enz SG 41 User manual

SG 41

SG 42

SG 43

SG 44

SG 45

Operating Manual

English

March 20

| Version 1.0

Spray guns

Preface

Operating Manual

Page 2 of 36

©2020 enz® technik ag 30.03.2020Version 1.0

Ta le of Contents

Preface .............................................................................................. 4

Purpose of the document ................................................................... 4

Safety ...................................................................................... 5

Noncompliance with the safety information and its conse uences .... 5

Target group ......................................................................................... 5

User re uirements ................................................................................ 5

Explanation of general safety instructions ........................................... 6

Information provided in these operating instructions ......................... 6

Intended use ......................................................................................... 7

Safety warnings for modifications ........................................................ 8

Protective e uipment ........................................................................... 8

General safety instructions ................................................................. 10

Legal ........................................................................................... 12

Copyright ................................................................................................. 12

Exclusion of liability ................................................................................. 12

Warranty conditions ................................................................................ 12

Environment ............................................................................... 13

Disposal .................................................................................................... 13

Environmental protection ....................................................................... 13

Spray guns .................................................................................. 14

Introduction ............................................................................................. 14

Application ............................................................................................... 14

Transport and storage ............................................................................. 15

Technical data .......................................................................................... 15

Scope of supply ........................................................................................ 16

Flow table ................................................................................................ 17

Reaction forces ........................................................................................ 18

Operating Manual

Preface

30.03.2020 Version 1.0 ©2020 enz® technik ag

Page 3 of 36

Tor ues .................................................................................................... 20

Installation .................................................................................. 23

Assembly .................................................................................................. 23

Setting up the work area ......................................................................... 23

Operation ................................................................................... 24

Operating the spray guns ........................................................................ 24

Replacing nozzle inserts ........................................................................... 27

Maintenance ............................................................................... 28

Inspections ............................................................................................... 28

Replacing the repair set ........................................................................... 29

Cleaning ................................................................................................... 31

Accessories/spare parts ............................................................... 32

Shoulder support ..................................................................................... 32

Swivel joints ............................................................................................. 32

Repair sets ............................................................................................... 32

Lance heads ............................................................................................. 32

Gun nozzles .............................................................................................. 33

Index .......................................................................................... 34

Notes .......................................................................................... 35

Version

Revision

Date

Initials

1.0

Created

March 20

fkr

Preface

Operating Manual

Page 4 of 36

©2020 enz® technik ag 30.03.2020Version 1.0

Preface

Dear Valued Customer,

Thank you for the confidence and trust you've placed in us by purchasing our products.

We always appreciate any ideas for improvement and constructive suggestions. Your

feedback will help us improve the design of our product and the associated documen-

tation.

If you have any uestions or suggestions, please contact our Customer Service Depart-

ment:

enz® technik ag Phone +41 41 676 77 66

Schwerzbachstrasse 10 Fax +41 41 676 77 67

www.enz.co

Person responsible for documentation:

Fabian Krasni i (Tech Support / QM Manager)

We reserve the right to modify and further enhance our products without prior notice

as a result of technological advances. Misprints reserved.

Purpose of the document

The purpose of this manual is to instruct you on how to use our product correctly,

effectively, safely, and for its intended purpose. The user will be informed about risks,

reasonably foreseeable misuse, and residual risks.

Important!

Before using your product for the first time, read this original operating

manual, follow it, and save it for later use.

Please read this operating manual thoroughly before using the cleaning tool. Make

sure that all people who work with the product know how to use it correctly.

The operating manual must be available to all operating personnel at all times. It must

be kept in an easily accessible place.

If the manual is misplaced or destroyed, a new copy can be re uested from your near-

est dealer or from the manufacturer directly.

Operating Manual

Safety

30.03.2020 Version 1.0 ©2020 enz® technik ag

Page 5 of 36

Safety

Noncompliance with the safety instructions and its

consequences

Disregarding these safety instructions may lead to accidents and severe personal

injuries, material damage, and damage to the environment.

