PUSHCORP, INC.

RPC100-75/125/150 Manual

2.0 General Overview

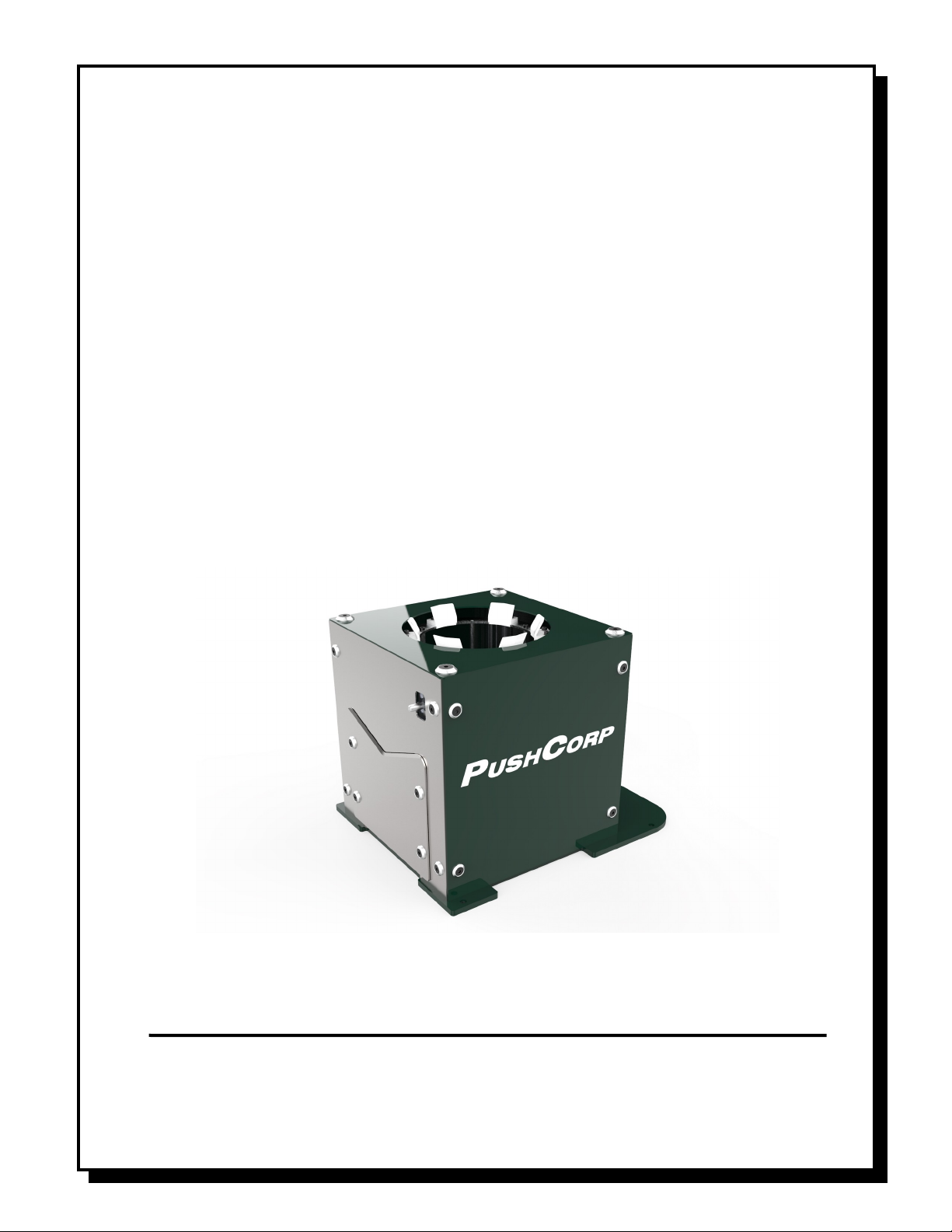

The PushCorp, Inc. Robotic Paper Changer or RPC100 provides an efficient and

robust method to change abrasive sanding discs for finishing applications with the

use of a robot and Random Orbital Sander. The RPC100 can allow a robot to

change 75mm (3”), 125mm (5”), or 150mm (6”) paper autonomousl through the

application of pneumatic actuators, sensors, and removal blade within the RPC100.

