Environics 6100 Series User manual

6100 USER’S GUIDE i REV15 -FEB2021

COPYRIGHT

© 2003-2021 Environics Inc. All Rights Reserved. This manual and the software contained

within the product(s) described are copyrighted with all rights reserved.

TRADEMARKS

Environics is a registered trademark of Environics Inc. All other brand names, company

names and product names mentioned are the property of their respective owners.

WARRANTY

Environics, Inc. warrants this product to be free from defects in material and workmanship for

a period of one year from the date of shipment. Environics warrants the following expendable

items for 30 days from the date of shipment: fuses, lamps, batteries. During the warranty

period, Environics will, at our option, either repair or replace any product that proves to be

defective.

To exercise this warranty, contact Environics at the address below for assistance and

instructions for returning the products. Repaired or replaced products are warranted for the

balance of the original warranty period or at least 30 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification made without

Environics’ express written consent, or misuse of any product or part. This warranty also does

not apply to software, damage from battery leakage or problems arising from normal wear or

failure to follow instructions.

This warranty is in lieu of all other warranties, expressed or implied, including any implied

warranty of merchantability or fitness for a particular use. The remedies provided herein are

the buyer’s sole and exclusive remedies.

Neither Environics nor any of its employees shall be liable for any direct, indirect, special,

incidental or consequential damages arising out of the use of its instruments and software

even if Environics has been advised in advance of the possibility of such damages. Such

excluded damages shall include, but are not limited to: costs of removal and installation,

losses sustained as the result of injury to any person or damage to property.

WARNING

READ THIS MANUAL CAREFULLY BEFORE USING THIS INSTRUMENT.

FAILURE TO DO SO MAY VOID THE WARRANTY,

DAMAGE THE INSTRUMENT OR CAUSE SERIOUS INJURY.

Environics Inc.

69 Industrial Park Road East

Tolland, CT 06084-2805 U.S.A.

Phone: (860) 872-1111 Fax: (860) 870-9333

WWW.ENVIRONICS.COM

6100 USER’S GUIDE ii REV15 -FEB2021

6100 User’s Manual changes

Manual

Revision

#

Software

Revision

#

Manual

Release

Date

Enhancements

3

1.28-03

03FEB2003

Initial release

4

1.28-04

31MAR2003

Page 19 –Way in which contrast adjustment works.

Added requirements for UL listing to preface

Added this page to log changes.

5

1.30-01

01JUL2003

Enhanced Status Output Mode - Pages 18, 36

Added flow mode remote commands –Page 31

Adjusted indexes and page references for addition of page in Remote

mode section; now pages 28-32

6

1.31-01

15SEP2003

N/A

7

1.32-01

23DEC2003

Additional status output programming options

8

1.33-02

23APR2004

Added section for Program Mode

Updated status input section, to include programming options.

Combined two status output sections into one.

Added automatic Table of Contents

Combined separate power warning sec. with power connection sec.

Added automatic Table of Figures (List of illustrations)

9

1.33-03

10NOV2004

Added SKIP and RUNNOW buttons to Run Schedule screen

Added SCHEDULE 1 as an option for Powerup Mode preference

10

1.34-01

31MAR2007

Added IDLE TIMER to Setting User Preferences section

11

1.35-01

03MAY2010

Changes to ozone preburn operation

Added information on serial data output

12

1.35-xx

14OCT2011

Adjusted power cable diagram, page 76

Updated MFC3 (optional) calibration information

Added P&ID for Series 6100 with optional MFC3

13

1.36-xx

10SEP2013

Added Remote Gas commands

14

1.36-xx and

2.01-xx

09OCT2019

Updated Ozone Calibration instructions

6100 USER’S GUIDE iii REV15 -FEB2021

SERIES 6100

MULTI-GAS CALIBRATOR

ENVIRONICS, INC

69 INDUSTRIAL PARK ROAD EAST

TOLLAND, CT 06084

EQUIPMENT SUMMARY –TYPE:

(X) Measurement; ( ) Control; ( ) Laboratory

Marked electrical rating:

115 VAC, 50/60 Hz, T2.0A FUSE TYPE T2.0/125

230 VAC, 50/60 Hz, T1.0A FUSE TYPE T1.0/250

Connection to Supply: Standard IEC Inlet Coupler/Cord Connected

Environmental rating: Standard

Operating temperature range: 0-50oC

Performance Temperature range: 15-35oC

Humidity: <95% RH @ 15-30 deg C

Altitude: up to 2000 Meters

Warmup Time 30 Minutes

Installation Category II,

Pollution Degree:2

Equipment Class 1

Equipment function/feature/description:

S6000 was designed for precision Multi-Gas Calibrations with Ozone.

