Environnement MIR 9000H User manual

TECHNICAL MANUAL

HEATED IR GAS FILTER CORRELATION

MULTIGAS MONITOR

MIR 9000H

- FEBRUARY 2012 -

111 bd Robespierre, 78300 POISSY - -TEL. 33(0)-1.39.22.38.00 – FAX 33(0)-1.39 65.38.08

http://www.environnement-sa.com

GENERAL

CHARACTERISTICS

OPERATION

OPERATING

INSTRUCTIONS

PREVENTIVE

MAINTENANCE

CORRECTIVE

MAINTENANCE

APPENDIX

Environnement S.A MIR 9000H Duplication prohibited

0-2 APRIL 2011

WARNING

The information in this document is subject to change without notice. The designer reserves

the right to upgrade his equipment without updating this document. Consequently, the

information in this document is not contractual.

Duplication prohibited MIR 9000H Environnement S.A

0-3

APRIL 2011

SUMMARY

CHAPTER 1 - GENERAL – CHARACTERISTICS

1.1 GENERAL 1–3

1.2 CHARACTERISTICS 1–12

CHAPTER 2 – OPERATION

2.1 INFRARED CORRELATION PRINCIPLE 2–3

2.2 PRINCIPLE APPLIED TO THE MIR 9000H 2–4

2.3 DESCRIPTION OF THE MAIN MODULES 2–7

2.4 SIMPLIFIED OPERATION FLOWCHART 2–12

CHAPTER 3 – OPERATING INSTRUCTIONS

3.1 FIRST TIME RUNNING 3–5

3.2 PROGRAMMING THE MIR 9000H 3–7

3.3 DESCRIPTION OF THE SCREENS 3–9

3.4 CALIBRATION 3–53

CHAPTER 4 – PREVENTIVE MAINTENANCE

4.1 SAFETY INSTRUCTIONS 4–3

4.2 MAINTENANCE CALENDAR 4–4

4.3 MAINTENANCE OPERATION SHEETS 4–4

4.4 EQUIPMENT REQUIRED FOR MAINTENANCE 4–23

Environnement S.A MIR 9000H Duplication prohibited

0-4 APRIL 2011

CHAPTER 5 – CORRECTIVE MAINTENANCE

5.1 LIST OF ALARMS AND CONTROLS 5-4

5.2 ADJUSTMENT AND INSPECTION OF THE MIR MODULE BOARD 5-9

5.3 CONFIGURING THE BOARDS 5-13

CHAPTER 6 – APPENDIX

DNP-ARM7 board

Duplication prohibited MIR 9000H Environnement S.A

0-5

APRIL 2011

LIST OF FIGURES

Figure 1–1 – Presentation of the MIR 9000H analyzer 1–2

Figure 1–2 – Display and keyboard 1–4

Figure 1–3 – Lower panel of the MIR 9000H 1–5

Figure 1–4 – Components location of the MIR 9000H – covers ON 1–7

Figure 1–5 – Detailed view of the stepping motor and IR detector assembly 1–8

Figure 1–6 – Detailed view of the thermo controlled enclosure 1–8

Figure 1–7 – Links between units 1–13

Figure 1–8 – Dimensions of the MIR 9000H 1–15

Figure 2–1 – Infrared absorption of MIR 9000H 2–2

Figure 2–2 – Synoptic diagram of the MIR 9000H analyzer 2–6

Figure 2–3 – Basic fluid diagram of MIR 9000H 2–8

Figure 2–4 – Interconnection diagram 2–10

Figure 2–5 – Simplified operation flowchart 2–12

Figure 3–1 – Terminal block definition 3–4