When purchasing, the disc size must be specified: RPC100-75 for 75mm (3”) discs,

RPC100-125 for 125mm (5”) discs and RPC100-150 for 150mm (6”) discs.

The RPC100 is comprised of a blade for removing the paper from a hook and loop

pad, a c linder for appl ing the paper to the pad and sensors to verif that the

process is completed successfull . Worn sanding discs are removed from the hook

and loop backing pad using an adjustable blade mounted to the side of the unit. The

RPC100’s blade can be set to accommodate an grit of abrasive disc b stacking

shim washers based on the thickness and grit. The paper changing process is

validated with the utilization of a probe sensor, which is calibrated to send a 24V

signal indicating that the paper has been successfull removed. This signal can be

used as an indicator in the robot program to proceed to the paper changing process.

A pneumatic c linder provides a repeatable force to consistentl appl new paper to

the backup pad. The design of the RPC100 allows concentric placement on the

ROS so the paper is aligned ever time. This is achieved with guides that center the

disc in relation to the pad. Sensors can be set to send 24V signals when paper is

low and/or completel out.

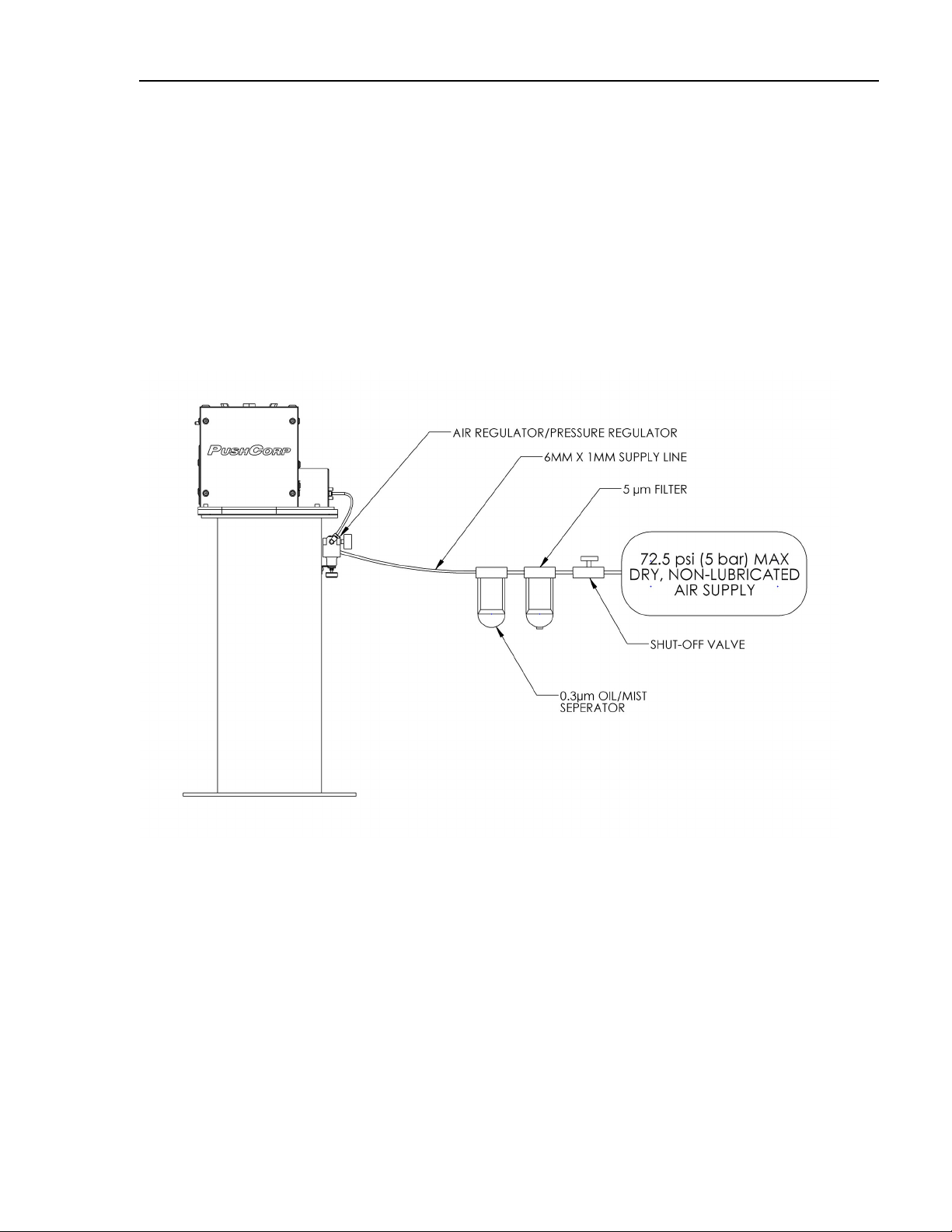

To operate the RPC100, electrical and pneumatic connections are required. The

electrical connection on the RPC100 is a male “A-code” M12 8pin connector. Power

as well as digital inputs and outputs are all fed through this single connection. The

pneumatic connection is a ¼” or 6mm line that connects to a solenoid valve. With a

24V signal the solenoid is actuated causing the c linder to extend. It is imperative

that the air connection is filtered, non-lubricated, and has air pressure ranging from