Mode of operation:

Concentration Mode, Flow Mode, Program Mode, Calibrate Mode.

Degree of mobility:

( ) Permanently Connected; (X) Other Cord Connected.

Overall size: 17”x7”x15” Weight: 27 lbs.

Ventilation requirements:

Do not cover or block the ventilation holes in the top cover or fan filter on

the rear panel.

6100 USER’S GUIDE iv REV15 -FEB2021

TABLE OF CONTENTS

LIST OF ILLUSTRATIONS v

LIST OF ABBREVIATIONS / ACRONYMS vi

FORWARD 1

UNPACKING AND INSPECTING THE SYSTEM 2

SYSTEM LAYOUT 3

FRONT PANEL LAYOUT 3

REAR PANEL LAYOUT 5

POWER AND GAS CONNECTIONS 9

POWER CONNECTION 10

GAS CONNECTIONS 11

SYSTEM OVERVIEW AND SETUP 12

OPERATING MODE SUMMARY 12

ENTERING DATA 14

MAIN SCREEN (READY) 15

GASES SETUP MODE (GASES) 16

RUNNING THE SYSTEM 19

SYSTEM WARMUP 19

CONCENTRATION MODE (CONC) 19

FLOW MODE (FLOW) 23

PROGRAM MODE 25

SETTING USER PREFERENCES 31

CONNECTING TO OTHER DEVICES 37

STATUS INPUT 37

STATUS OUTPUT 41

SERIAL PORTS 43

REMOTE MODE (REMOTE) 44

INTERFACE SPECIFICATION 44

REMOTE MODE COMMAND LIST 46

REMOTE MODE ERROR CODES 49

TECHNICAL MANUAL 50

THEORY OF OPERATION 50

GAS PHASE TITRATION 51

SYSTEM CALIBRATION 52

PCB FUNCTION and TEST POINTS 62

TEST POINT WAVEFORMS 68

TROUBLESHOOTING 70

DIAGRAMS AND SCHEMATICS 77

6100 USER’S GUIDE v REV15 -FEB2021

LIST OF ILLUSTRATIONS

FIGURE 1 - FRONT PANEL LAYOUT..................................................................3

FIGURE 2 - REAR PANEL LAYOUT....................................................................5

FIGURE 3 - INTERNAL LAYOUT (STANDARD 6100 WITH 2 MFCS)................6

FIGURE 4 - MFC ILLUSTRATION......................................................................57

FIGURE 5 - TEST POINT WAVEFORMS...........................................................68

FIGURE 6 - POWER CABLE DIAGRAM............................................................77

FIGURE 7 - PIPING AND INSTRUMENT DIAGRAM - STANDARD...................87

FIGURE 8 - PIPING AND INSTRUMENT DIAGRAM - OPTIONS......................90

6100 USER’S GUIDE vi REV15 -FEB2021

LIST OF ABBREVIATIONS / ACRONYMS

AC Alternating Current

ADC Analog to Digital Converter

CCM Cubic Centimeter Per Minute

CGC Cylinder Gas Concentration

DAC Digital to Analog Converter

EMI Electromagnetic Interference

EPA Environmental Protection Agency

Hz Hertz

lbs Pounds

LCD Liquid Crystal Display

LPM Liters Per Minute

MFC Mass Flow Controller

NIST National Institute of Standards and Technology

OGC Output Gas Concentration

P&ID Piping and Instrument Diagram

PPB Parts Per Billion

PPM Parts Per Million

PSIA Pounds per Square Inch Absolute

PSIG Pounds per Square Inch Gauge

RFI Radio frequency interference

SCCM Standard Cubic Centimeters per Minute

SLPM Standard Liters Per Minute

UHP Ultra High Purity

VAC Volts, Alternating Current

VDC Volts, Direct Current

FORWARD

6100 USER’S GUIDE 1 REV15 -FEB2021

FORWARD

The Environics Series 6100 Multi-gas Calibrator

was designed to be the finest instrument available

for producing highly precise mixtures of ozone and

other gases. The system incorporates user-friendly

software, mass flow controllers (MFCs) and a

custom-designed ozone generator module.