Figure 3–2 – Menu Tree 3–8

Figure 3–3 – Calibration device 3–53

Figure 4–1 – Checking and replacement of the ejector 4–8

Figure 4–2 – Maintenance of the source block 4–11

Figure 4–3 – Measurement chamber of MIR 9000H 4–12

Figure 4–4 – Removal of the chopper motor assembly 4–12

Figure 4–5 – Source block assembly 4–15

Figure 4–6 – Maintenance of the optical fork of the chopper 4–17

Figure 4–7 – Motor and belt replacement 4–20

Figure 4–8 – IR source centring 4–21

Figure 5–1 – MODULE board – MIR 9000H 5-15

Figure 5–2 – Pilot board 5-18

Figure 5–3 – Pressure sensor board 5-21

Figure 5–4 – VCP1 board - recto 5-22

Figure 5–5 – VCP1 board – verso 5-22

Environnement S.A MIR 9000H Duplication prohibited

0-6 APRIL 2011

LIST OF TABLES

Table 3–1 – Relays configuration 3–35

Table 3–2 – Remote controls configuration 3–36

Table 5–1 – Configuration of MODULE board 5-16

Table 5–2 – Configuration and tests points of the PILOT board 5-19

Table 5–3 – Configuration and test points of the VCP1 board 5-23

Duplication prohibited MIR 9000H

Environnement S.A

0-

7

FEBRUARY 2012

INDEX OF PAGES

Page Date

0-1 02.2012

0-2 04.2011

0-3 04.2011

0-4 04.2011

0-5 04.2011

0-6 04.2011

0-7 02.2012

0-8 04.2011

1-1 04.2011

1-2 04.2011

1-3 04.2011

1-4 04.2011

1-5 04.2011

1-6 04.2011

1-7 04.2011

1-8 04.2011

1-9 04.2011

1-10 04.2011

1-11 04.2011

1-12 04.2011

1-13 04.2011

1-14 04.2011

1-15 04.2011

1-16 04.2011

2-1 04.2011

2-2 04.2011

2-3 04.2011

2-4 04.2011

2-5 04.2011

2-6 04.2011

2-7 04.2011

2-8 04.2011

2-9 04.2011

2-10 04.2011

2-11 04.2011

2-12 04.2011

3-1 04.2011

3-2 04.2011

3-3 04.2011

3-4 04.2011

3-5 04.2011

3-6 04.2011

3-7 04.2011

3-8 04.2011

3-9 04.2011

Page Date

3-10 04.2011

3-11 04.2011

3-12 04.2011

3-13 04.2011

3-14 04.2011

3-15 04.2011

3-16 04.2011

3-17 04.2011

3-18 04.2011

3-19 04.2011

3-20 04.2011

3-21 04.2011

3-22 04.2011

3-23 04.2011

3-24 04.2011

3-25 04.2011

3-26 04.2011

3-27 04.2011

3-28 04.2011

3-29 04.2011

3-30 04.2011

3-31 04.2011

3-32 04.2011

3-33 04.2011

3-34 04.2011

3-35 04.2011

3-36 04.2011

3-37 04.2011

3-38 04.2011

3-39 04.2011

3-40 04.2011

3-41 04.2011

3-42 04.2011

3-43 04.2011

3-44 04.2011

3-45 04.2011

3-46 04.2011

3-47 04.2011

3-48 04.2011

3-49 04.2011

3-50 04.2011

3-51 04.2011

3-52 02.2012

3-53 04.2011

3-54 04.2011

3-55 04.2011

3-56 04.2011

4-1 04.2011

4-2 04.2011

4-3 04.2011

4-4 04.2011

4-5 04.2011

