entegris InVue NT6510 User manual

P/N 01-1032525 | REV. B 02/19

InVue®Integrated Flow

Controllers, Models

NT6510, NT6520

User guide

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

1Entegris, Inc. | P/N 01-1032525 | Rev. B 02/19

Table of Contents

Introduction .................................. 2

Identifying Nonstandard

Product Configurations ............ 2

Principle of Operation .............. 2

Factory Configured ................... 3

Continuous versus

Batch Control ............................. 3

Calibration Reference

Conditions ................................... 3

General Considerations .............. 4

Power Supply Requirements ... 4

Storage Temperature Range ... 4

Operating Ambient

Temperature Range .................. 4

Operating Process

Temperature Range .................. 4

Line Pressure .............................. 4

Pressure Drop.............................. 4

Dimensions ................................. 5

Installation .................................... 8

Provided Equipment ................. 8

Mounting Requirements .......... 9

Mechanical Installation .......... 10

Power Supply Requirements ... 11

Electrical Connections ........... 13

Wiring Diagrams ...................... 16

Optional Connections ............ 17

Setpoint Signal Setup .............. 18

Calibration Graphs .................. 19

Unit Operation ............................ 20

Operating Environment ........ 20

Performance ............................. 21

Operational Reliability ............ 22

Status and Alarming ................ 22

LED Status Codes .................... 23

Diagnostic Guide ........................ 24

Maintenance ............................... 27

Normal Operation ................... 27

Re-zero Function .................... 27

Reference .................................... 29

Physical Specifications .......... 29

Electrical Specifications ........ 29

Performance Specifications .... 29

Ordering Information ............... 30

Certifications ............................... 33

CE Compliance ........................ 33

Repair and Warranty Service ..... 33

Technical Support ...................... 33

For More Information ................ 34

Terms and Conditions of Sale .. 34

Limited Warranty ........................ 34

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

2P/N 01-1032525 | Rev. B 02/19 | Entegris, Inc.

Introduction

This manual is for use with a standard

InVue®Integrated Flow Controller,

Models NT6510 and NT6520. These

instruments have been designed for

use in high-purity fluid applications

within industries that need tightly

controlled chemical processes such

as the semiconductor, biomedical,

and solar cell industries. The wetted

parts are constructed with Modified

PTFE, PTFE, PFA, or other similar

high-purity inert materials.

WARNING! Attempting to install or

operate standard InVue Integrated

Flow Controllers without reviewing

the instructions contained in this

manual could result in personal

injury or equipment damage.

IDENTIFYING NONSTANDARD

PRODUCT CONFIGURATIONS

—

This User Guide applies to product

manufactured as the standard InVue

Integrated Flow Controller. Entegris

also manufactures nonstandard

product to meet the needs of specific

applications. Nonstandard product

may have dierent materials of

construction, accuracy specifications,

performance, and other specifications

that dierentiate the nonstandard

product from the standard oering.

NOTE: Nonstandard InVue Integrated

Flow Controllers may be identified

by the model number found on the

product label. Specifications for

nonstandard InVue Integrated Flow

Controllers are available by contacting

Entegris.

Nonstandard InVue Integrated Flow

Controllers, Model NT6510, are

identified with an “N" followed by

a number code.

For example, in part number

6510-T2-F03-B06-A-P7-U3-N02,

the “N02" designates the product

as a nonstandard product manu-

factured to certain specifications

designated under the “N02" code.

Nonstandard InVue Integrated Flow

Controllers, Model NT6520, are

identified with an “R" followed by

a number code.

For example, in part number

6520-T6-F03-B06-A-P7-U3-R02,

the “R02" designates the product

as a nonstandard product manufac-

tured to certain specifications

designated under the “R02" code.

Contact Entegris for assistance with

nonstandard product applications.

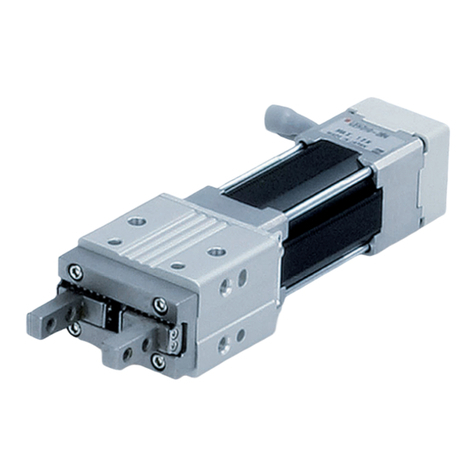

PRINCIPLE OF OPERATION

—

The user provides a setpoint signal

that corresponds to the desired

amount of flow. The standard InVue

Integrated Flow Controller compares

the setpoint to the actual flow signal

from the flow module. If the actual

flow is greater than the setpoint, the

unit closes the valve. If the actual

flow is less than the setpoint, the unit

opens the valve. The flow controller

does this in a precise manner until

the actual flow signal is equal to

the setpoint.