The Series 6100 automatically performs zero,

precision, span and multi-point calibrations using

NO, NO2, SO2, CO, 03, hydrocarbons and other

gases of interest. The 6100 meets all U.S. Environmental Protection Agency

requirements. The system consists of a single chassis supporting 2 thermal

mass flow controllers (optional third MFC available), an ozone generation

module, a mixing zone, a reaction chamber for gas phase titration, and control

electronics.

Commands are entered from the front panel and displayed on a backlit 4 line by

20 character liquid crystal display. The instrument may also be remotely operated

using contact closures or the RS-232 serial data interface, both are standard in

the Series 6100.

The mass flow controllers are calibrated to a NIST (National Institute of

Standards and Technology) traceable primary standard. Calibration data is

stored in non-volatile memory and may be updated by the user with a suitable

standard. The Series 6100 ozone generator is factory calibrated using a NIST

traceable ozone standard. This temperature controlled, ultra-violet (UV) based

ozone generator includes a precision photo-optical feedback circuit to

compensate for lamp aging effects.

Although the Series 6100 is very easy to operate, we strongly suggest that

you read the User’s Guide portion of this document completely prior to

operating the system. It describes all the functions and operations of the

system.

System Specifications, the Theory of Operation of the Series 6100 and

troubleshooting information are included in the Technical Manual portion of this

document.

Environics is pleased to provide this quality instrument that utilizes state-of-the-art

electronic technology. Our knowledgeable service team is ready to assist you in the

use of this instrument should the need arise.

Note: The Series 6100 is intended for use with ambient gases which don’t

interact (NO, NO2, SO2, CO, CO2 and O3). If you intend to connect other

gases to the system, consult with Environics prior to doing so.

UNPACKING AND INSPECTING THE SYSTEM

6100 USER’S GUIDE 2 REV15 -FEB2021

UNPACKING AND INSPECTING THE SYSTEM

The Series 6100 is shipped completely assembled and ready for use. The system

only needs to be properly unpacked and inspected prior to connecting the power and

gas sources.

The Series 6100 should be removed from its shipping container and inspected for

damage. Any damage to the shipping case should be noted and immediately

reported to the freight carrier.

Report any damage to the Series 6100 to the Environics home office or local

Environics distributor.

Place the unit at the desired operating location where there is easy access to both

the front and rear panels of the unit.

Important

Please allow the system to be powered up for 30 minutes before running

the system. This will allow the MFCs to warm up and the ozone block

temperature to reach 50C. Insufficient warm up will cause unstable ozone

and flow readings. During this warm up period, ozone should be

commanded in the FLOW or CONC mode, for conditioning and a better

response time when running the system during normal operation.