Page Date

4-6 04.2011

4-7 04.2011

4-9 04.2011

4-10 04.2011

4-11 04.2011

4-12 04.2011

4-13 04.2011

4-14 04.2011

4-15 04.2011

4-16 04.2011

4-17 04.2011

4-18 04.2011

4-19 04.2011

4-20 04.2011

4-21 04.2011

4-22 04.2011

4-23 04.2011

4-24 04.2011

5-1 04.2011

5-2 04.2011

5-3 04.2011

5-4 04.2011

5-5 04.2011

5-6 04.2011

5-7 04.2011

5-8 04.2011

5-9 04.2011

5-10 04.2011

5-11 04.2011

5-12 04.2011

5-13 04.2011

5-14 04.2011

5-15 04.2011

5-16 04.2011

5-17 04.2011

5-18 04.2011

5-19 04.2011

5-20 04.2011

5-21 04.2011

5-22 04.2011

5-23 04.2011

5-24 04.2011

6-1 04.2011

6-2 04.2011

Environnement S.A MIR 9000H Duplication prohibited

0–8

APRIL 2011

Page intentionally left blank

Duplication prohibited MIR 9000H Environnement S.A

1–1

APRIL 2011

CHAPTER 1

GENERAL CHARACTERISTICS

1.1 GENERAL 1–3

1.1.1 PRESENTATION 1–3

1.1.2 DESCRIPTION 1–3

1.1.2.1 Front panel 1–4

1.1.2.2 Electrical and pneumatic connections 1–6

1.1.2.3 Components location 1–9

1.1.3 VARIOUS OPERATION MODES 1–10

1.1.3.1 Standard 1–10

1.1.4 RELATED EQUIPMENT 1–11

1.2 CHARACTERISTICS 1–12

1.2.1 TECHNICAL CHARACTERISTICS 1–12

1.2.2 STORAGE CHARACTERISTICS 1–13

1.2.3 INSTALLATION CHARACTERISTICS 1–13

1.2.3.1 Links between units 1–13

1.2.3.2 Handling and storage 1–14

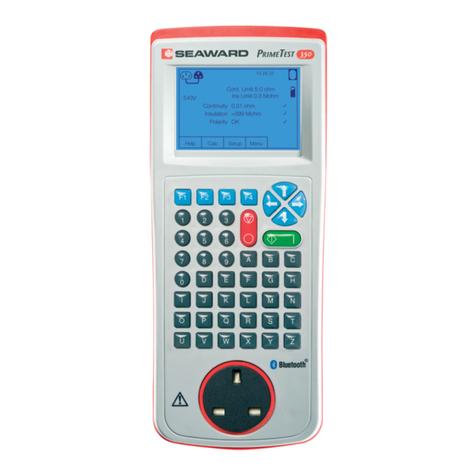

Figure 1–1 – Presentation of the MIR 9000H analyzer 1–2

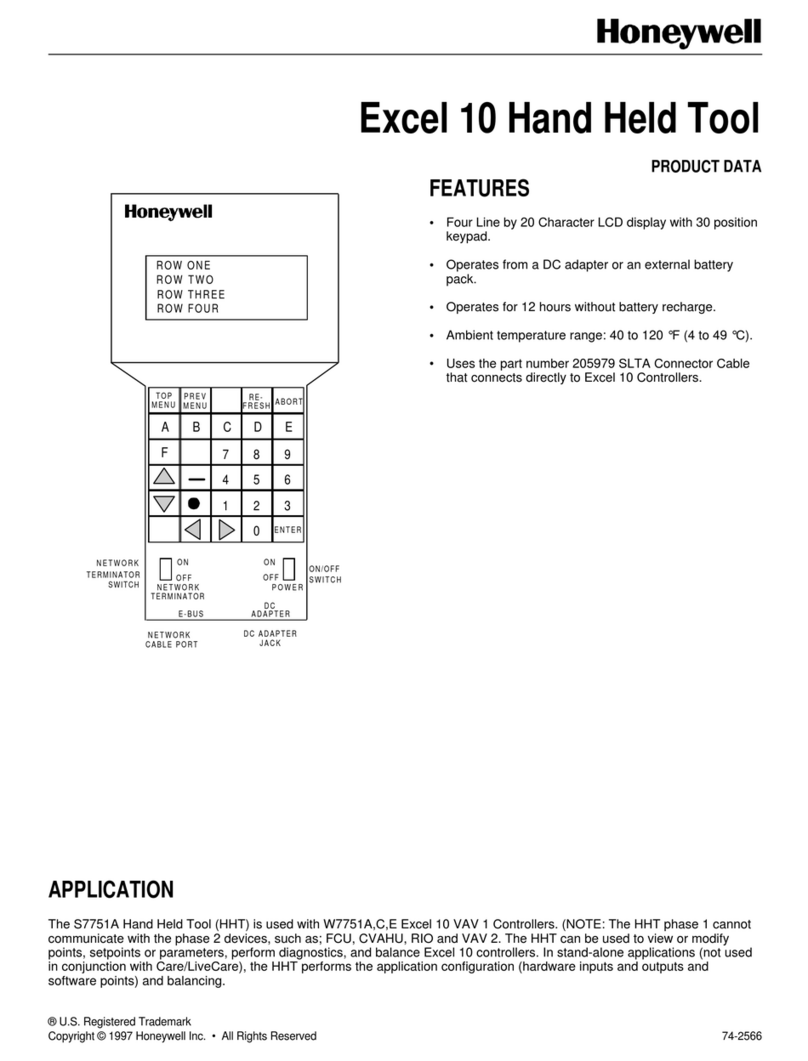

Figure 1–2 – Display and keyboard 1–4

Figure 1–3 – Lower panel of the MIR 9000H 1–5

Figure 1–4 – Components location of the MIR 9000H – covers ON 1–7

Figure 1–5 – Detailed view of the stepping motor and IR detector assembly 1–8

Figure 1–6 – Detailed view of the thermo controlled enclosure 1–8

Figure 1–7 – Links between units 1–13

Figure 1–8 – Dimensions of the MIR 9000H 1–15

Environnement S.A MIR 9000H Duplication prohibited

1–2

APRIL 2011

1. GENERAL CHARACTERISTICS

Figure 1–1 – Presentation of the MIR 9000H analyzer

Duplication prohibited MIR 9000H Environnement S.A

1–3

APRIL 2011

1.1 GENERAL

1.1.1 PRESENTATION

The MIR 9000H analyzer enables continuous measurement on a gaseous sample of 1 to 5 gases by

infrared spectroscopy with correlation, using a gaseous filter.

The principle on which this method is based is completely physical and enables specific measurement

of each gas.

The gas concentration is measured on a clean and non-explosive gaseous sample.

