entegris Aramus SU-2D Series User manual

ADVANCED MATERIALS HANDLING |MANUAL

Aramus™Standard

Bag Assemblies

User manual

1

ARAMUS STANDARD BAG ASSEMBLIES

User Manual | Rev. B 03/20 | Entegris, Inc.

TABLE OF CONTENTS

—

Introduction ................................................................... 2

Safety ............................................................................... 2

Aramus Standard Bag Subassemblies ........................ 3

Bag Description .............................................................. 3

Removing the Aramus Subassembly

from its Packaging ......................................................... 3

Connecting Bags ........................................................... 3

Filling and Freezing Bags ............................................. 3

Storage, Handling, and Shipping ............................... 3

Aramus Standard Bag Assemblies .............................. 3

Removing the Full Aramus Assembly

from its Packaging ......................................................... 4

Hanging the Full Aramus Assembly .......................... 4

Connecting Bags ........................................................... 4

Filling and Freezing Bags ............................................. 4

Storage, Handling, and Shipping ............................... 5

Specifications for Aramus Assembly

Standard Components ................................................. 5

Configurations ................................................................ 6

Ordering Information ................................................... 7

Aramus Standard Bag Assembly

with RoSS®Shell ......................................................... 10

Specifications ................................................................. 11

Shipping ......................................................................... 12

Inspection ...................................................................... 12

Assembly Instructions ................................................ 12

Ordering Information ................................................. 14

Aramus Standard Bag Assembly

with Cassettes .............................................................. 15

Specifications ................................................................ 16

Warnings ........................................................................ 16

Shipping ......................................................................... 17

Inspection ...................................................................... 17

Assembly Instructions ................................................ 17

Ordering Information ................................................. 19

RoSS Shell and Cassette Disclaimer ........................ 19

Limited Warranty ........................................................ 20

For More Information ................................................ 20

Terms and Conditions of Sale .................................. 20

2

ARAMUS STANDARD BAG ASSEMBLIES

User Manual | Rev. B 03/20 | Entegris, Inc.

INTRODUCTION

—

Standard Aramus™single-use 2D bag assemblies are

made of a high-grade, gamma-stable fluoropolymer,

providing higher purity, greater compatibility, and

increased safety for critical process fluids and final

products. With a new single-layer technology that

contains no curing agents, antioxidants, plasticizers,

or adhesives, the number of potential contaminants

is greatly reduced. These assemblies oer the widest

operating temperature range, making them more

durable in frozen applications (to -85°C [-121°F] or

lower) without negatively aecting the film.

Additionally, the fluoropolymer film oers universal

material compatibility, reducing the risk of material

and assembly failure. Aramus single-use assemblies

are manufactured in an ISO®Class 5 cleanroom using

methodologies that go beyond the standard. These

assemblies allow for easier validation and provide

high purity, performance, quality, and safety for

your process.

This user manual describes the instructions for use

for the Aramus bag and assemblies.

SAFETY

—

Before using any Aramus single-use assembly or

subassembly, you should read, understand, and

follow the instructions in this manual. Save these

instructions and make them available to users of

this product.

To prevent injury, follow these safety procedures:

• Do not hang bags on anything that cannot support

the weight; doing so can cause injury and/or

equipment damage from tipping over.

• Do not use the tubing to handle or carry the bags.

• Do not use this product in a manner inconsistent

with its intended use.

• Follow all appropriate chemical safety and disposal

regulations.

• Wear appropriate personal protective equipment

when handling components containing chemicals.

• Over pressurizing this product may cause injury

from flying debris and/or exposure to chemicals.

• DO NOToverfill this product. Overfilling may lead

to a spill and chemical exposure.

• Regularly inspect the product for leaks or other

damage.

• Please note that the user shall be solely responsible

and liable for validation and use of Aramus bags

beyond the range of our specifications for unit

operations, applications, and process parameters.

ARAMUS STANDARD BAG ASSEMBLIES

3User Manual | Rev. B 03/20 | Entegris, Inc.

ARAMUS SUBASSEMBLIES

—

If you ordered the full assembly, skip to Aramus

Standard Bag Assemblies on page 4.

Entegris oers the Aramus bag assembly in a sub-

assembly configuration; meaning without tubing,

connectors, or sterilization.

