entegris SemiChem APM 2000 User guide

ADVANCED MATERIALS HANDLING |APPLICATION GUIDE

SemiChem APM 200 with HF and

H2O2in DSP+

Application guide

2Application Guide | Entegris, Inc.

SEMICHEM APM 200 WITH HF AND H202IN DSP+

TABLE OF CONTENTS

—

Introduction ........................................................................ 3

A.1 Precautions................................................................... 3

A.2 Reassembly................................................................... 3

A.2.1 Start-up Kit .............................................................. 3

A.2.2 Glass Burettes......................................................... 4

A.2.3 Reagents and Tubing............................................ 5

A.2.4 ORP and Fluoride Sensors .................................. 5

A.3 Preparing to Run......................................................... 6

A.3.1 Facilities .................................................................... 6

A.3.2 Flush Burettes......................................................... 6

A.3.3 Settings..................................................................... 6

A.3.4 Recipes and Adjustments.....................................7

A.3.4.1 Recipes..........................................................7

A.3.4.2 Adjustments................................................ 8

A.3.5 ORP Sensor Calibration ..................................... 12

A.3.6 Fluoride ISE Sensor Calibration ....................... 12

A.3.6.1 Auto Cal Adjustments ............................ 13

A.4 Running ........................................................................13

A.4.1 First Run.................................................................. 13

A.4.2 Process Calibration ............................................. 14

SEMICHEM APM 200 WITH HF AND H202IN DSP+

3Application Guide | Entegris, Inc.

INTRODUCTION

—

Our SemiChem APM 200 (advanced process monitor)

application guide provides step-by-step instructions

for properly configuring the SemiChem APM 200 for

the DSP+ application for measuring low level HF and

hydrogen peroxide only. This guide is designed for

trained and qualified personnel. It is complimentary

to the SemiChem APM 200 Installation and Operating

Manual, not a replacement.

A.1 PRECAUTIONS

—

Be sure any personnel working on the SemiChem

APM 200 has read and understands the Installation

and Operating Manual. There are inherent hazards

to working with the SemiChem APM 200.

WARNING: Service of the SemiChem APM 200

may cause exposure to hazardous conditions

including chemical, electrical, and mechanical

dangers. Personnel should be properly trained

in all areas before attempting to service or

troubleshoot the analyzer.

WARNING: Electrical Precaution: High

voltage electronics (⁄ VAC) are located

throughout the electronics module. Printed

circuit boards are powered with 24 VDC. All

service should be performed by a qualified

electrician/electrical technician.

WARNING: Chemical Precaution: Corrosive

or poisonous liquids. Some reagents may

be corrosive to the eyes, skin, and respiratory

tract and may be hazardous if ingested. Wear

chemical resistant gloves, face shield, and

apron when changing the burette O-ring. See

MSDS for further health hazard information.

To minimize chemical exposure, purge the

burette with air by removing the reagent intake

line from the reagent bottle, then flush the

appropriate burette. This will remove most

of the reagent from the burette assembly.

If replacing the burette glass, consult with

on-site environmental personnel for proper

disposal of remaining reagents. If replacing

a burette O-ring, keep the burette glass

assembly within the enclosure for proper

exhaust of fumes.

It is the user's responsibility to fully understand the

use, application, and hazards associated with the

SemiChem APM 200. Refer to the SemiChem APM 200

Installation and Operating Manual for more information.

A.2 REASSEMBLY

—

A.2.1 START-UP KIT

To complete the start-up of the SemiChem APM 200,

you will need:

1. 1 ea. ⁄” ball driver (003642).

2. 4 ea. tube weights and barbs (001824 and 003529).

3. Silicone paste kit (002691).

Start-up kit items.

4

SEMICHEM APM 200 WITH HF AND H202IN DSP+

Application Guide | Entegris, Inc.

In addition, you will need:

1. Glass burettes (000503) – the number of glass

burette assemblies will vary depending on

the application.

2. 8 – 32 × ⁄” SHCS (000762-050).

3. The sensor, Electrode, ORP Combination (001836) and

the sensor Electrode, F-, ISE Half Cell (001770).

A.2.2 GLASS BURETTES

Burette installation:

1. Using the silicone paste kit, apply a small amount

of silicone to each burette piston’s O-ring.

NOTE: Silicone paste is not needed on jacketed O-rings.

2. Install the glass burette into the piston and

guideposts using a slight twist motion.

3. Secure the burette glass assembly with the

8 – 32 × ⁄” SHCS and ⁄” ball driver.

4. Repeat for burettes 2 and 3.

Installed burettes.