SYSTEM LAYOUT

6100 USER’S GUIDE 3 REV15 -FEB2021

SYSTEM LAYOUT

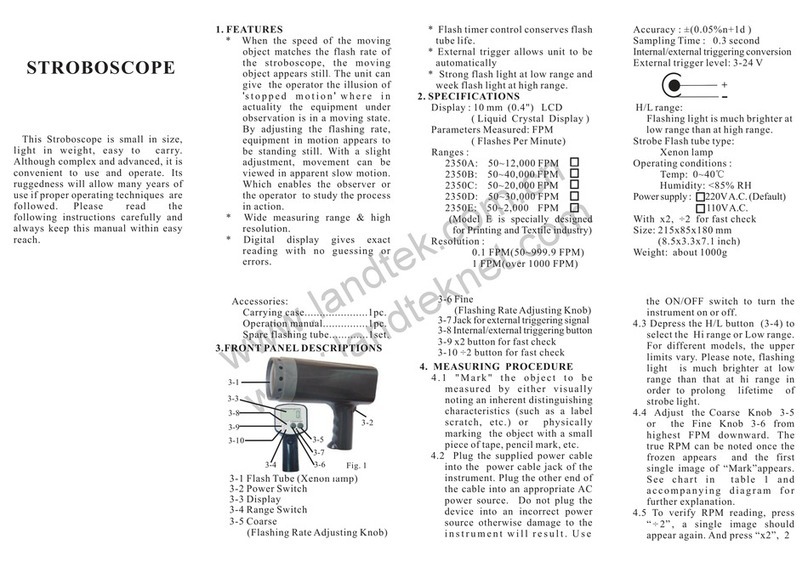

FRONT PANEL LAYOUT

Figure 1 - Front Panel Layout

Power Switch

To turn the system on, press the top of the rocker-type power switch. The switch and

display will illuminate and the READY message will appearon the display screen.

LCD Display

The liquid crystal display (LCD) is a four line, 20 characters display, protected by a

clear lens. The display is illuminated when the system is in operation.

Function Keys

Three function keys (F1, F2 and F3), located below the display, and are used to

make various selections from the menu displayed on the bottom line of the screen.

The current function of each key is displayed above each function key on the bottom

line of the display. The function of each key will change, depending on the current

operating mode.

SYSTEM LAYOUT

6100 USER’S GUIDE 4 REV15 -FEB2021

Numeric Keypad

The numeric keypad is used for data entry of numbers 0 through 9 and a decimal

point.Pressing the ENTER key completes the entry of the numeric data selected.

Arrow Keys

The arrow keys are used to move the cursor on the display screen to and from

differentfields located on the different entry screens orto scroll up or down a menu or

list information. Pressing and holding the arrowkeys will cause them to repeat.

Menu Key

The menu key will change the function menu currently being displayed. The functions

are displayed on the bottom line of the screen above the three function keys. Each

time the menu key is pressed, the menu will advance to the next menu (if applicable).

