence

TA must be programmed differently. When connected to an 858 CIU,

please note that the 858 CIU has three highways, containing the

following transmission addresses:

CIU highway Transmission address (TA)

TL 1 00 - 29

TL 2 30 - 59

TL 3 60 - 99

TI= Tank identifier Six characters. Used as a label; the tank name can be programmed in

the tank identifier item (spaces are not allowed!).

TS= Transmission speed Four digits; either 1200 (default) or 2400. Units: baud

GT= Gauge type One character. Represents the gauge type. For the 854 ATG, GT=B.

EX Exit Exit protection level 2. The gauge wil now initialize and after start-up,

the modified settings become active.

Commissioning

Page 20

Example:

On tank 102 is the nozzle height 21.350 m and the nozzle length is 300 mm. The displacer may not enter the

nozzle. The maximum operating level is 19.1 metres. Because of sludge, the motor limit switch low must be

set on 300 mm. A standard 90 mm carbon teflon displacer is used and the drum circumference is

338.025 mm. The gauge is connected to CIU highway TL1 and the address is chosen as 02. The level

dimension is metres.

Item (+setting) Description

W2=ENRAF2 <enter> Enter protection level 2 (ENRAF2 is the default level 2 password).

TT=+021.3500 <enter> Tank top is 21.35 metres.

MH=+021.0500 <enter> Motor limit switch high set at 21.35 - 0.3 = 21.05 metres.

MZ=+020.0000 <enter> Lock test limit switch level is set between maximum operating level

and MH.

ML=+000.3000 <enter> Motor limit switch low set at 0.3 metres.

DC <enter> Check whether the drum circumference is correct; if not, change it.

DW <enter> Check whether the displacer weight is correct; if not, change it.

DA <enter> Check whether the displacer area is set correct; if not, change it.

S1 <enter> Check whether the set point 1 is set correct; if not, change it.

TA=02 <enter> The transmission address becomes: 02.

TI=TK-102 <enter> Tank identifier programmed as TK-102.

TS <enter> Check whether the transmission speed is correct; if not, change it.

GT <enter> Check whether the gauge type is set correct; if not, change it.

EX <enter> Exit protection level.

3.3.5 Alarm settings

Refer to figure 3.7. The high level alarm (HA) and low level alarm (LA) conditions are transmitted to the host via

the 2-wire Enraf field bus (or optional RS-channel).

Item Name Description

W2= Protection level 2 Enter protection level 2 (default level 2 password: ENRAF2).

AH= Level alarm hysteresis Format according to item LD. Sets alarm hysteresis.

HA= High level alarm Format according to item LD. High level alarm set point.

HH= High high level alarm Format according to item LD. High high level alarm set point.

LA= Low level alarm Format according to item LD. Low level alarm set point.

LL= Low low level alarm Format according to item LD. Low low level alarm set point.

EX Exit Exit protection level.

Table of contents

Other enraf Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Mitutoyo

Mitutoyo 572-200-20 manual

Vega

Vega VEGACAP 64 operating instructions

Zorg

Zorg 3201 Installation & operating manual

Extech Instruments

Extech Instruments 382095 user manual

Endress+Hauser

Endress+Hauser Liquiphant FTL64 operating instructions

Digital Systems

Digital Systems DSF22 Installation and setup guide