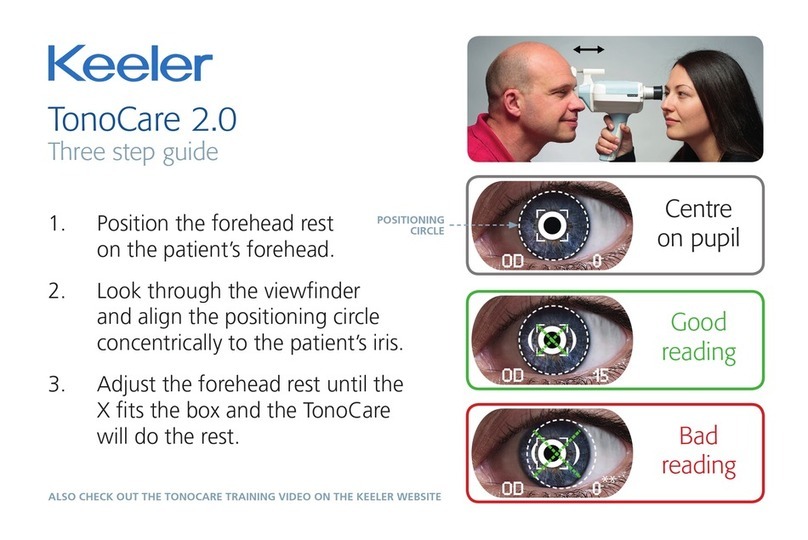

BAG DESCRIPTION

Aramus subassemblies are oered in 2D configura-

tions in various sizes with a 2- or 3-port boat fitment.

See Figure 1 for Aramus subassembly bag configu-

ration. See Ordering Information on page 9 for the

standard part numbers available; customization is

available upon request.

REMOVING THE ARAMUS SUBASSEMBLY FROM

ITS PACKAGING

CAUTION: DO NOT use anything sharp to remove

the Aramus subassembly from its packaging.

1. The Aramus subassemblies will arrive in a corru-

gated box. DO NOT use anything sharp to open

the box. Remove packing tape with caution to

avoid damaging the contents.

2. There are two sealed bags protecting the Aramus

subassembly. To open the outer bag, grip the side

of the protective packaging bag and use the “easy

tear" notches (see Figure 2) to pull in opposite direc-

tions, allowing the top section and main body of

the packaging to separate and subsequently open

the bag. Repeat this procedure to open the inner

protective package.

CONNECTING BAGS

Attach appropriately sized tubing to the hose barb

connections found on the boat fitment. The tubing

can then be combined with your desired connecting

piece or method.

FILLING AND FREEZING BAGS

The specified Aramus bag volume is the actual fill

volume the bag is capable of holding. The bags

are rated to 110% of the nominal volume to avoid

overfilling. For best freezing, it is recommended

that the Aramus bag be laid flat or in a horizontal

position and should be filled to no more than the

maximum rated volume.

STORAGE, HANDLING, AND SHIPPING

The Aramus subassembly has a recommended stor-

age temperature of 18° to 30°C (64° to 86°F), but due

to its material of construction, has a performance

temperature rating of -85° to 40°C (-121° to 104°F).

Handle with care to avoid dropping and when hang-

ing the bag vertically, ensure that it is hung securely.

To reduce the risk of damage, filled bags should be

stored, handled, and shipped in a secondary protec-

tive container. DO NOT use bubble wrap around filled

and frozen bags for shipping.

3-port Subassembly

2-port Subassembly

Figure 1. Aramus subassembly bag configurations

Figure 2. Easy tear notches

Easy tear

notches

4

ARAMUS STANDARD BAG ASSEMBLIES

User Manual | Rev. B 03/20 | Entegris, Inc.

ARAMUS STANDARD BAG ASSEMBLIES

—

Entegris oers the Aramus bag in a full assembly with

your desired configuration of tubing and connectors,

delivered sterilized with a Sterility Assurance Level

(SAL) of 10-6.

REMOVING THE FULL ARAMUS ASSEMBLY FROM

ITS PACKAGING

CAUTION: DO NOT use anything sharp to remove

the Aramus assembly from its packaging.

1. The Aramus assembly will arrive in a corrugated

box. DO NOTuse anything sharp to open the

box. Remove packing tape with caution to avoid

damaging the contents.

2. There are two sealed bags protecting the Aramus

assembly. To open the outer bag, grip the side of

the protective packaging bag and use the “easy

tear" notches (see Figure 3) to pull in opposite

directions, allowing the top section and main

body of the packaging to separate and subse-

quently open the bag. Repeat this procedure

to open the inner protective package.

HANGING THE FULL ARAMUS ASSEMBLY

The Aramus assembly has a convenient and

durable hanging slot, as shown in Figure 4.

CONNECTING BAGS

The standard mating hardware oered are Luer

connections and MPC connections. Please follow

the manufacturer’s guidelines when connecting to

these components. The pinch clamp must be in the

released position to ensure flow within the bag.

FILLING AND FREEZING BAGS

The specified Aramus bag volume is the actual

fill volume the bag is capable of holding. The bags

are rated to 110% of the nominal volume to avoid

overfilling.

For best freezing, it is recommended that the Aramus

bag be laid flat or in a horizontal position and should

be filled to no more than the maximum rated volume.

Easy tear

notches

Figure 3. Easy tear notches

Figure 4. Convenient hanging slot

ARAMUS STANDARD BAG ASSEMBLIES

5User Manual | Rev. B 03/20 | Entegris, Inc.