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

3Entegris, Inc. | P/N 01-1032525 | Rev. B 02/19

FACTORY CONFIGURED

—

The standard InVue Integrated Flow

Controller is pre-configured from the

factory for the flow range specified

by the user. The specified flow range

is found on the label of the unit. The

unit control algorithm uses pressure

and flow measurements to ensure

proper operation within specification.

CONTINUOUS VERSUS

BATCH CONTROL

—

The standard InVue Integrated Flow

Controller may be ordered as a con-

tinuous type controller or a batch

type controller.

The continuous controller type is

for applications requiring continuous

flow rate control, where the integral

valve module is never required to fully

close. Typically, another valve is used

in conjunction with the flow control-

ler to stop the liquid flow.

The batch controller type is for appli-

cations requiring flow rate control

where the integral valve module will

fully close between batch dispense

cycles. If total volume needs to be

controlled, an additional separate

totalizer device must be employed.

CALIBRATION REFERENCE

CONDITIONS

—

Unless otherwise noted, the specifi-

cations listed for the InVue Integra-

ted Flow Controller are referenced

under the following operating

conditions:

PARAMETER REFERENCE CONDITION

Process fluid Deionized water

Process

temperature

23°C ±3°C (73°F ±5°F)

Ambient

temperature

23°C ±3°C (73°F ±5°F)

Process

pressure

207 kPa (30 psig)

Supply voltage 24 VDC ±10%

Operation Re-zeroed

Power

Setpoint

Re-zero

Pressure signal

Flow signal

Alarm

InVue Integrated Flow Controller System Diagram

Sensor

measurement

Valve

control

Fluid

flow

Fluid

flow

InVue Integrated Flow Controller

control interface

Flow/valve module

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

4P/N 01-1032525 | Rev. B 02/19 | Entegris, Inc.

General Considerations

The following requirements and

specifications are briefly provided

here. Before installing and operating

the InVue Integrated Flow Controller,

see the Installation and Unit Opera-

tion sections of this user guide for

more detailed information.

NOTE: The flow controller has been

factory sealed. Do not attempt to

remove the cover of the unit. Any

attempt at removal of the unit cover

will void the warranty.

POWER SUPPLY REQUIREMENTS

—

The power supply range for the

flow controller is 24 VDC ±10%.

The power supply to the unit must

provide clean power and must be

used only to power similar measure-

ment-type devices.

STORAGE TEMPERATURE RANGE

—

The flow controller can withstand

storage temperatures between

-15°C–40°C (5°F–104°F) with no

permanent eect on the perfor-

mance of the device.

OPERATING AMBIENT

TEMPERATURE RANGE

—

The flow controller is designed to

operate in ambient temperature,

cleanroom environments. It is speci-

fied to operate at temperatures of

10°C–65°C (50°F–149°F).

OPERATING PROCESS

TEMPERATURE RANGE

—

The flow controller is designed to

operate in process temperatures of

10°C–65°C (50°F–149°F).

LINE PRESSURE

—

The system line pressure (measured

at the inlet of the unit) must be

69 kPa – 414 kPa (10 psig – 60 psig).

PRESSURE DROP

—

The flow rate is calculated using

Entegris' dierential pressure flow

technology. The minimum pressure

drop (inlet to outlet port dierential

pressure) required for the unit is

69 kPa (10 psig).

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

5Entegris, Inc. | P/N 01-1032525 | Rev. B 02/19

DIMENSIONS

—

NT6510

The following fitting size and flow range combinations are available

(Flaretek®, PrimeLock®, and Pillar®unless otherwise noted):

FITTING

SIZE

FLOW RANGE (ML/MIN)

TL

0–15

TT

0–25

T0

0–50

T1

0–125

T2

0–250

T3

0–500

T4

0–1250

1⁄4"Yes Yes Yes Yes Yes Yes Yes

3⁄8"Yes Yes Yes Yes Yes Yes Yes

1⁄2"—————Yes* Yes*

*Flaretek and PrimeLock only.

