Garnet SeeLevel I 705 Series User manual

PRINTED IN CANADA

GARNET

INSTRUMENTS LTD.

S

SS

S

EE

EEEE

EE

L

LL

L

EVE

EVEEVE

EVE

L I

L IL I

L I

TM

Tank Monitor

Model 705 Manual

Three and Four Tank Models

IMPORTANT OPERATOR INFORMATION

DATE INSTALLED:

SERIAL NUMBER:

Signal Level

Black Water Tank

Gray Water Tank

Galley Water Tank

Fresh Water Tank

GARNET INSTRUMENTS LTD.

S

SS

S

EE

EEEE

EE

L

LL

L

EVE

EVEEVE

EVE

L I

L IL I

L I

TM

Tank Monitor

Model 705 Manual

Three and Four Tank Models

TABLE OF CONTENTS

1) OVERVIEW

2) SYSTEM DESCRIPTION

3) OPERATING INSTRUCTIONS

4) DISPLAY PROGRAMMING

5) SENDER PROGRAMMING

6) INSTALLATION GUIDE

7) TROUBLESHOOTING GUIDE

8) SERVICE AND WARRANTY INFORMATION

9) SPECIFICATIONS

CHAPTER 1

OVERVIEW

The SeeLeveL I Tank Monitor represents a massive leap forward in level

measurement technology for the Recreational Vehicle industry. The

SeeLeveL has a combination of features, accuracy, reliability, and diagnostic

capability that have never been available before.

The SeeLeveL I will monitor the battery voltage, the water and sewer holding

tanks, and the LP Gas tank. The information is displayed on a 5 segment

color coded LED bar graph. In addition, the system can display the operating

characteristics of each of the tank sending units, giving it unsurpassed

diagnostic capability.

705-P3

705-P4

CHAPTER 2

SYSTEM DESCRIPTION

The SeeLeveL consists of a display unit that mounts inside the RV, and

sender panels that stick to the side of the holding tank. A single two

conductor wire is used to connect all the sender panels to the display.

The Sender: Each sender panel is a flexible self adhesive printed circuit

board which is stuck to the side of the holding tank. The sender panel can be

cut to length to match the height of the tank, and it auto calibrates itself so that

it can read from Empty to Full regardless of the height of the tank. The sender

scans the water level through the tank wall using patented digital techniques

programmed into the sender microprocessor. When the sender transmits the

water level information to the display, it sends a digital code that has built in

error detection, making it impossible for the display to read an incorrect level,

even if the wiring is bad. In addition to the level, the sender also transmits

diagnostic information about its operation. This information can be used to

determine if there is buildup of sludge on the inside of the tank, or to

determine if the sender is delaminating from the side of the tank. If sludge

buildup in the tank becomes extreme the gauge will cease to operate (the tank

will always read empty), so by monitoring the signal level the tank can be

cleaned before the buildup gets excessive. Various sender options are

available to monitor tanks from 4 inches to 24 inches tall.

The Display: The display receives the information from the three sender

panels via a single two conductor wire, and displays the level information in

percent of full on a five segment LED bar graph. When the front panel button

for a particular tank is pressed, the display powers up and displays the level

for that tank. If the button is pressed and released, the display will show the

level for about 5 seconds and then shut down automatically. If another button

is pressed before the display shuts down, then the new level will immediately

be shown. If the same button is pressed twice, the display will hold on that

tank and continue to show updated levels for 5 minutes before shutting off.

This allows the user to monitor the filling or draining of a tank. By pressing

two buttons at once, the diagnostic functions can be accessed, these are

described in detail in the troubleshooting chapter.

If a sender is operating properly and connected to the display with good

wiring, then the display will show the level normally. If the wiring is

disconnected, shorted, or cut, or if the sender panel is defective, then the

display will indicate an error code. The various error codes are shown in the

troubleshooting chapter.

With these diagnostic features and the digital nature of the tank level sensing

technology, it is almost impossible for the system to indicate an incorrect

water level, and in the very unlikely event it does occur, the user can verify

what is happening with the diagnostic information.

The system also shows the RV battery voltage by measuring the voltage

which powers the display. The voltage is shown with a resolution of one volt.

The display can use an existing LPG electrical sender to show the LPG level.

It can automatically calibrate to any sender, and shows level on the LED bar

graph.

CHAPTER 3

OPERATING INSTRUCTIONS

The display is the only system component that is accessed by the user. All

user input to the display is done using the five buttons along the bottom of the

display. Operation of the display is as follows:

To read a water or sewer tank level:

1. Press the button corresponding to the tank to be checked and release it,

the display will show the level in percent on the LED bar graph. If no

other button is pressed, then the display will shut off after about 5

seconds. The following diagrams show examples of the color coded bar

graph.

100%

75%

50%

25%

0% 11V

12V

13V

14V

15V

Fresh water tank or battery condition

100%

75%

50%

25%

0% 11V

12V

13V

14V

15V 100%

75%

50%

25%

0% 11V

12V

13V

14V

15V

Empty / 11V

½ Full / 13V Full / 15V

100%

75%

50%

25%

0% 11V

12V

13V

14V

15V

Gray, galley, or black water tank

100%

75%

50%

25%

0% 11V

12V

13V

14V

15V

100%

75%

50%

25%

0% 11V

12V

13V

14V

15V

Empty

½ Full

Full

2. If another button (including BATT or LPG) is pressed before the 5 second

time is up for the first button, the display will immediately switch to

showing the new level or voltage. The 5 second timeout is restarted

every time a button is pressed.

