Environmental Instruments Fluoroprobe FL-2-S0 User manual

FluoroprobeR

O & M Manual

MODEL FL-2-S0

NEW WEBSITE: WWW.thefluoroprobe.com

ENVIRONMENTAL INSTRUMENTS, LLC

144 Industrial Park Drive

SuiteA-3

Waynesville, NC 28786

From Process Control Services

Phone: (02) 9319 1808 Fax: (02) 9319 2786

Fluoroprobe

TABLE OF CONTENTS

Section 1 Product Description

Section 2 Control Settings - Description

Control and Set Points

Section 3 Introduction to Calibration

1. Air Saturated Water Calibration

2. Zero Calibration

3. Air Calibration

4. Calibration Using Hand Held DO Meter

5. Probe and Sensor Maintenance

6. Troubleshooting and Tips

Figure -1 Installation Illustration

Figure -2 Face Plate – Descriptions/Drawing

Figure -3 Relay Description - Terminal Location

Figure -4 4 to 20 mA Board Drawing/Connection

Figure -5 Fluoroprobe Specifications

Figure -6 Calibration Tables and Altitude Correction Factors

Figure -7 Warranty

Fluoroprobe

TM

(FL-2) O&M Manual

Product Description

Section 1

The Fluoroprobe

TM,

FL-2 is an environmental instrument with a newly patented optical

sensor designed for long term monitoring and control of dissolved oxygen in remote and

harsh environments. The probe is designed to provide years of service without the

constant maintenance required by galvanic or polargraphic type probes.

The Fluoroprobe

TM

is housed in a PVC body or stainless steel body with 0-ring sealed

Duran end caps. The entire contents of the probe are potted with epoxy to eliminate any

air space or leaks. Warning: If any attempt is made to open the probe, the end

connections will break loose and will not be able to be placed back together. The

warranty will then be voided.

The sensor is glass bonded on the end of the probe. There are no parts to replace or

maintain, the lifetime of the sensor is based solely on the user’s application and the

surrounding environment’s effect on the silicone rubber. It is suggested that the sensor be

wiped off as needed, (at least once a month with a soft toothbrush or cloth) for

preventative maintenance. An optional solar powered brush for cleaning the sensor can

be ordered mounted on a float for remote or aquaculture applications. Unlike polargraphic

and Galvanic probes, the Fluoroprobe

TM

sensor does not consume oxygen in order to

operate, and therefore flow is not required across the sensor to continuously monitor

oxygen.

The controller is housed in a weather proof NEMA 4X enclosure for permanent installation

either outdoors or indoors. The enclosure has a clear viewing window and a large backlit

display to read at a glance day or night.

Section 2 Control Settings - Description

The controller has several functions in its program. The rotary switch in the center is the

main selector switch for the controller (See, fig-2 for faceplate Drawing). The D.O. position

is the normal operating position that displays the level of oxygen in the environment to

which the probe is exposed. The HIGH and LOW set points are adjusting pots for the

main relay, which requires a small screwdriver to set. There is an optional pair of relays

with set points for a system with multiple aeration control. These adjusting pots tell the

relays when to turn on and are labeled SET 2 and SET 3 (See fig-3 for Relay Terminal

Location).

The 4 to 20 mA connections are located on (fig-4). Also, information on span adjustments

and wiring for data access.

Controls and Set Points

HIGH SET: Turn the rotary switch to HIGH SET and adjust the HIGH SET pot (on the right

side of the controller) to the level you select as a cut off point. This adjustment can be

made with a small screwdriver. This set point must be Higher than the LOW SET in order

for the Low- High relay to operate.

LOW SET: Turn the rotary switch to LOW SET and adjust the LOW SET pot (on the lower

right corner of the controller) to the level you select as the first relay cut on point. This

adjustment can he made with a small screwdriver. This set point must be Lower than the

HIGH SET in order for the Low-High relay to operate.

SET 2 is a back up relay for auxiliary equipment in case the oxygen level keeps falling.

This relay has one setting, the HIGH SET will act as the cutoff.

SET 3 operates the same as SET 2 and can be used for back up if the oxygen levels keep

decreasing or an alarm.