STORAGE, HANDLING, AND SHIPPING

The components on the full Aramus assembly are

commonly used in the market and have various

temperature claims. Entegris has tested the Aramus

bag assemblies while using these components.

The Aramus assembly has a recommended storage

temperature of 18° to 30°C (64° to 86°F), but due

to its material of construction, has a performance

temperature rating of -85° to 40°C (-121° to 104°F).

Handle with care to avoid dropping and when hang-

ing the bag vertically, ensure that it is hung securely.

To reduce the risk of damage, filled bags should be

stored, handled, and shipped in a secondary protec-

tive container. DO NOT use bubble wrap around filled

and frozen bags for shipping.

SPECIFICATIONS FOR ARAMUS ASSEMBLY

STANDARD COMPONENTS

Specifications for the components found on

full Aramus assemblies can be located on the

supplier websites:

Component supplier Website

Colder Product Company

MPC connections

https://www.cpcworldwide.com/

Saint-Gobain

C-Flex®tubing, platinum-cured silicone

tubing, BarbLock®, and pinch clamps

https://www.saint-gobain-northamerica.com/business/markets/life-sciences

Oetiker

Stepless®clamps

http://www.oetiker.com/

Nordson Medical

Luer connections

http://www.nordsonmedical.com/

AdvantaPure

AdvantaFlex®and AdvantaSil®tubing

http://www.advantapure.com/

6

ARAMUS STANDARD BAG ASSEMBLIES

User Manual | Rev. B 03/20 | Entegris, Inc.

CONFIGURATIONS

Full Aramus bag assemblies are oered in 2D con-

figurations in various sizes with a 2- or 3-port boat

fitment and the selected configuration of tubing and

ITEM DESCRIPTION

1Aramus fluoropolymer film with slot for hanging

2Fluoropolymer "boat" fitment

with 2 hose barb ports

3Tubing connection (BarbLock clamp, Oetiker

Stepless clamp, or zip ties*)

4Tubing ⁄" ID × ⁄" OD

(AdvantaFlex thermoplastic elastomer [TPE],

AdvantaSil silicone, Tygon®silicone, or

C-Flex 374 elastomer)

5Pinch clamps

6Tubing fittings ⁄" ID

(Luer male/female with plugs)

connectors. See Ordering Information on page 7 for

the standard part numbers available; customization

is available upon request.

ITEM DESCRIPTION

1Aramus fluoropolymer film with slot for hanging

2Fluoropolymer "boat" fitment

with 3 hose barb ports

3Tubing connection (BarbLock clamp, Oetiker

Stepless clamp, or zip ties*)

4Tubing for 500 mL, 1 L, and 2 L is ⁄" ID × ⁄" OD

Tubing for 5 L, 10 L, 20 L, and 50 L* is ⁄" ID × ⁄"

OD (AdvantaFlex TPE, AdvantaSil silicone, Tygon

silicone, or C-Flex 374 elastomer)

5Tubing for 500 mL, 1 L, and 2 L is ⁄" ID × ⁄" OD

Tubing for 5 L, 10 L, 20 L, and 50 L* is ⁄" ID × ⁄"

OD (AdvantaFlex TPE, AdvantaSil silicone,

Tygon silicone, or C-Flex 374 elastomer)

6Pinch clamps

7Tubing fittings (CPC MPC male/female

with plugs)

8Tubing fittings (Luer male/female with plugs)

9Rod (5 L, 10 L, 20 L, and 50 L*)

Full Aramus Assembly

Configuration Options

2-port: 20 mL, 50 mL, 100 mL, 250 mL

1

2

5

3

6

4

1

2

3

6

4

3

7

8

5

9

Full Aramus Assembly

Configuration Options

3-port: 500 mL, 1 L

Full Aramus Assembly

Configuration Options

3-port: 2 L (no rod),

5 L, 10 L, 20 L, 50 L* (with rod)

5

4

Note: See Ordering Information for the standard part numbers available; customization available upon request.

*Not a standard product, but is available upon request.

ARAMUS STANDARD BAG ASSEMBLIES

7User Manual | Rev. B 03/20 | Entegris, Inc.

ORDERING INFORMATION

Aramus Standard Bag Assemblies (2-port): part number

SU-2D- -

Notes: Assemblies sold sterilized. Assembly temperature

performance is component-dependent. Assemblies are

individually double-bagged.

*Not a standard product, but is available upon request.

Fasteners

O = Oetiker SS

ear clamps

B = BarbLock

clamps

Z = Zip ties*

Product family

SU= Single-use

Product type

2D= 2D bag

Volume

0.020 = 20 mL

0.050 = 50 mL

0.100 = 100 mL

0.250 = 250 mL

Tube material

F = AdvantaFlex thermoplastic elastomer

P = AdvantaSil silicone

S = Tygon silicone

T = C-Flex 374 elastomer

Tube length

0 = 6"

1 = 12"

2 = 18"

3 = 24"

Main connectors

L11 = Luer–1: female 1: female

L12 = Luer–1: female 2: male

L22 = Luer–2: male 2: male

8

ARAMUS STANDARD BAG ASSEMBLIES

User Manual | Rev. B 03/20 | Entegris, Inc.