SYSTEM LAYOUT

6100 USER’S GUIDE 5 REV15 -FEB2021

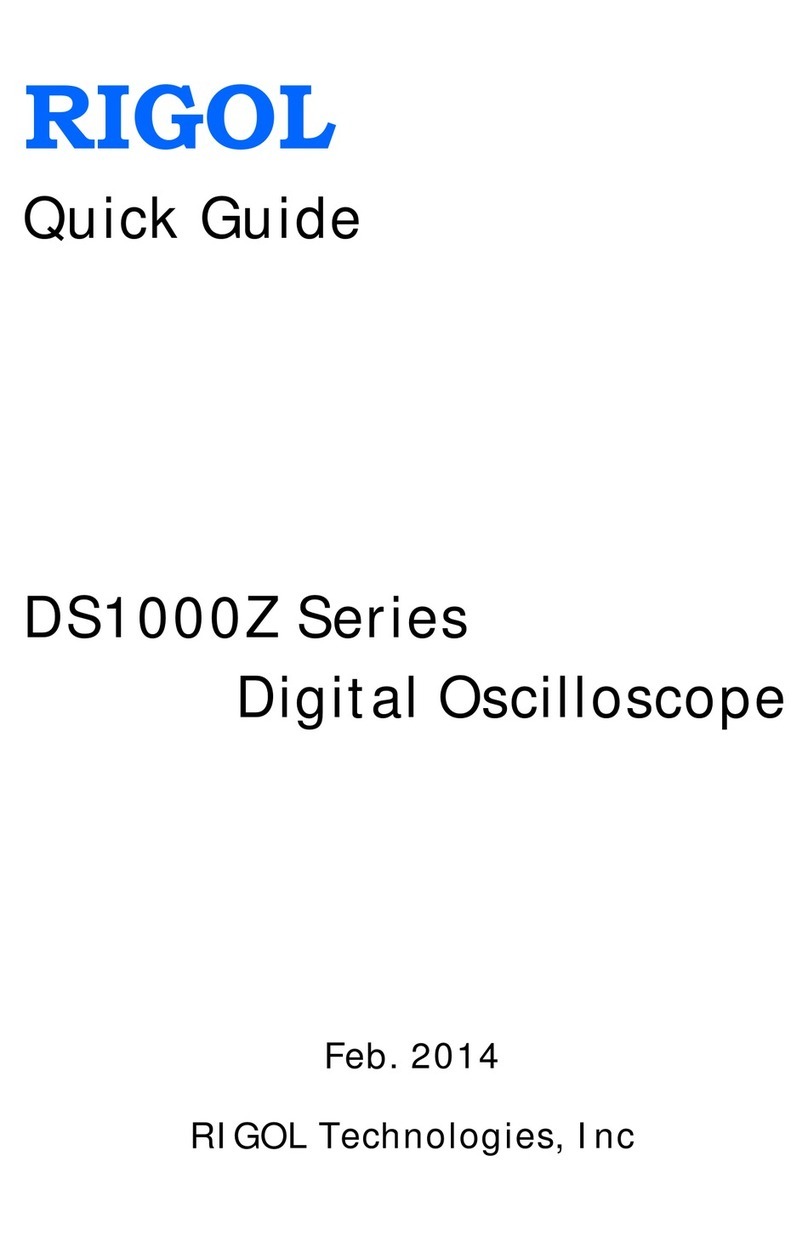

REAR PANEL LAYOUT

Figure 2 - Rear Panel Layout

Power Input

This supplies AC power to the system.

Gas Inputs

These supply source gas to the system. Port 1 is for the zero air connection. Ports 2

through 5 are for span gas connections.

Gas Output

This connection is for the output gas stream.

RS-232Ports

Two RS-232 serial ports are supplied for connection to a serial terminal or for remote

communications.

StatusInput/Output

The Status Inputs allow external devices to initiate various system actions. The

Status Outputs allow the system to signal external devices when certain operating

events occur.

Note: The remaining gas ports and electrical connector locations

are not used for the standard 6100. These ports are reserved for

other models and options.

