BA380701-en

Contents

1Safety .............................................................................................................................5

1.1 Introduction ...........................................................................................................................5

1.2 Symbols and Signal Words.....................................................................................................5

1.2.1 Personal Injury.......................................................................................................................5

1.2.2 Property Damage...................................................................................................................5

1.2.3 Information............................................................................................................................5

1.3 Intended Use..........................................................................................................................6

1.4 Requirements on Operating and Service Personnel..............................................................6

1.5 Safety Instructions .................................................................................................................6

2Description .....................................................................................................................7

2.1 Requirements for the Place of Installation............................................................................7

2.2 Technical Data........................................................................................................................7

2.3 Design.....................................................................................................................................8

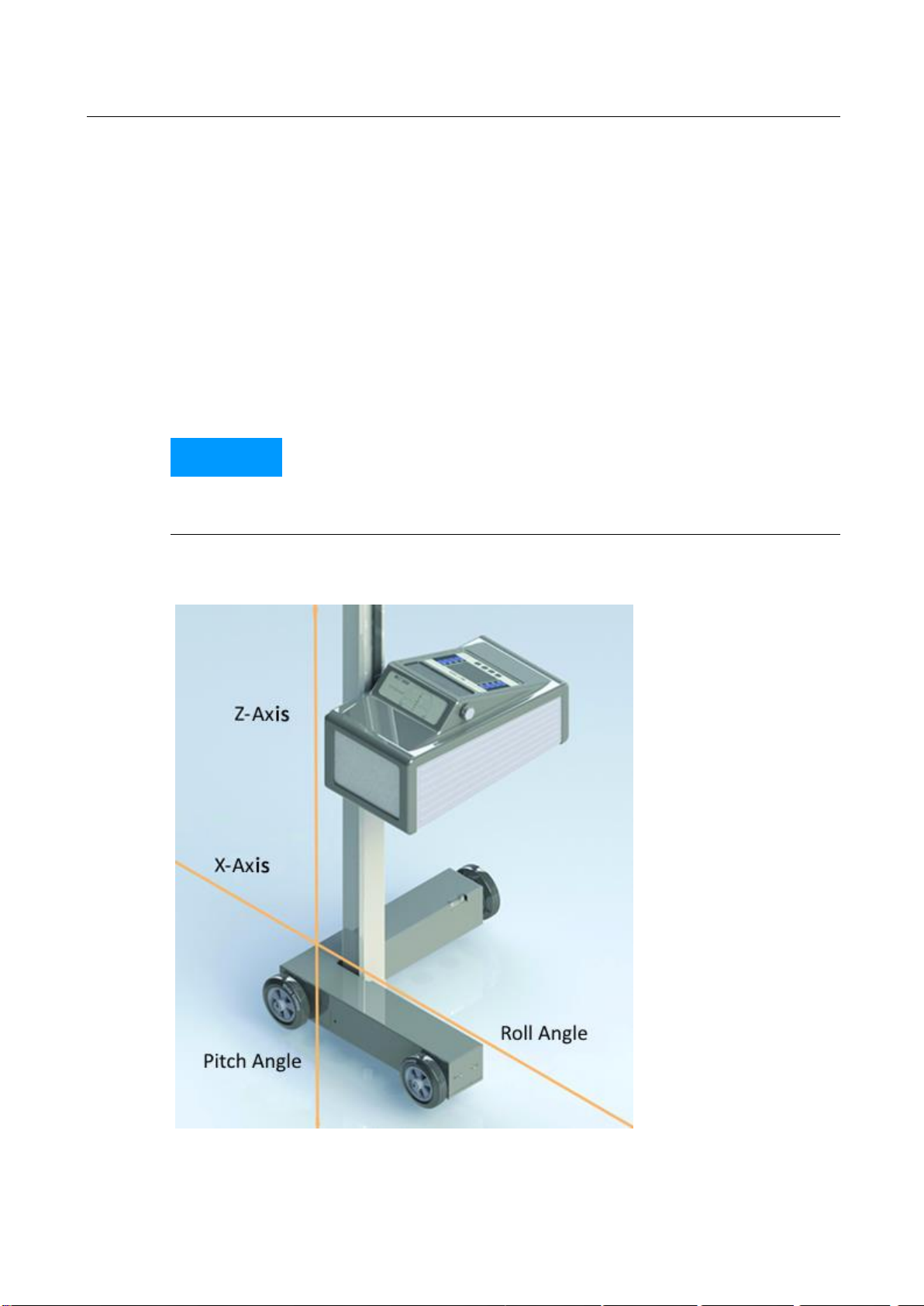

2.4 Electronic Levelling ................................................................................................................9