ORDERING INFORMATION (CONTINUED)

Aramus Standard Bag Assemblies (3-port): part number

SU-2D- -

B

A

B

A

Product family

SU = Single-use

Product type

2D= 2D bag

Volume

00.5 = 500 mL

0001 = 1 L

0002 = 2 L

0005 = 5 L

0010 = 10 L

0020 = 20 L

0050 = 50 L*

Tube length

0 = 6"

1 = 12"

2 = 18"

3 = 24"

Main connectors

CFM = MPC – A: female B: male

CFF = MPC – A: female B: female

CMF = MPC – A: male B: female

CMM = MPC – A: male B: male

Note: See drawing below for A and B indicators

for part numbers

Sample connectors

1 = Luer female

2 = Luer male

Notes: Assemblies sold sterilized. Assembly temperature

performance is component-dependent. Assemblies are

individually double-bagged.

*Not a standard product, but is available upon request.

Fasteners

O = Oetiker SS

ear clamps

B = BarbLock

clamps

Z = Zip ties*

Tube material

F = AdvantaFlex thermoplastic elastomer

P = AdvantaSil silicone

S = Tygon silicone

T = C-Flex 374 elastomer

ORDERING INFORMATION (CONTINUED)

Aramus Subassemblies (2-port): part number

SU-2D- -U

Product family

SU= Single-use

Product type

2D= 2D bag

Volume

0.020= 20 mL

0.050= 50 mL

0.100 = 100 mL

0.250 = 250 mL

Note: Subassemblies sold unsterilized.

Aramus Subassemblies (3-port): part number

SU-2D- -U

Product family

SU= Single-use

Product type

2D= 2D bag

Volume

00.5 = 500 mL

0001 = 1 L

0002= 2 L

0005= 5 L

0010 = 10 L

0020= 20 L

0050= 50 L*

Note: Subassemblies sold unsterilized.

*Not a standard product, but is available upon request.

ARAMUS SINGLE-USE 2D BAG ASSEMBLIES

9User Manual | Rev. B 03/20 | Entegris, Inc.

10

ARAMUS STANDARD BAG ASSEMBLIES

User Manual | Rev. B 03/20 | Entegris, Inc.

ARAMUS STANDARD BAG ASSEMBLY WITH ROSS®SHELL

—

Aramus single-use bag assembly, combined with the

RoSS (Robust Storage and Shipping) shell, provide

greater protection during handling, more consistent

freezing/thawing, and reduced storage density. The

following instructions explain how to most eectively

use the two together for filling, freezing, handling,

and thawing applications.

Please use the correct Aramus bag size and RoSS shell

combination. If filling to maximum volume, remove

excess air from bag to prevent the bag from over

expanding within the RoSS shell. Fill the bags to

greater than 30% of their maximum fill volume stated

in the specification table, page 11. For example, 30%

of a 10 L bag's maximum fill volume is 2.3 L (7.6 x 0.3).

To prevent adverse freezing conditions, do NOT fill

bags above their maximum fill volume, or below 30%

of this volume. This information is for guidance purposes

only. Optimal fill volumes and ranges should be

determined by the customer for each individual

product, freezing method, freezer type, and profile.

CAUTION: Failure to confirm fit for use under

the customer’s requirements may result in

product failure.

NOTE: Additional accessories such as foam inserts may

be necessary to ensure consistent freezing at dierent

fill volumes.

Aramus bag assembly and RoSS shell

ARAMUS STANDARD BAG ASSEMBLIES

11User Manual | Rev. B 03/20 | Entegris, Inc.

SPECIFICATIONS

Aramus bag

size

1 L 2 L 5 L 10 L 20 L

Maximum

fill volume

0.9 L 1.7 L 3.5 L 6.5 L 11.0 L

RoSS shell

part number

SU-FS-0001-01 SU-FS-0002-01 SU-FS-0005-01 SU-FS-0010-01 SU-FS-0020-01

RoSS shell

weight

1.96 kg

(4.31 lbs)

2.83 kg

(6.23 lbs)

4.45 kg

(9.79 lbs)

6.13 kg

(13.49 lbs)

8.73 kg

(19.21 lbs)

RoSS shell

dimensions

208 mm ×

483 mm ×

37 mm

(8.2" × 13.7" × 1.5")

288 mm ×

533 mm ×

37 mm

(11.3" × 21" × 1.5")

358 mm ×

643 mm ×

52 mm

(14.1" × 25.3" × 2.0")

408 mm ×

703 mm ×

70 mm

(16" × 27.7" × 2.0")

503 mm x

883 mm ×

70 mm

(19.8" × 34.8" × 2.0")

Contact Entegris technical support if you have questions regarding this information, and to confirm you have the most up-to-date version.