The MIR 9000H has many advantages due to recent optical and electronical techniques and requires

simplified maintenance only.

Measurements are given by:

a LCD display located on the front panel.

8 analog outputs (standard equipment).

3 digital outputs (standard equipment): RS422 – RS232, RJ45 for network link, USB for stored

data.

When the analyzer is connected to a sampling box, as LCPD or HOFI, it can be used for various

applications, and in particular for:

The monitoring of combustion.

The monitoring of combustion installation discharges.

The monitoring of the discharges of household refuse incineration installations.

The monitoring of the discharges of industrial waste incineration installations

Process monitoring

Gas analysis in the chemical industry, oil industry, etc.

Most of these analyses require preparation of samples. Such a preparation has to be studied carefully.

1.1.2 DESCRIPTION

There are two different versions of the analyzer:

Fixed IP64 tight box (Figure 1–1).

19-inch 4-unit rack.

Environnement S.A MIR 9000H Duplication prohibited

1–4

APRIL 2011

1.1.2.1 Front panel

On all versions, the front panel of the MIR 9000H is fitted with:

A backlit liquid crystal display (Figure 1–2)

16 lines, 40 columns (240 * 128 pixels),

It provides the measurement values according to the selected unit and the information required for

the programming and the checking of the analyzer.

Figure 1–2 – Display and keyboard

The keyboard with 6 sensitive keys

The control and check functions of the unit are controlled through the keyboard.

The function of each key varies with the screens or menus.

Duplication prohibited MIR 9000H Environnement S.A

1–5

APRIL 2011

(1) sample outlet (vent), (2) heated line connection of sample inlet, (3) ejector air supply, (4) span/zero

inlet, (5) manual switch valve of sample / zero-span inlet, (6) connection terminal block of inputs /

outputs (analog inputs/outputs, remote control input, remote signalling), (7) TCP/IP network

connection, (8) electric connection of the heated line, (9) cable of electric power supply, (10)

connection of the zero / span solenoid valves.

Figure 1–3 – Lower panel of the MIR 9000H

Environnement S.A MIR 9000H Duplication prohibited

1–6

APRIL 2011

1.1.2.2 Electrical and pneumatic connections

Figure 1–3

The gas inlets/outlets

–The "SAMPLE OUTLET" for connection to an open air venting system, if necessary, is made up

with a 6/8 mm stainless steel connection (1).

