WOOD'S POWR-GRIP

®

GUIDE TO MAINTENANCE,

TROUBLESHOOTING AND REPAIR

THE ORIGINAL

& TRUSTED NAME

IN VACUUM LIFTING

EQUIPMENT

Wood's Powr-Grip products are sold

through authorized dealers.

800.548.7341

WPG.com

908 West Main - P.O. Box 368

Laurel, Montana 59044 U.S.A.

406.628.8231 (phone)

406.628.8354 (fax)

Rev. 4.6/ 10-21 Metal Troubleshooter 1MTS

%DVHGRQSURGXFWLQIRUPDWLRQDWWLPHRISXEOLFDWLRQ(QYLURQPHQWDOFRQGLWLRQVFDQDႇHFWSURGXFWSHUIRUPDQFHDQGORQJHYLW\

consult the product instructions on www.WPG.com or contact a Technical Sales Representative for more information.

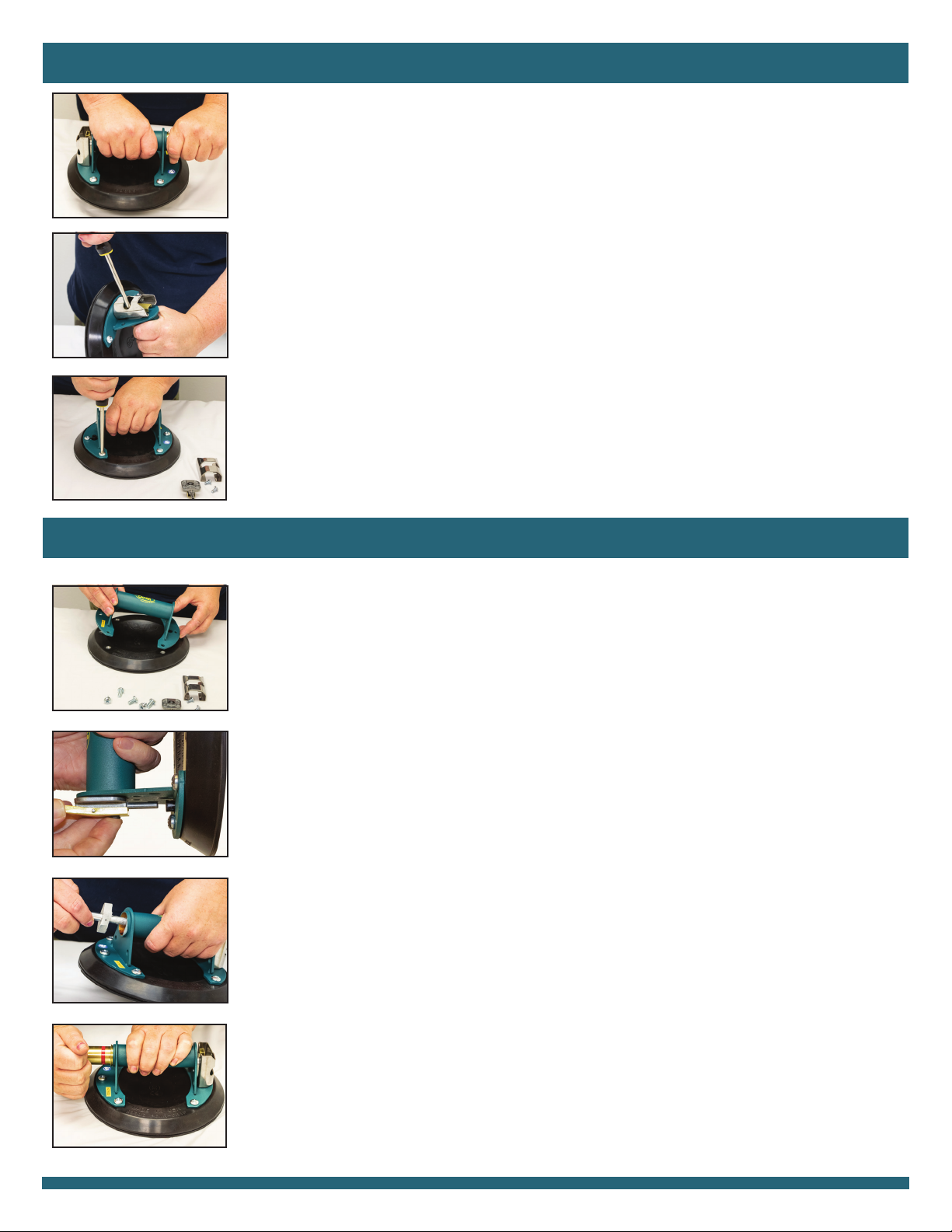

General Maintenance

Inspect the Hand Cup Regularly:

0DNHVXUHWKHDLU¿OWHULVLQSODFHLIQRWGLVFRQWLQXHXVHXQWLOWKH¿OWHULVUHSODFHG

([DPLQHWKHSOXQJHUDVVHPEO\DQGKDQGOHIRUGHQWVFUDFNVRURWKHUGDPDJH

0DNHVXUHWKHIDFHRIWKHYDFXXPSDGIHHOVJULSS\QRWVOLFN2WKHUZLVHUHSODFHWKHSDG

• Examine the vacuum pad for cuts or roughness on the sealing edges (see Inspect the Sealing Edges below).

3HULRGLFDOO\WHVWWKHFXSIRUH[FHVVLYHOHDNDJHVHH/HDN7HVWWKH+DQG&XSEHORZVOXJJLVKQHVV

in plunger action or radical changes in the number of strokes needed to keep the red line hidden.

,IWKHFXSGRHVQRWIXQFWLRQQRUPDOO\UHYLHZWKH7528%/(6+227,1**8,'(RYHUOHDIWR

determine which corrective action is needed.

Clean the Vacuum Pad:

5HPRYHWKHDLU¿OWHUIURPWKHSDGIDFH

8VHDFOHDQVSRQJHRUOLQWIUHHFORWKWRDSSO\VRDS\ZDWHURUDQRWKHUPLOGFOHDQVHUWRWKHSDGIDFH

• Never use solvents or rubber conditioners as a cleaning agentVHH:$51,1*6

• To prevent liquid from contaminating the pump during cleaning, hold the cup facedown

RUFRYHUWKHVXFWLRQLQOHWLQWKH¿OWHUUHFHVV

• If the pad has a felt strip at the edge, be careful not to dampen it.

:LSHDOOUHVLGXHIURPWKHSDGIDFHDQGDOORZWKHFXSWRGU\

5HLQVWDOOWKHDLU¿OWHU

Inspecting and Testing the Cup for Leakage

Inspect the Sealing Edges:

6ORZO\GUDZ\RXU¿QJHUDORQJWKHHQWLUHOHQJWKRIWKHVHDOLQJHGJHVWRFKHFNIRUURXJKQHVVRU

foreign material.

([DPLQHWKHVHDOLQJHGJHVIRUFXWVE\EHQGLQJWKHHGJHRIWKHSDGIDFHWRZDUGV\RXWRFUHDWH

DKXPSWXUQLQJWKHKDQGFXSDVQHFHVVDU\

• If cuts or cracks are present in a sealing edge, a V-shaped gap will appear.

$Q\SDGWKDWH[KLELWVDJDSRUH[FHVVLYHURXJKQHVVLQDVHDOLQJHGJHPXVWEHUHSODFHG

Leak-Test the Hand Cup:

$WWDFKWKHFXSWRDFOHDQVPRRWKVFUDWFKIUHHSLHFHRIJODVVRUPHWDOIRUDSSUR[LPDWHO\KRXUV

• The red line on the plunger serves as a vacuum indicator:

ƒ,IWKHUHGOLQHdoes not appear during the test period, the cup is usable.

ƒ,IWKHUHGOLQHdoes appear, perform general maintenance and repeat the test.

,IWKHSUREOHPSHUVLVWVFKHFNWKH7528%/(6+227,1**8,'(RYHUOHDIWRLGHQWLI\SRVVLEOH

causes and appropriate corrective actions.