OPERATION: Turn the rotary switch to the DO position and the system will operate

automatically in accordance with the setting you have selected. NOTE: If 4-20 mA output

is being monitored by a computer or data logger, etc. The rotary switch must be in

the D.O. position. The relay set points are not affected by the position of the rotary

switch.

Section 3 Introduction to Calibration

After installing the unit, allow the sensor 2 or 3 days in its new environment to stabilize

before calibrating. The Fluoroprobe

TM

is very stable and the longer it stays in the water,

the better. The Fluoroprobe

TM

is calibrated before shipping to a known zero (0) ppm

standard, and air saturated water (8.47 D.0. @ 20

o

C / 3000ft). Generally, the Fluoroprobe

will not require calibration after installation, however, it is recommended to check the

calibration at first use.

The operator should take D.O. readings with their hand held probe over the first few days

at the location where the probe is installed. It is important that several days of readings

with your handheld be observed before you make any adjustments to the Fluoroprobe

TM

.

The best thing to do if the units' readings appear odd is to do nothing and investigate

thoroughly before making any adjustments. If your operation range is from 4.0 ppm down

to 0.0 ppm, you should calibrate to a portable meter or a know standard in that range.

Always use the ZERO calibration pot to make adjustments below 4.0 ppm. When the

range is from 4.0 ppm and higher or you are calibrating to ambient air, use the AIR

calibration pot only.

Note-. If air calibrating, allow thirty (30) minutes or more to stabilize the unit before

comparing readings or making any adjustments. If the FL-2 reads zero (0.0) ppm,

check the oxygen level with a handheld and then check the probe for trash blockage

and/or clean the probe sensor with a small toothbrush. If the display stays at 19.90 all the

time the unit has other problems and should be sent back to the manufacturer. You may

give us a call anytime for help - please see the back of the manual for the telephone

number.

Note: If the probe is being air calibrated in a pipe where the end of the pipe is

submerged,

vent holes must be drilled on both ends of the pipe to allow ambient

air to purge the gases, which might give a false air calibration value. Drill holes in

pipe just above the water line and at the top of the pipe. When air calibrating, the

probe should be suspended between the holes in a white PVC pipe to help reflect

heat from the sun.

Do not air calibrate the FL-2 if air temperatures is + 10 or -10 degrees from water

temperature. Leave the probe in the water and use a handheld to compare readings. The

FL-2 has temperature compensation, so never calibrate it until you know the probe has

had ample time to adjust to temperature. If the readings do not look right to you

investigate everything involved and wait till the next day to try again.

Suggested calibration for wastewater treatment: There are four (4) basic ways to

calibrate the Fluoroprobe

TM

controller, which are described in the following sections.

If you are using the FL-2 in a wastewater application and your operation range is 3 or 4

ppm down to 0 ppm use a hand held instrument to compare or calibrate. The sensor is

more responsive and stable when left continuously in the water and calibrated within its

normal operating environment. Always clean sensor with a toothbrush and place back in

aeration 30 minutes or longer before any calibration. Bio-growth or debris covering the

sensor will cause oxygen reading to slowly fall to zero, the only maintenance needed is

once a month toothbrushing. Many aeration basins never have this growth problem.

1. Air Saturated Water Calibration:. For this technique, a volume of water must be

aerated for twenty (20) minutes or longer at a constant temperature. The operator can

use an aquarium pump and a stone diffuser (air stone). A cylinder of some type is best.

PVC pipe (2"or 3") with a cap on the bottom is a good vessel to use for this method.

Place the probe in the aerated water keeping the probe sensor near the top of the

container for maximum efficiency. To obtain the correct current atmospheric pressure

reading, use the local altitude or the true atmospheric pressure from a mercury

barometer or weather bureau report. The same air calibration table used for

polargraphic or galvanic calibration may also be used for reference. This technology is

for long term monitoring and taking your time is very important when calibrating this

instrument. After the probe has been submerged for twenty (20) minutes or more in the

air-saturated water, press the READ button on the faceplate of the instrument. The

operator will have about two (2) minutes to adjust the air calibrate adjustment screw on

the faceplate to the air saturated water concentration. No water flow or movement in

the probe is necessary in order to obtain 0

2

concentration readings. A hand held

oxygen meter can be used in calibration to assure air saturation. If you are also zero

calibrating, be sure to clean the probe before changing from one liquid to the next.