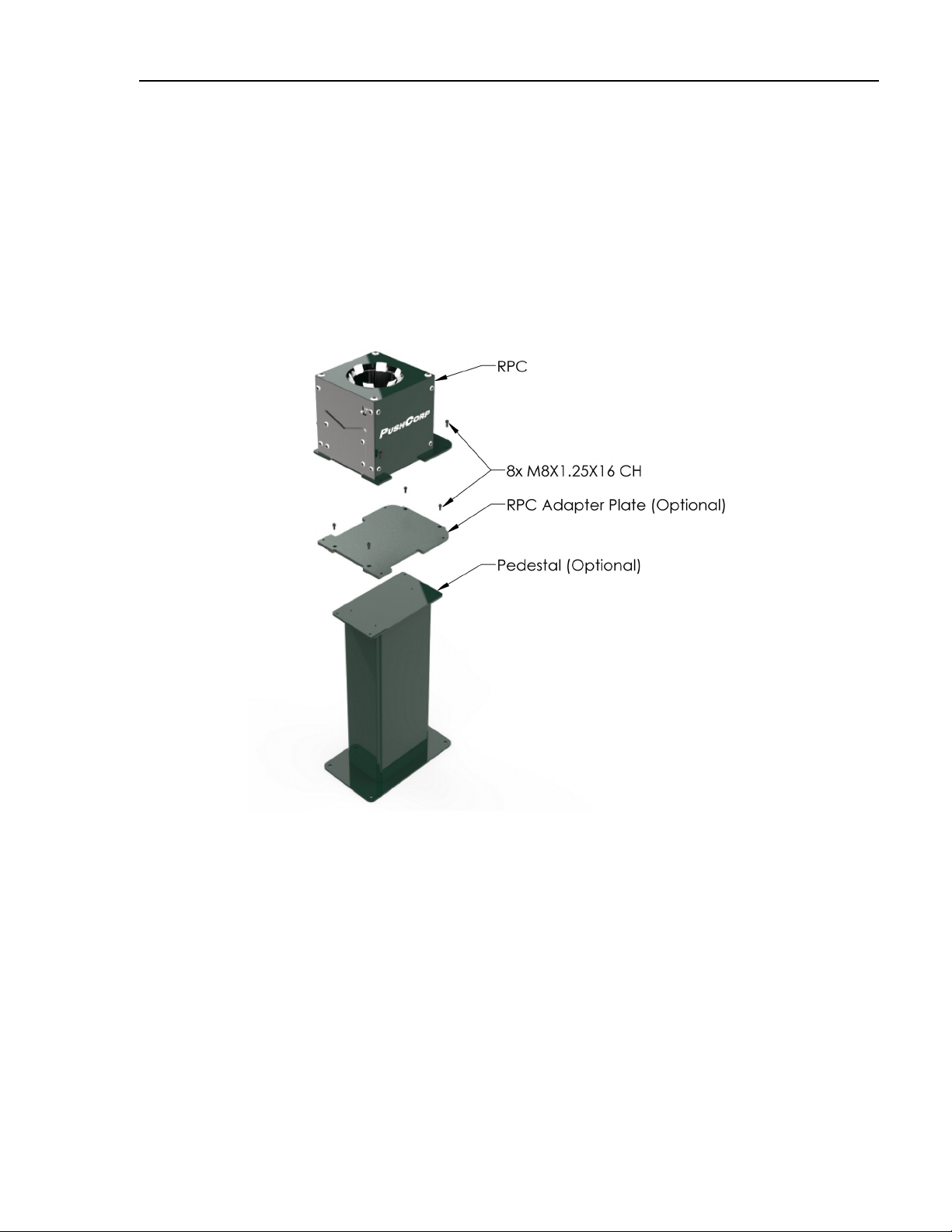

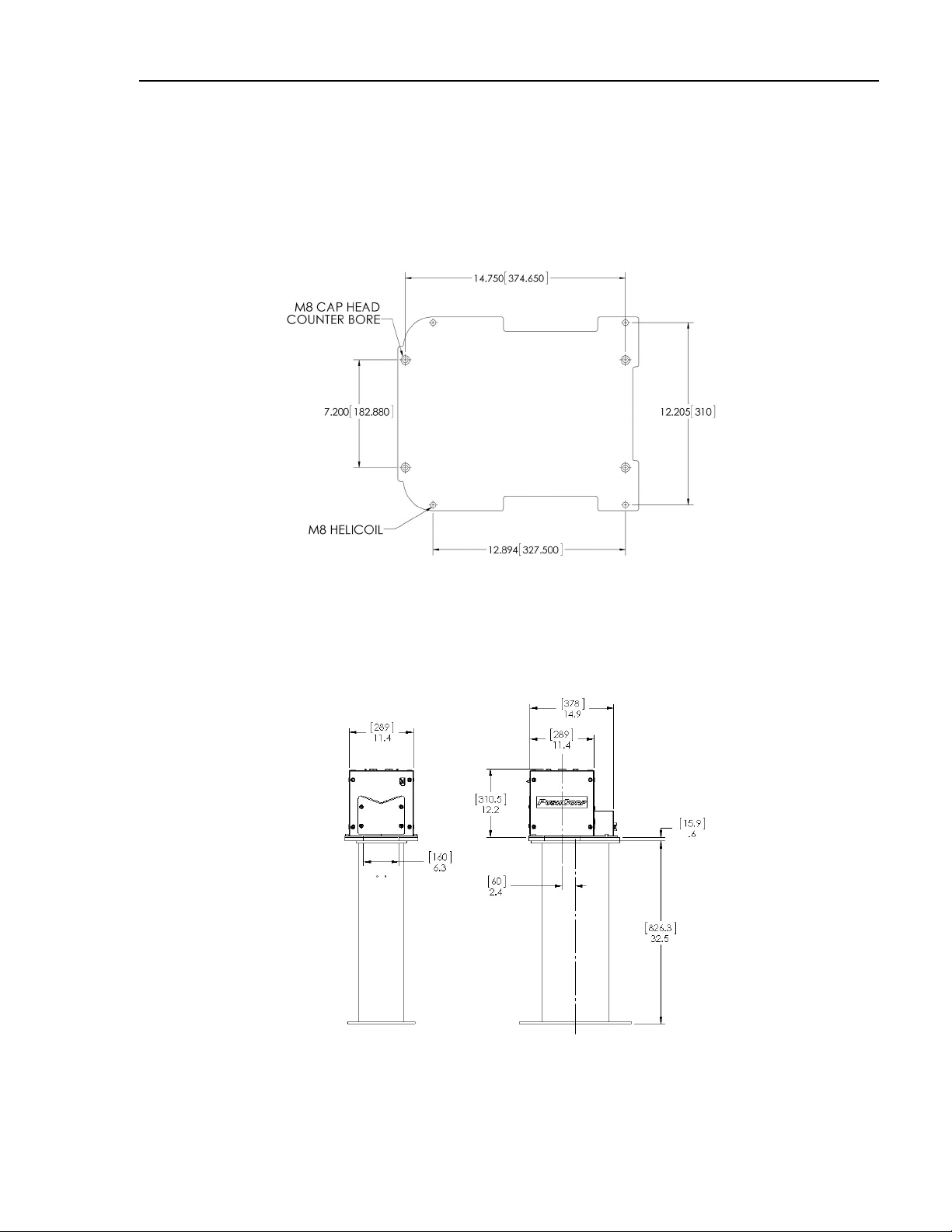

43.5 to 72.5 psi (3 – 5 bar). It is recommended that the RPC100 is securel mounted

to the RPC100 Base with the appropriate bracket both designed and manufactured

b PushCorp, Inc.

4