3. To continuously display a reading, press and release the desired button,

and then press the same button a second time. When the button is

released, the display will be in hold mode, which is indicated by the bar

graph flashing on and off. While the display is in the hold mode it will

recheck the level once per second so the user can watch the level

change while the tank is being filled or drained. The display will

automatically shut off after 5 minutes in hold mode. To end the hold

mode before the 5 minutes is up, press any tank button, and the display

will shut off.

To read the battery voltage:

1. Press the BATT button and release it, the display will show the battery

voltage on the LED bar graph.

2. If no other button is pressed, then the display will shut down after about 5

seconds. If the BATT button is held down, the display will continuously

recheck the voltage and show the updated value.

3. If another button is pressed before the 5 second time is up for the BATT

button, the display will immediately switch to showing the value for the

new button. The 5 second timeout is restarted every time a button is

pressed.

4. There is no hold mode for the battery voltage.

To read the LPG tank level:

1. Press the LPG button and release it, the display will show the level on

the LED bar graph. If no other button is pressed, then the display shut

off after about 5 seconds.

2. If the LPG button is pressed again, a new reading will be obtained and

displayed, and the 5 second timer will be restarted. If the button is held

down, the existing reading is held for as long as the button is pressed,

and the display will shut off 5 seconds after the button is released.

3. If another button is pressed before the 5 second time is up for the LPG

button, the display will immediately switch to showing the new level or

voltage. The 5 second timeout is restarted every time a button is

pressed.

4. There is no hold mode for the LPG. The LPG tank level cannot change

fast enough to justify the use of the hold function, except during filling of

the tank. The gauge should not be used as a full tank shutoff indicator

since the LPG sender in the tank is not reliable or accurate enough to be

used as a safe indicator of a full tank.

CHAPTER 4

DISPLAY PROGRAMMING

To program the LED brightness:

1. If the display is to be used inside the coach, the LED brightness should

be low. If it is to be used in the service bay area where sunlight can

reach it, the LED brightness should be high.

2. To program the LED brightness, the display needs to enter the

brightness programming mode. To do this, press and hold down the

BATT button, the display will show the battery voltage.

3. While continuing to hold down the BATT button, press and hold down the

GRAY button, do this for about 5 seconds until the display shows the

brightness programming mode. When this occurs release both buttons.

100%

75%

50%

25%

0% 11V

12V

13V

14V

15V

Brightness programming

4. Press the GRAY tank button to increase brightness, or the FRESH tank

button to decrease brightness.

5. When the display shows the correct brightness, press the BATT button to

exit the programming mode.

To program the number of senders for each tank:

Note: for the 4 tank model, the grey and galley tanks can only have one

sender each, so for these tanks no programming is possible for the number of

senders.

1. To program the number of senders for each tank, the display needs to

enter the sender programming mode. This should only be done at the

time of installation, there is no reason to change the number of senders

afterward. Make sure that the number of senders programmed into the

display matches with the number of senders connected, otherwise the

display will show an error.

2. To enter the sender programming mode, press and hold down the button

for the tank to be programmed, the display will show a level or an error

message.

3. While continuing to hold down the button for the tank, press and hold

down the BATT button. The display will immediately show the

diagnostics code, continue to hold down both buttons until the display

enters the number of senders programming mode, this should take about

5 seconds. When the programming mode is entered, release both

buttons.

100%

75%

50%

25%

0% 11V

12V

13V

14V

15V

Diagnostics

100%

75%

50%

25%

0% 11V

12V

13V

14V

15V

Number

of senders

4. The display will now show the code for one sender or two senders, based

on what is currently programmed into the display. These are the only two

options, the display will not work with more than two senders per tank.

100%

75%

50%

25%

0% 11V

12V

13V

14V

15V

One sender

100%

75%

50%

25%

0% 11V

12V

13V

14V

15V

Two senders

5. To change the number of senders, press the tank button, each time the

button is pressed the display will switch to the other number.

6. When the display shows the correct number of senders, press the BATT

button to exit the programming mode. Each tank will need to be

calibrated individually using this procedure.

To calibrate the LPG sender:

1. The LPG tank must be full when the sender is calibrated, otherwise the

calibration will be invalid. Fill the LPG tank by using an alternate

measurement method, such as weight, a spit valve, or a mechanical

gauge on the tank.

2. To calibrate, press and hold down the LPG button, the display will show

some LPG level.

3. While continuing to hold down the LPG button, press and hold down the

BATT button. Continue to hold down both buttons for about 5 seconds

until the display shows the LPG calibration code.

100%

75%

50%

25%

0% 11V

12V

13V

14V

15V

LPG Calibration

4. When this occurs release both buttons, the display will shut off,

completing the calibration procedure.

5. The LPG can be recalibrated as many times as desired, although

recalibration should not be needed unless the LPG tank sender or the

display has been replaced.

The battery voltage is calibrated at the factory, this should never need to be

changed.

CHAPTER 5

SENDER PROGRAMMING

Long Stackable Senders

These senders are 12 inches long and can be either single or double stacked.

They are identified by the “TOP” on the middle tab.

To program the sender for the correct tank:

1. Since the senders are all connected in parallel to save wiring and to

simplify installation, the senders must be programmed so they know

which tank they are on. The senders can be programmed for either the

fresh, gray, or black tank for three tank models, or for fresh, gray, galley,

or black for four tank models. This is done with the tabs on the top of the

sender. See the following diagram.

