enraf Ensite Pro User manual

Instruction manual Ensite Pro Configuration Tool Page 1

Instruction manual

Ensite Pro

Configuration Tool

Version: 2.0

June 2001

Part no.: 4416.593

Enraf B.V.

P.O. Box 812

2600 AV Delft

Netherlands

Tel.: +31 15 2698600, Fax: +31 15 2619574

Email: [email protected]

http://www.enraf.com

Offices in: Netherlands - France - Germany - Russia - UK - USA - China - Singapore

Page 2

Copyright 1999 - 2001 Enraf B.V. All rights reserved.

Reproduction in any form without the prior consent of Enraf B.V. is not allowed.

This instruction manual is for information only. The contents, descriptions and specifications are

subject to change without notice. Enraf B.V. accepts no responsibility for any errors that may

appear in this instruction manual.

The warranty terms and conditions for Enraf products applicable in the country of purchase are

available from your supplier. Please retain them with your proof of purchase.

Preface

Instruction manual Ensite Pro Configuration Tool Page 3

A Caution draws attention to an action which may damage

(the operation of) the equipment.

A Note points out a statement deserving more emphasis than the

general text.

Preface

This manual describes how to work with the configuration tool Ensite

Pro. It has been written for the technicians involved in the

commissioning and service of the series 880 CIU Prime and Plus.

Safety and prevention of damage

‘Cautions’ and ‘Notes’ have been used throughout this manual to

bring special matters to the immediate attention of the reader.

Legal aspects The information in this instruction manual is copyright property of

Enraf B.V., Netherlands.

Enraf B.V. disclaims any responsibility for personal injury or damage

to equipment caused by:

• Deviation from any of the prescribed procedures;

• Execution of activities that are not prescribed;

Additional information

Please do not hesitate to contact Enraf or its representative if you

require additional information.

Table of contents

Page 4

Table of Contents

Preface ......................................................................3

Introduction ...................................................................6

Ensite Pro configuration tool - General ............................................. 7

Configuration Procedure ........................................................ 8

Procedure steps ........................................................... 8

Preparation ...................................................... 8

Retrieving configuration data of gauges ......................................... 9

Configuration of the Tanks ................................................... 9

Configuration of CIU Prime’s ................................................. 9

Configuration of CIU Plus’s .................................................. 10

Linking Gauges, Tanks and CIU’s ............................................ 10

Downloading configuration data .............................................. 10

Start Ensite Pro ..............................................................11

Select site ...................................................................13

Global settings ............................................................... 14

Configure data inputs ..........................................................17

Gauge ..................................................................18

Level ...................................................................20

Water ..................................................................21

Temperature .............................................................22

Density .................................................................23

Pressure ................................................................24

Vapour .................................................................25

Scan ...................................................................26

Tank ...................................................................27

Configure tanks ..............................................................28

Tank ...................................................................29

Product .................................................................30

Vapour .................................................................32

Shell ...................................................................33

Flow ...................................................................34

Roof ...................................................................35

TCT....................................................................36

Links ...................................................................37

Configure CIU Prime ..........................................................38

Table of contents

Instruction manual Ensite Pro Configuration Tool Page 5

HostPort 1 ...............................................................39

HostPort 2 ...............................................................40

Hot standby .............................................................. 42

FieldPorts ...............................................................43

Tambient ................................................................46

Configure CIU Plus ............................................................ 47

HostPorts ...............................................................48

Modbus settings ..............................................................50

Data ...................................................................50

Tanks ..................................................................51

Entities .................................................................52

Hot standby .............................................................. 53

FieldPort 1 & 2 ...........................................................55

Configure links ............................................................... 56

Data inputs ..............................................................56

Tanks ..................................................................57

CIU Prime ...............................................................58

Communication setup .......................................................... 59

Download configuration ........................................................ 61

Upload configuration .......................................................... 63

Service note(s) ...............................................................65

Set date and time .............................................................66

Print configuration ............................................................ 67

Show diagnostic data ..........................................................69

Tank viewer .................................................................72

Scan viewer ................................................................. 73

Help .......................................................................74

User privileges ............................................................... 75

Stop Ensite Pro ..............................................................76

Appendix A: related documents .................................................. 77

Introduction

Page 6

Introduction

The configuration of the new tank inventory system consists of

modular parts:

• Entis Pro

• CIU Plus

• CIU Prime

• field instrumentation

Entis Pro This system displays calculated data from the CIU Plus.