2. Zero Calibration: First prepare a container of oxygen depleted water. One of the

chemicals that are effective in depleting the 0

2

in water is Sodium Sulfite (NaSO

2

). Use

one gram/quart of water, mix well and allow up to one hour to deplete the oxygen before

using. Warning: let probe sit in prepared water for (30) minutes or longer in order

to allow the sensor to equilibrate prior to adjustment. It may take as long as (45)

minutes or more to go from air to zero level, so make sure a stable zero level has been

obtained before adjusting the instrument. The probe can be gently moved up or down

to speed the process, however no flow is required to calibrate or operate the instrument.

When ready, press the red read button on the faceplate of the unit. This will allow (2)

minutes to adjust the instrument using the zero calibrate set point. After adjustment, the

unit will be calibrated to zero (0). Changing the probe from zero to air can contaminate

the calibration solution so be sure to rinse the probe clean before each step.

3. Air Calibration: Air calibration is an easy and reliable method to use to calibrate the

unit. This technique must be performed out of direct light. If the probe is mounted in a

float device for aquaculture or mounted in a pipe for wastewater, pull the probe out of

the water and wipe off the sensor end. After making sure the sensor is clean. Note: If

the end of the probe is dried cleaned with a soft toothbrush the sensor will air saturate

quicker. To calibrate, place the probe back in the pipe and leave probe suspended

between the holes above the water for about twenty (20) minutes. Do not air calibrate if

air and water temperatures are + or – 10

o

C difference.

Using the enclosed pressure/altitude chart (fig-3) and the altitude of the location where

the unit will be housed, select the proper calibration value. Press the red Read button

on the faceplate of the unit. The operator will have two (2) minutes to adjust the Air

calibrate pot using a small screwdriver. After completing the adjustment, replace the

probe back in to the water. Warning: If the pipe is submerged it has to be vented

below the point at which the probe is in the air due to treatment gases in the pipe.

4. Calibration using hand held DO meter: Take handheld readings in the location where

the Fluoroprobe

TM

has been installed. As soon as the hand held reading has been

taken, make sure the selector switch is on DO, then press the red READ button. The

operator will have two ( 2 ) minutes to make the adjustment to the unit. Allow the

reading to stabilize before making adjustments. Uses the Air calibrate pot for 4ppm and

greater or use the zero for 4ppm and below. Adjust to the handheld DO meter reading.

The instrument is now ready to operate and needs no further adjustment.

Warning:. If the unit has just been put in the water, allow at least two (2 or 3) days

to equilibrate to the type of environment the sensor will be used in before

calibrating. Do not calibrate if probe has been removed from water, wait 30

minutes or longer before adjusting.

5. Probe and Sensor Maintenance: The factory request that the probe be inspected at

least once a month. The probe can be washed down in the probe holder before the

inspection of the sensor takes place. A soft toothbrush should be used on the black

sensor on the end of the probe. Place back in water and allow at least (1) one hour to

stabilize.

1

2

3

4

1

2

3

4

ABCD

ABCD

Title

Size Number Rev

Date

File Name

Drawn By

Sheet of

RELAY LOCATION

RELAY 3

10A 250VAC

RELAY 2

10A 250VAC

RELAY 15A

250VAC

TERMINAL

POS

WARRANTY ZERO

LEAVE ALONE

1

2

3

4

1

2

3

4

ABCD

ABCD

Title

Size Number Rev

Date

File Name

Drawn By

Sheet of

THIS POT ADJUSTS

THE 4mA AT 0 PPM

THIS POT ADJUSTS THE SPAN

CAN BE ADJUSTED FOR 20mA

AT 10 PPM TO 19.99 PPM

BLUE WIRE 4-20 (+)

WHITE WIRE 4-20 (-)

NOTE: MAX LOOP RESISTANCE IS 550 ohms

TO S.C.A.D.A.

OR OTHER

DATA ACCESS

FL-2 4-20mA CONNECTION

MODEL FL-2-SWING OUT

WIRING DIAGRAM

LINE

NEU.