SEMICHEM APM 200 WITH HF AND H202IN DSP+

5Application Guide | Entegris, Inc.

A.2.3 REAGENTS AND TUBING

Reagents installation:

1. Within the reagent storage, locate and uncoil the

reagent tubing.

NOTE: Each reagent tube is labeled with its

corresponding burette.

2. Insert the barb into the tube weight.

3. Remove the reagent cap from the reagent bottles

and slide the reagent 1 tube through the cap.

4. Install the barb/tube weight combination onto the

end of the reagent tube.

5. Repeat for reagents 2 and 3.

Installed tube weight.

6. Fill each reagent bottle with the reagents:

– Reagent bottle 1: 500 ppm fluoride

standard

– Reagent bottle 2: TISAB buer

– Reagent bottle 3: 0.25 N ceric sulfate in

1.0 N sulfuric acid

7. Carefully insert the tube weight/tube/cap

combination into corresponding reagent bottle.

Be sure the tube weight falls to the bottom and

sits flat. Secure the cap. Place reagent bottles

into the corresponding slots within the reagent

storage area.

NOTE: To follow the recipe parameters it is important that

the reagents are correctly assigned to the proper burettes.

A.2.4 ORP AND FLUORIDE SENSORS

1. Remove any caps and covers on the ORP sensor.

NOTE: There may be residual white crystals. These

crystals are saturated potassium chloride solution.

They are normal and can simply be wiped away.

2. Remove all caps and covers on the fluoride ion

selective electrode (ISE).

3. Remove the electrode retaining nut(s) from the

measuring cell. Remove the 3 mm × 11 mm O-ring

from the electrode port. You can choose to use any

of the open ports.

4. Slide the electrode into the retaining nut. Be

careful, the electrode is glass and can break.

Slide the O-ring onto the electrode shaft.

5. Insert the electrode/retaining nut/O-ring

combination into the measuring cell.

Repeat for the fluoride ISE.

6. Locate the electrode cable labeled “Input 1”.

Connect the ORP electrode and the electrode

cable. Locate the electrode cable labeled “Input 2”.

Connect the fluoride ISE and the electrode cable.

NOTE: To follow the recipe parameters it is important

that the electrodes are connected to the proper inputs.

Fluoride ion selective electrode with protective cap.

ORP electrode with protective cap.

6

SEMICHEM APM 200 WITH HF AND H202IN DSP+

Application Guide | Entegris, Inc.

A.3 PREPARING TO RUN

—

A.3.1 FACILITIES

At this point, the SemiChem APM 200 should be

fully installed and reassembled. All utilities can now

be energized.

1. Close all doors and be sure the exhaust is

connected and active.

2. Power up the SemiChem APM 200. The SemiChem

APM 200 information system will turn on. The MAIN

screen will be available shortly.

NOTE: If the system has been provided with safety

interlocks, the screen will have a RED background

indicating the safety interlocks require a reset. Press the

"GREEN" button below the EPO button to initiate the

safety circuits. Once pressed, and all safety interlocks

have been satisfied, the system is now ready.

3. Turn on CDA, water, and sample. Visually verify

there are no leaks.

4. From the MAIN screen, press "Service," then

press "Recipes."

5. From the service screen, select the recipe "Flush Cell."

Press "Run Now."

6. Verify water sprays into the cell from the top. It will

spray into the cell with the drain open for about 20

seconds, the drain closes and the water level will

reach the level sensor and stop the spray.

Service > Recipes.

Entegris / Service / Recipes

Recipe Menu:

Edit

New

Delete

Set As Main

Run Now

Done

Recipe Name

HF and Total Acid Sample 1 and 2

HF and Total Acid Sample 1

HF and Total Acid Sample 2

Flush Cell A

Empty Cell A

Flush Burette 1

Flush Burette 2

Flush Burette 3

Flush Burette 4

Flush All Burettes

Homemotors

Import

HF and H2O2 Sample 1 and 2

HF and H2O2 Sample 1

HF and H2O2 Sample 2

H2O2 in CMP Slurry Sample 1

H2O2 in CMP Slurry Sample 2

A.3.2 FLUSH BURETTES

Flushing the burettes with the appropriate reagents:

1. From Recipes, choose "Refill_Burette_1." Press

"Run Now." The burette will proceed to cycle

up and down three times. During which, it will

displace the air in the burette with the reagent.

Once complete, the reagent tubing and glass

burette will be completely filled with reagent.

Repeat for burettes 2 and 3.