It is a Windows NT based program, displaying data in windows,

®

boxes, tables, graphs, etc.

CIU Plus This unit calculates volume and mass. It requests input data from the

CIU Prime and calculates all other data. It presents data to higher

layered systems like Entis Pro, SCADA, DCS, ENSITE, etc.

CIU Prime This unit is an interface between the field instrumentation

(e.g. 854 ATG, 873 SmartRadar, etc.) and inventory systems

(CIU Plus, PLC, ENSITE, etc.).

Field instrumentation

The instruments in the field collect data such as level, temperature,

density and/or pressure. The instruments are based on several

principles: mechanical, servo, radar, hydrostatic and capacitive or a

combination. The instruments measure the data and transmit it upon

request of higher layered systems.

Ensite Pro Ensite Pro is a configuration tool for commissioning, diagnostics and

documentation of the series 880 CIU Prime / Plus.

Commissioning

Some information will be asked to fill in, needed to program the CIU

Prime / Plus. Ensite Pro automatically puts the input on the right

(default) positions.

Diagnostics

The build in diagnostic data views, reads and writes data direct from

and to the CIU Prime / Plus.

Documentation

The whole configuration can be printed to have a hard back-up.

See later in this manual.

Ensite Pro configuration tool - General

Instruction manual Ensite Pro Configuration Tool Page 7

Ensite Pro configuration tool - General

The configuration tool works with windows. Within these windows are

buttons, on which the function is written. One of the characters on a

button is underlined.

Throughout the configuration tool, common buttons are used.

Their description is given once:

Press the ‘Ok’-button to set the parameters and work with it

accordingly.

Press the ‘Cancel’-button to ignore any changes made. The program

returns to the previous window. In some cases this button has been

renamed into Close”

Press the ‘Apply’-button to set the parameters and work with it

accordingly, but remain in the active window.

Check the ‘Advanced’-button to activate the advanced part in the

active window.

Activate functions

The function of a button can be activated in several ways:

- mouse

•move the mouse pointer to the button and click the left mouse

button

- ‘Alt’-key

•press the ‘Alt’-key simultaneously with the underlined character

key of the text on the button

- ‘Tab’-key

•press the ‘Tab’-key to scroll over all buttons. When the desired

button is reached (marked), press the ‘Enter’-key

Configuration procedure

Page 8

Configuration Procedure

This chapter describes the general configuration procedure for the

880 CIU Prime, CIU Plus. For programming the 880 series CIU’s, it is

necessary to use

Ensite Pro.

It is programmable to communicate via one of the higher levels, i.e.

via a CIU Plus to a CIU Prime, or even via Entis Pro to any of the

connected CIU’s.

Procedure steps The complete configuration procedure consists out of the

following steps:

•Preparation

•Retrieving configuration data of gauges.

•Configuration of Tanks

•Configuration of the CIU Prime(s)

•Configuration of CIU Plus(‘s)

•Linking Gauges, Tanks and CIU’s

Preparation Before you start configuring 880 series CIU and possible one or

more Entis Pro stations, certain preparations are necessary.

Be sure that the following information is available:

•Site layout

•Field cabling information (which gauges are connected on the

same pair of field wires, etc.)

•Tag names of field devices (gauges, CIU and tanks)

•Tank information (strapping tables, or tank capacity tables, roof

details, etc.)

