TM1 manual

Contents

Introduction.........................................................................................................................................................4

Recommended Steps....................................................................................................................................................................... 4

Operation..............................................................................................................................................................5

Parameters Acquisition.................................................................................................................................................................... 5

Temperatures (T1 thru T3)........................................................................................................................................................ 5

Pressures (P1 thru P3)................................................................................................................................................................. 5

Speeds (N1 and N2).................................................................................................................................................................... 5

Fuel Flow and Count (FF1 and FC1)....................................................................................................................................... 6

Voltage and Amps (V1 and A1)............................................................................................................................................... 6

Discrete Inputs (D1 thru D5).................................................................................................................................................... 6

Parameters Communication.......................................................................................................................................................... 7

CAN Bus Interface Basics........................................................................................................................................................... 7

Information Message #1............................................................................................................................................................ 7

Information Message #2............................................................................................................................................................ 7

Information Message #3............................................................................................................................................................ 8

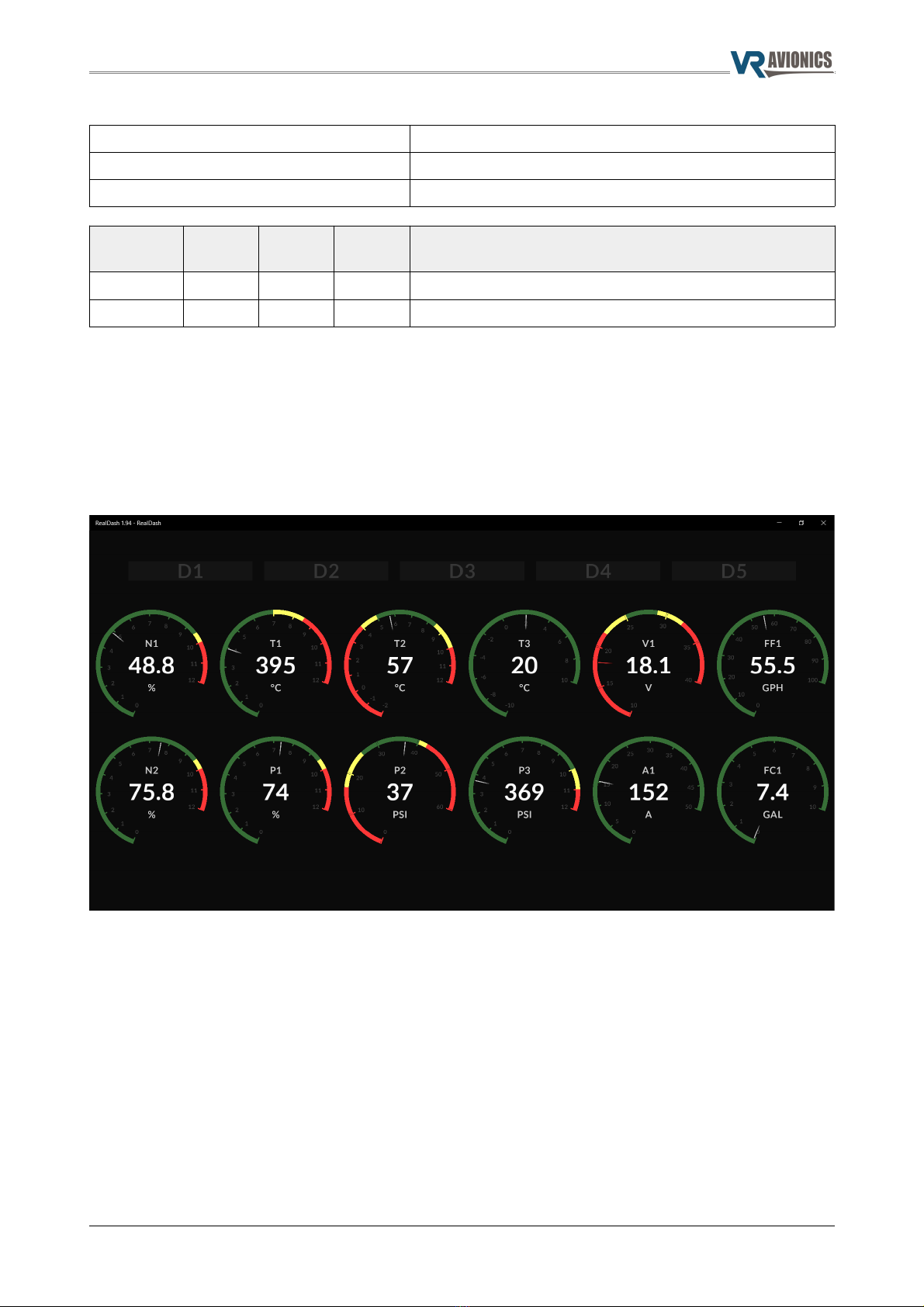

Human-Machine Interfaces............................................................................................................................................................ 8

Dashboard Devices...................................................................................................................................................................... 8

