Dillon Precision Products Square Deal B User manual

Square Deal “B” Reloading System Assembly

and

User Instructions

Dillon Precision, Inc.

Copyright © 2020 by Dillon Precision, Inc.--All rights reserved. This publication is for personal use only. No part of this publication may be reproduced, distributed, or

transmitted in any form or by any means, including photocopying, recording, or other electronic or mechanical methods, for commercial use without the prior written permission of

Dillon Precision.

Square Deal™ and Dillon Square Deal B Reloading System™ are trademarks of Dillon Precision Inc.

Rev. 0 January 2021

2

TABLE OF CONTENTS

1. THE BASIC RISK OF RELOADING---Page 4

2. MANDATORY SQUARE DEAL “B” USER SAFETY MINIMUM REQUIREMENTS—Page 4

3. SQUARE DEAL LIMITED LIFETIME WARRANTY—Page 5

4. SQUARE DEAL SHIPPING CONTENTS—Page 5-6

5. SQUARE DEAL ASSEMBLY GUIDE—Pages 6-11

6. OPTIONAL EQUIPMENT FOR THE SQUARE DEAL—Page 12

7. THE DILLON SQUARE DEAL RELOADING STATIONS AND CONFIGURATIONS—Pages 13-15

8. SETUP PROCEDURES FOR THE SQUARE DEAL—Pages 16-30

8.1. Description of Square Deal Die Assemblies

8.2. Square Deal Friction Plate

8.3. Station 1--Sizing and Depriming

8.4. Station 2a--Primer Feeding and Seating

8.5. Station 2b—Powder Measure Setup and Case Mouth Belling

8.6. Station 3--Bullet Seating

8.7. Station 4--Bullet Crimping

9. CONVERSION LIST AND REPLACEMENT PROCEDURES—Pages 30-39

9.1. Caliber Conversion List

9.2. Shellplate Caliber and Primer Size Conversion

9.3. Die Caliber Conversion

9.4. Powder Measure Bar Conversion

9.5. Depriming Pin Replacement

9.6. Primer Early Warning Battery Replacement

10. ADJUSTMENT AND REPLACEMENT PROCEDURES—Pagers 40-43

10.1. Shellplate Indexing Adjustment

10.2. Adjusting Primer Feeding/Alignment

11. TROUBLESHOOTING THE SQUARE-DEAL—Pages 44-46

12. CLEANING AND LUBRICATING THE SQUARE DEAL—Pages 47-49

13. SUB-ASSEMBLIES AND PARTS IDENTIFIER—Pages 50-56

13.1. Main Assembly

13.2. Frame and Lower Assembly

13.3. Automatic Primer Assembly

13.4. Primer Early Warning Assembly

13.5. Primer Slide Assemblies

13.6. Primer Early Warning System

13.7. Automatic Powder System

14. RELOADING BASICS--Pages 57-59

15. NOTES--Page 60

3

DILLON PRECISION DISCLAIMER, EXPLANATION OF SAFETY WARNINGS, DILLON CONTACT INFORMATION

DISCLAIMER

The material in this manual is for informational purposes only. The products it describes are subject to change without prior

notice. Dillon Precision Inc. makes no representations or warranties with respect to this manual.

Dillon Precision Inc. shall not be liable for any damages, losses, costs or expenses, direct, indirect or incidental, consequential

or special, arising out of, or related to the use of or the inability to use the products described herein.Read this manual

before using this product. Failure to follow the instructions and safety precautions in this manual can result in serious injury

or death. Keep this manual in a safe location for future reference.

EXPLANATION OF SAFETY WARNINGS

DANGER!

Danger! indicates a hazard with a high level of risk that if not avoided, will result in death or serious injury.

WARNING!

Warning! indicates a hazard with a medium level of risk that if not avoided, could result in death or serious injury.

CAUTION!

Caution! indicates a hazard with a low level of risk that if not avoided, could result in minor or moderate injury.

Dillon Contact Information

Dillon Precision Inc.

8009 E. Dillon’s Way

Scottsdale, AZ 85260

480-948-8009 1-800-223-4570

FAX 480-998-2786

Website: www.dillonprecision.com

E-mail: dillon@dillonprecision.com

Sales, Technical Support and Customer Service

800-223-4570

Document Revisions

Date Version Number Document Changes

1-1-2021 0 Initial Release Updated Manual

4

MANDATORY SAFETY PRECAUTIONS—MUST BE READ

1. The Basic Risk of Reloading, and Overall Square Deal Design Usage Safety:

1. DANGER! The reloading of ammunition and the handling of reloading components used in the reloading process is inherently

dangerous. Accidents and mistakes in loading can and do occur, sometimes with disastrous results resulting in, but not limited

to loss of hearing, vision, limbs or life. These accidents can occur with the novice and experienced reloader.

2. Dillon Precision Inc. has designed the Square Deal “B” with user safety in mind, doing everything Dillon Precision Inc. knows to

make the use of the Square Deal “B” as safe as possible.

2. Mandatory Square Deal User Safety Minimum Requirements:

1. Dillon Precision Inc. cannot guarantee the complete safety of the reloader/user of the Square Deal “B”. To minimize the user’s

risk, use common sense when reloading and follow these basic safety rules at a minimum.

2. KNOWLEDGE: Study and learn the basics, processes and specifications used in the reloading of ammunition from reputable

sources and publications by prominent bullet and powder manufacturers such as Sierra, Hornady, Speer, Western Powders and

Alliant Powders; including reloading manuals such as the Lyman Reloading Manual and the Western Powder Reloading Guide.

3. EYE AND EAR PROTECTION: Never operate the Square Deal without eye and ear protection.

4. PAY ATTENTION: Give your full attention to the reloading process. Do not watch television, the internet or converse with

anyone while loading. It is a full-time operation.

5. INTERRUPTIONS: If you are interrupted in any manner, always inspect the cases at every station and know exactly what has

been done to ensure that proper process steps have or have not been completed.

6. SMOKING/IMPAIRMENT: Do not smoke or allow anyone to smoke in the reloading area. Do not allow open flames. Do not

load if you have been drinking alcohol or are impaired in any way.

7. SAFETY: Do not remove any safety device(s) from the reloader or modify the reloader in any way. Keep components and

ammunition out of the reach of children.

8. LEAD--CAUTION! Almost all bullets have a lead component, which may or may not be exposed. Be sure to have proper

ventilation while handling the lead component (bullet) or when shooting. Lead causes birth defects, reproductive harm and

cancer. Wash your hands thoroughly after handling lead components or shooting.

9. POWDERS--DANGER! There are many kinds of powders (propellants) used in the reloading process and are in general specified

as rifle, pistol or shotgun powders. Powder selection is specific to the bullet caliber, weight and type of bullet being reloaded.