•Information on the types of stored product

•Host communication setup

(if applicable, i.e. modbus memory maps, etc.)

•Modems and possible other communication hardware connected

to the CIU’s

The first step in Ensite Pro is the creation of a site.

This allows the program to store multiple configuration sets, with each

a separate database. After a new site has been created, the program

will prompt for a set of global settings. These settings are required for

initiating the configuration database.

Once the global settings are entered, Ensite Pro will create a site

database. If there is a .LOG file available for this gauge it can be

extracted by Ensite Pro. The data extraction pre-sets all the relevant

configuration parameters. The next step is the creation off all tanks.

Configuration procedure

Instruction manual Ensite Pro Configuration Tool Page 9

Retrieving configuration data of gauges

As first step the gauges should be configured correctly. This can best

be done by means of the DOS program ENSITE.

With ENSITE the so called .LOG files can be created. These .LOG

files contain all the programmable settings of relevant gauge.

If no gauges are installed yet, it is also possible to prepare these in

ENSITE. They can then later be down loaded into the gauge.

Configuration of the Tanks

Also the creation of the tanks is a straightforward process.

At the creation of a new tank, the user is always prompted for a name.

Preferably use the same name as the name already in use on site.

Once the tank has been created, the user has to enter specific tank

details, like Tank shape, Roof details, etc.

Tank strapping tables or capacity tables can be linked via an external

file. This file needs to be conform the TCT specification as specified

in this manual. The format is a simple ASCII, comma delimited format.

The straps can either be manually entered, or be calculated out of a

formula, depending on what information is available. The strapping file

can contain a maximum of 2000 straps. The total capacity of the CIU+

is 20000 straps.

The data can best be prepared by means of a spreadsheet program

like Excel or Lotus 123. Users already using Entis+, can contact the

factory for a TCT extraction program.

This program extracts the strapping table out of the internal Entis+

database, and converts it into an Ensite Pro compatible format.

Once all the tanks are created in the database, the user can either

start with the configuration of the CIU Primes or the CIU Pluses.

Configuration of CIU Prime’s

In the 880 series CIU Prime, the following parts can be configured:

•HostPort 1

•HostPort 2

•Hot standby (if applicable)

•Field ports

•The hot stanby settings are required if redundant CIU Primes

are installed.

The Field ports settings depend on the type of interface card installed

in the CIU Prime.

Configuration procedure

Page 10

Always make a backup of the site database before making any

modifications. In doubt upload the configuration.

Configuration of CIU Plus’s

In the 880 series CIU Plus, the following parts can be configured:

•Hostports

•Hot standby (if applicable)

•FieldPort 1

•FieldPort 2

•The hot standby settings are required if redundant CIU Primes

and/or CIU Pluses are installed.

The host port setting are required to make the CIU Plus compatible

with the connected hardware and software, i.e. a PLC, Entis Pro or a

DCS system. The FieldPort settings inform the CIU Plus about the

communication setting to one or more CIU Primes.

Linking Gauges, Tanks and CIU’s

After all the data inputs, Tanks, CIU Primes and CIU Pluses are

configured the linking of all devices can commence. On basis of the

actual or planned installation, the user has now to link the hardware:

•the data inputs to the tanks,

•the tanks to the CIU Primes,

•the CIU Primes to the CIU Pluses.

Downloading configuration data

Once you have verified all the settings of all the devices, you can

download the configuration database into the respective CIU’s.

The first time it is advised to do downloading directly on the targeted

CIU (Prime of Plus). Ensite Pro offers this downloading as a standard

feature, even over modem lines.

Later modifications on the CIU configuration can also be done via a

CIU Plus into a CIU Prime, or even via Entis Pro from any of the

network stations.