• If these measures do not restore the cup to normal performance, contact the Wood's Powr-Grip

&XVWRPHU6HUYLFHGHSDUWPHQWRUDQDXWKRUL]HGGHDOHUIRUDVVLVWDQFH

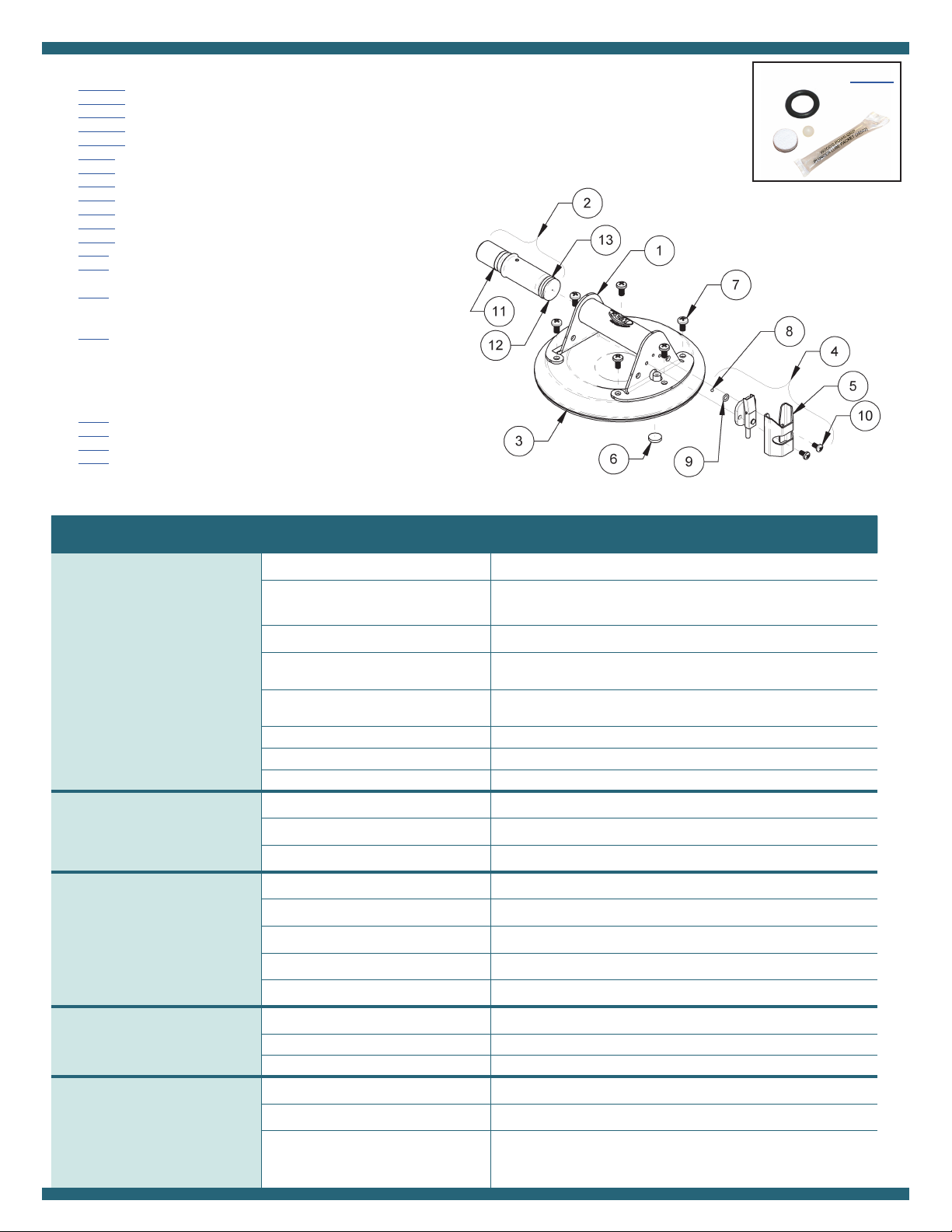

32620

N4950, N5450, N6450,

N4300*, N5300*, N6300*

N4950TS, N5450CS

Metal Handle Hand Cups

6RPHGHWDLOVPD\QRWDSSO\WRKDQG

cups with plastic plunger assemblies.