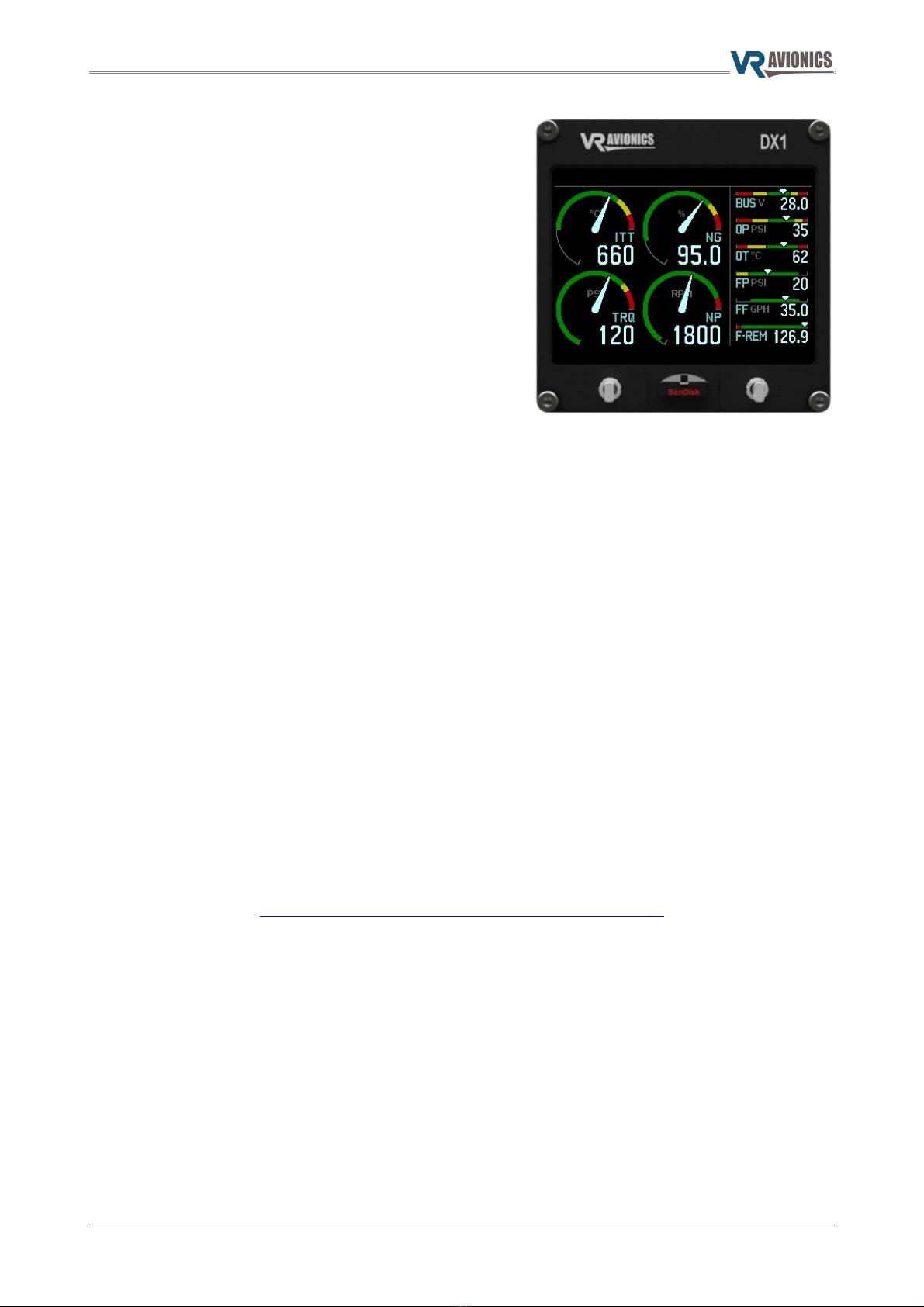

DX1 Displa s.................................................................................................................................................................................. 9

Maintenance Support....................................................................................................................................................................... 9

The SetView App.......................................................................................................................................................................... 9

Installation..........................................................................................................................................................10

Mounting and Wiring.................................................................................................................................................................... 10

Basic Power & Communication.................................................................................................................................................. 10

Temperature Sensing..................................................................................................................................................................... 11

Pressure Sensing.............................................................................................................................................................................. 11

Speed Sensing.................................................................................................................................................................................. 12

Fuel Flow Sensing............................................................................................................................................................................ 12

Voltage and Amps Sensing.......................................................................................................................................................... 12

Discrete Input Sensing................................................................................................................................................................... 13

Sensors / Transducers / Senders / Probes............................................................................................................................. 13

Configuration.....................................................................................................................................................14

Operational Settings...................................................................................................................................................................... 14

CAN Bus Base ID........................................................................................................................................................................ 14

CAN Bus Interface Speed........................................................................................................................................................ 14

N1 & N2 Speed Sensor Full-Scale Frequenc (Hz)........................................................................................................ 15

N1 & N2 Speed Sensor Full-Scale Value........................................................................................................................... 15

FF Fuel Flow Sensor K-Factor................................................................................................................................................. 15

FF Fuel Flow Sensor Full-Scale Value.................................................................................................................................. 15

A1 Current Sensor/Shunt Full-Scale Value....................................................................................................................... 15

A1 Current Zero Deadband Value....................................................................................................................................... 15

P1, P2 & P3 Pressure Sensor Full-Scale Value................................................................................................................. 16

Factor Calibration Settings........................................................................................................................................................ 16

2023-09-21 © 2023 VR Avionics page 3 of 16