Please consult Entegris for custom flow range requirements.

INLET/OUTLET PORT

CONNECTION

DIMENSIONS

ABC

1⁄4" Flaretek tube fitting 118.1 mm (4.65") 17.0 mm (0.67") 187.5 mm (7.38")

3⁄8" Flaretek tube fitting 119.6 mm (4.71") 17.0 mm (0.67") 191.0 mm (7.52")

1⁄2" Flaretek tube fitting 119.6 mm (4.71") 17.0 mm (0.67") 195.1 mm (7.68")

1⁄4" PrimeLock tube fitting 118.1 mm (4.65") 17.0 mm (0.67") 177.8 mm (7.00")

3⁄8" PrimeLock tube fitting 119.6 mm (4.71") 17.0 mm (0.67") 177.8 mm (7.00")

1⁄2" PrimeLock tube fitting 119.6 mm (4.71") 17.0 mm (0.67") 182.4 mm (7.18")

1⁄4" Super 300 Pillar

tube fitting

118.1 mm (4.65") 17.0 mm (0.67") 159.3 mm (6.27")

3⁄8" Super 300 Pillar

tube fitting

119.6 mm (4.71") 17.0 mm (0.67") 167.1 mm (6.58")

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

6P/N 01-1032525 | Rev. B 02/19 | Entegris, Inc.

NT6520

The following fitting size and flow range combinations are available

(Flaretek, PrimeLock, and Pillar unless otherwise noted):

FITTING

SIZE

FLOW RANGE (L/MIN)

T5

0–2.5

T6

0–5

T7

0–10

T8

0–20

T9

0–40

3⁄8"Yes* Yes* ———

1⁄2"Yes** Yes** Yes — —

3⁄4"———Yes Yes

*Flaretek and Pillar only.

**Flaretek and PrimeLock only

Please consult Entegris for custom flow range requirements.

137.2 mm (5.40")

154.9 mm (6.10")

167.6 mm (6.60")

C

53.2 mm

(2.10")

39.4 mm

(1.55")

Top View

5.1 mm

(0.20")

A

Side View

B

End View

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

7Entegris, Inc. | P/N 01-1032525 | Rev. B 02/19

INLET/OUTLET PORT

CONNECTION

DIMENSIONS

ABC

3⁄8" Flaretek tube fitting 117.3 mm (4.62") 15.7 mm (0.62") 224.0 mm (8.82")

1⁄2" Flaretek tube fitting 120.9 mm (4.76") 18.3 mm (0.72") 228.0 mm (8.98")

3⁄4" Flaretek tube fitting 129.0 mm (5.08") 23.6 mm (0.93") 234.2 mm (9.22")

1⁄2" PrimeLock tube fitting 120.9 mm (4.76") 18.3 mm (0.72") 215.4 mm (8.48")

3⁄4" PrimeLock tube fitting 129.0 mm (5.08") 23.6 mm (0.93") 229.1 mm (9.02")

3⁄8" Super 300 Pillar

tube fitting

117.3 mm (4.62") 15.7 mm (0.62") 200.2 mm (7.88")

1⁄2" Super 300 Pillar

tube fitting

120.9 mm (4.76") 18.3 mm (0.72") 205.2 mm (8.08")

3⁄4" Super 300 Pillar

tube fitting

129.0 mm (5.08") 23.6 mm (0.93") 214.1 mm (8.43")

Top View

47 mm

(1.85")

187.5 mm (7.38")

170.2 mm (6.70")

200.2 mm (7.88")

7.1 mm

(0.28")

71.1 mm

(2.80")

C

B

A

Side View

End View

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

8P/N 01-1032525 | Rev. B 02/19 | Entegris, Inc.

Installation

PROVIDED EQUIPMENT

—

Verify:

Remove Unit from the Bag

NOTE: This unit has been assembled

and double-bagged under cleanroom

conditions. To maintain purity, only

open under cleanroom conditions.

CAUTION! Do not tighten the nuts that

protect the tube connections during

shipment. (See the Prepare Fluid Lines

section on page 10). Tightening these nuts

without the proper tubing installed may

damage the unit's tube connections.

Gloves

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

9Entegris, Inc. | P/N 01-1032525 | Rev. B 02/19

MOUNTING REQUIREMENTS

—

The flow controller may be mounted

in any orientation. The unit does not

require straight lengths of tubing at

the inlet or the outlet connection.