2. The senders default to fresh tank operation if the programming is not

altered. Consequently, if the sender is for the fresh tank, nothing further

needs to be done to it.

3. If the sender is for the gray tank, remove the tab that says “GRY” next to

it.

4. If the sender is for the galley tank (4 tank models only), remove the tab

that says “GRY” next to it, and the tab that says “TOP”. Even though this

would normally be a gray top sender, the 4 tank display interprets this as

the galley sender.

5. If the sender is for the black tank, remove the tab that says “BLK” next to

it.

6. This is all that is required to program the senders for the correct tank.

However, if you make an error, you have one chance to correct it, as

described below.

7. If the “GRY” tab has been removed and it should be a black tank sender,

or if the “BLK” tab has been removed and it should be a gray tank

sender, then cut out the recessed gray-black correction tab that says

“GBC” next to it. This reverses the effect of the gray and black tabs.

8. If either the “GRY” or “BLK” tabs have been removed and it should be for

a fresh tank, then remove the other “GRY” or “BLK” tab. When both the

“GRY” and “BLK” tabs are removed, it is equivalent to neither of them

being removed.

9. If the sender is single, no further programming is required.

10. If dual stacked senders are used, the top sender must have additional

programming, as described below.

To program the sender as top or bottom:

1. Note that for 4 tank models, the gray and galley tanks can only have

single senders, so this section does not apply to them.

2. Since the senders are all connected in parallel to save wiring and to

simplify installation, the senders must be programmed so they know

whether they are a single, top, or bottom sender. This is done with the

tab at the top center of the sender. See the following diagram.

3. The senders default to single or bottom operation if the programming is

not altered. Consequently, if the sender is for single or bottom operation,

nothing further needs to be done to it (beyond programming it for the

correct tank).

4. For a top sender, remove the tab that says “TOP” next to it.

5. This is all that is required to program the senders for single, top, or

bottom use. However, if you make an error, you have one chance to

correct it, as described below.

6. If the “TOP” tab has been removed and it should be a single or bottom

sender, then cut out the recessed top correction tab that says “TC” next

to it. This reverses the effect of the top tab.

7. Verify that both the top and bottom senders have been programmed for

the correct tank.

GND

<<--UP

SIG

T

C

GB

C

GND

<<--UP

SIG

T

C

G

B

C

GND

<<--UP

SIG

T

C

G

B

C

GND

<<--UP

SIG

GRY

BLK

TOP

TC

GBC

G

N

D

<

<

-

-

U

P

S

I

G

GRY

BLK

TOP

TC

GBC

G

N

D

<

<

-

-

U

P

S

I

G

GRY

B

L

K

T

O

P

T

C

GBC

Example of corrected FRESH TOP

sender programming

(GRY or BLK cut by mistake)

Example of corrected SINGLE

or BOTTOM sender programming

(BLK cut by mistake)

GRAY Example of corrected SINGLE

or BOTTOM sender programming

(TOP cut by mistake)

FRESH

Cut for GRAY tank

GRY

B

L

K

T

O

P

Cut for BLACK tank

Cut for TOP sender

G

R

Y

B

L

K

T

O

P

Example of GRAY TOP

sender programming

G

R

Y

B

L

K

T

O

P

Example of BLACK

BOTTOM sender programming

SINGLE

or

Long stackable sender programming examples

Short Single Senders

These senders are 6 inches long and cannot be stacked, they must be single.

They are identified by the “ALT” on the middle tab.

To program the sender for the correct tank:

1. Since the senders are all connected in parallel to save wiring and to

simplify installation, the senders must be programmed so they know

which tank they are on. The senders can be programmed for either the

fresh, gray, or black tank for three tank models, or for fresh, gray, galley,

or black for four tank models. This is done with the tabs on the top of the

sender. See the following diagram.

2. The senders default to fresh tank operation if the programming is not

altered. Consequently, if the sender is for the fresh tank, nothing further

needs to be done to it.

3. If the sender is for the gray tank, remove the tab that says “GRY” next to

it.

4. If the sender is for the galley tank (4 tank models only), remove the tab

that says “GRY” next to it, and the tab that says “ALT”.

5. If the sender is for the black tank, remove the tab that says “BLK” next to

it.

6. This is all that is required to program the senders for the correct tank.

There are no correction tabs on this sender. However, if either the

“GRY” or “BLK” tabs have been removed and it should be for a fresh

tank, then remove the other “GRY” or “BLK” tab. When both the “GRY”

and “BLK” tabs are removed, it is equivalent to neither of them being

removed.

UP-->>

Cut for

GRAY

tank

B

L

K

A

L

T

Cut for

BLACK

tank

GND

SIG

U

P

-

-

>

>

Cut both for

GALLEY tank

B

L

K

A

L

T

G

N

D

S

I

G

CHAPTER 6

INSTALLATION GUIDE (NEW OEM INSTALLATIONS ONLY)

1. The installation consists of mounting the display inside the RV, cutting and

fastening the senders to the sides of the holding tanks, connecting wiring,

and programming the display.

2. Mount the display by cutting a hole in the wall 3” wide by 1 7/8” high and

bringing the wiring out through the hole to connect to the display panel

connector.

3. Connect the wiring according to the following table. It is easier to connect

the wiring to the display connector first, and then plug the connector into

the display panel. The sender needs to be grounded to a single ground

wire from the display.