WARNINGS

Aramus Bag Assembly

• Do not handle or carry the bags by the tubing

• Do not overfill or over pressurize the bag

• Regularly inspect for leaks and other damage

• Always ensure that all bag assembly components

are secure within the RoSS shell before use

• Do not use this product in a manner inconsistent

with its intended use

NOTE: User shall be solely responsible and liable for

validation and use of the Aramus bag assemblies beyond

the range of our specifications.

12

ARAMUS STANDARD BAG ASSEMBLIES

User Manual | Rev. B 03/20 | Entegris, Inc.

SHIPPING

Based on currently available information, the RoSS

shells may give user the best chance for successfully

shipping your product in an Aramus bag assembly.

However, since each company’s product likely has

unique freezing characteristics, the combined use

of RoSS shells and Aramus bag assemblies should

be fully validated by the customer.

As always, the customer is responsible for verifying fit

for use in combination with their product and in their

specific application.

INSPECTION

When unpacking the RoSS shell, be sure not to

scratch the stainless-steel shell cover when removing

the plastic overwrap. If a knife is used, keep the blade

point away from the stainless-steel shell cover.

Place the RoSS shell horizontally on a table making

sure the product label is oriented correctly.

ASSEMBLY INSTRUCTIONS

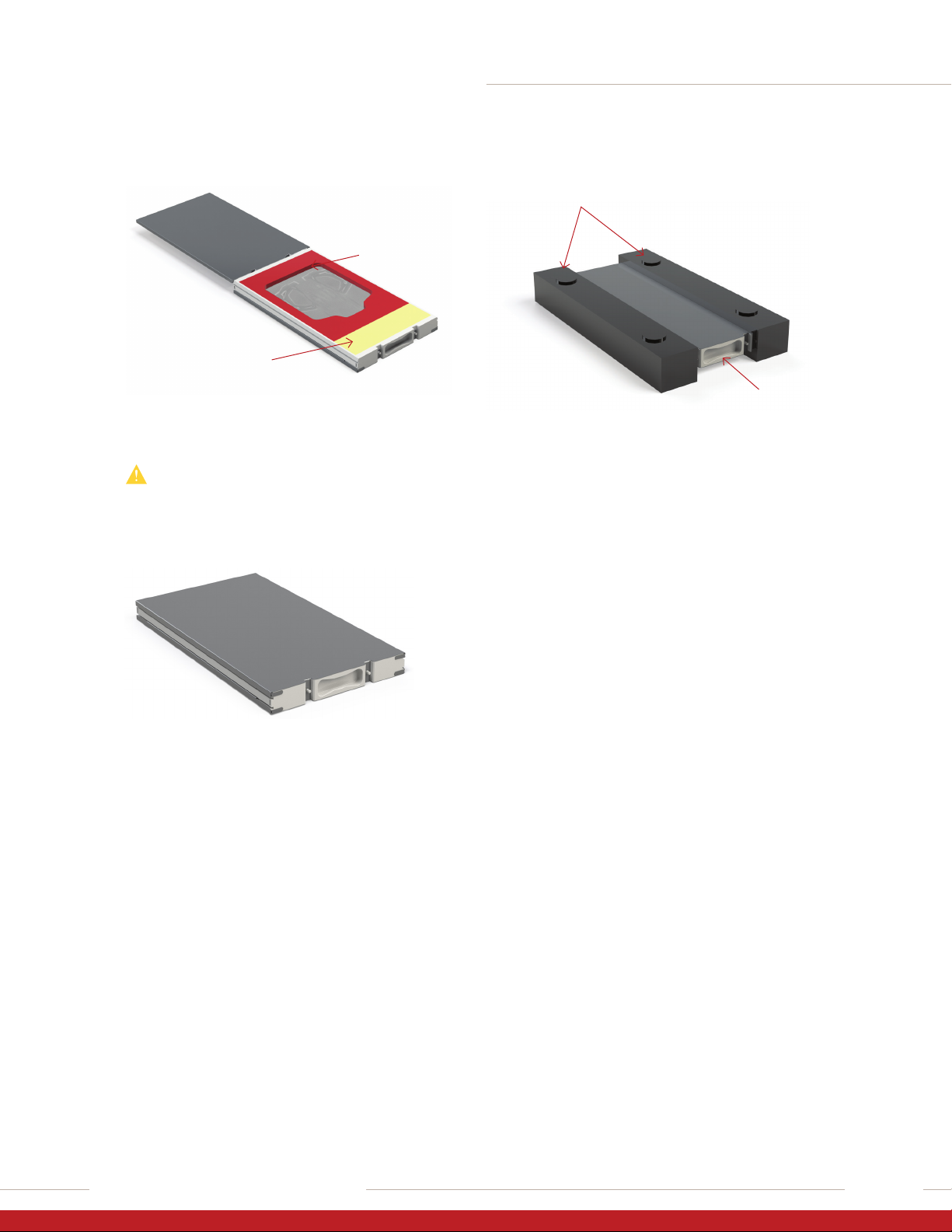

Step 1: Open RoSS Shell

Pull open the four, stainless-steel upper tabs; two

on the sides and two in the middle near the recessed

handle. Slide open the stainless-steel top lid until

completely removed.