The manufacturer cannot be held responsible for any damage resulting from noncom-

pliance with these instructions.

Target group

This manual is intended for all persons who will be involved in the assembly, start-up

and operation of high-pressure spray guns.

User requirements

All persons involved with assembly, start-up, and operation of high-pressure spray

guns must

• Be familiar with the field of cleaning work and possess the appropriate technical

knowledge.

• Be trained and instructed appropriately in the use of the product.

• Have read and understood the operating manual, in particular the section on

Safety.

If your personnel do not possess the necessary knowledge, they must be trained and

instructed on it. If necessary, the cleaning tool supplier can provide this instruction and

training.

Only the maintenance and service activities described in this manual may be

performed by users who have met the above-listed re uirements. Any additional

maintenance and service work may be performed only by ualified specialist person-

nel from the manufacturer.

Please refer to the section on MAINTENANCE.

Safety

Operating Manual

Page 6 of 36

©2020 enz® technik ag 30.03.2020Version 1.0

Explanation of general safety instructions

The general safety instructions in this chapter provide information on the potential

residual risks that are inherent in the product or may occur unexpectedly, despite its

proper use.

In order to prevent personal injuries, material damage, and damage to the environ-

ment, all personnel working with this product must comply with these safety instruc-

tions. It is mandatory for said personnel to read and to understand the information

provided in this section.

Information provided in this operating manual

DANGER

Noncompliance may lead to severe injury or even loss of life.

WARNING

Noncompliance may lead to serious injury or even loss of life and/or

cause a long-term disability.

CAUTION!

Noncompliance may lead to injuries and considerable material

damage, financial losses or contamination of the environment.

Information on the technically correct and efficient use of the product.

Operating Manual

Safety

30.03.2020 Version 1.0 ©2020 enz® technik ag

Page 7 of 36

Intended use

Due to the high pressures and temperatures, there is a danger of material damage and

a risk of injury for users and other persons. The following points must be observed to

ensure proper use of the product:

The spray gun may not be operated with abrasive material.

Do not use the device if people who are not wearing protective clothing are

in the area.

The reaction force may not exceed 150 N. With body support, a reaction force

higher than 250 N is not allowed.

The product may be operated only with correct and faultless hose connec-

tions.

The maximum pressure indicated on the nozzle may not be exceeded.

Wastewater may not be drained into bodies of water (creeks, rivers, etc.).

The product must be inspected to ensure it is in proper working order before

every start-up.

Defects must be rectified before start-up.

Use the tool only as intended. (Use only the correct wrench on nuts).

Secure the hose lines in such a way that they cannot become damaged during

operation.

Only the accessories provided and approved by enz® technik ag may be used.

In addition, read the operating manual for the pressure generator to ensure that it is

being used as intended.

Safety

Operating Manual

Page 8 of 36

©2020 enz® technik ag 30.03.2020Version 1.0

Safety warnings for modifications

The spray guns may be used only if they are in technically perfect condition, their con-

struction has not been changed, and following the instructions in this user manual in

terms of intended use, awareness of safety, and awareness of risk. Only adults who

have been instructed on how to operate high-pressure cleaners may use the guns.

The manufacturer is not liable for damage resulting from unauthorized changes to the

product.

Protective equipment

The employer must provide suitable personal protective e uipment. He or she must

ensure that it is worn by the employees during work.

In the following section, the protective e uipment prescribed by Schweizerische Un-

fallversicherung SUVA (the Swiss Accident Insurance Organization) will be described.

For more information on this, refer to the brochure:

Safe entry and working in manholes, excavation pits, and channels

Order number: 4406 .d Suva

Schweizerische Unfallversicherungsanstalt

Arbeitssicherheit

Postfach, 6002 Lucerne, Switzerland

For information

Phone +41 41 419 51 11

For orders

www.suva.ch/waswo

Fax +41 41 419 59 17

Phone +41 41 419 58 51

Respirators

Self-contained respiratory e uipment for spending time in dangerous

atmospheres and for use during rescue operations.

