2 Curtis 1212 Manual

1 — OVERVIEW

✓ The vehicle is brought to a complete stop before the electromagnetic

brake is applied, ensuring safe and secure stops under all conditions

✓ Charger inhibit input prevents driving while charger is attached

✓ Key Off Decel function ensures a smooth “brake to stop” when the

key is turned off while driving or when a fault occurs that requires the

vehicle to stop

✓ Anti-Rollback/Roll-forward function provides smooth and safe vehicle

control on hills and ramps

✓ Internal main contactor provides secure power-off

✓ Boost current gives a brief boost of current greatly improving

transient loads such as starting on a hill, crossing thresholds, etc.

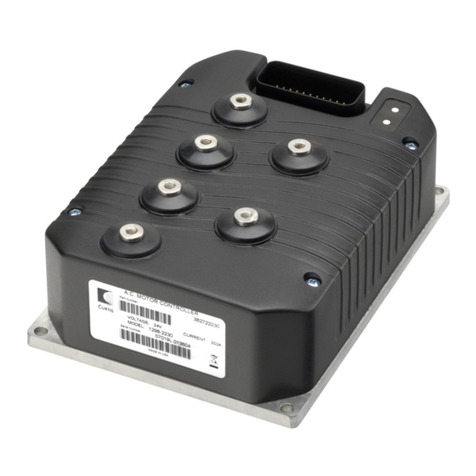

Easy Installation and Setup

✓ Industry standard footprint, mounting centers, and wiring allows

drop-in replacement of other controllers

✓ Model 1212 controllers are easily programmed with Model 1311

handheld or Model 1314 PC programmers, or can be supplied

pre-programmed

✓ Accepts all standard throttle types, including single-ended, wigwag,

and unipolar

✓ Simplified troubleshooting and diagnostics

✓ Standard Mini-Fit Molex Jr. and Faston terminals provide proven,

robust wiring connections

Valuable Additional Features

✓ Optional Push Switch input releases the brake and allows the motor

to free-wheel

✓ Push-Too-Fast feature restricts the vehicle’s speed while it is being

pushed, even with the key off or the batteries disconnected

✓ Automatic compensation for changes in motor condition to ensure

optimum drive preformance at all times

✓ Multi-mode provides for two distinct and programmable control

modes (indoor/outdoor)

✓ Power Saver function prevents the controller draining the battery

when the vehicle is inactive

✓ Battery Discharge Indicator output

✓ Optional Speed Inhibit input offers flexibility to reduce speed or

prevent drive under certain conditions, such as when the seat is lifted

✓ Adjustable brake hold voltage reduces heating of the brake coil

✓ Reverse Beeper function alerts bystanders

✓ Electronics sealed to IPX5