2. Carefully inspect the burette glass and all tubing to

verify that all the air and bubbles have been purged

from the burette system. If not, repeat the above

step. For proper performance, the burette system

must be completely free from air bubbles.

3. Select "Flush_cell." Press "Run Now."

A.3.3 SETTINGS

The SemiChem APM 200's operation and behavior

within a process environment can be configured

to suit specific user needs. The settings allow the

SemiChem APM 200 to fit into the user’s process

control systems. There are eight setting screens.

Use the following to program the settings. Refer to

the “Software Flow Chart” in the SemiChem APM

200 Installation and Operating Manual for more

information on each setting.

1. From the MAIN screen, press "Service," then

press "Settings."

Service/Settings.

Entegris / Service / Settings

OK Cancel

Back Next

Labels

Labels

Analog Outputs

Channel 1-4 Configuration

Channel 5-8 Configuration

Calibration Data / Trigger / Calculation Factors

pH Buffer Concentrations

Remote Input Triggers

Analysis Timing

Channel 2 Label

Channel 3 Label

Channel 4 Label

Channel 5 Label

Channel 6 Label

System Date / Time

SEMICHEM APM 200 WITH HF AND H202IN DSP+

7Application Guide | Entegris, Inc.

Labels: The “Labels“ menu is used for labeling the

SemiChem APM 200. As an example:

– Burette 1 Label: Fluoride Standard

– Burette 2 Label: TISAB

– Burette 3 Label: 0.25 N Ceric Sulfate

– Sample 1 Label: Tank 1 DSP+

– Sample 2 Label: Tank 2 DSP+

– Output 1 Label: HF Tank 1

– Output 2 Label: Hydrogen Peroxide Tank 1

– Output 3 Label: HF Tank 2 (if used with the

dual sample system option)

– Output 4 Label: Hydrogen Peroxide Tank 2

(if used with the dual sample

system option)

Analog Outputs: Sets the range for each output.

NOTE: The SemiChem APM 200 utilizes 4 – 20 mA analog

signals. 4 mA will be 0, 20 mA will correspond

to the high range.

Relays: Sets the behavior and threshold for each alarm.

Calibration Data/Trigger/Calculation Factors:

1. Trigger: If set to local, the SemiChem APM 200 will

run independent and will run whichever recipe

is set as default based on the internal analysis

frequency. If set to remote, the SemiChem APM

200 will run with PLC handshaking. In addition,

the user can select which recipe to run when using

the recipe select feature. If set to computer, the

SemiChem APM 200 will respond to commands

from the RS232. Refer to the SemiChem APM 200

Installation and Operating Manual, section 4.2.

2. Calculation Factors: These are set as part of the

process calibration.

pH Buer Concentration: When using an ORP

electrode, these are not used.

Remote Trigger Inputs: Each remote trigger input

can be tied to a recipe. Therefore, when either a

PLC (remote mode) or a PC (computer) send the

input (as per the SemiChem APM 200 Installation

and Operating Manual, section 4.2) the SemiChem

APM 200 will run the recipe tied to the input. For

example, Remote Recipe 0 may be the "HF and

Hydrogen Peroxide in Sample 1" recipe, and Remote

Recipe 1 may be the "HF and Hydrogen Peroxide in

Sample 2" recipe, and Remote Recipe 1 may be the

"HF and Hydrogen Peroxide in Sample 2" recipe.

In this case, the user can select which analysis

to perform depending on the control needs of

the process.

Analysis Timing: Sets the analysis frequency and sensor

equilibration time.

NOTE: The SAMPLE TRANSFER VOLUME must be set to

whatever the cell volume is in milliliters. This is typically

set to 200.

System Date and Time: Sets the date and time.

A.3.4 RECIPES AND ADJUSTMENTS

A.3.4.1 Recipes

The SemiChem APM 200 is provided with a variety of

recipes as a set of application defaults. These recipes

should be considered “starting points” and will most

likely need to be adjusted to meet individual needs.

The recipes available for the DSP+ process for HF and

H2O2are:

HF and Hydrogen Peroxide Sample 1: This recipe will

measure both HF and Hydrogen Peroxide in series on

sample 1 only.

HF and Hydrogen Peroxide Sample 2: This recipe will

measure both HF and Hydrogen Peroxide in series on

sample 2 only.

HF and Hydrogen Peroxide Sample 1 and 2: This recipe

will measure both HF and Hydrogen Peroxide in series

on sample 1 and sample 2.

AutoCal channel 2: This recipe sets the calibration

parameters to calibrate the fluoride ISE on input 2.

HF self test: This recipe allows the user to confirm

the operation of the fluoride ISE by creating an

internal sample.