Start Ensite Pro

Instruction manual Ensite Pro Configuration Tool Page 11

Start Ensite Pro

Ensite Pro can be started in the following way:

Windows 95/98/NT •press ‘Start’-button

•select ‘Programs’

•activate ‘Ensite Pro’-shortcut

The splash screen is shown, followed by the login window:

Ensite Pro login

Start Ensite Pro

Page 12

When the correct password is given (the Administrator’s default

password is ‘Ensite Pro’), the program starts up with the following

window:

Only three buttons are illuminated:

Select site

A site gives an overview of the configuration at a specific customer’s

site. Selecting a site gives you access to a database

Help

The build in help document assists at any time.

User privileges

Access parameters for different users can be set or selected.

A site must be created to be able to work with the configuration tool.

Press the upper left button to illuminate all other buttons.

Select site

Instruction manual Ensite Pro Configuration Tool Page 13

Select site

A site gives an overview of the configuration at a specific customer’s

site. Selected sites are highlighted.

Press this button to copy the highlighted site from the list.

Only specific data must be changed afterwards.

When the site is not in the list (yet), a new site has to be created.

Press the ‘New’-button to add a site:

Press the ‘Ok’-button to let the new site appear in the listbox.

Press this button to select the highlighted site to work with. You can

also double click on the highlighted site name.

Press this button to import an earlier made site database.

Press this button to remove the highlighted site from the list.

Global settings

Page 14

Data in the fields ‘Dimensions’and ‘Text’ can only be changed/set

after a new site has been created, all other data can also be

changed/set at a later stage.

Level and volume dimensions entered must be consistent with the

dimensions of the tank strap tables intend to use.

