Table of Contents

1. General Safety Requirements.......................................................................................... 1

2. Safety Terms and Symbols............................................................................................... 2

3. General Characteristics................................................................................................... 4

4. Junior User Guidebook ................................................................................................... 5

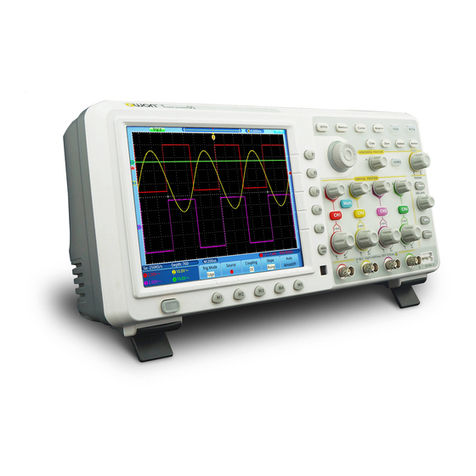

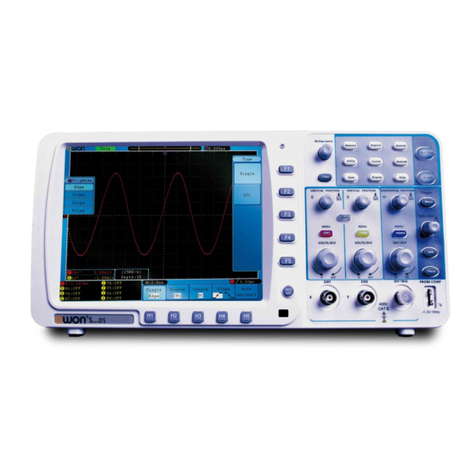

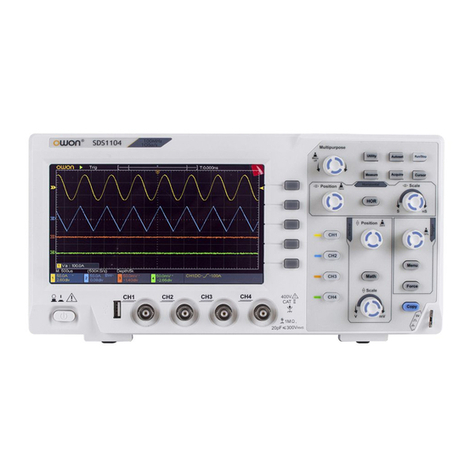

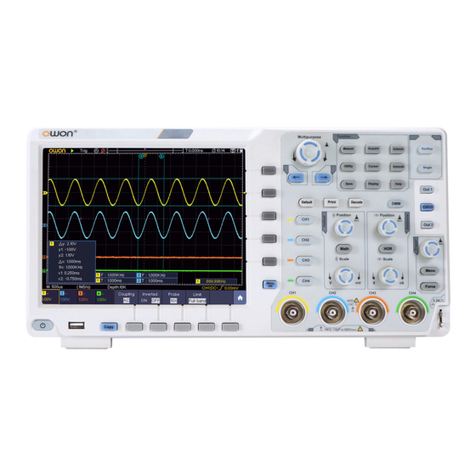

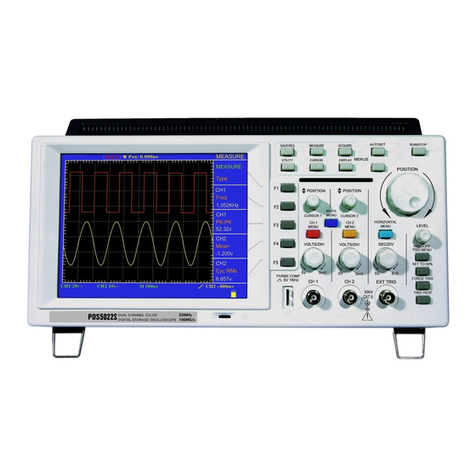

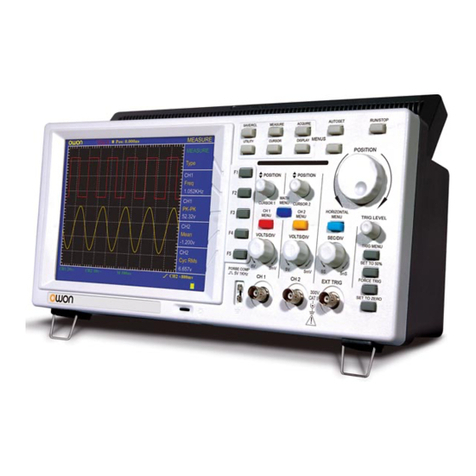

Introduction to the Structure of the Oscilloscope..................................................................... 6

Front Panel ............................................................................................................................................... 6

Left Side Panel ......................................................................................................................................... 7

Right Side Panel ....................................................................................................................................... 7

Rear Panel ................................................................................................................................................ 8

Control (key and knob) Area.................................................................................................................... 9

User Interface Introduction...................................................................................................... 10

How to Implement the General Inspection ............................................................................. 12

How to Implement the Function Inspection............................................................................ 12

How to Implement the Probe Compensation .......................................................................... 13

How to Set the Probe Attenuation Coefficient ........................................................................ 14

How to Use the Probe Safely..................................................................................................... 15

How to Implement Self-calibration.......................................................................................... 15

Introduction to the Vertical System......................................................................................... 16

Introduction to the Horizontal System .................................................................................... 17

Introduction to the Trigger System ......................................................................................... 18

5. Advanced User Guidebook ............................................................................................ 19

How to Set the Vertical System ................................................................................................ 20

Use Mathematical Manipulation Function ............................................................................................. 26

Using FFT function ................................................................................................................................27

Use VERTICAL POSITION and VOLTS/DIV Knobs.......................................................... 31

How to Set the Horizontal System............................................................................................ 32

How to Set the Trigger System................................................................................................. 35

Single trigger.......................................................................................................................................... 35

Alternate trigger ..................................................................................................................................... 39

How to Operate the Function Menu ........................................................................................ 43

How to Implement Sampling Setup ....................................................................................................... 43

How to Set the Display System.............................................................................................................. 45

How to Save and Recall a Waveform..................................................................................................... 49

How to Record/Playback Waveforms .................................................................................................... 52

How to Implement the Auxiliary System Function Setting.................................................................... 55

i