Keep the lid fully removed and stored in a horizontal

position until step 5.

Step 2: Remove Foam Layers

Remove only the upper tubing foam and the rod foam

before placing the bag inside.

CAUTION! Safe foam pads along the sides

are attached to the RoSS shell and will be

damaged if they are removed.

Step 3: Fill and Insert Aramus Bag

Fill the Aramus bag to correct fill volume (see Specifi-

cations, page 11). It is suggested to fill to maximum

volume. If the bag is 10 L or greater, fill the bag while

it is inside the RoSS shell.

NOTE: The RoSS system will not work correctly if the

Aramus bag is positioned improperly.

Place the Aramus bag in the middle with the bag

chamber on the stainless-steel base, between the

side foam pads. The rod section needs to be placed

to the very back of the shell.

Wrap the tubing in a loose coil and place on top of

the lower tubing foam. Ensure the clamps on the

tubing are placed in a horizontal orientation to fit in

the shell and that the tubing and bag do not overlap.

Upper tabs

Lower foam,

DO NOT remove

Upper foam

Rod foam

Safe foam

Rod section

ARAMUS STANDARD BAG ASSEMBLIES

13User Manual | Rev. B 03/20 | Entegris, Inc.

Step 4: Secure Tubing

Place the upper foam and rod foam pads back in

their initial positions while making sure there are

no overhanging parts.

CAUTION! If the tubing and/or foam pads are

not placed in a snug, correct manner, they can

be damaged when closing the RoSS shell.

Step 5: Close the Shell

Insert and slide stainless-steel lid back onto the

shell. You may need to push down on the foam

while sliding the lid. Close the upper stainless-steel

tabs to secure the system.

Step 6: Insert Cryo Control Unit (CCU) Supports

CCUs are used to facilitate controlled freezing. When

freezing in standard static or blast freezers, insert CCU

onto the long sides of the RoSS shell, one at a time.

The CCU should fit snuggly with the shell.

NOTE: If using a plate freezer, CCUs are not needed with

the RoSS shell. Please refer to plate freezer manufacturers’

recommended procedures.

Step 7: Lift and Place in Freezer

(Static and Blast Freezing Only)

Lift by the recessed handles on each end and place

horizontally in a freezer. For consistent freezing,

ensure the RoSS shell bottom plate is not in direct

contact with the freezer shelf.

Always use the recessed handles for carrying the

RoSS shell and use a cart for the 20 L size.

Step 8: Thawing

Inspect the RoSS system to ensure no damage

or significant bulging occurred during freezing.

The stainless-steel tabs should all be secure, and

neither the bag nor tubing should be visible.

To thaw, store the RoSS system at ambient tempera-

ture on a bench or table. Thawing can be accelerated

using a fan.

Thawing can also be done in a plate freezer, refer to

manufacturer’s recommended procedures.

Rod foam

Upper foam

Handle

CCU supports

14

ARAMUS STANDARD BAG ASSEMBLIES

User Manual | Rev. B 03/20 | Entegris, Inc.

ORDERING INFORMATION

To order RoSS shells and CCUs for filling, freezing,

handling, and thawing applications, refer to the

following:

RoSS Shell

Part number Compatible Aramus bag assembly

SU-FS-0001-01 1 L

SU-FS-0002-01 2 L

SU-FS-0005-01 5 L

SU-FS-0010-01 10 L

SU-FS-0020-01 20 L

Cryo Control Unit (CCU)

Part number Compatible Aramus bag assembly

SU-CC-0001-01 1 L

SU-CC-0002-01 2 L

SU-CC-0005-01 5 L

SU-CC-0010-01 10 L

SU-CC-0020-01 20 L

ARAMUS STANDARD BAG ASSEMBLIES

15User Manual | Rev. B 03/20 | Entegris, Inc.

