3

R. 06/21 838 861

SAMOA Industrial, S.A. · Pol. Ind. Porceyo, I-14 · Camino del Fontán, 831 · 33392 - Gijón - Spain · Tel.: +34 985 381 488 · www.samoaindustrial.com

2021_06_11-10:00

EN

INDEX

4.4 END OF LINE (EOL) RESISTORS (FOR THREE-CONNECTOR UDATS)................................................................. 27

4.5 LOCAL PARAMETERS SETUP.................................................................................................................................... 28

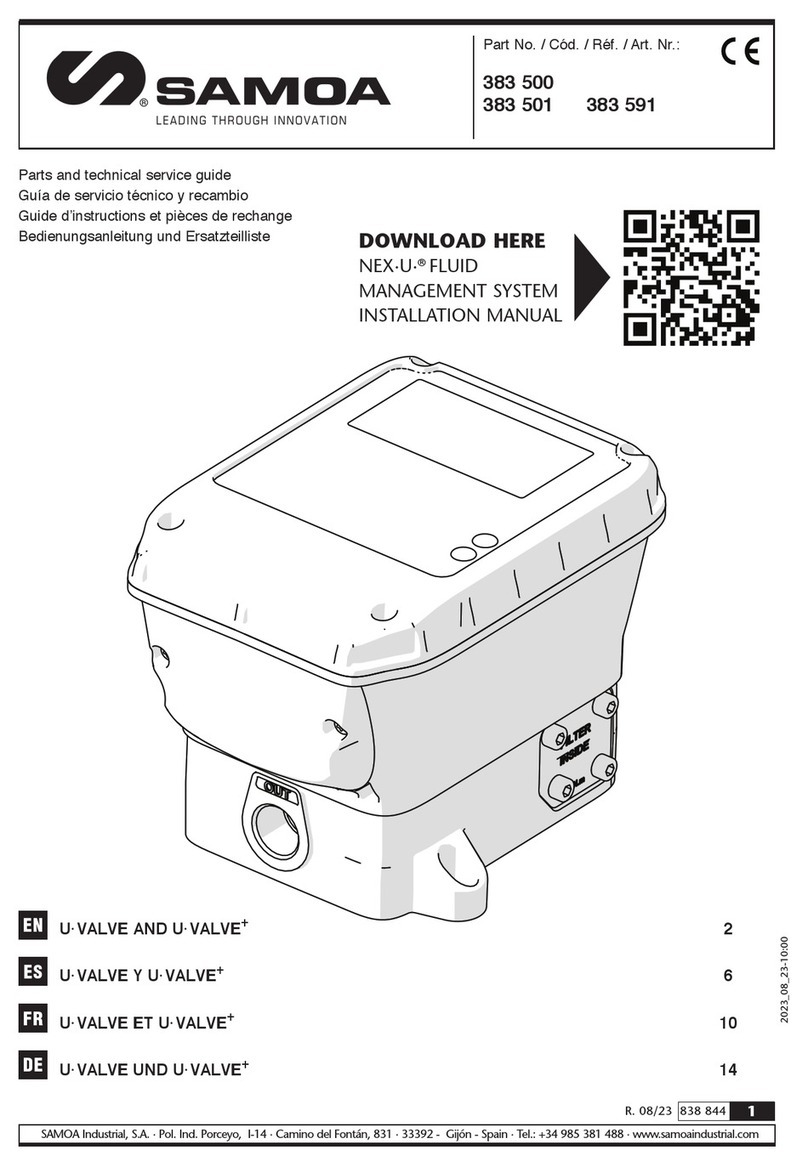

4.5.1 LOCAL PARAMETERS SETUP ON A UVALVE / UVALVE +........................................................................................... 28

