Table of content:

FAA074F0EMEI Issued 2004-12-15 3

1. Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

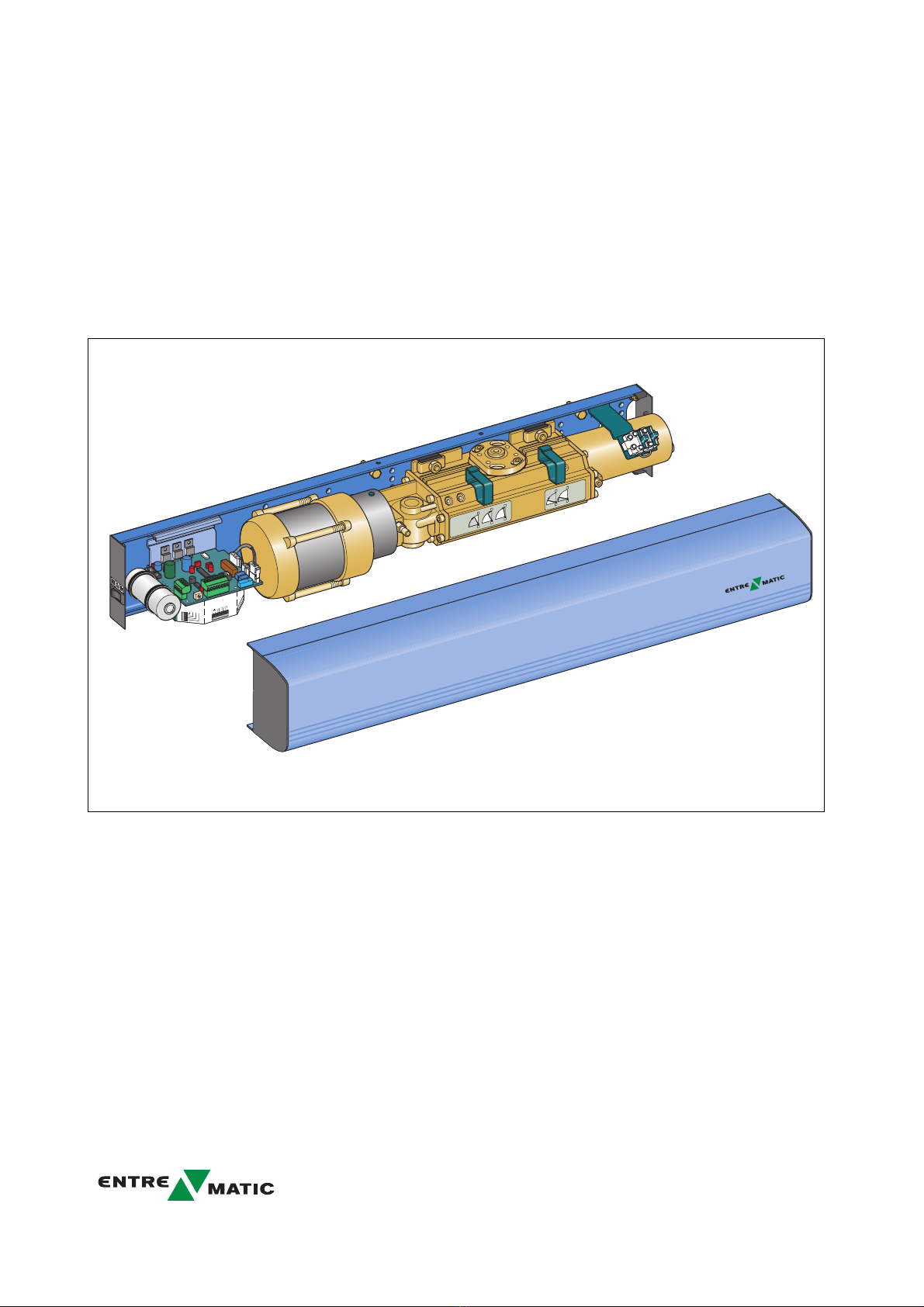

3. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4. Function description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5. Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6. Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 EMSW, standard cover wall mounted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

6.2 EMSW-SPEC, cover with optional length (wall-mounted). . . . . . . . . . . . . . . . . . .11

6.3 EMSW-2, double door operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

7. Part identification & Accessories . . . . . . . . . . . . . . . . . . . . . 12

7.1 Further Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

8. Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.1 Wall-mounted operator with arm system PUSH . . . . . . . . . . . . . . . . . . . . . . . . .16

8.1.1 Establish the installation height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

8.1.2 Mounting the drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

8.1.3 Mounting the door fitting with telescopic part. . . . . . . . . . . . . . . . . . . . . . . . .16

8.1.4 Mounting the drive arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

8.1.5 Adjusting the arm system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

8.1.6 Checking the door movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

8.2 Wall mounted operator with arm system PULL / PULL-P . . . . . . . . . . . . . . . . . . .18

8.2.1 Changing the direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

8.2.2 Establish the installation height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

8.2.3 Mounting the drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

8.2.4 Mounting the drive arm and door fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

8.2.5 Checking the door movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

9. Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9.1 Control units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

9.2 Connection of control unit CSDA – single doors . . . . . . . . . . . . . . . . . . . . . . . . .22

9.3 Connection of control units CSDA and CSDA-S – double doors. . . . . . . . . . . . . .23

10. Start-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

10.1 Connection of activation units and accessories . . . . . . . . . . . . . . . . . . . . . . . . . .26