–The "SAMPLE" inlet is made up with a 4/6 mm stainless steel connection (2), it is designed to be

connected to the sample heated line,

–The air inlet for the ejector is to be connected to a dry and oil-free air instrument; it is made up with

a 4/6 mm stainless steel connection (3).

–The "SPAN" inlet, for connection to a gas cylinder is made up with a 4/6 mm stainless steel con-

nection (4).

Electrical connections and equipment

–An electric terminal block (6) for the connection of analog inputs / outputs, remote control inputs,

remote signalling,

–A TCP/IP network connection (7),

–A socket for the connection of the sample heated line (8).

When the heated line length is below 25 m, its electrical connection can be

performed directly on the analyzer.

When the heated line length is within 25 and 60m, it electrical connection can be

performed from an interconnection box assembled at MIR 9000H analyzer outlet and

powered to 115/230V mains.

Duplication prohibited MIR 9000H Environnement S.A

1–7

APRIL 2011

(1) stepping motor and IR detector assembly, (10) thermo controlled enclosure dedicated to

measurement, (20) automaton Module board, (21) inputs/outputs Interface board (piloting board), (22)

stepping motor control board, (23) location of ARM7 calculator board, (24) location of RS4i board, (25)

power static relays of the heated line, (26) counter of operating time, (27) connector block of chamber

and manifold heating, (28) TCP/IP connector.

Figure 1–4 – Components location of the MIR 9000H – covers ON

Environnement S.A MIR 9000H Duplication prohibited

1–8

APRIL 2011

(1) stepping motor and IR detector assembly, (2) filter wheel enclosure, (3) stepping motor, (4) IR

detector, (5) IR source, (6) cell wheel enclosure, (7) stepping motor of the cell wheel, (8) chopper, (9)

motor of chopper, (a) belt of the motor.

Figure 1–5 – Detailed view of the stepping motor and IR detector assembly

(10) thermo controlled enclosure, (11) thermal safety, (12) measurement chamber, (13) flow meter,

(14) stainless steel filter, (15) pressure sensors, (16) 3-way valve for span / sample, (17) ejector, (18)

Manifold (180°C), (19) span inlet.

Figure 1–6 – Detailed view of the thermo controlled enclosure

Duplication prohibited MIR 9000H Environnement S.A

1–9

APRIL 2011

1.1.2.3 Components location

For the MIR 9000H boxes, the two locks need to be unlocked (RITTAL™ key no. 3524) and the door

needs to be opened to get access to the internal components.

Physical and mechanical elements:

The stepping motor and IR detector assembly (1) includes :

The filter wheel enclosure (2),

The stepping motor (3),

The IR detector (4),

The IR source (5),

The cell wheel enclosure (6),

The stepping motor of the cell wheel (7),

The chopper (8),

The motor of the chopper (9), and its belt (a).

The thermo controlled enclosure (10) includes :

The thermal safety, (11),

The measurement chamber heated to 180°C (12),

The flow meter (differential pressure measurement) (13),

The stainless steel filter (14),

The pressure sensors (15),

The 3-way valve for span / sample (16),

The ejector (17).

The manifold heated to 180°C (18),

The sample inlet (9).

Electric and electronic elements:

The 24V power supply is located behind the Module board,

The automaton Module board (20),

The Inputs/outputs Interface board (21).

The assembly of the stepping motor control board (22),

The Arm7 board (23) and the RS4i board (24) mounted at the connector level,

The power static relays of the heated line (25),

The counter of operating time (26),

The motor connection block (27),

The TCP/IP connector (28),

Environnement S.A MIR 9000H Duplication prohibited

1–10

APRIL 2011

1.1.3 VARIOUS OPERATION MODES

1.1.3.1 Standard

Expression of measurement values in ppm, mg/Nm3or as %.

Reference zero, zero and automatic calibration sequence are programmable.

Integration time is automatic or programmable.

Automatic checking of multiplexed parameters and correct operation tests.

Analog output of measured concentrations.

Remote signalling of "zero", "calibration" and "alarm" functions.