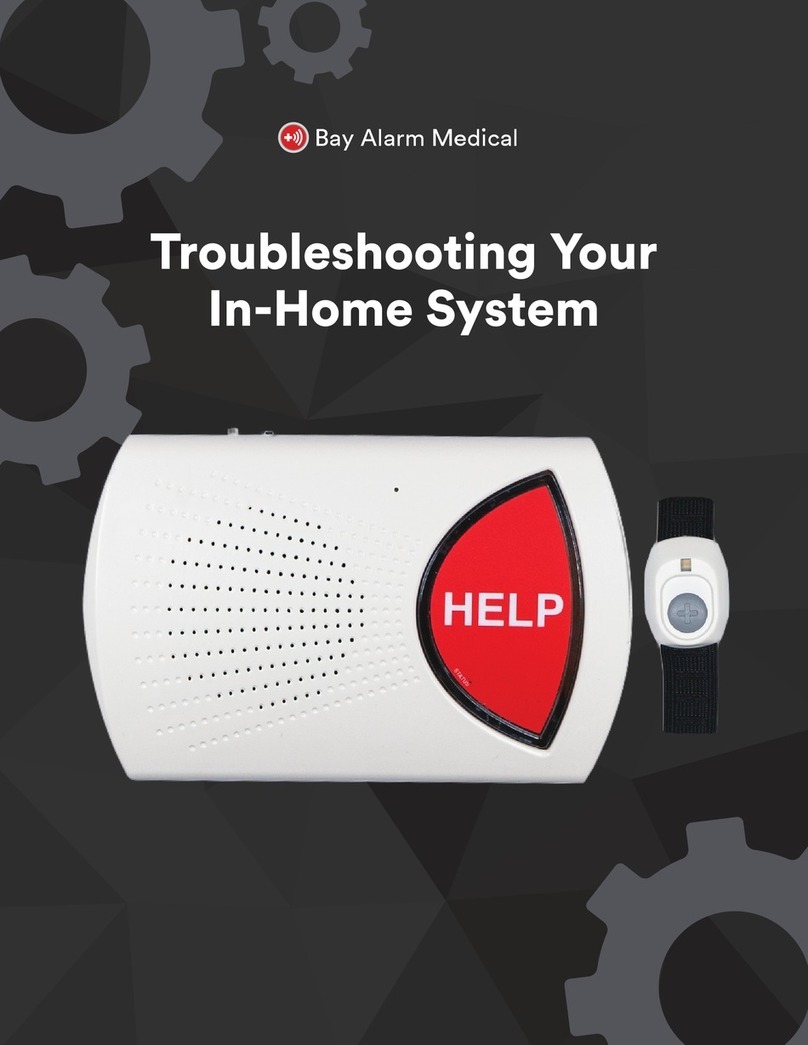

ARAMUS STANDARD BAG ASSEMBLY WITH CASSETTES

—

At lower volumes, the Aramus single-use bag

assemblies can be combined with cassettes to

provide greater protection during freezing and

handling. The following instructions explain how

to most eectively utilize the two together for fill-

ing, freezing, handling, and thawing applications.

Please use the correct Aramus bag size and cassette

combination. These cassettes are designed to be

used with standard pinch clamps allowing for sterile

connections. In general, do not use tubing lengths

longer than 12", which can be dicult to fit into the

cassette.

Fill the bags to greater than 25% of their maximum

fill volume stated in the specification table, page 16.

For example, 25% of a 250 mL bag's maximum fill

volume is 50 mL (200 x 0.25). To prevent adverse

freezing conditions, do NOT fill bags above their

maximum fill volume, or below 25% of this volume.

This information is for guidance purposes only.

Optimal fill volumes and ranges should be deter-

mined by the customer for each individual product,

freezing method, freezer type, and profile.

CAUTION: Failure to confirm fit for use under

the customer’s requirements may result in

product failure.

Aramus 50 mL bag assembly and cassette

16

ARAMUS STANDARD BAG ASSEMBLIES

User Manual | Rev. B 03/20 | Entegris, Inc.

SPECIFICATIONS

Aramus bag

size

20 mL 50 mL 100 mL 250 mL 500 mL

Maximum

fill volume

20 mL 50 mL 100 mL 200 mL 350 mL

Cassette

part number

SU-FS-0.05-C2 SU-FS-0.05-C2 SU-FS-0.10-C2 SU-FS-0.25-C2 SU-FS-0.50-C2

Cassette

dimensions

203 mm x

160 mm x

21 mm

(8.0" x 6.3" x 0.8")

203 mm x

160 mm x

21 mm

(8.0" x 6.3" x 0.8")

213 mm x

161 mm x

21 mm

(8.4" x 6.3" x 0.8")

302 mm x

157 mm x

22 mm

(11.9" x 6.2" x 0.9")

305 mm x

190 mm x

23 mm

(12.0" x 7.5" x 0.91")

Contact Entegris technical support if you have questions regarding this information, and to confirm you have the most up-to-date version.

WARNINGS

Aramus Bag Assembly

• Do not handle or carry the bags by the tubing

• Do not overfill or over pressurize the bag

• Regularly inspect for leaks and other damage

• Always ensure that all bag assembly components

are secure within the cassette before usage

• Do not use this product in a manner inconsistent

with its intended use

NOTE: User shall be solely responsible and liable for

validation and use of the Aramus bag assemblies beyond

the range of our specifications.