4-20+

4-20-

Earth

RELAY 1

RELAY 1

RELAY 2

RELAY 2

230 VAC

RELAY 3

RELAY 3

FL2-FLUOROPROBE SPECIFICATIONS

Application Temperature Range:

Instrument -30°C to +50°C

Sensor Material 0°C to +50°C

Operation Range:

Aqueous Solutions 0

ppm

to Supersaturation

Response Time:

Aqueous Solutions 10 min

Gaseous Phases 80 sec

Accuracy:

Aqueous Solutions – Range 0 to 10

ppm

Accuracy 0.2

ppm

Sensor Lifetime: Based solely upon the application

environment and the effect on Silicone

Rubber. 3 year Sensor warranty on approved

applications.

4-20 mA Max. Resistance 550 ohms

Features:

Temperature Compensation Yes

Ambient Excitation Compensation Yes

Instrument Measurement Steady State (Amplitude)/Lifetime

NOTE 1: Response Time based upon approximately 1 ft/minute flow across sensor-

Response time will decrease with increased flow, however,

FLOW IS NOT REQUIRED FOR MEASUREMENTS!

Table of contents

Other Environmental Instruments Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

VR Avionics

VR Avionics TM1 Operational and installation manual

Rish

Rish Master 3430 operating manual

Digga

Digga TORQUE LOGIC Installation, operating and troubleshooting instructions

DPS Telecom

DPS Telecom NetGuardian SUI user manual

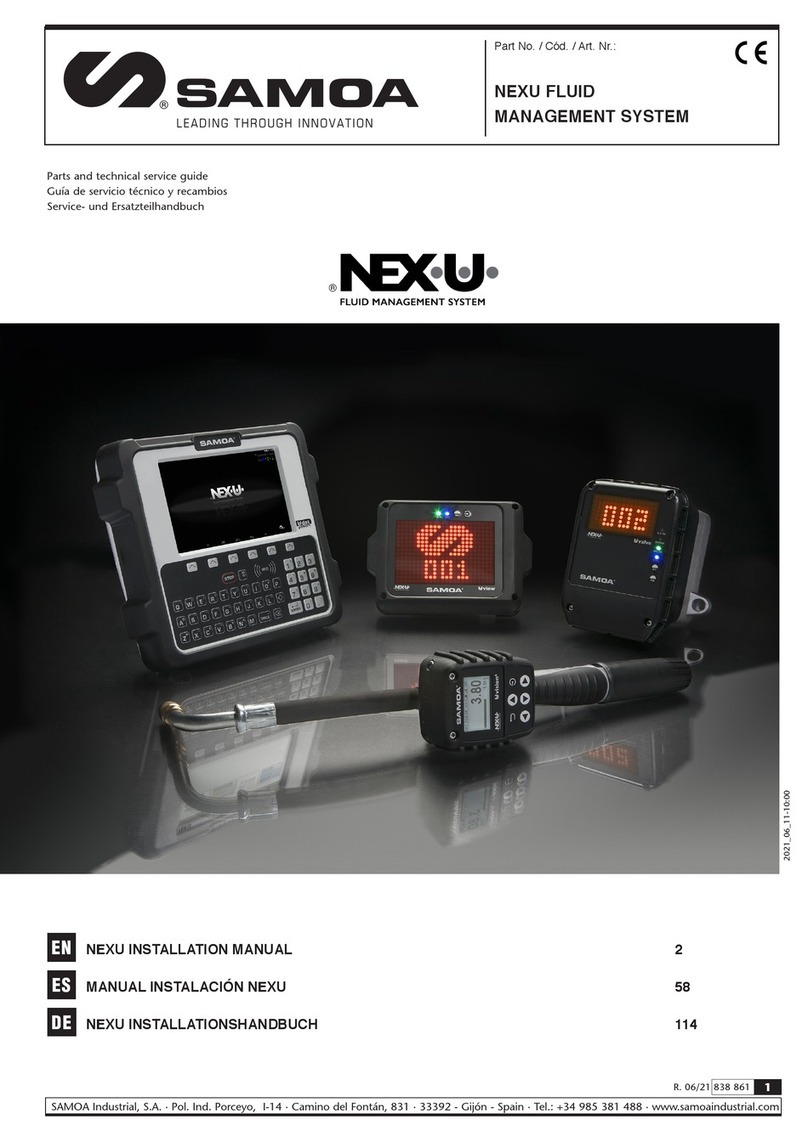

Samoa

Samoa NEXU Parts and technical service guide

Precaster

Precaster PRF Series manual