Respirators

Self-rescue respiratory e uipment (devices with compressed air tanks

or regeneration devices) for working in channels and for first aid for

injured persons.

Rescue harness

Rescue harness or protective clothing with a loop sewn into the neck.

During rescue, the rescue rope will be attached to the neck loop.

Injured persons will be lifted out using a rescue lifting device with a

self-actuating load brake.

Operating Manual

Safety

30.03.2020 Version 1.0 ©2020 enz® technik ag

Page 9 of 36

Suita le working clothing

Leak-proof working clothing protects the skin from becoming soiled

and from possible infections. Visually conspicuous working clothing

makes the employee more visible to traffic.

Appropriate footwear

Safety footwear should, in particular, have good grip and be slip-

resistant and leak-proof (e.g. rubber boots).

Gloves

Appropriate gloves will protect you from hand injuries and contact

with materials that could impair your health and from untreated

water.

Hardhat

The hardhat will protect your head from falling objects and from

bumping into fixed components and objects.

Hearing protection

If there is noise that could damage your hearing, you can wear, e.g.

earmuffs with built-in headphones and microphone.

Eye protection

Your eyes should be protected against slivers, sprayed dangerous

substances, etc.

Lighting independent of the power grid

For example, you should carry a waterproof flashlight or wear a flash-

light attached to your hardhat.

Safety

Operating Manual

Page 10 of 36

©2020 enz® technik ag 30.03.2020Version 1.0

General safety instructions

Danger! | High-pressure water jets

Defects in or improper use of the product could cause hazards due to

pressurized water spray. Ensure that the product is in perfect condi-

tion before operation. Highly concentrated water jets could cause

severe injury and could even sever limbs. Noncompliance with these

safety instructions can be fatal or could lead to severe injury.

Warning! | Falling o jects

Dust particles and other loose particles are removed from the surface

to be cleaned during high-pressure cleaning. These particles are

accelerated to high speeds by the energy of the water jet, and can

cause property damage and injuries. When conditions are unfavora-

ble, for example, when working above your head, use protective

e uipment appropriate for this task. Noncompliance with these

safety instructions can be fatal or could lead to severe injury.

Warning! | Risk of falling

You will be affected by a reaction force due to the high-pressure jet

discharged. If you are working on scaffolding, protect yourself from

falling. Falling from height can be fatal or could lead to severe injury.

Caution! | Sharp o jects

If the product is tampered with, there is a risk of hand injuries due to

sharp edges. Wear gloves during work. Pay attention to where you

grip the product. If you do not do so, this could result in cutting

injuries to your hands or other parts of your body.

Caution! | Trip hazard

Lines and other objects are to be expected on the ground in the area

around where the product is being used. Pay attention to where you

are walking. Keep the area of use tidy. Tripping and falling could cause

injuries.

CAUTION!

Wear hearing protection. The water jet hitting the material will cause

additional noise. Being exposed to noise can lead to hearing loss,

tinnitus, or physiological disorders.

Operating Manual

Safety

30.03.2020 Version 1.0 ©2020 enz® technik ag

Page 11 of 36

CAUTION!

The machines may not be used by children. Children must be watched

to ensure that they do not play with the device.

CAUTION!

This machine may not be used by persons (including children) with

impaired physical, sensory, or mental abilities or a lack of experience

and knowledge.

CAUTION!

High-pressure hoses, valves, and couplings are important for machine

safety. Only use high-pressure hoses, valves, and couplings that are

recommended by the manufacturer.

CAUTION!

Water that has flowed through the backflow preventer is not drinka-

ble.

Figure 1: Warning SN EN 60335-2-79

Legal

Operating Manual

Page 12 of 36

©2020 enz® technik ag 30.03.2020Version 1.0

Legal

Copyright

This manual shall not be duplicated partially or in its entirety without the prior written

permission of enz

®

technik ag. It shall not be photocopied, reproduced, translated, or

converted into an electronic or machine-readable format.