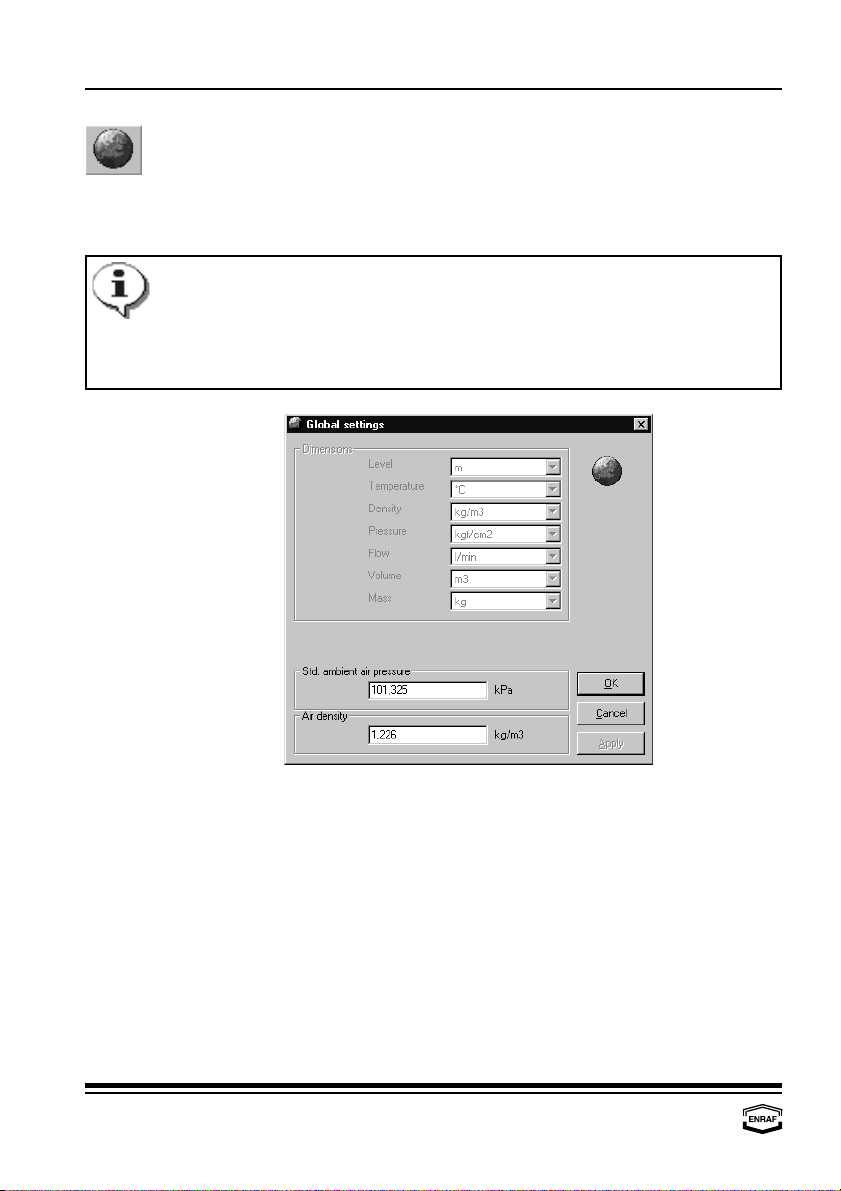

Global settings

This window automatically pops up after a site has been created. In

this window, global settings for the selected site can be programmed.

These global settings cover the way data is represented.

Dimensions

Level

Select: m, mm, ft, in, in/16, fis or 1/256 in

Temperature

Select: °C, °F

Density

Select: kg/m , °API, lbs/ft , dens60/60 or lbs/USgal

33

Pressure

Select: kgf/m , Pa, kPa or psi (lbf/in )

22

Flow

Select: m /min, m /h, l/min, bbls/min, bbls/h, USgal/min, Usgal/h

33

or UKgal/h

Volume

Select: l, m , USgal, bbls or UKgal

3

Mass

Select: kg, metric ton, USton, lbs or long ton

Std. ambient air pressure

Enter ambient air pressure in kPa (default = 101.325 kPa).

Air density

Enter air density in kg/m (default = 1.226 kg/m ).

33

Global settings

Instruction manual Ensite Pro Configuration Tool Page 15

After all global settings are made, the program warns the user that it

is not possible to change the settings anymore:

When confirmed, the program displays the following window:

The following buttons are available:

Select site.

A site gives an overview of the configuration at a specific customer’s

site.

Global settings.

Global settings cover the way data is represented, as well as some

local figures. These settings are valid for the particular site only.

Configure data inputs.

The data inputs collect data such as level, temperature, density and/or

pressure.

26

Configure tanks.

A tank is a (large) container to store liquids or gases.

Configure CIU Prime.

The CIU Prime is an interface between the field instrumentation and

inventory systems. To setup the CIU Prime, the port configuration

must be programmed.

Configure CIU Plus.

The CIU Plus calculates volume, standard volume, mass, density,

flow rate etc. To setup the CIU Plus, the port configuration must be

programmed.

Global settings

Page 16

Configure links.

After all individual components (CIU Prime, CIU Plus, tanks and data

inputs) have been configured, they have to be linked to each other.

Communication setup.

To be able to communicate via the configuration tool, communication

parameters must be set.

Download configuration.

The (new) programmed configuration must be downloaded for the CIU

Prime / Plus to work with.

Upload configuration.

The upload function is standard disabled in the toolbar.

Service note(s).

The build in text editor gives the possibility to store information about

the current site.

Set date and time.

The current date and time of the CIU Prime / Plus , can be (re-)set.

Print configuration.

The whole configuration can be printed to have a hard copy.

Show diagnostic data.

The build in diagnostic data views, reads and writes data direct from

and to the CIU Prime / Plus.

Tank viewer.

All measured and calculated data from one tank can be viewed.

Scan viewer.

The field scan can be viewed.

Help.

The build in help document assists at any time.

User privileges.

Access parameters for different users must be set.

Configure data inputs

Instruction manual Ensite Pro Configuration Tool Page 17

Configure data inputs

The data inputs (instruments in the field) collect data such as level,

temperature, density and/or pressure. The instruments measure the

data and transmit it upon request of higher layered systems.