PORT 5 PORT 4 PORT 3 PORT 2

PORT 1

POWER

INPUT

RS232-2

RS232-1

OUTPUT

STATUS INPUT

STATUS OUTPUT

SYSTEM LAYOUT

6100 USER’S GUIDE 6 REV15 -FEB2021

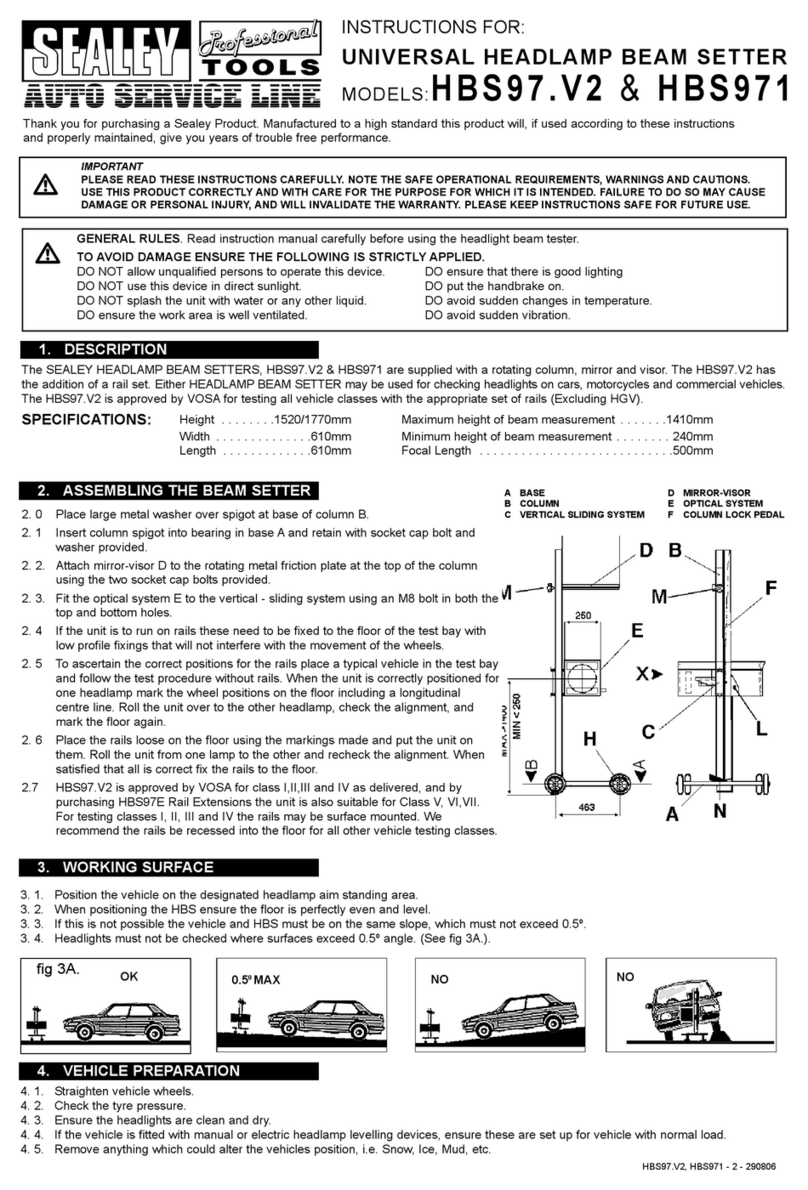

Figure 3 - Internal Layout (Standard 6100 with 2 MFCs)

9

10

11

12

15

19

20

13

1

5

8

7

4

2

3

14

17

18

6

16

SYSTEM LAYOUT

6100 USER’S GUIDE 7 REV15 -FEB2021

INTERNAL LAYOUT (Standard 6100 With 2 MFCs)

1. Status input and output connectors

2. Rear panel

3. Fan assembly

4. RS232 connectors

5. Status input and output, solenoid valve driver PCB (PC416)

6. Power entry module (RFI/EMI filtering)

7. Input port 1 solenoid isolation valve for MFC1

8. Solenoid valve manifold for gas ports to MFC2

9. Glass reaction chamber for GPT

10. Mass flowcontroller (MFC2), for the calibration (span) gas

11. Mass flow controller (MFC1), forthe dilution gas

12. A/D and D/A analog interface PCB (PC412)

13. Ozone generatormodule (cover removed) with ozone analog PCB (PC410)

14. Switching power supply, quad output (+24VDC, +/-15VDC, +5VDC)

15. Microcomputer board (PC401)

16. Keyboard ribbon cable

17. Main DC power cable from power supply to PC412

18. Power switch

19. Display and keypad interface PCB (PC406)

20. Front panel

SYSTEM LAYOUT

6100 USER’S GUIDE 8 REV15 -FEB2021

INTERNAL LAYOUT, HINGED PANELS DOWN

POWER AND GAS CONNECTIONS

6100 USER’S GUIDE 9 REV15 -FEB2021

POWER AND GAS CONNECTIONS

After the Series 6100 is unpacked and inspected, the system should be connected

to power and the appropriate gas sources to the gas inlet ports on the rear panel.

We recommend the use of a UPS (uninterruptible power supply), as is typically

used for computers, to eliminate power problems from affecting system operation.

WARNING

Operating the Series 6100 at an incorrect line voltage will damage the

instrument and void the manufacturer’s warranty. Check the line voltage

before you plug the instrument into any power source.

For 230 volt input power, only qualified personnel shall determine the

correct input power connections needed to be supplied to the system.

The standard supplied 115 volt power cord should be plugged into the rear

panel power entry module of the Series 6100, the other end should then be

plugged into a properly grounded outlet.

IMPORTANT

Before connecting or disconnecting any cables, wiring harnesses or other

sources of potential electrical impulse, be sure the unit is powered OFF.

The main power disconnect for the unit shall be the power cord that is

plugged into the rear of the unit. The instrument is totally enclosed at all

times with a top and bottom cover for safety.

Position the equipment so that it is not difficult to operate the

disconnecting device.