©2020 enz® technik ag, 6074 Giswil, Switzerland.

All rights reserved

Exclusion of lia ility

The manufacturer is not liable for damage that:

Is caused as a result of unauthorized changes to the product.

Is caused by not following the safety instructions.

Warranty conditions

In accordance with our sales and delivery conditions, we offer a warranty. However,

the warranty is voided if:

The product is used under conditions that are not permitted by us.

Replacement and accessory parts that are not original replacement or accessory

parts from enz® technik ag are used.

If there is damage due to:

o Improper use

o Not following the operating instructions

o Unsuitable operating e uipment

o Incorrect or improper routing of the hose or pipelines

o Unauthorized changes or modifications to or conversions of the product

Operating Manual

Environment

30.03.2020 Version 1.0 ©2020 enz® technik ag

Page 13 of 36

Environment

Disposal

Legacy e uipment contains valuable recyclable materials that should be sent to a

recycling center. Therefore, please dispose of legacy e uipment at suitable collection

points.

Environmental protection

Please note that surfaces are to be cleaned only if the composition is known. Under no

circumstances may chemicals or other toxic substances be allowed to enter the envi-

ronment. Do not use excessive amounts of water. This will help preserve our natural

resources.

Spray guns

Operating Manual

Page 14 of 36

©2020 enz® technik ag 30.03.2020Version 1.0

Spray guns

Introduction

enz® spray guns are universally usable surface cleaning devices. They can be config-

ured individually to ensure the most efficient use possible. The spray guns are designed

for temperatures of up to 150 °C.

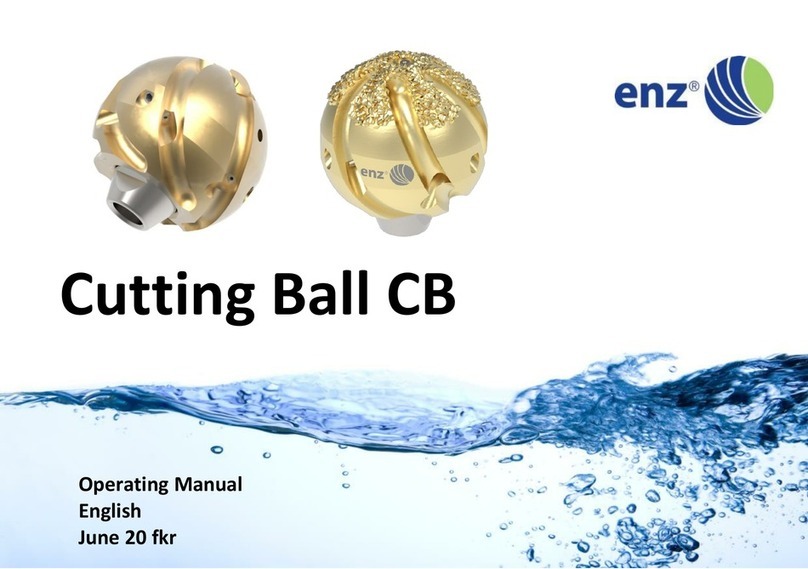

Figure 2: Overview of the spray guns

Application

The application is professional high-pressure cleaning (hot and cold water). The guns

are intended only for applying li uids. This could be water or commercially available

cleaning or disinfecting agents (li uids of Group II in accordance with 97/23/EC). The

application areas include:

Cleaning manholes

General surface cleaning work

General high-pressure cleaning work

Art. no.: 18.41

Name: SG

-

41

Art. no.: 18.42

Name: SG-42

Art. no.: 18.43

Name: SG-43

Art. no.: 18.44

Name: SG-44

Art. no.: 18.45

Name: SG-45

Operating Manual

Spray guns

30.03.2020 Version 1.0 ©2020 enz® technik ag

Page 15 of 36

Transport and storage

Ensure that the spray gun is protected from soiling during transport and storage. Pro-

tect the spray gun from frost. If exposed to frost, the spray gun can become seriously

damaged, to the extent that flawless operation cannot be guaranteed.