8

SEMICHEM APM 200 WITH HF AND H202IN DSP+

Application Guide | Entegris, Inc.

A.3.4.2 Adjustments

Once the desired recipe is selected, there are a number of parameters that can be adjusted to optimize the perfor-

mance of the SemiChem APM 200. As an example, the recipe shown below is for HF and H2O2for Sample 1.

# Recipe: APM 200 HF and H2O2Sample 1

# Process: HF at 300 ppm, SHydrogen Peroxide at 4%

# Loop Size: 1 mL

# Burette Assignments: 1.500 ppm Fluoride Standard 2. TISAB Buer 3. 0.25 N Ceric Sulfate in Strong Acid

# Sensor Inputs: 1. ORP 2. F ISE

# Output Assignments: 1. HF in ppm 2. Hydrogen Peroxide in %

function main

# HF Analysis

call HOMEMOTORS motor1=yes motor 2=yes motor3=yes motor4=no

call CONDITION number=2 volume=0.25 valve=EV02

These recipes can be edited and adjusted. Additionally,

recipes can be imported via the USB.

Text notations of the recipe assumptions are within

each of the recipes. These assumptions are based on

the SemiChem APM 200 configuration, the sample

loop volume, the burette assignments, the electrode

input assignments, the reagent concentrations, and

the process concentration range. Generally, it is

assumed that:

1. Sample loop is 1.0 mL. This is the factory default.

2. Burettes and electrode are assigned as per A.2.3

and A.2.4 (page 5).

3. Fluoride standard is 500 ppm and Ceric Sulfate

is 0.25 N.

4. The expected HF concentration is 300 ppm, and

the Hydrogen Peroxide expected concentration

is 4%. If the expected concentrations vary the

system configuration and reagent concentration

may need to be adjusted. Please contact Entegris.

for more information.

SEMICHEM APM 200 WITH HF AND H202IN DSP+

9Application Guide | Entegris, Inc.

call CONDITION number=3 volume=0.25 valve=EV03

call BURETTE number=1 action=setvol volume=0.00 valve=EV01

call BURETTE number=2 action=setvol volume=0.00 valve=EV02

call BURETTE number=3 action=setvol volume=0.00 valve=EV03

call EMPTY_APM200_CELLA time=15

call FLUSH_APM200_CELLA time=25

call EMPTY_APM200_CELLA time=15

call SAMPLE time=8 valve=AV01

call TRANSFER_APM200_CELLA time=6000

call CONTROLIO io=MIXERA value=1 time=0

call TITRATE cell=1 number=3 channel_id=2_sensor_ch=1 endpoint=850 window=1.00 end=10.5 sensor=pH

algorithm=seek_set direction=up_1 min_inc=.03 max_inc=.4 goal=4.1 formula=normal units=mL oset=0.00 equib=3

call CONTROLIO io=MIXERA value=0 time=0

call CONDITION number=2 volume=4 valve=EV02

call CONTROLIO io=MIXERA value=1 time=10

call ISE cell=1 number=1 channel_id=1 sensor_ch=2 ph_sensor_ch=1 addn_mode=default meas_mode=fixed

meas_time=30 cell_volume=200 std_conc=500 units=ppm def_conc=.75 factor=9 sensor=mV cal=no cal_ch=1

call EMPTY_APM200_CELLA time=15

call FLUSH_APM200_CELLA time=25

call EMPTY_APM200_CELLA time=10

call CONTROLIO io=MIXERA value=0 time=0

call FLUSH_APM200_CELLA time=10

call HOMEMOTORS motor1=yes motor2=yes motor3=yes motor4=no

end

10

SEMICHEM APM 200 WITH HF AND H202IN DSP+

Application Guide | Entegris, Inc.

HOMEMOTORS: This brings the burettes motors to

their uppermost position.

CONDITION number=1 volume=0.25 valve=EV01:

Injects 0.25 mL of burette 1 using electric valve 1. This

essentially prepares the burette for use and clears the

reagent dispensing tip of any bubbles.

BURETTE number=1 action=setvol volume=0.00

valve=EV01: Resets the system’s tracking of the

volume of reagent injected.

EMPTY_APM200_CELLA time=15: Opens the drain

valve for 15 seconds. The time can be adjusted

to ensure that the drain fully empties prior to the

next step.

FLUSH_APM200_CELLA time=25: Spray rinses the cell

for 25 seconds. This time can be adjusted to ensure

the cell is completely rinsed prior to the next step.