POWER AND GAS CONNECTIONS

6100 USER’S GUIDE 10 REV15 -FEB2021

POWER CONNECTION

(1) Insert the standard power cord supplied with the system into the power

connector on the rear panel and insert the plug into a properly grounded

outlet. The standard unit allows for100 –250 VAC (50/60 Hz).

(2) Turn the front panel switch to the ON position. The screen will indicate that a

self-test is being performed and then READY will appear. When READY

appears on the screen, turn the power switch to the OFF position and proceed

to the section on Gas Connection.

SYMBOLS

USED

PUBLICATION

MEANING

ISO 3864, No. B.3.1

CAUTION (Refer to accompanying

documents).

Refer to specific WARNINGs and

CAUTIONs in Operating Manual.

IEC 417, No. 5019

PROTECTIVE CONDUCTOR TERMINAL

IEC 417, No. 5007

ON (SUPPLY)

IEC 417, No. 5008

OFF (SUPPLY)

POWER AND GAS CONNECTIONS

6100 USER’S GUIDE 11 REV15 -FEB2021

GAS CONNECTIONS

Input and Output GasConnections

Gas connections are standard ¼-inch (optional 1/8-inch) compression fittings.

PORT 1 will serve as a diluent or balance port for use with zero air. PORTS 2

through 5 are routed to a solenoid manifold; the output of which is sent to MFC2

and MFC3 (if applicable). We recommend connecting span gases sequentially,

beginning with PORT 2 and proceeding to PORT 5.

Turn the compression fittings with a wrench following the standard procedure for

compression tube connections.

(1) On the rear of the Series 6100, connect a source of zero air, at a pressure

between 20 and 25 PSIG, to PORT 1 (dilution gas port). Connect all span

gases to PORTS 2 through 5 (span gas ports) at a pressure between 15 and

25 PSIG.

It is important that the gas pressures stay within the ranges specified for

each gas port. Otherwise, the system may produce gas blends that fall

outside the accuracy specifications of the system.

Call your Environics representative or the Environics home office with any

questions regarding input pressure.

(2) Open the cylinder valves and pressurize the lines to within the ranges listed

above.

(3) Make the output gas connection. Connect the output port to a vented

distribution manifold.

- IMPORTANT-

Do not pressurize the output of the Series 6100.

The Series 6100 is now ready for set up and operation.

SYSTEM OVERVIEW AND SETUP

6100 USER’S GUIDE 12 REV15 -FEB2021

SYSTEM OVERVIEW AND SETUP

OPERATING MODE SUMMARY

The system software provides a number of different operating modes, which are

selected with the MENU and F1/F2/F3 function keys.

These operating modes are described briefly below, and in more detail in other

sections of the manual. The text shown in parentheses is the name of the mode as it

is shown on the LCD display.

ConcentrationMode(CONC)

The CONC Mode allows the creation of a gas mixture by specifying the desired

span gas type and its concentration (OGC). The dilution gas (MFC1) is used to

dilute the CGC of the span gas to acquire the span gas OGC.

The User defines the required output gas concentration from a single or multi-

component gas cylinder and the total flow rate required. If ozone is required in

this mix, the ozone concentration is also entered. The Series 6100 software then

translates these output concentrations into gas flow rates and, using the dilution

flow controller (MFC1), proceeds to dilute the span gas to the defined output

concentration.

Flow Mode (FLOW)

The FLOW Mode is used to specify the amount of flow for the diluent (MFC1)

and the span gas. The difference between the FLOW mode and the CONC Mode

is that in FLOW mode, the user enters the flow rate for each MFC, instead of

having the system software compute the flows as it does in Concentration Mode.

Gas Setup Mode (GASES)

The gas setup mode is used to specify the gas types connected to the ports on

the rear panel of the system. This information is used internally for error checking

and all concentration and flow calculations. The CGC of the calibration gas is

entered for ports two through five; port one is typically 100% zero air. A total of

20 gases can be identified in this mode allowing for multi-gas (multi-component)

cylinders.

SYSTEM OVERVIEW AND SETUP

6100 USER’S GUIDE 13 REV15 -FEB2021

Program Mode (PROG)

The Program Mode allows you to build sequences of Concentration Mode settings,

and to schedule these sequences to run on a repeating schedule.