Technical data

Article num er

Total length [mm]

Weight [kg]

Connecting thread

[

″]

Swivel joint

integrated

Temperature [°C]

Water jet

Jet nozzles

Recycled water

Max. flow rate

[l/min]

Max. working

pressure [ ar]

18.41 950 1.2 1/2 Yes 5-150 Round or flat 1 No 45 300

18.42 1180 1.8 3/8 Yes 5-150 Round and flat 2 No 36 300

18.43 1100 2.1 1/2 Yes 5-150

Round or flat 1 Yes 200

350

18.44 1070 1.9 3/8 Yes 5-150 Round or flat 1 No 30 200

18.45 780 2.3 1/2 No 5-90 Round 1 Yes 45

250

Table 1: Technical data

Article num er

Total length [yd]

Weight [kg]

Connecting thread

[

″]

Swivel joint

integrated

Temperature [°C]

Water jet

Jet nozzles

Recycled water

Max. flow [US

gpm]

Max. working

pressure [psi]

18.41 1.04 1.2 1/2 Yes 5-150 Round or flat 1 No 12 4,350

18.42 1.29 1.8 3/8 Yes 5-150 Round and flat 2 No 10 4,350

18.43 1.20 2.1 1/2 Yes 5-150

Round or flat 1 Yes 53

5,000

18.44 1.17 1.9 3/8 Yes 5-150 Round or flat 1 No 8 2,900

18.45 0.85 2.3 1/2 No 5-90 Round 1 Yes 12

3,600

Table 2: Technical data for the US

Spray guns

Operating Manual

Page 16 of 36

©2020 enz® technik ag 30.03.2020Version 1.0

Scope of supply

Art. no. Standard equipment Included

18.41 Ø 2.7 mm round jet

18.42 Ø 1.7 mm flat jet

Ø 1.7 mm round jet Ø 2.7 mm round jet

18.43 Ø 3.2 mm round jet Ø 4.0 mm round jet

18.44 Ø 1.3 mm round jet Ø 2.1 mm round jet

18.45 Ø 3.0 mm round jet

Table 3: Scope of supply

Operating Manual

Spray guns

30.03.2020 Version 1.0 ©2020 enz® technik ag

Page 17 of 36

Flow ta le

Pres-

sure

ar 20 40 60 80 100 120 140 160 180

psi 290 580 870 1,160 1,450 1,740 2,030 2,320 2,610

Ø [mm] Flow l/min and US gpm

1.7 8.0 11.4 13.9 16.1 18.0 19.7 21.3 22.7 24.1

2.1 3.0 3.7 4.2 4.7 5.2 5.6 6.0 6.4

2.0 11.4 16.1 19.7 22.8 25.5 27.9 30.1 32.2 34.2

3.0 4.3 5.2 6.0 6.7 7.4 8.0 8.5 9.0

2.1 12.9 18.3 22.4 25.8 28.9 31.7 34.2 36.6 38.8

3.4 4.8 5.9 6.8 7.6 8.4 9.0 9.7 10.2

2.7 20.2 28.5 34.9 40.3 45.1 49.4 53.3 57.0 60.5

5.3 7.5 9.2 10.6 11.9 13.0 14.1 15.1 16.0

2.8 22.3 31.6 38.7 44.7 49.9 54.7 59.1 63.2 67.0

5.9 8.3 10.2 11.8 13.2 14.5 15.6 16.7 17.7

3.0 25.6 36.3 44.4 51.3 57.3 62.8 67.8 72.5 76.9

6.8 9.6 11.7 13.5 15.1 16.6 17.9 19.2 20.3

3.2 29.2 41.3 50.5 58.3 65.2 71.4 77.2 82.5 87.5

7.9 11.2 13.8 15.9 17.8 19.5 21.0 22.5 23.8

4.0 45.6 64.5 78.9 91.2 101.9 111.6 120.6 128.9 136.7

12.0 17.0 20.9 24.1 26.9 29.5 31.9 34.1 36.1

Pres-

sure

ar 200 220 240 260 280 300 320 340 360

psi 2,900 3,190 3,480 3,770 4,060 4,350 4,640 4,930 5,220

Ø [mm] Flow l/min and US gpm

1.7 25.4 26.7 27.9 29.0 30.1 31.1 32.2 33.1 34.1

6.7 7.0 7.4 7.7 7.9 8.2 8.5 8.8 9.0

2.0 36.0 37.8 39.5 41.1 42.6 44.1 45.6 47.0 48.3

9.5 10.0 10.4 10.9 11.3 11.7 12.0 12.4 12.8

2.1 40.9 42.9 44.8 46.6 48.4 50.1 51.7 53.3 54.8