SAMPLE time=8 AV01: This command prepares the

6-port valve to take a sample. Additionally, it opens

valve AV01, the sample 1 inlet valve, and diverts sample

to the 6-port valve for eight seconds. This time can be

adjusted to accommodate varying sample inlet flow

rates. Note, the sample time only has to be long

enough for a fresh sample to go from the 3-way

recirculating AV01 to the 6-port valve.

TRANSFER_APM200_CELLA time = 6000: Prepares

the 6-port valve to deliver sample to the measuring

cell. Opens AV03 to transfer the contents of the

sample loop to the measuring cell. AV03 will remain

open until either the cell level sensor trip or the time

is reached. If the level sensor is not tripped within the

defined time (6000 seconds), the system will respond

with an error code: 64.

CONTROLIO = MIXERA value = 1 time = 10: Turns

the mixer motor on. This is not adjustable.

TITRATE (for the H2O2measurement):

– cell = 1: Cell 1 in single cell system, cell 1 or 2 in

dual cell system.

– number = 3: Defines which burette is used to

perform the titration.

– channel_id = 2: Defines which displayed and

analog output is used for this measurement.

– sensor_ch = 1: Defines the ORP electrode is

connected to sensor input 1.

– endpoint = 850: Defines the titration endpoint

value. Can be optimized for the chemistry’s

endpoint.

– window = 100: Defines the tolerance in which

the SemiChem APM 200 will seek for the actual

endpoint. In this case, the SemiChem APM 200

will search from 750 to 950 for the endpoint.

– end = 1050: Defines when the titration

is terminated.

– sensor = mV: Defines the displayed sensor

graph scale.

– algorithm = seek/set: Defines how the SemiChem

APM 200 determines the endpoint. Seek allows the

SemiChem APM 200 to determine the endpoint

within the window. Setpoint assigns the endpoint

at a fixed value. Seek/set allows the SemiChem

APM 200 to first search for the endpoint within

the window. If unable, then it will revert to the

setpoint value.

– direction = up_1: Defines the direction of the

titration. It also defines the method of reagent

injection. Up value configures the reagent

injection volumes based on the slope of the

sensor response curve using the min. and max.

increments. Up-1 value configures the reagent

injection volumes based on a goal volume of

where the endpoint is expected.

– min_inc = 0.03 and max_inc = 0.4: Sets the range

of reagent volume injections. Min. increment is

usually 0.03. Max. increment is usually 10% of

the expected goal volume.

– goal = 4.1: When using the up-1 (or down-1)

titration direction, the SemiChem APM 200

will optimize reagent volume injections based

on the expected endpoint volume. As the total

reagent volume injections get closer to the goal

volume, the system will inject smaller and smaller

increments as it slowly approaches the endpoint.

Thus, giving the SemiChem APM 200 more data

points in the critical portion of the sensor response

curve to determine the most precise endpoint.

This value can be adjusted to match the expected

endpoint value. This feature is only suitable for

applications in which the process is fairly stable.

SEMICHEM APM 200 WITH HF AND H202IN DSP+

11Application Guide | Entegris, Inc.

– formula = normal: The calculation formula simply

takes the endpoint volume and multiplies by a

calibration factor to report sample concentration.

Other formulas can be used, but are not applicable

for the DSP+ application.

– units = %: Defines the units labeled on the

display output.

– oset = 4.00: Defines if there is a reagent injection

oset. This volume is subtracted from the overall

reagent used in the recipe from a given burette

to that point.

– equib = 3: Defines the amount of time (seconds)

between reagent injection, mix, and sensor reading.

In this case, the system is allowed three seconds

for the solution to be mixed prior to a sensor

reading. This can be adjusted if the sensor response

curve is not smooth.

CONDITION number = 2 volume=4.00 valve=EV02:

Injects 4.00 mL of burette 2 using electric valve 2.

This step injects 4.00 mL of TISAB buer into the cell

to prepare for the HF measurement. This step brings

the pH value to about 5.5. This is the proper pH to

measure the fluoride ion.

ISE (for the HF measurement).

– cell = 1: Cell 1 in single cell system, cell 1 or 2 in

dual cell system.

– number = 1: Defines which burette is used to

perform the standard addition.

– channel_id = 1: Defines which displayed and

analog output is used for this measurement.

– sensor_ch = 2: Defines the pH electrode is

connected to sensor input 2.

– pH sensor_ch = 1: Defines the pH electrode

input. When using the ORP electrode, this selects

the input the ORP is connected to.

– addn_mode = default: This defines the single

point standard addition method.

– meas_mode = fixed: Defines duration of the

sensor’s measuring time. Fixed time is defined

in meas_time. Auto time is defined as self

determined sensor’s stability.