Wire Color Function

Red 18 gauge +12V power input to monitor

Black 18 gauge Ground

Blue 18 gauge Tank senders

Yellow 18 gauge Pump power output

Green 18 gauge LPG tank (optional)

4. Determine where to mount the senders on the tanks. They will need to

have a flat area on the side of the tank large enough so the whole width of

the sender is in contact with the side of the tank, all the way from the top to

the bottom of the tank. Make sure that any metal is at least an inch away

from the sender. Clean the area well so that there is no dust, grease, oil,

water, etc., that would prevent the adhesive on the sender from sticking.

5. Measure the height of the tank to determine how long the senders should

be. For tanks less than 7” tall, follow step 6. For tanks from 7” to 13” tall,

follow step 7. For tanks greater than 13” tall, follow step 8.

6. For tanks less than 7” tall, a single short sender is used. The sender ends

should be 1/4” to 3/4” away from the top and bottom of the tank, to allow for

the thickness of the tank top and bottom and any bows in them (see the

diagrams). The senders are calibrated to account for this distance from

the bottom of the tank. The sender is cut to the nearest even 1 inch in

length, for example, a system with a tank height of 5.75 inches, cut the

sender to be 5 inches long, this allows 3/8” at each end when the sender is

centered vertically on the tank. IMPORTANT: Do not cut the sender

shorter than 4 inches! The sender will not work if it is cut less than 4

inches. Proceed to step 9.

7. For tanks less than 13” tall, a single long sender is used. The sender ends

should be 1/4” to 3/4” away from the top and bottom of the tank, to allow for

the thickness of the tank top and bottom and any bows in them (see the

diagrams). The senders are calibrated to account for this distance from

the bottom of the tank. The sender is cut to the nearest even 1.5 inch in

length, for example, a system with a tank height of 11.75 inches, cut the

sender to be 10.5 inches long, this allows 5/8” at each end when the

sender is centered vertically on the tank. IMPORTANT: Do not cut the

sender shorter than 4-1/2 inches! The sender will not work if it is cut

less than 4-1/2 inches. Proceed to step 9.

8. For tanks greater than 13” tall, two stacked long senders are used. The

sender ends should be 1/4” to 3/4” away from the top and bottom of the

tank, to allow for the thickness of the tank top and bottom and any bows in

them (see the diagrams). The senders are calibrated to account for this

distance from the bottom of the tank. In addition, there needs to be a gap

of 1/16” to 1/8” to between the two senders. Therefore total length of both

senders will be: tank height -1/4”-1/4”-1/8”, then rounded down to the

nearest 1.5 inches. The top and bottom senders should be approximately

the same length for best results. For example, if the tank height is 22”,

then 22”-1/4”-1/4”-1/8”=21 3/8”, so the total length of both senders will be

21 inches. Make both senders 10.5” long. Proceed to step 9.

9. To make the senders the right length (assuming they are too long) they will

need to cut off with a pair of scissors. The end to be cut is the bottom end,

which is the opposite end from the top where the wires come out (see the

diagrams). DO NOT cut the sides, and DO NOT cut the sender shorter

than 4-1/2 inches (long sender) or 4” (short sender). The cut must be in

between the sensor pads, and the cut must be made parallel to the existing

bottom end. Double check your measurements, if the sender is cut too

short, it cannot be lengthened.

10.The senders need to be programmed so they know which tank they are on.

This is done by selectively cutting off the tabs on the top of the sender.

See the chapter entitled “SENDER PROGRAMMING” and the section “To

program the sender for the correct tank” for details.

11.For two stacked sender systems, the senders need to be programmed so

they know that they are being used as top or bottom senders. See the

chapter entitled “SENDER PROGRAMMING” and the section “To program

the sender as top or bottom” for details.

12.Once the sender is cut to length and programmed, carefully peel the

backing paper off the adhesive. Do this slowly to prevent the adhesive

from being ripped off the sender, and to prevent the backing paper from

ripping. Be careful not to bend the sender sharply in the process. Position

the sender over the side of the tank and carefully stick it down. MAKE

SURE THAT THE END WITH WIRES IS POINTING UP!! Position the

bottom of the sender at least 1/4” above the bottom of the tank, and more if

required to equalize the space at the top and bottom of the tank. Make

sure that the sender is square with the tank. You only have one shot at

this, if you try to peel it off the tank once it is stuck the sender may be

damaged by the sharp bending. Carefully press the sender down to the

tank so that all of the adhesive is contacting the tank wall.

GND

UP-->

>

SIG

SIGNAL

WIRE

Route wires to the right,

away from the sender

T

C

G

B

C

TOP OF SENDER

GROUND

WIRE

4-1/2 Inch

minimum

measurement

length

G

R

Y

B

L

K

T

O

P

1-1/2 Inches

BOTTOM OF SENDER

ONLY CUT BETWEEN PADS WHEN CUTTING THE SENDERTO LENGTH

13.Connect the all the blue wires from the senders together, and to the blue

wire from the display. Connect the black wire from each sender to ground.

Use Marrette or crimp connectors to fasten the wires together. Make sure

that the wires from the sender are routed away from the sender, if they

drape over the sender they could affect the reading. Secure the wires with

tie wraps or something similar so that the wires do not rattle or press

against the sender, this may result in sender damage or wires breaking

over time.

14.Do steps 4 to 12 for the other holding tanks.

15.All that remains now is calibration and testing. The tank senders will self

calibrate to whatever length they are cut, so they will always read from 0 to

100%. The display needs to be set to a one or two sender system for each

tank. See the chapter entitled “DISPLAY CALIBRATION” and the section

“To calibrate the number of senders for each tank” for details. Make

sure you do it for each tank.