PreferencesMode (PREFS)

The PREFS mode allows the user to set various user options such as Time/Date,

Display Contrast, Status Input/Output settings, Ozone configuration and Power-up

mode.

System Mode (SYSTEM)

The SYSTEM mode is used to enter, view or edit calibration information for various

system devices such as MFCs, ozone generator and analog to digital converters

(ADC). Calibration data compares measured versus desired performance of the

various devices, so that corrections can be made to improve their accuracy in the

FLOW and CONC modes.

A detailed description of the SYSTEM Mode appears in the Technical Manual portion

of this document.

RemoteMode(REMOTE)

The Remote mode prepares the system to be run from the RS232 port using

Environics’ remote mode protocol.

Info Mode(INFO)

The INFO mode displays the system model number, software version and serial

number.

Table of contents

Other Environics Test Equipment manuals

Popular Test Equipment manuals by other brands

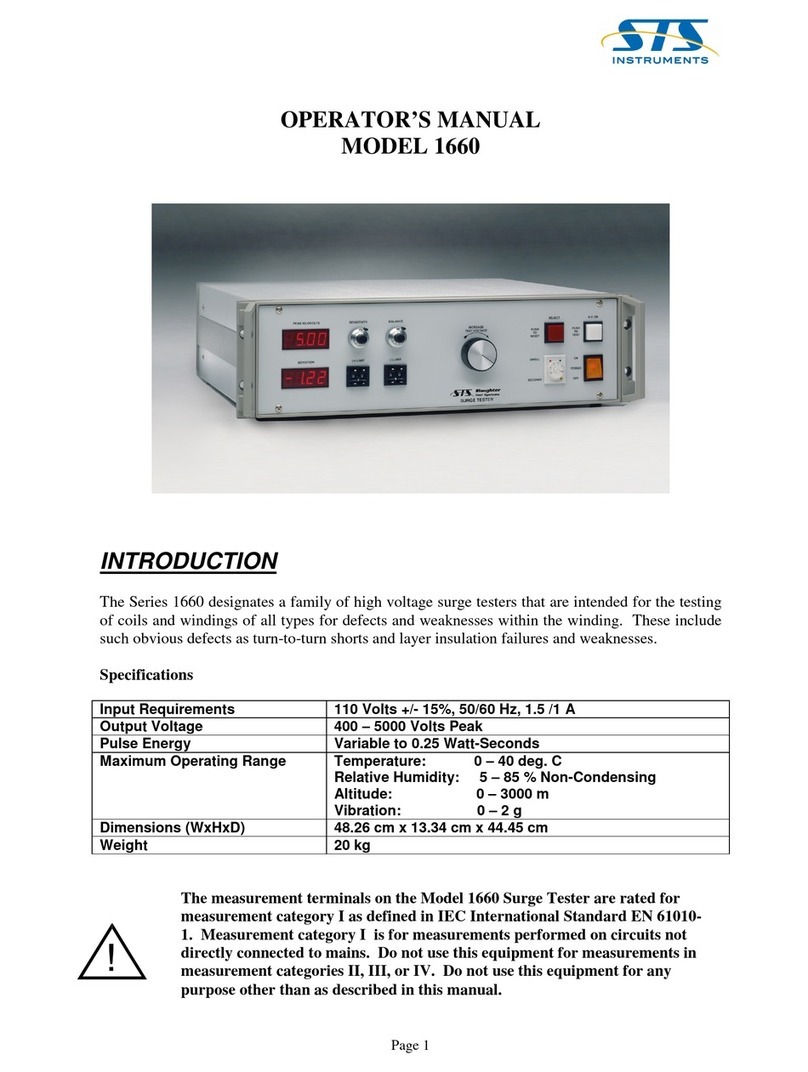

STS

STS 1660 Operator's manual

Aeroflex

Aeroflex IFR 4000 Operation manual

Alliance Sensors

Alliance Sensors SC-200 quick start guide

PCB Piezotronics

PCB Piezotronics 482A23/NP Installation and operating manual

Megger

Megger tan Delta Test Attachment operating instructions

Klein Tools

Klein Tools ET45 instructions