– meas_time = 30: Can be adjusted shorter or

longer based on the ISE’s measuring stability.

– cell_vol = 200: Defines the total volume in the

cell during the measurement. This value is used

to determine the proper volume of standard to

be added to create the upper calibration limit.

– std_conc = 500: Defines the fluoride standard

concentration. This is used to calculate the

calibration and addition volumes.

– def_conc = 0.75: Defines the lower calibration

range. The formula is:

– Cell Volume/Sample Volume = Sample

Dilution. 200 (cell volume)/1 (sample

loop volume) = 200 Sample Dilution.

– Expected concentration in the cell =

Expected concentration/sample dilution.

– 1.5 (ppm expected concentration

in the cell= 300 ppm (process HF

concentration)/200.

– Def_Conc= Expected concentration in

the cell × 0.5. 0.75 = 1.5 × 0.5.

– factor = 9: This sets the top value for

the calibration range. It also defines the

standard injection volume for the standard

addition during the measurement. If the

default concentration is 0.75 (which

represents 150 ppm), the factor sets the

high as 7.5 (or 1500 ppm). This sets the

calibration range at 150 ppm to 1500 ppm.

ISE calibration slopes are characterized by

a slope value over a “decade” change in

concentration. The fluoride ISE, it has

a slope of 57 mV for every 10 times change

in value. 1 ppm to 10ppm is 57 mV slope. 10

ppm to 100 ppm is another 57 mV slope,

and on and on.

– The factor sets the decade change to be:

– def conc x factor + def conc = 7.5

(or 1500 ppm).

– 0.75 × 9 + 0.75 = 7.5 This defines the

calibration range (in ppm in the cell) at

0.75 and 7.5.

– sensor = mV: This defines the sensor

response graphical display’s y-axis scale.

12

SEMICHEM APM 200 WITH HF AND H202IN DSP+

Application Guide | Entegris, Inc.

A.3.6 FLUORIDE ISE SENSOR CALIBRATION

The pH sensor requires periodic calibration to set the

slope of the sensor’s response. The calibration is

performed using a two-point calibration.

1. Idle the system.

2. From the MAIN screen, press "Calib." Press the

"ISE Calibration" tab.

3. Set the Channel to “2”, which is the Fluoride ISE

input. Press "Auto Cal."

The system will begin performing the calibration

routine as described in the recipe “ISE 2 Auto Cal”.

Briefly, the system will create the low range fluoride

concentration in the cell, measure the created sample

with the ISE, then create the high range fluoride

concentration in the cell and measure again. The

system will then determine the dierence in the

sensor response to calculate the sensor’s slope. This

slope will be updated in the “ISE Slope History”. The

slope should be 61 ±3 mVs.

If the sensor does not report back an acceptable

slope, verify electrode electrical connections,

reagent assignments, and the recipe to ensure

proper calibration range.

Entegris / Service / Calibrate

Done

Set Low pH

Auto Cal

(ISE) Slope History 1:

Parameters

Channel: Readings:

Titration Calibration

ISE Calibration

Ch:

mV:

Parameter Value

gpHStdLow

gpHStdHigh

gpHSlope

gpHOffset

1

-42.09

1

Calibration/ISE Calibration.

– cal = no: These parameters are used for

the sample. If this recipe was to define the

sensor calibration this would be “yes."

– cal_ch = 1: These parameters are used for

the sample. If this recipe was to define the

sensor calibration this would be 2 because

the ISE is connected to sensor input 2.

The recipe shown above is for the above stated

assumption. However, these parameters can be

adjusted to optimize the system. Additionally, if the

process concentrations vary from the above stated

assumption, then there may need to be further

adjustments in the recipe, reagent concentrations,

and/or sample loop size.

A.3.5 ORP SENSOR CALIBRATION

The ORP does not require calibration.

SEMICHEM APM 200 WITH HF AND H202IN DSP+

13Application Guide | Entegris, Inc.

If in remote mode:

1. Using the host PLC system, initiate a

measurement sequence.

2. If using recipe select function, the SemiChem APM

200 will perform that recipe. It will flush the cell,

drain the cell, fill the sampling loop, and transfer

the sample to the cell with DI water until it trips the

level sensor. Next it will then add 5.0 mL of TISAB

solution to bring the pH to about 5. The system

will continue with the HF measurement. Once

complete, the cell will drain, flush, and drain again.

The SemiChem will flush and rinse the cell, take

another sample and it will begin with the titration

of the hydrogen peroxide. Once complete, the cell

will again empty and flush, the burettes will reset

and the displayed results will update. It will close

the “READY” contact.