2.4.1 Compensation Coordinate Axes of MLT 3000 .......................................................................9

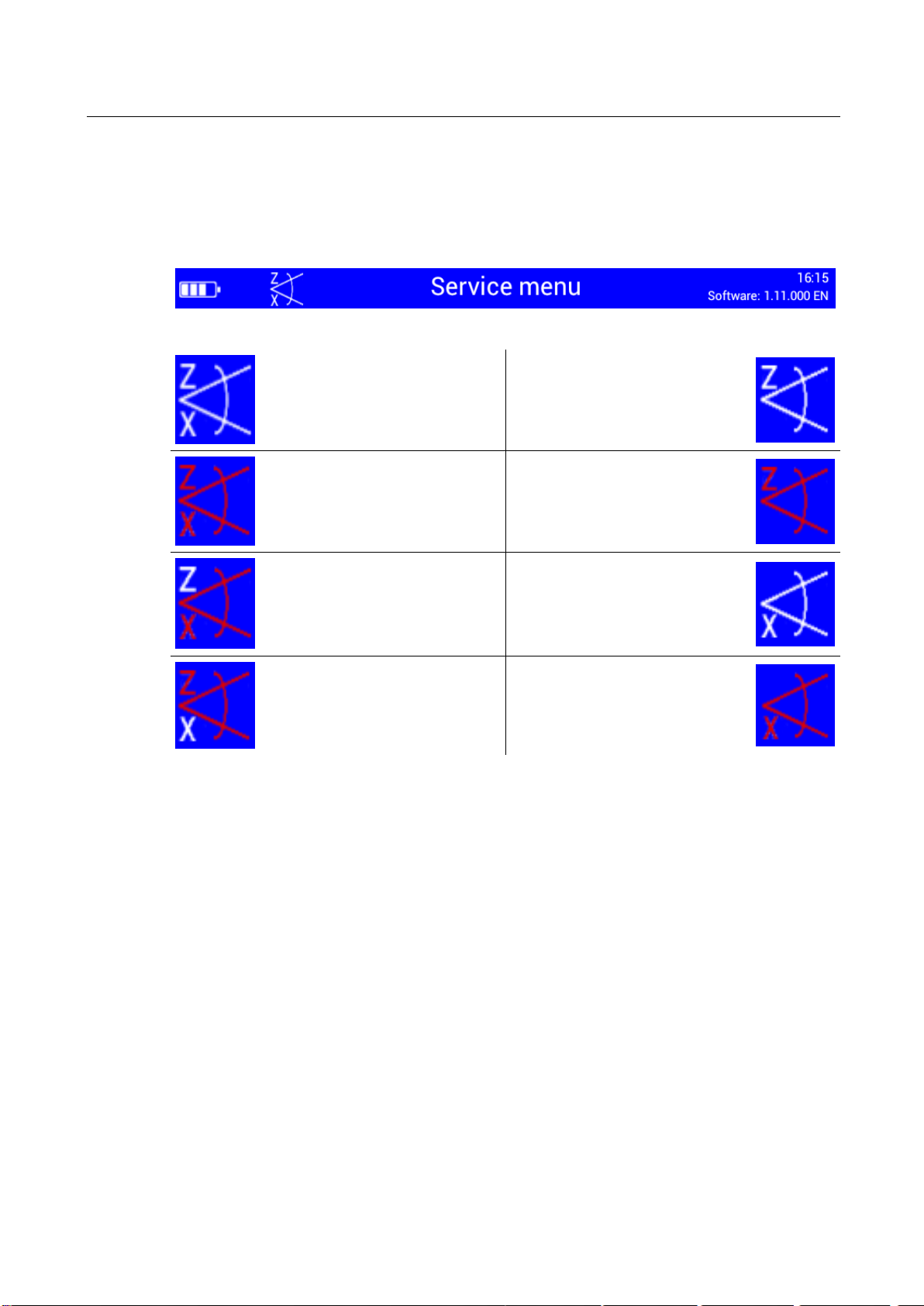

2.4.2 Angle Symbols......................................................................................................................10

2.5 Definition of Technical Terms..............................................................................................11

2.5.1 Pitch Angle ...........................................................................................................................11

2.5.2 Low Beam.............................................................................................................................11

2.5.3 High Beam............................................................................................................................12

3Operation .....................................................................................................................13

3.1 Switching On / Off................................................................................................................13

3.2 Aligning ................................................................................................................................14

3.2.1 Laser Alignment Unit (Option).............................................................................................14

3.2.2 LED Adjustment Aid (Option)...............................................................................................15

3.3 Light Selection Buttons........................................................................................................16

3.3.1 Headlight Test according to § 29 StVZO (Germany)............................................................16

3.3.2 Showing the Button Labels ..................................................................................................17

3.3.3 Adjusting the Pitch Angle.....................................................................................................17

3.3.4 Choosing the Vehicle Class ..................................................................................................18

3.3.5 Browsing back through the Test Screens.............................................................................18

3.3.6 Choosing between Left-Hand or Right Hand Traffic............................................................19

3.3.7 Manufacturer-Specific Test Instructions (OEM)..................................................................19

3.3.8 Navigating through the Test Levels .....................................................................................21

3.4 Testing the Headlights .........................................................................................................22