Mount the Unit

The flow controller and base bracket

assembly must be mounted to a solid

surface to ensure stability. Verify the

valve and the electrical cable are free

from mechanical stress from the

surrounding equipment.

NOTE: The flow controller requires

mounting in the direction of the

fluid flow.

#10 (M4)

Pan head

#10 (M4)

Flat washer

Recommended hardware

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

10 P/N 01-1032525 | Rev. B 02/19 | Entegris, Inc.

MECHANICAL INSTALLATION

—

The standard InVue Integrated Flow

Controller must be used with the

proper tubing size and fittings.

NOTE: For detailed Flaretek and

PrimeLock tube fitting assembly

instructions, visit www.entegris.com.

For detailed Super 300 Type Pillar tube

fitting assembly instructions, contact

Nippon Pillar Packaging Company, Ltd.

CAUTION! Over-tightening of

the nuts will result in damage

to the fitting.

Slide the nut onto the tube

Prepare Fluid Lines

Process fluid tube

Prepare each tube end

prior to installation

Connect Fluid Lines

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

11Entegris, Inc. | P/N 01-1032525 | Rev. B 02/19

Care should be taken when install-

ing the flow controller to avoid fluid

leaks. Do not use excessive torque or

subject the unit to high heat during

installation. The unit and base bracket

assembly must be mounted to a solid

surface to ensure stability. Verify the

body and the electrical cable are free

from mechanical stress from the

surrounding equipment.

POWER SUPPLY REQUIREMENTS

—

The power supply range for the flow

controller is 24 VDC ±10% regulated.

The power supply must provide con-

tinuous 1.0 ampere (nominal) service

for each flow controller installed. The

power supply requirements must be

met at the wire connections or con-

nector of the flow controller, not only

at the power supply itself.

The power supply to the unit must

provide clean power and must be

used only to power similar measure-

ment-type devices. The power supply

must not be used to power other

inductive loads, such as motors,

relays, or solenoids. These devices

may produce electrical transients

that may aect unit measurements.

An induced power spike, creating

an interruption in power greater than

10 milliseconds in duration, may

cause the unit to reset.

In addition to providing clean power,

the instrumentation signals and

power return lines must not be run

within the same conduit or cable

along with heavy current demands

from motors, charging capacitors, or

other inductive loads. This may cause

a voltage change within the instru-

mentation signal line, causing errone-

ous output readings from the flow

controller. Loss of power will not

cause the loss of any system para-

meters or calibration values.

Input Impedance of the

Voltage Setpoint

The input impedance of the voltage

setpoint is 37 kOhm.

Voltage Drop at the 4–20 mA

Setpoint Input

The 4–20 mA input will drop

<5 V at 20 mA. Input impedance

is <250 ohms.

Lift-o Voltage of the 4–20 mA

Output Loops

The minimum lift-o voltage of

the 4–20 mA output loops (flow,

pressure measurements) is 12 VDC.

The minimum lift-o voltage is

the voltage required at the unit for

proper operation. The maximum

load resistance for a 24 VDC supply

is 600 ohms and includes the

resistance of measurement devices

and the interconnecting cable.

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

12 P/N 01-1032525 | Rev. B 02/19 | Entegris, Inc.

Output Load Resistance Eects

Using a 24 VDC power supply, the

two 4–20 mA output loops (flow and

pressure) will experience no shift if

the load resistance is 0–600 ohms.

Reverse Polarity Protection

The flow controller is reverse polarity

protected; connecting the 24 VDC

power to any wires will not harm the

unit. To operate properly, the polarity

must be correct.

Over-voltage on any Wire (DC)

In the event of accidental application

of voltage greater than 24 VDC ±10%,

the flow controller will withstand

continuous 30 VDC on any wire

without compromising the unit.

Over-voltage on any Wire (AC)

The flow controller is not designed

to withstand the accidental applica-

tion of 110/220 VAC to any wire.

Application of AC voltage will

damage the unit.

Short Protection

The flow controller will not be damag-

ed or compromised in any way if any

combination of wires are shorted

together.

Circuit Protection

Fuse the three input power lines to

each individual InVue Integrated Flow

Controller. The three lines are:

• 2-Red/Pin R, +24 VDC (main

power, 1.0 Amp nominal)

• 3-Orange/Pin M, Flow output,

+24 VDC supply

• 4-Yellow/Pin T, Pressure output,

+24 VDC supply

Use a 2 Amp rated, time lag fuse. A

single fuse can be used for all three

input power lines combined, or in-

dividually, as preferred. Place the

fusing on the input power lines to

the unit at the equipment electrical

enclosure to ensure that both the

wiring to the unit and the unit itself

are protected from any over-current

condition. Best practice is to locate

the fuse away from the typical liquid

exposure or harmful vapor areas.