If in computer mode:

1. Using the host PC system, initiate a measurement

sequence.

2. If using recipe select function, the SemiChem APM

200 will perform that recipe. It will flush the cell,

drain the cell, fill the sampling loop, and transfer

the sample to the cell with DI water until it trips the

level sensor. Next it will then add 5.0 mL of TISAB

solution to bring the pH to about 5. The system

will continue with the HF measurement. Once

complete, the cell will drain, flush, and drain again.

The SemiChem will flush and rinse the cell, take

another sample and it will begin with the titration

of the hydrogen peroxide. Once complete, the cell

will again empty and flush, the burettes will reset

and the displayed results will update. It will close

the “READY” contact.

A.3.6.1 Auto Cal Adjustments

The “Auto Cal 2” recipe is similar to the “HF and H2O2”

recipe with these notes:

1. The “Auto Cal 2” does not take a sample. It creates

the low and high concentrations of the calibration

range using the Fluoride Standard.

2. The ISE measurement parameters between the

“Auto Cal 2” and “HF and H2O2” have to match with

the exception of the cal=xxx parameter in the “Auto

Cal 2” recipe, which has to be cal=yes to indicate

this recipe will be used to create and store the slope.

3. The ISE calibration should be run two to three times to

ensure repeatability. Each calibration slope should

be 1.5 to 3 mVs within each other.

A.4 RUNNING

—

A.4.1 FIRST RUN

If in local mode:

1. From the service screen, press "Recipes." Select

recipe “HomeMotors." This recipe will reset the

motors. Press "Run Now."

2. From the Recipe screen, choose the appropriate

Auto Cal recipe for the situation. Press "Save As

Main." This will make this the default recipe.

3. Press "Run Now." The SemiChem APM 200 will

proceed to perform the recipe. It will flush the cell,

drain the cell, fill the sampling loop, and transfer

the sample to the cell with DI water until it trips

the level sensor. Next it will add 5.0 mL of TISAB

solution to bring the pH to about 5. The system

will continue with the HF measurement. Once

complete, the cell will drain, flush, and drain again.

The SemiChem will flush and rinse the cell, take

another sample and it will begin with the titration

of the hydrogen peroxide. Once complete, the cell

will again empty and flush, the burettes will reset

and the displayed results will update.

Entegris®, the Entegris Rings Design®, and other product names are trademarks of Entegris, Inc. as listed

on entegris.com/trademarks. All third-party product names, logos, and company names are trademarks or

registered trademarks of their respective owners. Use of them does not imply any aliation, sponsorship,

or endorsement by the trademark owner.

©2013-2021 Entegris, Inc. |All rights reserved. |Printed in the USA |7133-11560TAN-0421

129 Concord Road

Billerica, MA 01821

USA

Tel +1 952 556 4181

Fax +1 952 556 8022

Toll Free 800 394 4083

Corporate Headquarters Customer Service

LIMITED WARRANTY

Entegris' products are subject to the Entegris, Inc. General Limited Warranty. To view and print this information,

visit entegris.com and select the Legal & Trademark Notices link in the footer. Entegris does not warrant any

failure in the case of customers using unapproved foreign components.

FOR MORE INFORMATION

Please call your Regional Customer Service Center today to learn what Entegris can do for you.

Visit entegris.com and select the Contact Us link to find the customer service center nearest you.

TERMS AND CONDITIONS OF SALE

All purchases are subject to Entegris’ Terms and Conditions of Sale. To view and print this information,

visit entegris.com and select the Terms & Conditions link in the footer.

www.entegris.com

Installation and Use Manual | PS4-MT50-H

A.4.2 PROCESS CALIBRATION

The following procedure calibrates the SemiChem

APM 200 to the process. The system can be calibrated

with either the factor or process calibration method.

Factor Calibration:

1. The analyzer's calculation factor can be derived

from first principals using the following equation:

Calculation Factor = (Ctit × RR × U × MW)/Vsamp

Ctit = Titrant concentration (normality)

RR = Reaction ratio (moles of sample that will react

with each mole of titrant)

U = Unit factor (typical values: "1" for g/L, "0.1" for %,

"1000" for mg/L, etc.)

MW = Molecular weight of sample species

(e.g., H2SO4= 98)

Vsamp = Volume of sample taken (typically 0.25– 1 mL)

For example:

Ctit = 0.2

RR = 0.5

U = 0.1

MW = 98

Vsamp =0.5

4.900 = (Ctit × RR × U × MW)/Vsamp

This factor is used in the Settings/Calculation Factors

for output 1.