There is no way to overstate the care and selection of a powder to be used in the reloading process. Again, refer to

established bullet and powder manufacturers. Using the wrong powder or amount of powder or mixing powders can result in

serious injury or death. Never mix powders. Always store the powder in its original container. Never have more than one

type of powder in the reloading area at one time—preferably store powders in a separate room. Observe all maximum load

warnings.

10. PRIMERS—DANGER! Primers contain a small amount of a shock-sensitive chemical that explodes when struck by a firing pin

or hammer or accidentally crushed. Never force primers. If they get stuck in the operation of the loader, carefully disassemble

the reloader and gently remove the obstruction. Never attempt to clear primers that are stuck in either the primer pickup tube

or the primer magazine tube. Never, under any circumstance, insert any type of rod into these tubes to attempt to push out

stuck primers—PRIMERS CAN “CHAIN DETONATE.” If a primer(s) gets stuck in the magazine or pickup tubes flood the tube

with penetrating oil/WD-40, throw it away and call Dillon for a free replacement. Never attempt to deprime a cartridge case

with a live primer. Depriming a live primer is one of the most dangerous things you can do in reloading and can cause serious

injury or death. Never attempt to further seat primers on a loaded cartridge. Use only the primer for the specific application

for which you are loading.

11. BLACK POWDER--DANGER! Do not use black powder or black powder substitutes in any Dillon Powder Measure. Doing so can

result in severe injury or death.

12. LOAD AND LOADED LENGTH—WARNING! Use only recommended load specifications from manuals and information supplied

by established, known component manufacturers. Avoid maximum loads listed in loading manuals. Be extremely careful to

avoid a double charge. Dillon has no control over the components and specifications used when reloading with the Dillon

equipment. No responsibility is implied or assumed for results obtained through the use of or inability to use any such

components or reloading specifications.

13. QUALITY CHECKS--At a minimum, perform periodic quality checks every 50-100 reloads-ESPECIALLY the powder charge.

14. PROPERLY LABEL RELOADED AMMUNITION: Label the reloaded cartridge with the overall length, bullet manufacturer, type

and weight-- primer manufacturer and type--powder manufacturer, type and powder charge and date loaded.

15. RELOADING AREA-- The reloading area should be well lit, dry and comfortable without breezes.

16. BE PATIENT and OBSERVANT— Users should have no trouble achieving published loading rates that are conservative. Be

smooth and steady. The reloading process is not a process to hurry--- If something does not LOOK RIGHT, SOUND RIGHT, OR

FEEL RIGHT —STOP, LOOK and THINK! If the problem is not obvious—CALL Dillon Technical Support (800) 223-4570 or visit the

troubleshooting section at www.dillonprecision.com.

5

3. SQUARE DEAL “B” LIMITED LIFETIME WARRANTY

Dillon Precision Inc. warrants the Square Deal “B” for the life of the system against defects in material

and workmanship. Dillon Precision Inc. will either repair or replace any part(s) that prove defective.

Dillon Precision Inc. will provide repaired or replacement parts at Dillon’s choice on an exchange basis.

This limited warranty does not cover any damage to the product that results from improper installation,

accident, abuse, misuse, natural disaster, abnormal mechanical or environmental conditions, or any

unauthorized disassembly, repair or modification. This limited warranty shall not apply if: (i) the product

was not used in accordance with any accompanying instructions, (ii) the product was not used for its

intended function or (iii) the addition of any non-authorized equipment.

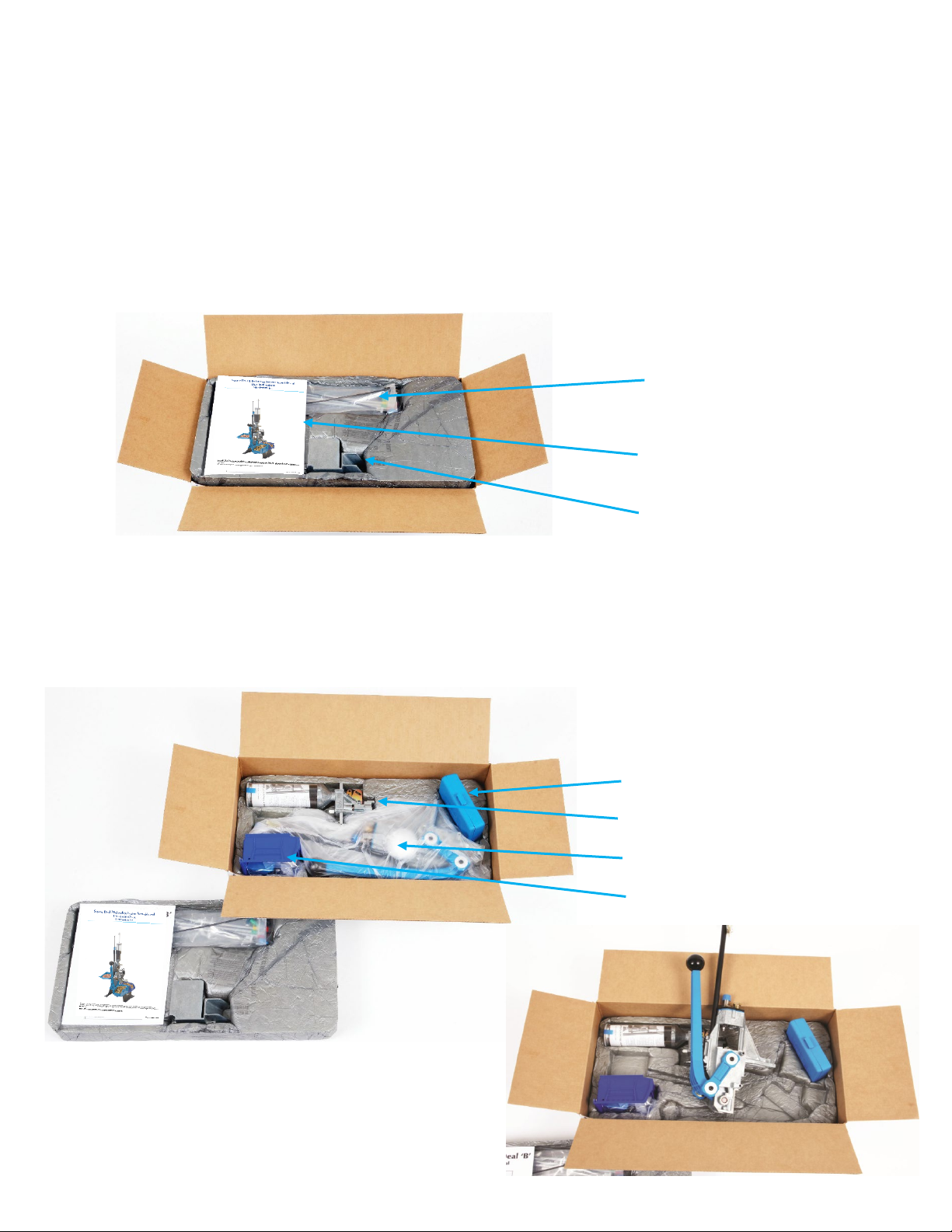

4. SQUARE DEAL “B” SHIPPING CONTENTS

4.1. Remove the following items from the top protective foam layer of the Square Deal “B” shipping

box:

4.2. Remove the following items from the second layer of protective foam

•Primer Early Warning System,

Follower Rod, Battery and

Tube Pack

•Square Deal “B” System

Manual

•Square Deal Chute and Bin

Bracket

•Square Deal “B” Conversion Box

•Dillon Powder Measure

•Square Deal Press

•

Bin and Accessory Bag

6

4.3. Contents of Square Deal “B” Shipment

5. SQUARE DEAL “B” ASSEMBLY GUIDE

5.1 To mount the Square Deal “B”, select a clear area on your reloading bench. Your bench must be strong

enough to support the weight and the force required to operate the Square Deal “B”. If possible, attach

your bench to the wall. Remove the Square Deal “B” Reloader from the packaging and place it on your

selected area. You will need 7/16” wrenches, a drill motor and a 9/32” drill bit and the included Allen

wrenches.

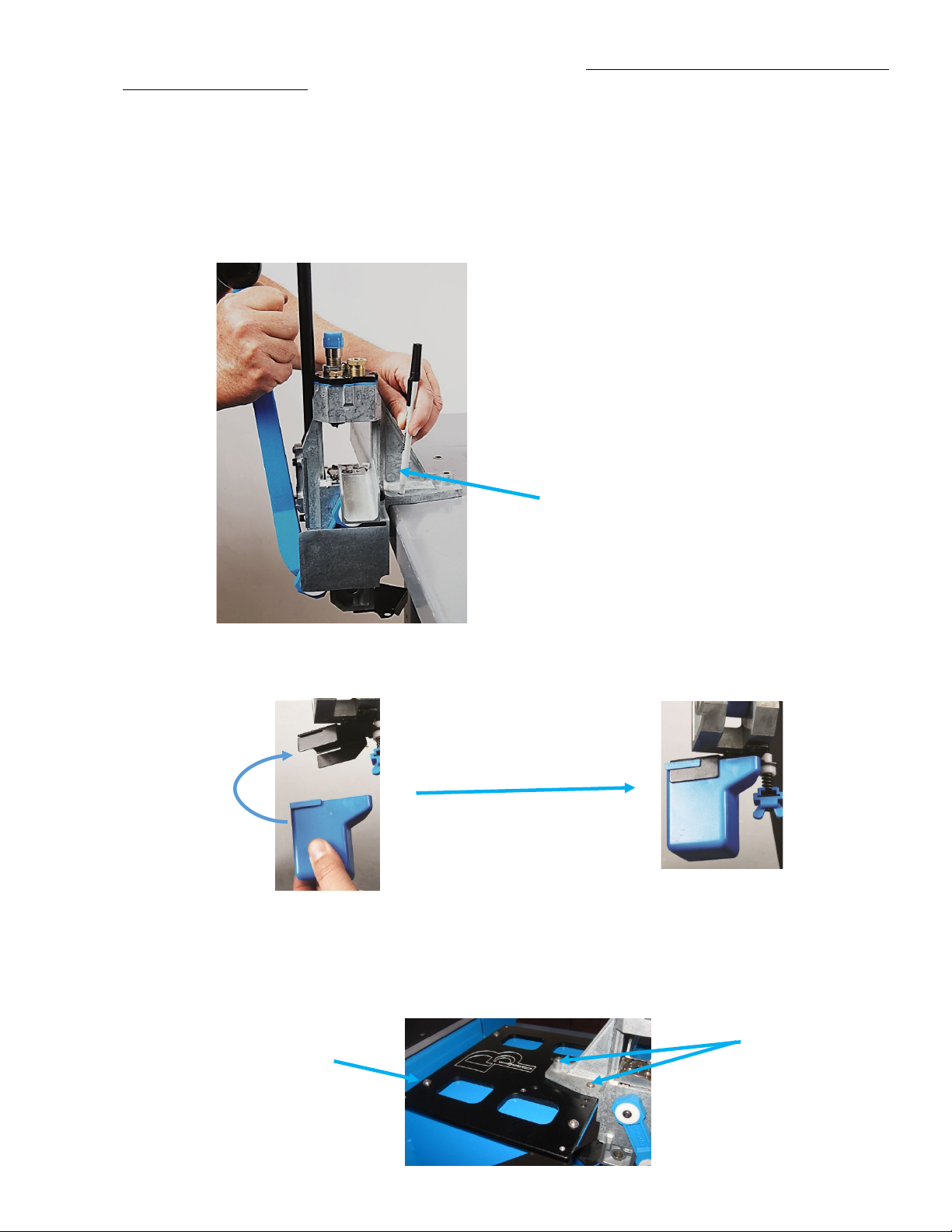

5.2 Locate the provided Ejected Cartridge Chute/Bracket and two ¼-20 x 3/8” Socket Head Mounting Screws

and fasten the Bracket to the side of the Square Deal “B” as shown:

5.3 Locate the provided Spent Primer Bracket and two 8-32 x 3/8” Button Head Mounting Screws and mount

Spent Primer Cup Bracket securely to the bottom of the Square Deal “B” as shown below:

1. Primer Early Warning System and

Primer Follower Rod

2. Caliber Conversion Box—Parts

installed

3. Tube Pack accessory parts bag—

Primer Pickup and Magazine

Tubes, and Spare Tips—Large

Tube Pack PN22016

Small Tube Pack PN22017

4. Powder Measure

5. Completed Cartridge Bin

6. Square Deal “B” with Caliber

Specific Dies Installed

7. Used primer cup and Powder

Measure Return Bracket

8. Ejected Cartridge Chute and

Completed Cartridge Bin Bracket

9. Large Powder Bar (Small Bar

installed in Powder Measure)

10. Included Allen Wrenches

11. Square Deal “B” Instruction

Manual

Mount

Ejected

Cartridge

Chute

Bracket

Mount

Spent

Primer

Cup

Bracket

Spent Primer

Cup Bracket

and Screws

Cartridge

Chute/Bracket

and Mounting

Screws

7

5.4 The Square Deal “B” can be mounted directly to your bench (If you are using the Dillon Strong Mount

proceed to 5.4.4 below). The preferred method of operating the Square Deal “B” is standing up. This

gives you the leverage for the force needed to properly seat primers.

5.4.1 For mounting directly to a bench, bring the Square Deal “B” to the forward edge of your bench as shown

below. The Square Deal “B” requires ¾” clearance under the front edge of the bench. See below.