Locating it within the electrical

enclosure shared by the power

supply enables accessibility for

troubleshooting or replacement.

NOTE: Do not power down the unit

until the homing cycle is complete.

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

13Entegris, Inc. | P/N 01-1032525 | Rev. B 02/19

ELECTRICAL CONNECTIONS

—

Pigtail Electrical Cable

Units specified with a pigtail electrical

connection are manufactured with a

permanently attached cable.

Table 1 details the wire connections

for the flow controller type with pigtail

electrical cable.

Table 1: Wire connections – pigtail cable

WIRE COLOR MARKER NUMBER FUNCTION

Yellow 4Pressure output, +24 VDC supply

Brown 1Pressure output, 4–20 mA output

Orange 3Flow output, +24 VDC supply

Blue 5Flow output, 4–20 mA output

Green 9Re-zero input

Pink 11 Setpoint, voltage, 0–10 or 0–5 VDC

Gray 12 Setpoint, common

Tan 10 Setpoint, current, 4–20 mA

Black 8Ground (+24 VDC common)

Red 2+24 VDC

Violet 6Factory use only – do not connect

White 7Factory use only – do not connect

White/Red Dot-Dash 13 Alarm (non-polarized)

White/Red Dot-Dash 14 Alarm (non-polarized)

Pigtail Cable

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

14 P/N 01-1032525 | Rev. B 02/19 | Entegris, Inc.

G-coded Electrical Connector

(Units where the electrical connector

type has a code starting with “G", e.g.,

G01.)

Units specified with a G-coded con-

nector use a Turck®brand, versafast

style, BSMK type, constructed of

polyurethane with a coupling nut.

The connector is over-molded onto

an electrically shielded, PVC-jacketed

cable. The pin contacts for the

electrical connection are gold-plated

for performance and corrosion resis-

tance. The connector is physically

“keyed," making it easy to connect to

a receptacle. Press it into a receptacle

and turn the threaded coupling nut to

draw the connector and receptacle

together until finger tight. G-coded

connectors to pigtail mating cables

are available. See the Ordering

Information section of this user guide.

The following pin diagram and Table

2 detail the wire connections for the

flow controller type with G-coded

electrical connector.

Mandatory Connections

2-Red/Pin R and 8-Black/Pin E

wires must be connected according

to Table 1, Table 2 and the Wiring

Diagram on page 16.The setpoint

must also be connected to 10-Tan/

Pin U wire (4–20 mA setpoint)

and 12-Gray/Pin S wire (common

setpoint) or to 11-Pink/Pin G wire

(voltage setpoint) and 12-Gray/Pin S

wire (common setpoint). Connect

9-Green/Pin J (re-zero input) to

switched, normally open 24 VDC

±10% main power supply in order

to have the same ground as the

8-Black/Pine E (ground).

NOTE: The 24 VDC connected to

re-zero must be the main power supply

in order to have the same ground as

8-Black/Pin E. See the Maintenance

section of this user guide for re-zero

instructions.

Consult Entegris with any questions

about electrical installation.

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

15Entegris, Inc. | P/N 01-1032525 | Rev. B 02/19

Table 2. Wire connections – G-coded connector

PIN COLOR FUNCTION

RRed +24 VDC

EBlack Ground (+24 VDC common)

TYellow Pressure output, +24 VDC supply

ABrown Pressure output, 4–20 mA output

MOrange Flow output, +24 VDC supply

LBlue Flow output, 4–20 mA output

JGreen Re-zero input

UTan Setpoint, current, 4–20 mA

GPink Setpoint, voltage, 0–10 or 0–5 VDC

SGray Setpoint, common

OViolet Factory use only – do not connect

PWhite Factory use only – do not connect

CRed w/ blue stripe Alarm (non-polarized)

NGray w/ brown stripe Alarm (non-polarized)

Unused Connections

The 6-Violet/Pin O and 7-White/Pin P

wires are for factory use only. Do not

connect to power supply or ground.

These wires must remain

disconnected.