Duplication prohibited MIR 9000H Environnement S.A

1–11

APRIL 2011

1.1.4 RELATED EQUIPMENT

For some applications, the MIR 9000H is integrated in a "ready-for-use" system that consists of:

a LCPD or HOFI sampling box,

an air-conditioned analysis cabinet that consists of:

A unit for conditioning and distributing compressed air (M.D.S.).

An electrical distribution unit.

An air conditioner (as an option for air-conditioned cabinet).

The MIR 9000H can also be fitted to the following equipment:

a multiparameter acquisition system,

a PC compatible microcomputer equipped with data acquisition software, and a printer,

Environnement S.A MIR 9000H Duplication prohibited

1–12

APRIL 2011

1.2 CHARACTERISTICS

1.2.1 TECHNICAL CHARACTERISTICS

Unit (programmable) : ppm, mg/Nm3or %

Gases analyzed : NH3, and H2O (*)

Analog inputs : 8 (programmable)

Detectable minimum : 2% full scale

Repeatability : 2 % full scale on calibration bench

Zero drift : 2 % full scale in 30 days

Span drift : 2 % full scale in 30 days

Linearity : +1 % full scale

Integration time : Automatic

Analog outputs (1 per gas analyzed) : 4-20 mA

Output scales : Programmable

Sample flow : 0,83 to 1,66 l / min. approximately

Sample temperature : 180°C at the inlet of the analyzer

Maximum H2O concentration : 30 %

Display : LCD 240 x 128 in and text and graphic mode

Control keyboard : 6 keys

Microprocessor : ARM7 32 bits

Power supply : 230V ; 50Hz (100V; 50-60Hz on request) + ground

Consumption : 200 VA

Working temperature (Rack version) : +10°C to + 35°C

Working temperature(Tight box version) : -10°C to + 35°C

Alarm checking : Permanent

Detection and indication of operation

malfunctions: temperature, electrical

parameters, etc.

Overshooting of measurement threshold

(programmable thresholds)

Tests and diagnostics for maintenance : Selection on the keyboard and display of all pa-

rameters

NOTE : These characteristics correspond to a standard analyzer. They can vary depending on the

application to which the analyzer is related.

(*) a widest range of gases analyzed will be provided in a near future.

Table of contents

Other Environnement Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Mindray

Mindray BeneVision TMS60 Service manual

LINSHANG

LINSHANG LS136 user manual

Hanna Instruments

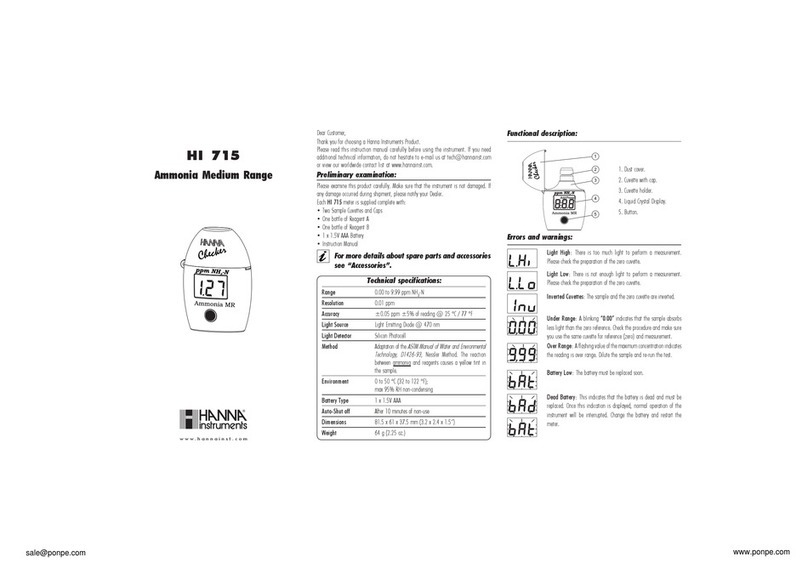

Hanna Instruments Ammonia Medium Range manual

Digi-Pas

Digi-Pas DWL-1300XY user manual

Endress+Hauser

Endress+Hauser Deltapilot S FMB70 Functional safety manual

JDS Uniphase

JDS Uniphase Wavetek DSAM Series quick start guide