16.For the initial test, have the tank at least 1/4 full of water or sewage, and

verify that the percent level reading looks correct (see the chapter entitled

“OPERATING INSTRUCTIONS” and the section “To read a water or

sewer tank level” for details). Check to see that the signal power is

adequate (see the chapter entitled “TROUBLESHOOTING GUIDE” and

the section “To review the sender diagnostics” for details). If the signal

power is too low, make sure that the sender(s) is well stuck to the side of

the tank and that the tank is reasonably clean inside, as a large buildup will

reduce signal strength. Note that the system “learns” about the

characteristics of the tank with use, so the readings may be inaccurate

when the tank is empty or almost empty when the system is first tested.

Once the tank has been filled at least 1/4 full the system will be properly

“taught” and should read correctly after that.

17.Calibrate the LPG by filling the tank and following the instructions in the

chapter entitled “DISPLAY CALIBRATION” and the section “To calibrate

the LPG sender”.

18.Connect the pump switch as required.

WARNING: The pump switch is rated for a maximum of 6 amps. The use

of a relay is required if more than 6 amps is needed.

19.Verify that the battery voltage reads correctly. If it appears low, make sure

you have good wiring for the 12 volt power and the ground.

This manual suits for next models

2

Table of contents

Other Garnet Measuring Instrument manuals

Garnet

Garnet PC-732G User manual

Garnet

Garnet SeeLevel II User manual

Garnet

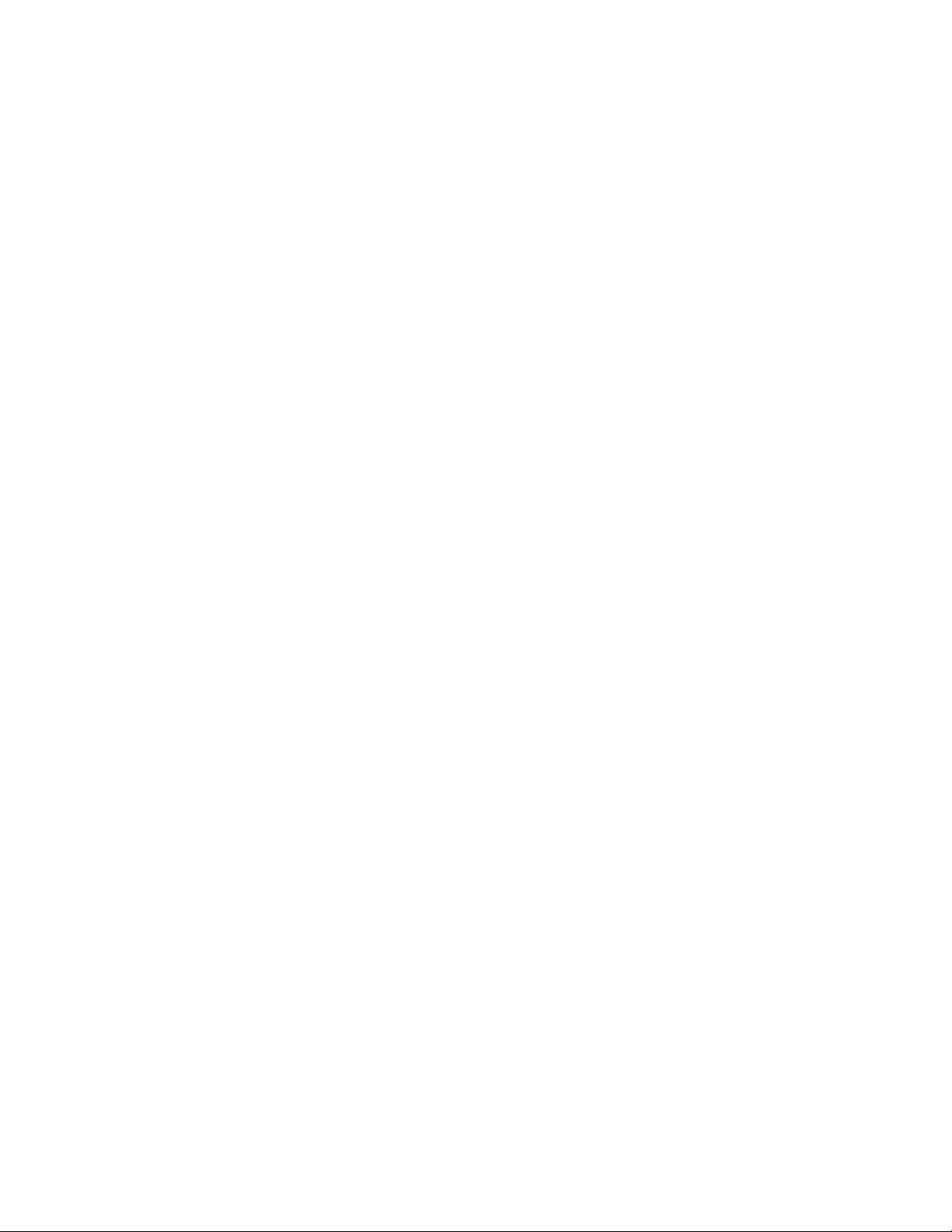