Cassette

• Always wear appropriate personal protective

equipment including gloves when handling

cassette

• Use two hands when transporting frozen cassettes

• Do not disassemble cassette before use

• Though reusable, inspect cassette prior to each use

• To prevent damage to the product, do not

mishandle the cassette

Note: User shall be solely responsible and

liable for validation and use of the Aramus

bag assemblies and cassettes beyond the

range of our specifications.

ARAMUS STANDARD BAG ASSEMBLIES

17User Manual | Rev. B 03/20 | Entegris, Inc.

SHIPPING

Based on currently available information, the cas-

settes may give user the best chance for successfully

shipping your product in an Aramus bag assembly.

However, since each company’s product likely has

unique freezing characteristics, the combined use of

cassettes and Aramus bag assemblies should be fully

validated by the customer.

As always, the customer is responsible for verifying fit

for use in combination with their product and in their

specific application.

INSPECTION

When unpacking the cassette, be sure to check for

damage such as dents or missing components. Also,

open and close the cassette to ensure functionality.

ASSEMBLY INSTRUCTIONS

Step 1: Open Cassette

Swivel open the locking bar and then lift the

tab vertically.

Step 2: Fill and Insert Aramus Bag Assembly

Place filled, Aramus bag into cassette. Orient any

connected tubing, clamps, and connectors as shown

to fit into the cassette. Ensure no components are

raised above the cassette’s side walls.

Tab

Locking bar

18

ARAMUS STANDARD BAG ASSEMBLIES

User Manual | Rev. B 03/20 | Entegris, Inc.

Step 3: Close Cassette

Close tab and then swivel locking bar into a closed

position. There should be little to no resistance from

the bag when closing. Ensure the cassette does not

bulge once closed.

NOTE: If the cassette bulges when closed, go back to

step 2 and reposition the components.

Step 4: Freezing and Storage

For ultra-low temperatures, the cassette assembly

can be placed directly into static and blast freezers

in a horizontal orientation (flat on shelf).

For freezing in a liquid nitrogen Dewar, a rack is

recommended. Be sure to slide the cassette com-

pletely inside the rack, and lock if applicable, before

immersing in liquid nitrogen vapor.

CAUTION! Always use cryogenic gloves when

handling cassettes or racks in low temperatures.

Step 5: Thawing

Inspect the cassette assembly to ensure no damage

or significant bulging occurred during freezing. The

locking bar and tab should be secure.

To thaw, remove the bag from the cassette assem-

bly and store at ambient temperature on a bench

or table. Other methods are available to accelerate

thawing such as using a fan or immersing the bag

in a water bath.

Locking bar

ARAMUS STANDARD BAG ASSEMBLIES

19User Manual | Rev. B 03/20 | Entegris, Inc.

ORDERING INFORMATION

To order cassettes for filling, freezing, handling, and

thawing applications, refer to the following:

Cassette

Part number Compatible Aramus bag assembly

SU-FS-0.05-C2 20 mL, 50 mL

SU-FS-0.10-C2 100 mL

SU-FS-0.25-C2 250 mL

SU-FS-0.50-C2 500 mL

ROSS SHELL AND CASSETTE DISCLAIMER

—

The items identified above as Special Products are

experimental prototype products. Special Products

have not been subjected to the testing, validation and

quality assurance procedures normally implemented

by Entegris pursuant to the process of commercial

introduction of standard Entegris Products. As a re-

sult, Entegris is unable to oer purchasers of Special

Products the same assurance as to the operating

capabilities and appropriate applications use that it

provides with respect to standard Entegris Products.

Entegris makes no representation as to such matters

or as to the physical characteristics or operating spec-

ifications of Special Products. Special Products are

sold to those customers willing to purchase them

on the terms of this Special Products Quotation as

an accommodation and are further subject to the

following terms.

Customer acknowledges that:

a) The Special Products may have defects or deficien-

cies in design, manufacture and/or materials, and

Entegris can provide no assurance that the Special

Products will operate uninterrupted or error free.

b) Entegris can provide no assurance that it will be

able to support the Special Products after sale, that it

will commercially introduce the Special Products, that

it will not make significant changes to future versions

of the Special Products or that the Special Products

will be available in the future.

c) Entegris can provide no assurance that the use

of the Special Products or any information relating

thereto or contained therein will not infringe any

patent, copyright, trade secret, or trademark of any

third party.

Furthermore, Special Products are sold WITH NO

WARRANTY on an “AS IS" and “WITH ALL FAULTS"

basis. ENTEGRIS MAKES NO OTHER WARRANTY,

EXPRESSED OR IMPLIED. THERE IS NO WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTIC-

ULAR PURPOSE. AT THIS TIME, ENTEGRIS CANNOT

WARRANTY SPECIAL PRODUCTS FOR STERILITY,

SHIPPING, OR SHELF LIFE. IT IS THE USERS’ RESPON-

SIBILITY TO ENSURE PRODUCT SUITABILITY FOR

USE WITHIN THEIR APPLICATION

This manual suits for next models

1

Table of contents