5.4.2 Mark the three mounting holes using the Square Deal “B” as a template. Remove the machine and drill

three 9/32” holes through the bench. Bolt the Square Deal “B” securely to the bench with ¼” Grade 5

hardware or available Dillon Mounting Hardware Kit P/N14355. Use small diameter washers on the top

and large diameter washers on the bottom, especially if using a wooden bench.

5.4.3 Slide the Spent Primer Cup into the mounting slots on the Bracket.

.

5.4.4 There are three other optional methods for mounting the Square Deal “B” to your bench.

•The first option is to use the available Billet Dillon Mounting Plate PN62005 by fastening the Plate to

your bench and then mounting the Square Deal “B” to the Plate and as shown below:

Mount Square Deal “B” with Base Mounting

Flange tight against the bench making sure there

is clearance below for the Crank, Operating

Handle and the Spent Primer Cup

Slide Cup on

Bracket

Square Deal “B”

mounted directly to

Dillon Mounting Plate

with two ¼”-20 x 3/4”

Screws and one ¼”-20 1

¼ “Screw

Dillon Billet Mounting

Plate fastened to your

bench

8

•The second method is to install the Square Deal “B” on the Dillon optional Strong Mount using The

Dillon Strong Mount Kit PN62395 and then mount the Strong Mount to the bench. Installation

instructions are included with the Strong Mount. The Dillon Strong Mount improves the stability of the

system by distributing the loading forces over a larger area of the bench and provides mounting

locations for an optional Empty Case Bin and the provided Completed Cartridge Bin.

•The Third method is to fasten the Strong Mount with the Square Deal “B” to the optional Dillon Billet

Mounting Plate PN62006 and then fasten the Billet Mounting Plate to the Bench as shown below.

5.4.5 Install the completed Cartridge Bin on the Chute/Bin Bracket of the Strong Mount by sliding the lip on the

bin over the bracket and the lip of the Empty Case Bin over the other bracket as shown below.

5.4.6 Install the optional Dillon Bullet Tray PN22214 on the left side of Strong Mount in the two holes as shown

below with the hardware provided with the Bullet Tray Kit.

Dillon Billet Mounting

Plate fastened to the

bench—4 places

Fasten Strong Mount to Billet

Mounting—4 places

Square Deal “B” with Strong

Mount PN62395 and Dillon

Billet Mounting Plate

PN62006

Fasten Strong

Mount directly to

the bench in each of

the 4 corners

Completed Cartridge Bin

Bracket

Empty Case Bin Bracket

Mount Bullet Tray PN22214

with provided Screws,

Washers and Nuts

Dillon Square Deal

“B” Strong Mount

Kit with Empty

Case Bin and

Mounting

Hardware

PN62395

Empty Case Bin

Completed

Cartridge Bin

9

5.4.7 Install the optional Dillon Tool Holder with Wrench Set PN19441 as shown below. Remove the two 7/16”

Hex Mounting Screws and nuts underneath for the Square Deal” B” and install the Tool Holder using the

same two screws and nuts and tighten securely. Insert the Allen wrenches and Bench Wrench in their

appropriate labeled positions in the Tool Holder.

5.5 Install the Powder Measure

5.5.1 Remove the Blue shipping Cap from the Powder Die. Retrieve the Powder Measure from the shipment and

remove the Powder Measure Clamp Screw and Clamp using the provided Allen wrench.Note--The

Powder Funnel for the cartridge specified for the Square Deal purchased ships in the Powder Die.

5.5.2 Slide the Square Deal “B” Powder Measure down over the Powder Die and install the Clamp and lightly

tighten the Clamp Screw. Further adjustment of the Powder Die is required later.