Process Calibration:

1. At the same time the SemiChem APM 200 takes

a sample, take a grab sample.

2. Once the SemiChem APM 200 is complete, note

the result. For example: 0.816 mL.

3. Make a note of a trusted laboratory’s result. For

example: 4.00% H2SO4.

4. Divide the laboratory result by the SemiChem APM

200 result. For example: 4.00/0.816 = 4.900.

5. In this case, 4.900 is the factor to be used in

the Settings.

The calculation factor converts the SemiChem APM

200's milliliters of titrant to reach the endpoint into a

concentration that the customer can use for process

control. Once the SemiChem APM 200 is calibrated to

the process, it should not have to be repeated unless

maintenance is performed on the burette O-rings,

there is a change in reagent, or there is a change

in electrode.

At this point, the SemiChem APM 200 is reassembled,

calibrated, and ready for use.

Table of contents

Popular Test Equipment manuals by other brands

Hanna Instruments

Hanna Instruments HI 98103 instruction manual

ULTIMATE SPEED

ULTIMATE SPEED UAWSB 2 B1 Operation and safety notes

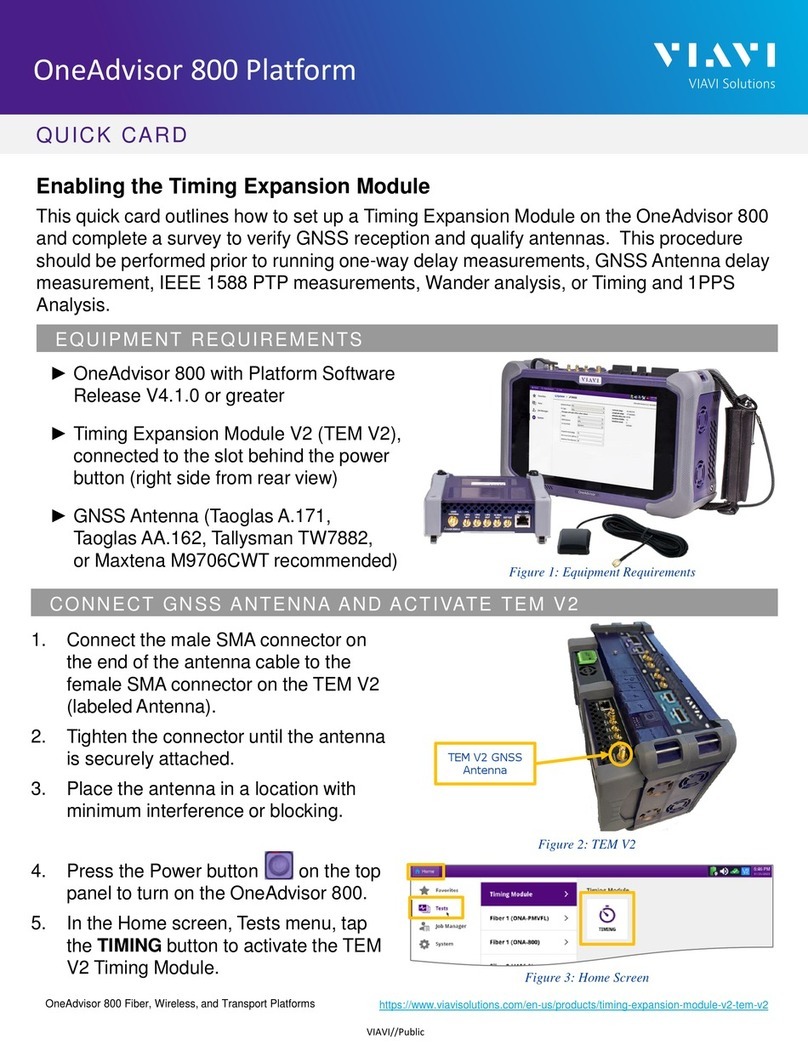

Viavi

Viavi OneAdvisor 800 Platform Quick Card User Guide

Fluke

Fluke 6100B Getting started

JDS Uniphase

JDS Uniphase IP Video Test Option HST-3000 Product guide

Forch

Forch EBT 03 manual

Glas-Col

Glas-Col 099D HST230N User instructions

Keithley

Keithley Interactive SourceMeter 2450 Reference manual

Laversab

Laversab 6500 user manual

Tintometer

Tintometer Lovibond TB 350 quick start guide

Megger

Megger PFL22M1500 Series user guide

Sanyo Denki

Sanyo Denki San Ace 9AT2560 Series instruction manual