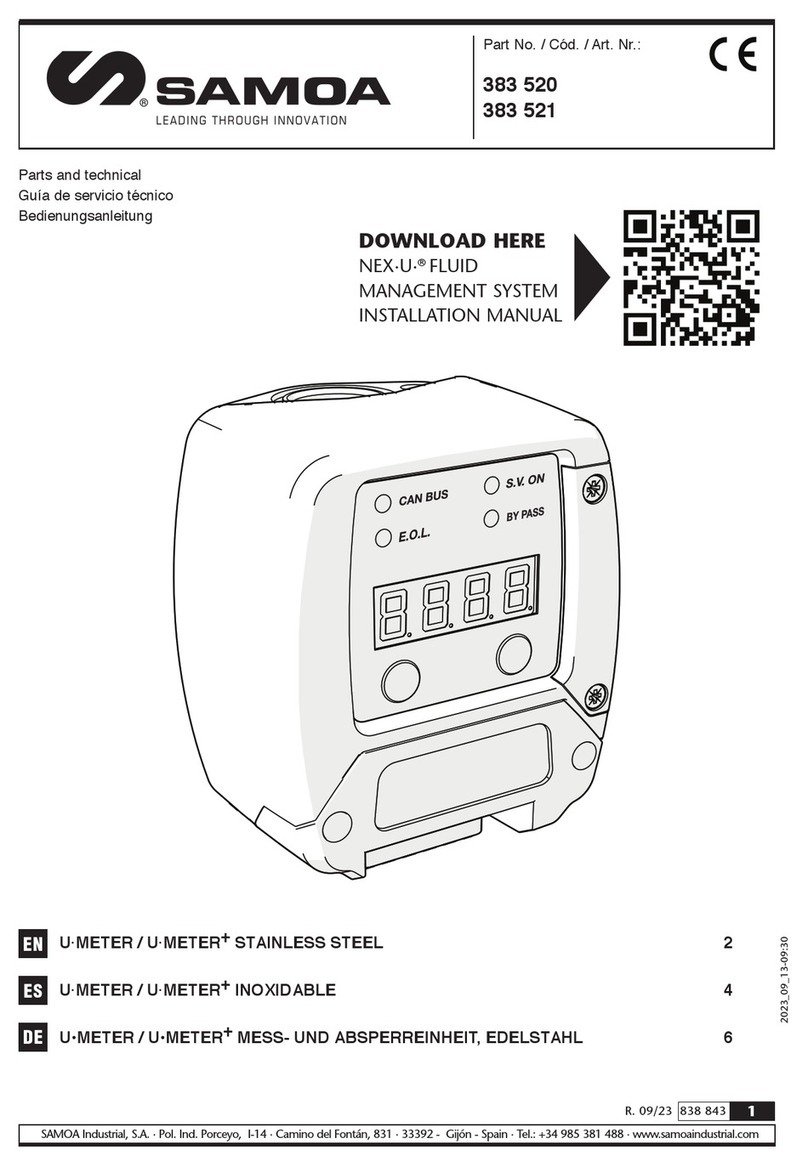

4.5.2 LOCAL PARAMETERS SETUP ON A UMETER / UMETER+.......................................................................................... 29

4.5.3 LOCAL PARAMETERS SETUP ON UDAT / UDAT POWER+ ......................................................................................... 30

4.5.4 LOCAL PARAMETERS SETUP ON UCOUNT ................................................................................................................ 31

4.5.5 LOCAL PARAMETERS SETUP ON UVIEW .................................................................................................................... 31

4.5.6 LOCAL PARAMETERS SETUP ON UVISION ................................................................................................................. 31

4.5.7 LOCAL PARAMETERS SETUP ON UVISION+............................................................................................................... 32

4.5.8 LOCAL PARAMETERS SETUP ON UTANK.................................................................................................................... 33

4.5.9 LOCAL PARAMETERS SETUP ON UNET ...................................................................................................................... 33

4.6 DIAGNOSIS OF THE NETWORK STATUS.................................................................................................................. 33

5. NEXU REQUIREMENTS ................................................................................................................................. 34

6. SOFTWARE CONFIGURATION...................................................................................................................... 34

6.1 INSTALLATION PROCESS .......................................................................................................................................... 34

6.1.1 HOW TO CHANGE THE IPV4 ADDRESS FOR A LOCAL NETWORK............................................................................ 34

6.2 CONFIGURATION PROCESS ..................................................................................................................................... 35

6.2.1 PRODUCTS.................................................................................................................................................................... 36

6.2.2 DEVICES ........................................................................................................................................................................ 37

6.2.2.1 UTANK.................................................................................................................................................................... 38

6.2.2.2 TANK ...................................................................................................................................................................... 38

6.2.2.3 UDAT...................................................................................................................................................................... 38

6.2.2.4 UVALVE / UVALVE+............................................................................................................................................... 39

6.2.2.5 UMETER / UMETER+ ............................................................................................................................................. 39

6.2.2.6 UCOUNT ................................................................................................................................................................ 40

6.2.2.7 UVIEW .................................................................................................................................................................... 40

6.2.2.8 UVISION ................................................................................................................................................................. 40

6.2.2.9 UVISION+............................................................................................................................................................... 40

6.2.2.10 AIR SV .................................................................................................................................................................. 40

6.2.2.11 MOBILE UNIT....................................................................................................................................................... 40

6.2.2.12 LUBE TRUCK ....................................................................................................................................................... 41

6.2.3 GROUPS ........................................................................................................................................................................ 42

6.2.4 DISPENSE SCRIPT......................................................................................................................................................... 42

6.2.5 ERP / DMS...................................................................................................................................................................... 43

6.2.6 SEND.............................................................................................................................................................................. 43

6.2.7 SYSTEM TOOLS............................................................................................................................................................. 43

6.2.8 NETWORK...................................................................................................................................................................... 44

7. MANAGER ...................................................................................................................................................... 44

7.1 HOME ........................................................................................................................................................................... 44

7.2 TRANSACTIONS.......................................................................................................................................................... 45

7.3 TANKS / MOBILE UNITS / TANK TRUCKS................................................................................................................. 47

7.3.1 TANKS............................................................................................................................................................................ 47

7.3.2 MOBILE UNITS............................................................................................................................................................... 48

7.3.3 TANK TRUCKS............................................................................................................................................................... 48

7.4 USERS.......................................................................................................................................................................... 49

7.5 EVENTS........................................................................................................................................................................ 50

7.6 DEVICES ...................................................................................................................................................................... 50

7.6.1 DISPENSE POINT........................................................................................................................................................... 50

7.6.2 UDAT.............................................................................................................................................................................. 52

7.6.3 UTANK ........................................................................................................................................................................... 52

7.6.4 UVISION+....................................................................................................................................................................... 52

7.6.5 AIR SV ............................................................................................................................................................................ 53

7.6.6 MOBILE UNIT................................................................................................................................................................. 53

7.6.7 LUBE TRUCK ................................................................................................................................................................. 53

8. QUICK PANEL................................................................................................................................................. 54

9. VIRTUAL TERMINAL...................................................................................................................................... 54

10. UDAT OPERATION ......................................................................................................................................... 55

11. UVISION+ OPERATION.................................................................................................................................. 55

12. HOSE REEL CALIBRATION........................................................................................................................... 56