Install Powder

Measure oriented

as shown and

lightly tighten the

Clamp Screw with

the provided Allen

wrench

Mount Tool Holder

with Wrench Set

PN169441 using the

two existing Square

Deal Mounting

Screws, Washers

and Nuts

Remove the Blue Cap

from the Powder Die

Remove the Powder

Measure Screw and Clamp

The Powder Funnel is shipped/installed

inside the Powder Die

Place Powder

Measure down

over the top of

the Powder Die

10

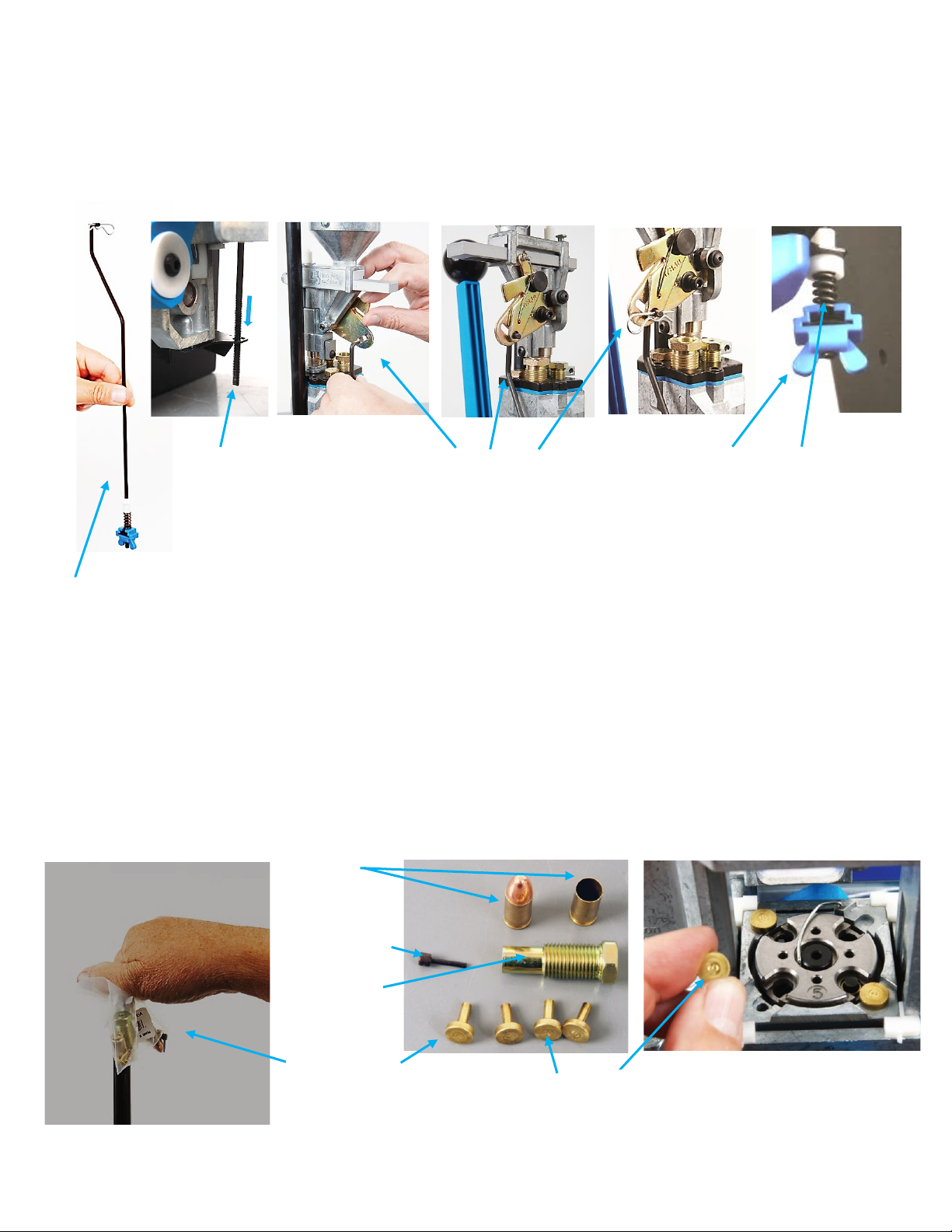

5.5.3 Locate the Failsafe Powder Measure Return Rod in the shipment and remove the top Spring Clip and the

lower Blue Wing Nut, Spring and Bushing. Rotate the Powder Measure, aligning the Failsafe Rod vertically

with the Failsafe Rod Bracket as shown below. Install the bottom threaded section of the Rod down

through the hole in the Failsafe Bracket on the bottom of the Square Deal and slide the top hook through

the hole and slot in the Lock-link Assembly of the Powder Measure. Reinstall the Spring Clip as shown

below. Reinstall the White Bushing, Spring and Wing Nut on the Bottom of the Rod. Cycle the Operating

Handel of the Square Deal “B” all the way down compressing the Failsafe Rod Spring. Adjust the Blue

Wing Nut up leaving .030” of clearance (two credit card thicknesses) between coils when fully compressed.

Re-adjustment may be necessary after setting the case mouth belling discussed later.

5.6 A plastic bag is secured to the top of the Primer Magazine Shield Tube and contains four (one spare)

numbered Brass Locator Buttons for the caliber ordered, a spare Depriming Pin, an alternate Seating Stem

(Two for .38/.357’s), a sample case with a primer and a sample reloaded cartridge showing how the press

was configured. Take three of the Brass Locator Buttons and install them in the Square Deal as shown

below.

Failsafe Return Rod

Assembly –Remove

Spring Clip and Blue

Wing Nut, Spring

and Bushing

Insert Failsafe

Return Rod

Assembly down

through hole in

Failsafe Bracket

Slide the Failsafe

Return Rod Hook

through the slot and

hole in the Lock-link

Assembly and

reinstall the Spring

Clip

Reinstall the White

Bushing, Spring

and Wing Nut on

the Bottom of the

threaded Rod

Cycle the Operating

Handle down and

adjust the Wing Nut

to leave .030”

clearance between

the coils of the Spring

when compressed

Brass Locator Buttons--Caliber specific—Install

3 in Square Deal “B” as shown (1 spare)

Sample

primed case

and cartridge

Spare

Depriming Pin

Alternate

Seating Stem

Bag Fastened to

Primer Mag

Shield—Contents

11

5.7 Note: The Square Deal ships with the Primer System size installed for the cartridge ordered. The

alternate small or large Primer Assembly is shipped in the Accessory box. Refer to Section 8.3 on the

Primer Conversion Procedures for changing primer size.

5.8 Install the Primer Early Warning System

5.8.1 The Primer Early Warning system emits a “beeping” sound when the Primer Magazine is down to the last

three or four primers.

5.8.2 Simply push the Primer Early Warning System down over the Primer Magazine Shield Knurled Cap until it

stops.

5.8.3 WARNING! Do not put primers in the Magazine Tube until you have read this entire manual.

5.8.4 Install the Primer Magazine Follower Rod as shown below. You can store the plastic Primer Follower Rod

in the Magazine Tube when there are no primers in the Magazine Tube by putting it under the Operating

Lever to stop the alarm from sounding when it is not being used.

5.9 Your assembly is complete. Cycle the Operating Handle making a full stroke down and up again and push

fully to the rear to the priming position. The Shellplate should index clockwise. The Primer Slide should

move back and forth and the Primer Punch will project up through the hole in the Shellplate.

Store Rod as

shown to

disable the

audio alert

when no

primers are

present

Press EWS down over the Knurled Nut

Install Follower

Rod

12

6. OPTIONAL EQUIPMENT FOR THE SQUARE DEAL “B”:

•Square Deal Strong Mount and Case Bin: PN22051

•Tool Holder with Wrenches: PN19441

•Low Powder Warning Sensor: PN16306

•Square Deal “B” Toolhead Assy: PN20113

•Deluxe Quick Change & Stand: PN62265

•Spare Parts Kit: PN97015

•Bullet Tray: PN22214

Note-- Conversion Kit

Shellplate and Dies sold

separately

13

7. THE DILLON SQUARE DEAL “B” HAS FOUR RELOADING STATIONS AND USES UNIQUE DIES

AND A POWDER MEASURE ASSEMBLY. The Toolhead and Shellplate are specific to the Square

Deal” B” and are not compatible with any other dies or reloading system—see the description of the

four stations and the operations below:

•STATION 1—DEPRIME AND SIZE CASE--(Number 1 engraved in the Toolhead)

•STATION 2--SEAT PRIMER, BELL CASE MOUTH AND DISPENSE POWDER (Number 2 in the Toolhead)

•STATION 3--SEAT BULLET--(Number 3 in the Toolhead)

•STATION 4--CRIMP BULLET AND EJECT COMPLETED CARTRIDGE--(Number 4 in the Toolhead)

Note--cases are automatically indexed from station to station every time the Operating Handle is cycled down and

up.

Station 1

Station 2

Station 4

Station 3

Station 4

Station 1

Station 2

Station 3

Each Station is numbered on the

Toolhead 1 thru 4 as are the Size

Die #1, the Seat Die #3 and the

Crimp Die #4

Station 1-Size

and Deprime

Station 2-Prime and

Dispense Powder

Station 3-

Seat Bullet

Station 4-Crimp Bullet

and Eject Cartridge

Toolhead Assembly

with Blue Friction Plate

Square Deal Powder Measure

and Clamp Assembly

Square Deal Powder

Die and Clamp

14

7.1. Station 1— Case is Deprimed and Sized

•The user inserts a case into the Shellplate

•Cases are de-primed and sized on the downstroke of the Operating Handle

•On the upstroke, the case is indexed to Station 2 and a Primer is picked up by the Primer Slide and fed into

Station 2

Station 1—Case Deprimed and Sized

7.2. Station 2—Primers Are Automatically Fed and Seated, The Case Is Flared (Belled) and the Powder

Dispensed

•Primers are seated on the “full-push stroke” of the Operating Handle from the “at-rest” position of the

Operating Handle

•On the downstroke, the case mouth is belled (flared) and powder dispensed into the case