A

E

C

G

J

L

M

N

O

PR

T

U

S

Plug Orientation, Face View

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

16 P/N 01-1032525 | Rev. B 02/19 | Entegris, Inc.

WIRING DIAGRAMS

—

Normally open switch

Power supply

Power supply

Setpoint control signal

Setpoint control signal

4–20 mA

Normally open switch

For re-zeroing

24 VDC ±10%

24 VDC ±10%

0–5 VDC or

0–10 VDC

For re-zeroing

Electrical cable

Electrical cable

09-Green/Pin J

02-Red/Pin R

(+)

08-Black/Pin E

(-)

12-Gray/Pin S

(-)

10-Tan/Pin U

(+)

02-Red/Pin R

(+)

08-Black/Pin E

(-)

12-Gray/Pin S

(-)

11-Pink/Pin G

(+)

09-Green/Pin J

03-Orange/Pin M

05-Blue/Pin L

04-Yellow/Pin T

01-Brown/Pin A

13-Stripes/Pin C

14-Stripes/Pin N

02-Red/Pin R

09-Green/Pin

J

06-Violet/Pin

O

07-White/Pin P

A

V

11-Pink/Pin G

10-Tan/Pin U

12-Gray/Pin

S

8-Black/Pin E

InVue

NT6510/NT6520

Flow Controller

Flow

Alarm

Pressure

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

17Entegris, Inc. | P/N 01-1032525 | Rev. B 02/19

OPTIONAL CONNECTIONS

—

To monitor flow rate, apply 24 VDC

to 3-Orange/Pin M wire and measure

the 4–20 mA flow output signal from

5-Blue/Pin L wire.

To monitor inlet pressure, apply

24 VDC to 4-Yellow/Pin T wire and

measure the 4–20 mA pressure

output signal from 1-Brown/Pin A

wire.

These outputs are electronically

isolated from all other circuit

connections. Using a separate

power supply is possible.

Power supply

24 VDC ±10%

Flow display/

measurement device

Pressure display/

measurement device

Electrical cabl

e

03-Orange/Pin M

Flow loop

05-Blue/Pin L

04-Yellow/Pin

Pressure loop

01-Brown/Pin A

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

18 P/N 01-1032525 | Rev. B 02/19 | Entegris, Inc.

SETPOINT SIGNAL SETUP

—

Use the following formulas to adjust

your setpoint signal output device

to match the flow range of the unit.

Repeat the calculations for multiple

control points.

Formulas and Example Calculations

FLOW

6510-T4-F02-B06-K-P7-U3

99999

1/4“Flaretek®

0 –1250 mL/min

Flow Range = 0–1250 mL/min

4 mA or

0 VDC

at 0 mL/min

20 mA or

5 or 10 VDC

at 1250 mL/min

Product label

F = Desired flow (mL/min/L/min)

FS = Full scale flow (mL/min/L/min)

Span

= Range of the output signal

4–20 mA Setpoint Control Signal

Range of product= 0-1250 mL/min

F = 125 mL/min

Span = 20 mA - 4 mA = 16 mA

FS = 1250 mL/min

SetpointmA = (125 mL/min) × (16 mA) +4 m

A

(1250 mL/min)

SetpointmA = 5.6 mA

Range of product= 0-1250 mL/min

F = 500 mL/min

Span = 10 VDC - 0 VDC = 10 VDC

FS = 1250 mL/min

SetpointVDC= (500 mL/min) (10 VDC)

(1250 mL/min)

Setpoint

VDC

= 4.0 VDC

0–5 VDC or 0–10 VDC Setpoint Control Signal

SetpointmA = F × Span +4 mA

FS

SetpointVDC = F × Span

FS

INVUE INTEGRATED FLOW CONTROLLERS, MODELS NT6510, NT6520

19Entegris, Inc. | P/N 01-1032525 | Rev. B 02/19

CALIBRATION GRAPHS

—

NOTE: Specifications are subject

to change without notice. Please

consult Entegris for the most

current information.

24

20

16

12

8

4

0

mAdc Output

24

20

16

12

8

4

0

mAdc Output

Percent of Full Scale Flow

Pressure (psig)

020406080100 120

Output not specified

below 5.6 mAdc (10% FS flow)

Do not operate

above 60 psig.

Do not operate

below 10 psig.

mAdc Output vs. Full Scale Flow: 10–100% of Full Scale Flow

mA Output vs. Pressure

0510 15 20 25 30 35 40 45 7050 55 60 67

⁄”, ⁄”, ⁄”, ⁄“ and ⁄”

5.6 mAdc

20.0 mAdc

20.5 mAdc

20.0 mAdc

20.5 mAdc

This manual suits for next models

1

Table of contents

Other entegris Controllers manuals