10.8 11.3 11.8 12.3 12.8 13.2 13.7 14.1 14.5

2.7 63.7 66.8 69.8 72.7 75.4 78.1 80.6 83.1 85.5

16.8 17.7 18.4 19.2 19.9 20.6 21.3 22.0 22.6

2.8 70.6 74.1 77.4 80.5 83.6 86.5 89.3 92.1 94.7

18.7 19.6 20.4 21.3 22.1 22.8 23.6 24.3 25.0

3.0 81.1 85.0 88.8 92.4 95.9 99.3 102.5 105.7 108.8

21.4 22.5 23.5 24.4 25.3 26.2 27.1 27.9 28.7

3.2 92.2 96.7 101.0 105.2 109.1 113.0 116.7 120.3 123.8

25.1 26.4 27.5 28.7 29.7 30.8 31.8 32.8 33.7

4.0 144.1 151.2 157.9 164.3 170.5 176.5 182.3 187.9 193.4

38.1 39.9 41.7 43.4 45.1 46.6 48.2 49.6 51.1

Table 4: Flow table

Spray guns

Operating Manual

Page 18 of 36

©2020 enz® technik ag 30.03.2020Version 1.0

Reaction forces

The water jet discharging at high pressure causes a reaction force. This can be so large

that the spray gun can no longer be held securely. EU directives re uire the use

of shoulder supports as mandatory when working with a reaction force of more

than 150 N. If the reaction force is over 250 N, then hand-operated use is no longer

permitted.

Figure 3 below shows two examples.

Figure 3: Reaction force with straight spray guns

Example 1: With a nozzle insert with Ø 1.2 mm and 200 bar working pressure, the re-

action force is less than 150 N. Here, you do not need to take any additional measures.

Example 2: With a nozzle insert with Ø 3.0 mm and 140 bar working pressure, the re-

action force is greater than 150 N. The spray gun must additionally be fitted with a

shoulder support.

Determine the working pressure in [psi] based on the flow table on

Page 17.

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

2.2

2.4

2.6

2.8

3

3.2

3.4

3.6

3.8

4

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360

ø Nozzle insert [mm]

Working pressure at the spray gun [ ar]

Reaction force [N]

Example 2

Example 1

With support

Without

support

Only with

mechanical

support

Operating Manual

Spray guns

30.03.2020 Version 1.0 ©2020 enz® technik ag

Page 19 of 36

Reaction force for spray guns SG-41, SG-43, and SG-45

Figure 4: SG-41

Figure 5: SG-43

Figure 6: SG-45

Figure 7: Reaction force with straight spray guns

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

2.2

2.4

2.6

2.8

3

3.2

3.4

3.6

3.8

4

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360

ø Nozzle insert [mm]

Working pressure at the spray gun [ ar]

Reaction force [N]

With support

Without

support

Only with

mechanical

support

Spray guns

Operating Manual

Page 20 of 36

©2020 enz® technik ag 30.03.2020Version 1.0

Torques

The SG-42 and SG-44 spray guns have angled lances, which generate a tor ue. In

accordance with DIN EN 60335, a maximum tor ue of 20 Nm is permissible on the

spray gun grip. The user is more limited by this tor ue than by the reaction force.