•On the upstroke, the case is automatically indexed to Station 3

Station 1--Case entering Depriming/Sizing

Die as the Operating Handle is lowered

raising the Shaft/Shellplate

Station 2—Primer Seated, Case Flared, Powder Dispensed

Station 1--Case manually

inserted into Shellplate

Station 2—Case being pushed over

the nose of the Powder funnel

belling the case mouth and dropping

powder into the case

Station 2— Typical

Dillon Powder Funnel—

fits inside the Powder

Die

Station 1—On the upstroke the case is indexed to

station 2 and a primer is picked up and presented to

Station 2

Case not shown

in Station 2 for

clarity

Station2--Primer seated push stroke of the Operating Handle

from the at rest position

Neutral

“at-rest”

Position

Primer

seating

position

Station2--Case mouth flared and powder dispensed

on the down stroke of the Operating Handle

Belling Feature of

Powder Funnel

15

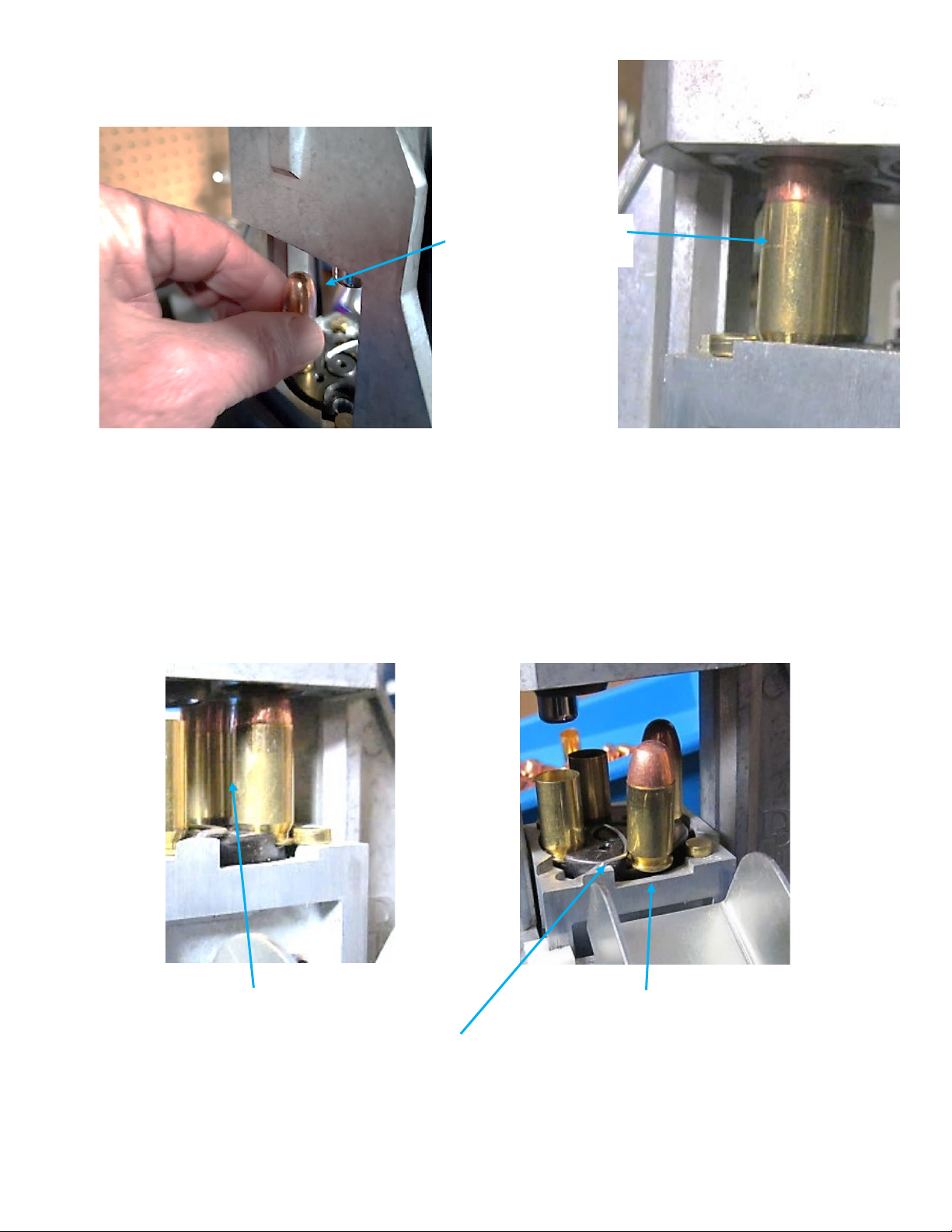

7.3. Station 3—Bullet Placed and Seated

•User places bullet on the case in Station 3

•On the downstroke, the bullet is seated

•On the upstroke, the case is automatically indexed to Station 4

7.4. Station 4—Bullet Crimped and Completed Cartridge Ejected.

•The Bullet is crimped on the downstroke

•The Cartridge is ejected on the upstroke

Station 3--Bullet Placed

and Seated

Station 3—Bullet Seating

Ejector Wire Ejects Cartridge

into Cartridge Chute/Bin

Station 4 (Crimp)

Station 4 (Eject)

16

8. SETUP PROCEDURES FOR SQUARE DEAL “B”—WARNING! Due to variations in components, check

all stations for proper adjustments for the cartridge you are loading. You must read the following

instructions. If there is something you do not understand, call (800) 223-4570 for technical assistance.

8.1. The Dies and Toolhead are unique to the Square Deal.

8.3.1 The Dies are numbered #1-Size Die, #3-Seat Die and #4-Crimp Die. They drop into the Square Deal Frame

Station #1, #3 and #4 respectively as shown below.

8.2. Another unique part of the Square Deal Toolhead Assembly is the Blue Friction Plate which is sandwiched

between the Frame below and the Numbered Toolhead above. The Friction Plate keeps the threaded parts

of the dies from easily turning. The remaining parts are assembled as described below:

Station #1--Size

Station #3--Seat

Station #4--Crimp

Friction Plate

Numbered Toolhead

Square Deal “B” Toolhead Assembly

17

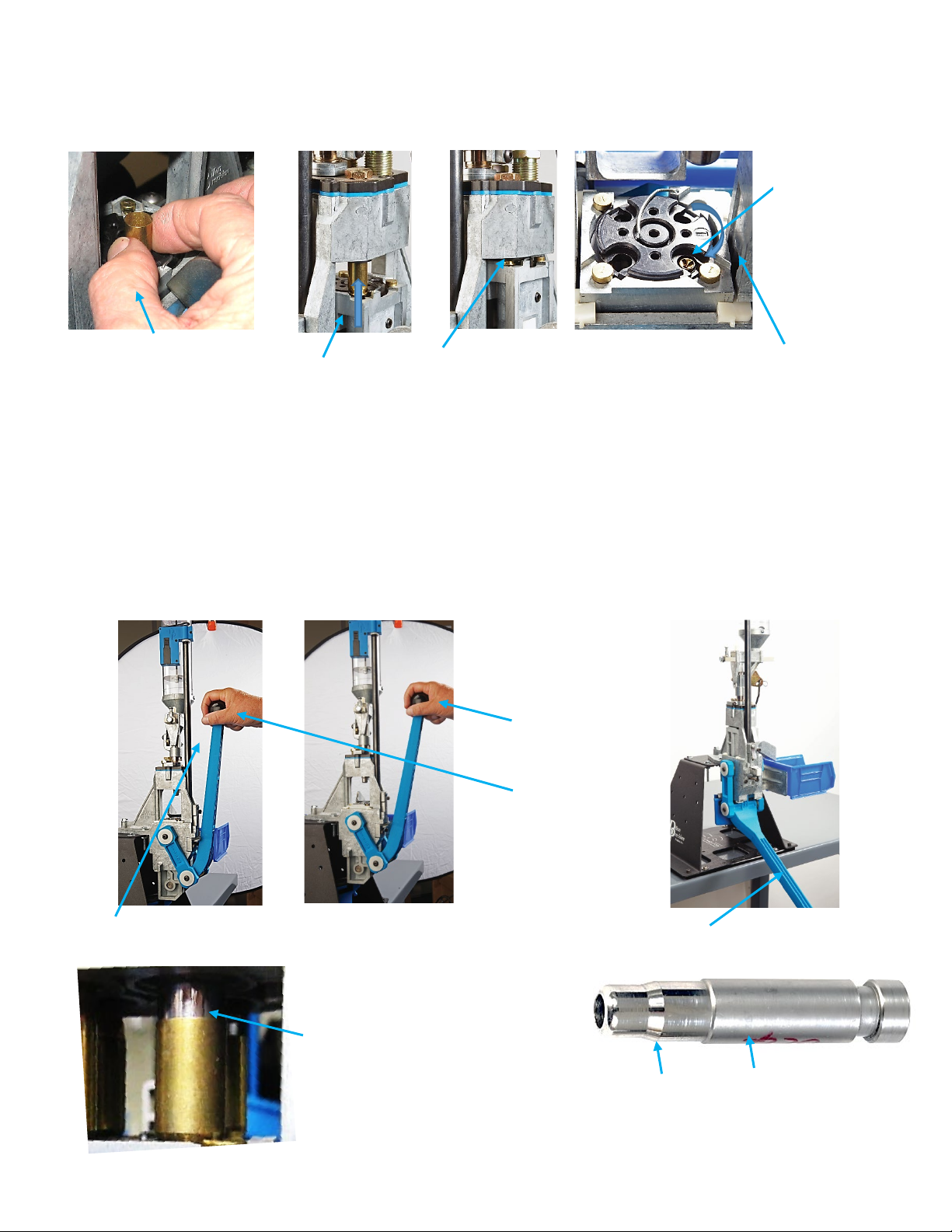

8.3. Station 1—Sizing and Depriming

8.3.1 There is no adjustment required for Station 1--The Size Die with its Carbide insert drops into Station 1 and is

secured by the Toolhead. The Depriming Assembly threads flush into the Toolhead. The Deprime and Size

Components are shown below. The case is sized and Deprimed in Station #1 on the downstroke of the

Operating Handle.(Note—a Primer is picked up by the Primer Slide in Station #2 during the downstroke of the

Operating Handle during the Sizing/Depriming Operation in Station #1).

8.4 Station 2a--Primer Feeding, Seating, Case Belling and Powder Dispensing--The First Operation of Station 2 is

(a) to seat a primer on the full push stroke of the Operating Handle. The Second Operation of Station 2 is to

(b) expand the case mouth and dispense powder on the downstroke of the Operating Handle.

8.4.1 The Square Deal “B” incorporates an Automatic Linear Primer Feed System utilizing standard Large or Small

Primer Magazine Tubes and interchangeable Large and Small Primer Slides. The Square Deal “B” comes with

the primer size specific to the cartridge ordered. The alternate size Primer Slide is shipped separately. A Large

Powder Bar for the Powder Measure is also included. These components are in the “Tube Pack” --see shipping

contents.

8.4.2 A Primer Early Warning System (EWS)/Low Primer Alarm system is provided. The Primer Follower Rod is the

Actuator for the Primer Early Warning System.

8.4.3 A primer is automatically picked up by the Primer Slide and Primer Cup Assembly from the Primer Magazine.

It is then positioned under the hole in the Shellplate in Station 2 as the case is indexed from Station 1 during the

upstroke of the Operating Handle. The Primer is then seated with a complete push stroke of the Operating

Handle.