Press the ‘Copy’-button to copy the highlighted data input from the list.

Only specific data must be changed afterwards.

When the data input is not in the list (yet), a new data input has to be

created. Press the ‘New’-button to add a data input:

Press the ‘Edit’-button to edit data from the highlighted data input:

- Gauge - Water - Density - Vapour

- Level - Temperature - Pressure - Scan

Press the ‘Delete’-button to remove the highlighted data input from the

list.

Configure data inputs

Page 18

A warning is generated before a log file is extracted while settings

have been entered already.

All dimensions in a gauge log file must be compatible with the

system dimensions.

Gauge

Gauge LOG file

Press the ‘Browse’-button to select a gauge log file.

Press the ‘Extract’-button to fill in the data from the gauge log file in

the next tabs.

Configure data inputs

Instruction manual Ensite Pro Configuration Tool Page 19

Gauge types ‘816' and ‘818' are only supported via 858 CIU.

Gauge type ‘829' is only supported in 867 emulation mode.

All three gauge types require the extended field address for 858 CIU

or 867 receiver (TOI 858 = P or R, TOI 867 = L).

Gauge type ‘999' is a generic Enraf gauge with no special

processing (default processing used).

General limits:

All instruments from one tank must be connected to the same

FieldPort.

Using BPM cards:

Up to 50 data inputs can be equally divided over the four FieldPorts

of the CIU Prime, with a maximum of 15 data inputs per line.

The instrument address on each port is free selectable between

00...99. The instrument address must be unique for all data inputs on

the same CIU.

Using RS232/485 cards:

Field addresses may contain 3 digit address numbers.

Gauge

Gauge type

Select:: Unknown, 802, 811, 812, 813, 816, 818, 829, 854, 865,

866, 872, 873, 877, 894, 973 or 999

Gauge details

Select:: hfor 854 gauges using the ZLQ record

(up to software version SPUA1.0)

- for 854 gauges

(with software version SPUA2.0 onwards)

Allowed gauge commands

Test gauge

Check if allowed (TG; 811, 854, 894 only)

Block gauge

Check if allowed (BL; 811, 854, 894 only)

Tank profile

Check if allowed (TP; 854, 894 only)

Gauge alarm test

Check if allowed (AT; 873 only)

Lock test

Check if allowed (LT; 811, 854, 894 only)

Water dip

Check if allowed (I3; 811, 854, 894 only)

Interface profile

Check if allowed (IP; 854, 894 only)

Verify command

Check if allowed (CA; 854, 894 only)

Reset gauge

Check if allowed (RS)

Interface 2 command

Check if allowed (I2; 854, 894 only)

Configure data inputs

Page 20

Level

Level enabled

Check to enable level scan.

0.1 mm level

Check to enable. This selection is only possible if the level dimension

resolution

is set to ‘m’or ‘mm’and if the gauge type is not 811, 813, 866 or 872.

Negative levels

Check to enable. This selection is only possible for gauge types

enabled

854, 872, 873 and 894.

No alarm when gauge in test

Check to disable gauge alarms during operational commands.

Level killed

Check to disable level scan.

Manual overwrite

Enter manual product level.

First enable level.

Level address

Enter level transmission address

Level TOI

Select: A, B, C, E or M

Level TOR

Select: B, J, L, M or ZLQ (the combination of level TOR ‘ZLQ’and

level type ‘Ullage’is not possible. With level type ‘Ullage’,

use level TOR ‘L’).

Table of contents

Other enraf Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

OHAUS

OHAUS MB90 quick start guide

Unipulse

Unipulse F320 Operation manual

Hanna Instruments

Hanna Instruments HI769828 instruction manual

TASKING

TASKING iSYSTEM ARM HSSTP II user manual

Hanna Instruments

Hanna Instruments HALO 2 HI9810302 instruction manual

LaserLiner

LaserLiner BeamControl-Master BCM operating instructions