Therefore, with SG-42 and SG-44 spray guns, you must pay attention to the tor ue

table.

Figure 8: Torque calculation

Calculating the torque on the SG-42 grip

To calculate:

T = tor ue [Nm]

Given:

F = reaction force [N] = 70 N

l = length [m] = 1.05 m

sin α = sin (15°) = 0.259

∗ sin ∗

70 ∗ 0.259 ∗ 1.05

19.02

Table of contents

Other enz Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Dillon Precision Products

Dillon Precision Products Square Deal B Assembly and user instructions

ABB

ABB HT612293 Operation manual

Siemens

Siemens 3RV1948-1K operating instructions

ABB

ABB HT567273 Operation manual

LNS

LNS ALPHA ST212 S2 instruction manual

jost

jost JSK 39 Installation and Operating Instrucitons

WPG

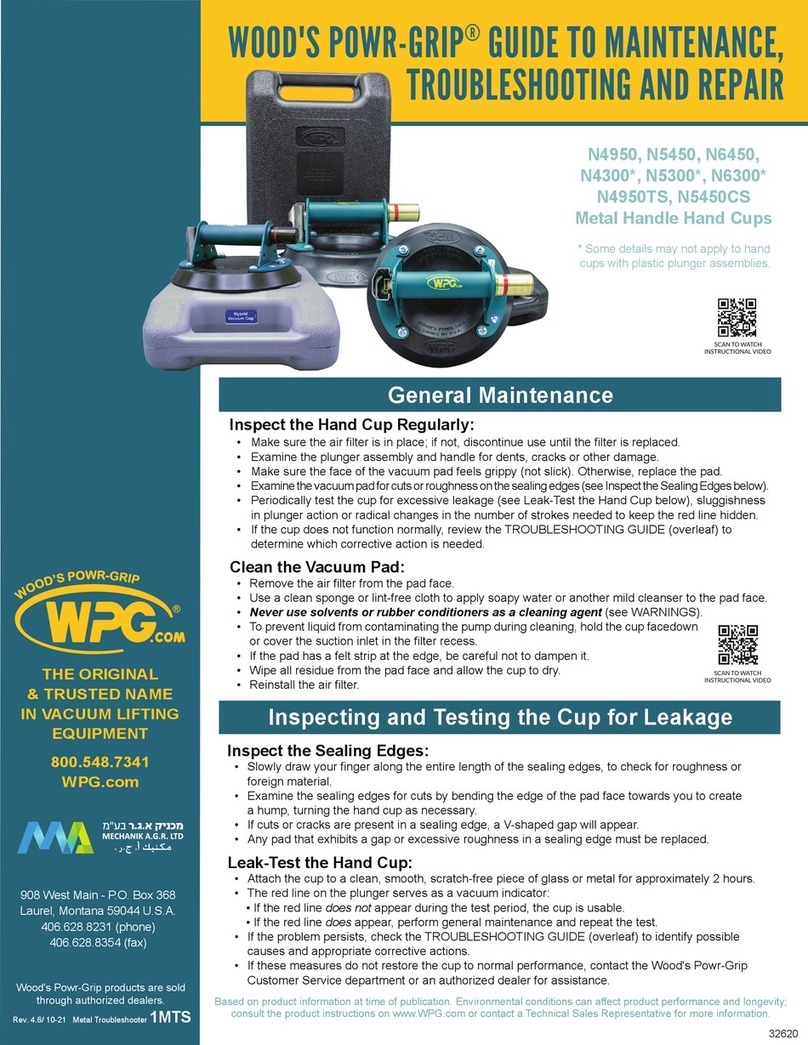

WPG N4300 Series Guide to maintenance, troubleshooting, and repair

Trejon

Trejon OPTIMAL VPX Plough Instruction Manual and Maintenance Directions

ABB

ABB HT609934 Operation manual

Arroyo Instruments

Arroyo Instruments LaserSource 4205 manual

Toray

Toray NHPA Series instruction manual

Milwaukee

Milwaukee MSL2000 Original instructions