Size Die drops

into the

Square Deal

Primer pushed up by Primer

Punch ready to be installed

if a case was present

Large Primer

Slide Assembly -

-Silver Cup

Primer Follower Rod and

Assembly and Primer Early

Warning System

Depriming Assembly threads

down against the Tool head

Primer Follower Rod

showing there are

Primers left in magazine

Tube

18

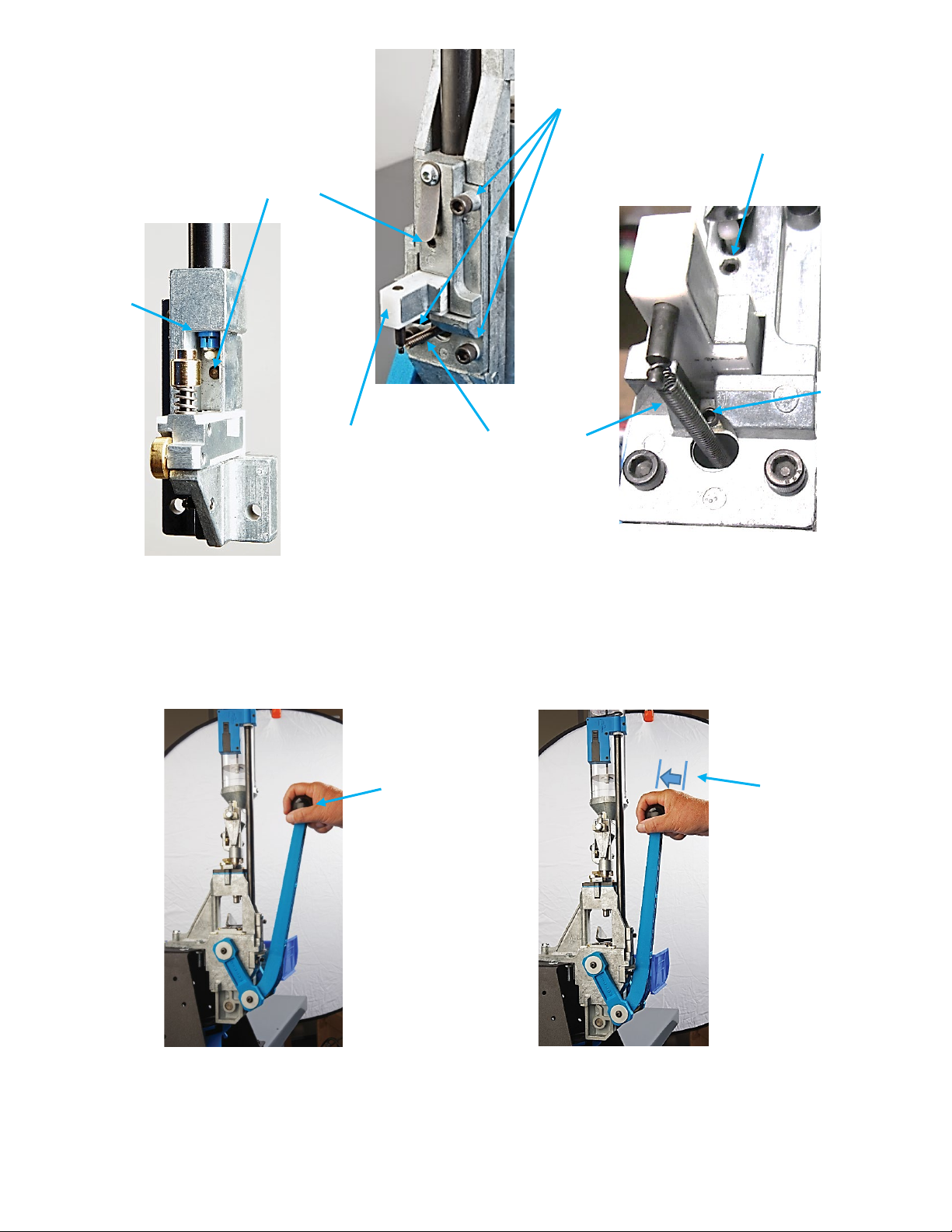

8.4.4 The Operation of The Automatic Primer System

•The Square Deal “B” comes set up in the primer size for the cartridge ordered.The alternate size

Primer Slide Assembly ships separately.

•Primers are seated by pushing the Operating Handle fully to the rear, from the Operating Handle’s

“at rest position” at the top of the Square Deal’s stroke.

•CAUTION!

•Learning to feel the correct force to seat a primer is a critical method in the reloading process.

•The Prime will not be seated to the proper depth if the Handle is not pushed firmly and fully to

the rear primer seating position.

Primer Slide in primer

pickup position—

Operating Handle Down

Primer

Magazine

Blue Tip

Operating

Handle

“at-rest

position

Primer Slide

return Spring

Primer Slide

Forward

Travel Set

Screw Stop—

Primer

seating

position

Adjustable

Set Screw

Stop-Primer

pickup

position

Primer

Assembly

Mounting

Screws

Primer Slide in primer

pickup position—Rear

Travel Adjustable Set

Screw Stop

Push Handle fully

to the rear to seat

a primer

19

•If the primer takes too much force to be seated and the Handle cannot be pushed fully

to the rear—STOP and inspect the case. The primer pocket may be damaged or could

have a crimped primer pocket or the Primer Cup may not be aligned properly with the

Shellplate.

•Low resistance to seating a primer can indicate an enlarged primer pocket that may

not retain the primer. Discard this case.

•Verify that the system feeds primers as follows:

•Remove the plastic Follower Rod and unscrew the Magazine Cap.

•Remove and verify the Magazine Tube is of the correct size/color--The blue tip for

small primers and the red tip for large primers. Note: Any primers left in the

Magazine Tube will fall out in the Magazine Shield Tube.

•Install the Magazine Tube in the Magazine Shield. The tab on the plastic Magazine

Tip, red or blue, must be gently aligned with the slot down in the Primer Feed Body

Housing and then should slide down about a 1/4” more. Tighten the knurled

Magazine Cap just snug.

•With the Operating Handle up in its at-rest position, manually take one primer that

you will be using and drop it anvil side up in the hole in the Magazine Cap as below:

•Cycle the handle smoothly down and back up to the top of the stroke to the “at rest position.”

•The primer should present itself in the Priming Station on top of the Primer Punch as shown below—

repeat this step 3 times--if successful proceed to the next step, if not, proceed to Primer Drop Alignment

Section 10.2.

Drop one primer in

Magazine Shield/Cap

Correct presentation

of primer—Single

primer drop test—

Primer ready to be

seated Station 2

Magazine Tip Alignment Tab

Tighten knurled

Magazine Cap

just snug

Magazine Cap fits over

end of Magazine Tube

Red Large Tip and Magazine Tube

Blue Small Tip and Magazine Tube

20

8.4.5 Verify Primer Seating Depth

•With a primer in the cup as above and the Operating Handle in its up at-rest position, put a de-

primed case in Station 2. Push the Operating Handle fully to the rear seating the primer. Remove

the case and verify the primer is seated flush or slightly below flush.

•The primer seating depth is an important parameter to control when reloading and can be a safety

issue. The ideal seating depth is .002” to .006” (.008” Max) below the case head. WARNING!

“High” or protruding primers can lead to slam fires in semi-autos or firing out of battery and can

stop the cylinder from rotating in revolvers. Seating the primer too deep can cause damage to the

primer, causing misfires and or inconsistent ignition. Refer to Section 14 on Primer Basics.

8.4.6 Filling the Primer Magazine-- Dillon offers two choices for filling the primer magazine:

•Manually as below with an optional Dillon Primer Flip Tray and Dillon Primer Pickup Tubes. Pickup

Tubes are included with the Square Deal “B”.

•The Primer Pick-Up Tubes have different colored tips. They have been color-coded to identify size

easily. The color code is as follows:

•WARNING! Put on safety glasses!

•Place primers on the half of the Flip Tray with the ribs. Oscillate the tray and primers around until all

the primers are flat. Pick up all the primers that are shiny side up by placing the Plastic Pickup Tip—

yellow or green, over the shiny side up primers in the Primer Flip Tray and gently pressing down. Put

the other half of the Flip Tray on the ribbed half with the primers that are anvil side up. Hold the two

Primer Pickup Size Pickup Tip Color Dispense Tip Color

Small Yellow Blue

Large Green Clear

Courtesy of Western Powders

Primer on right is

seated properly--

the one on the

left is high

Table of contents

Other Dillon Precision Products Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

HBM

HBM C16A Series installation instructions

steute

steute STM 295 Mounting and wiring instructions

KINSHOFER

KINSHOFER KM 506 HD operating instructions

KTR

KTR SYNTEX Hub design 1.0 Operating & assembly instructions

eXact

eXact PipeCut Infinity operating instructions

Sumitomo

Sumitomo Taper Grip installation guide