Garnet SeeLevel II 900-D4S Single User manual

Garnet

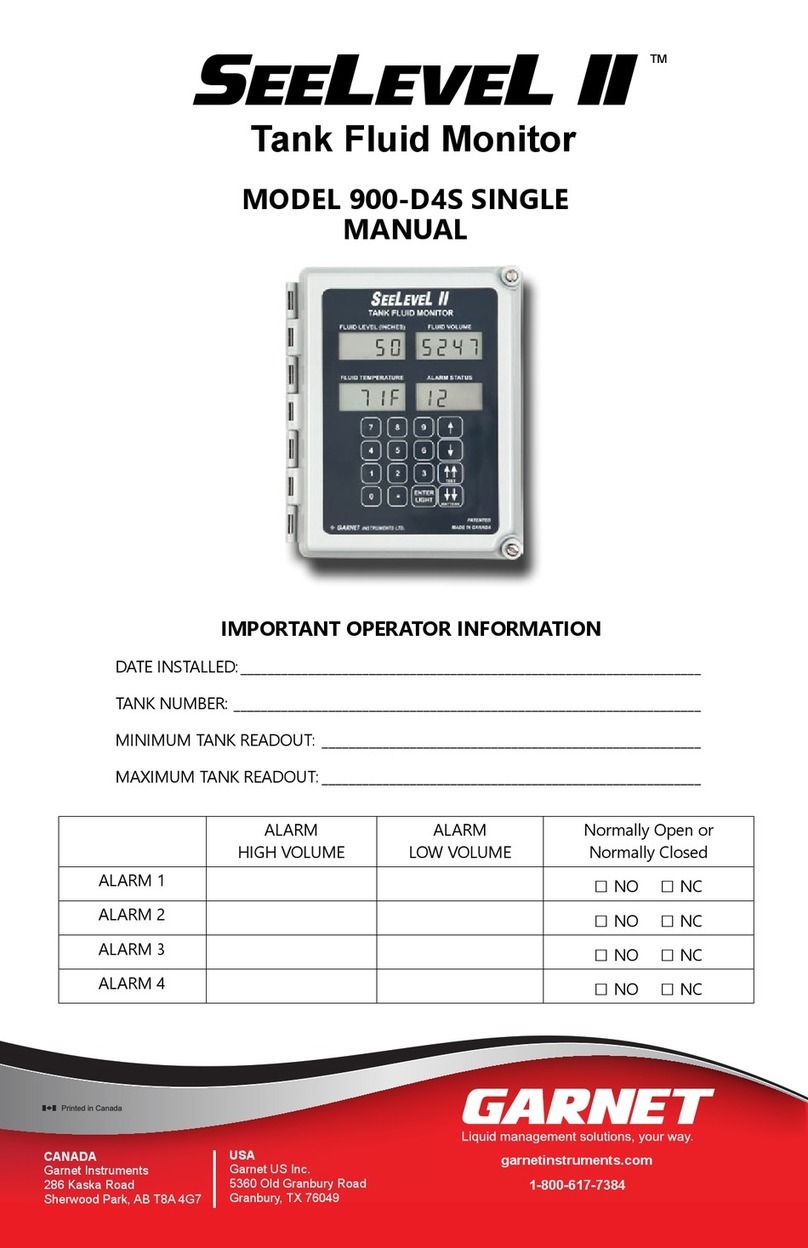

Garnet 709-RVC NLP User manual

Garnet

Garnet SeeLevel II User manual

Garnet

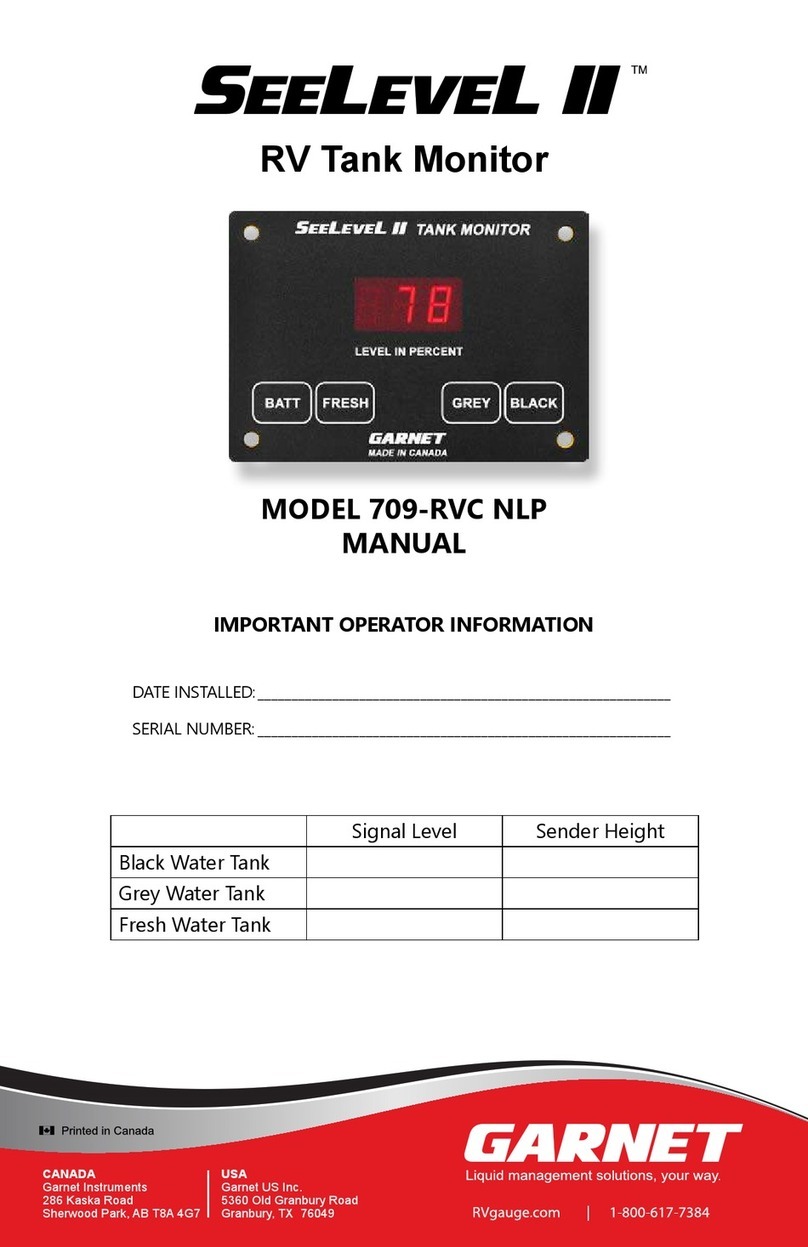

Garnet SeeLeveL Special 809-DM User manual

Garnet

Garnet 900D6 DUAL User manual

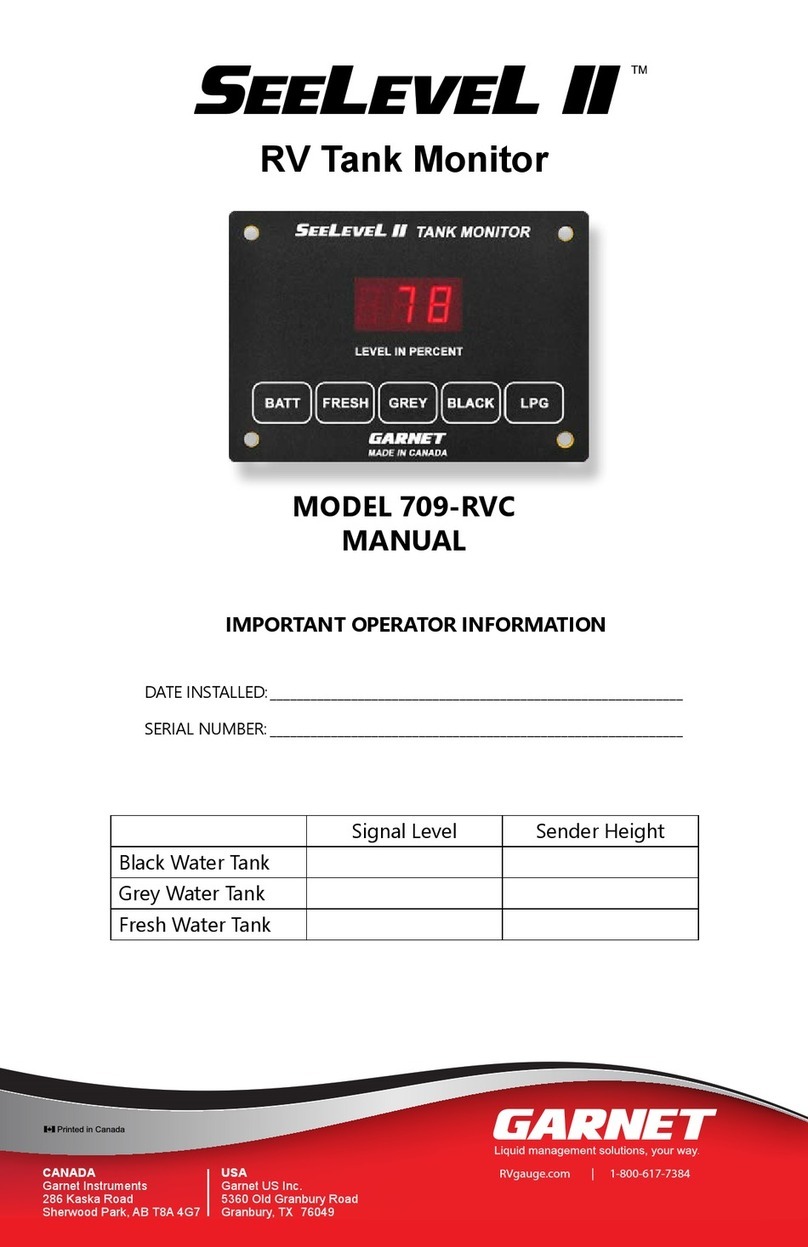

Garnet

Garnet SeeLeveL II 709-RVC User manual

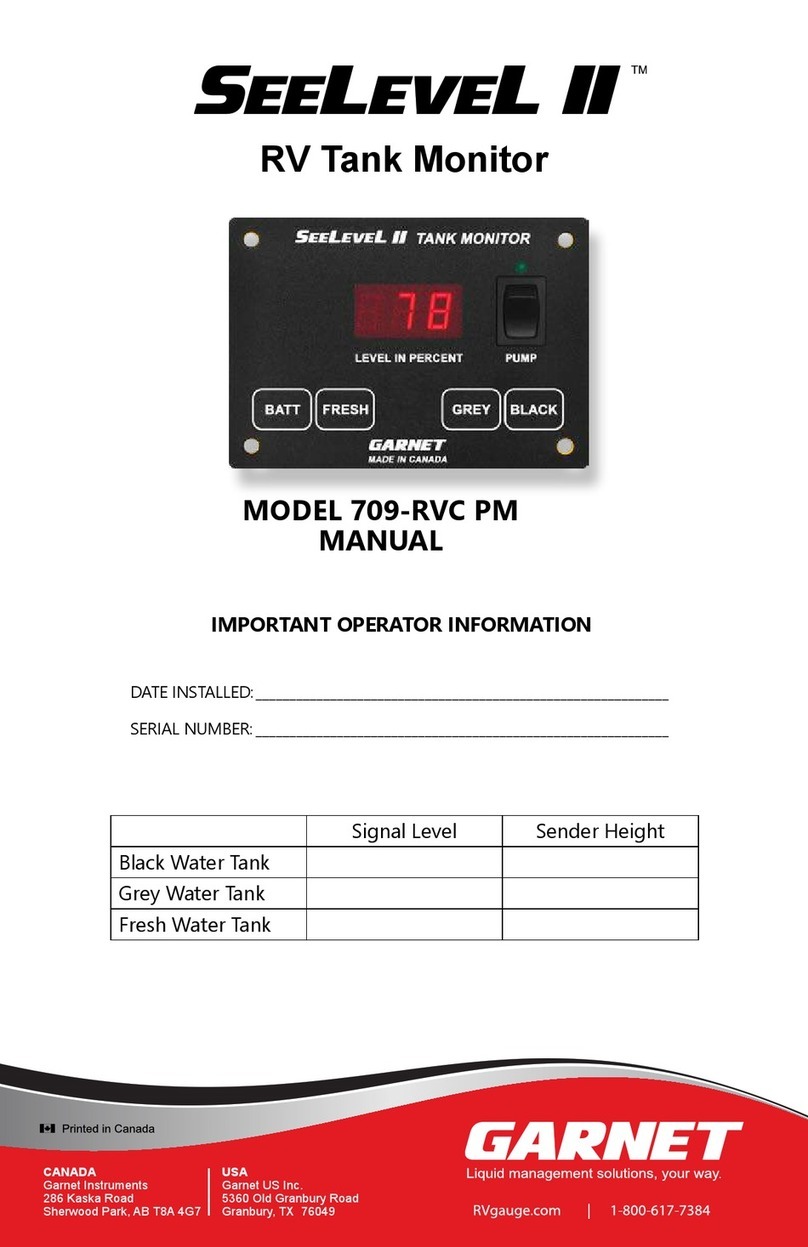

Garnet

Garnet SeeLeveL II 709-RVC PM User manual

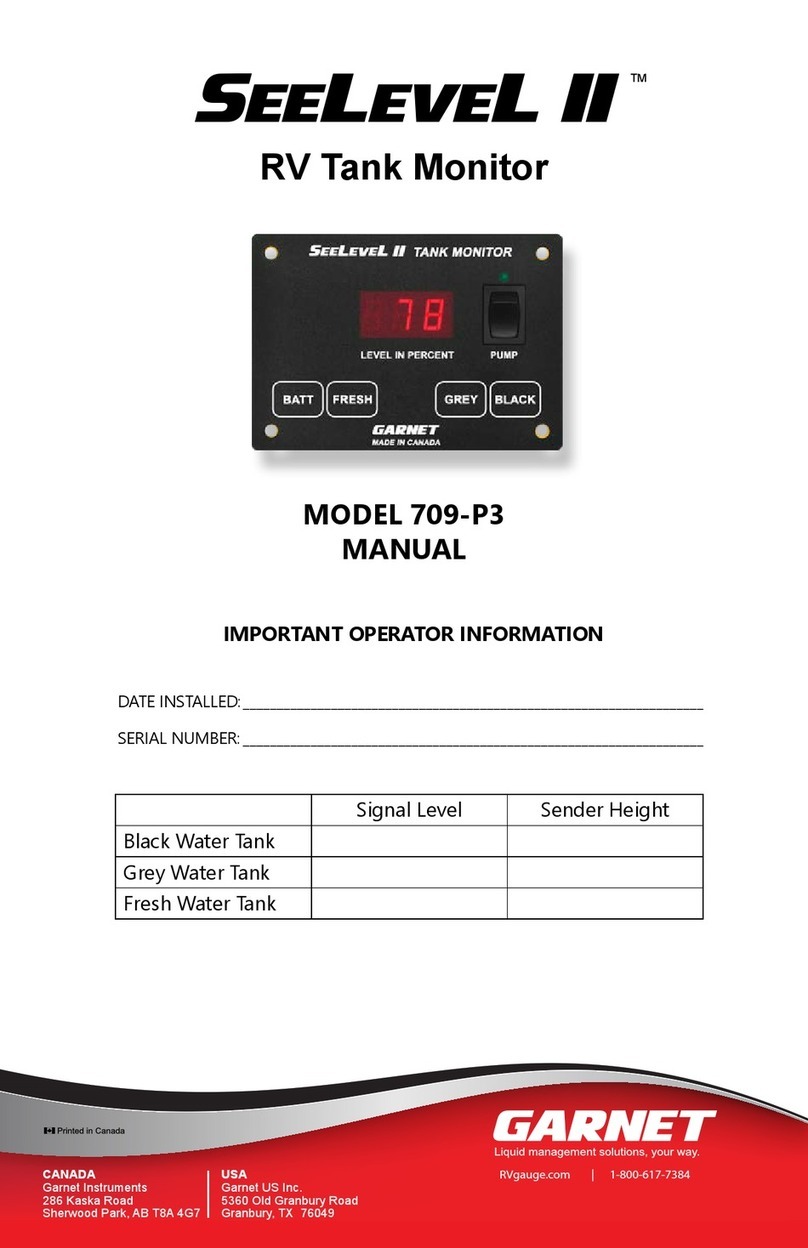

Garnet

Garnet SeeLeveL II 709-P3 User manual