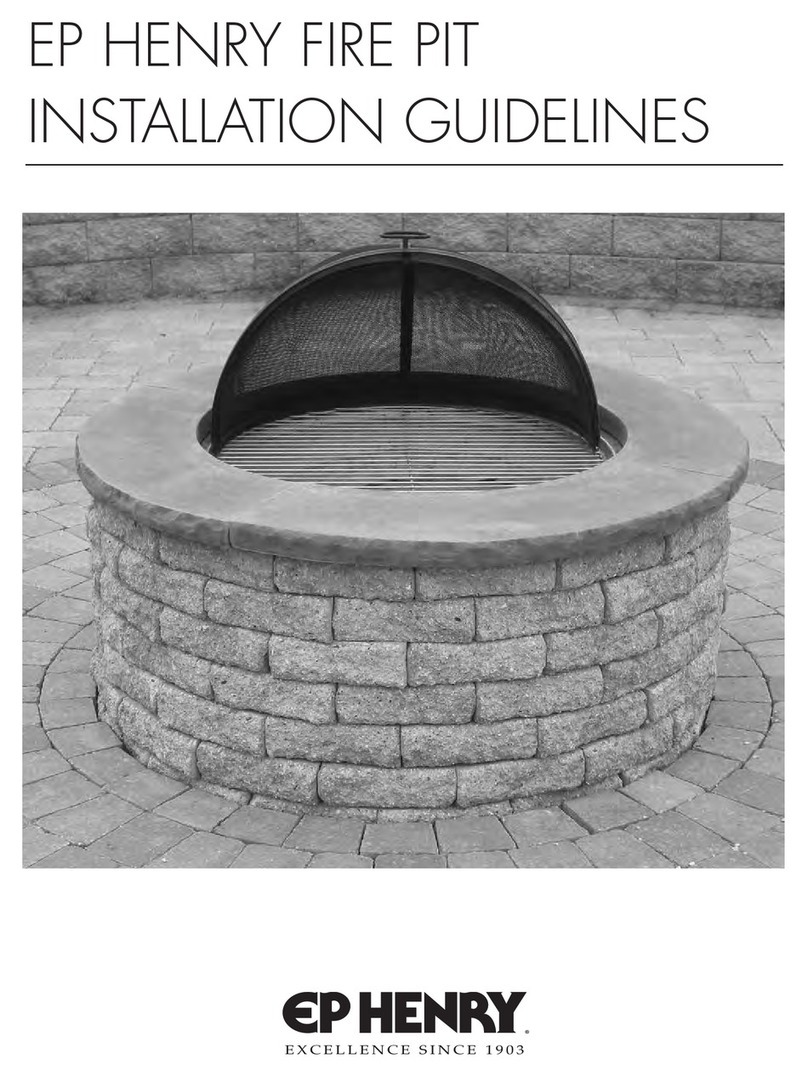

EP HENRY CAST STONE WALL SQUARE FIRE PIT KIT Instruction sheet

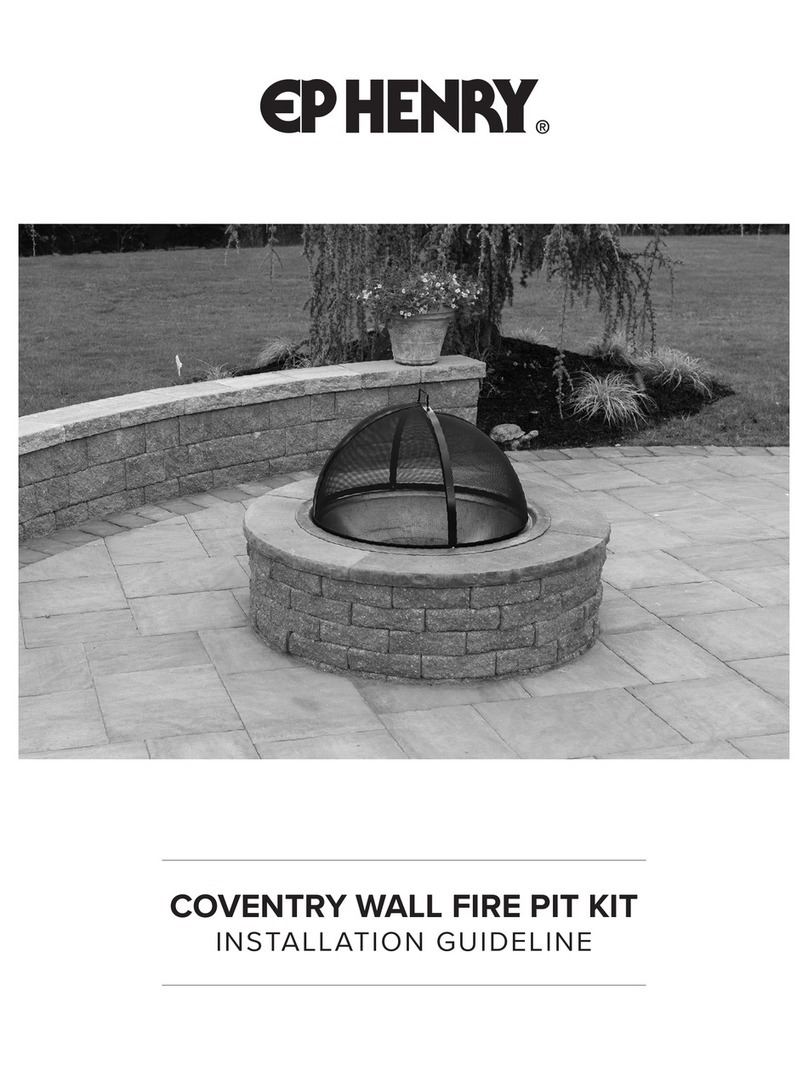

CAST STONE WALL SQUARE FIRE PIT KIT

INSTALLATION GUIDELINE

IMPORTANT:

BE SURE TO READ ALL SAFETY GUIDELINES BEFORE INSTALLING OR

USING YOUR EP HENRY FIRE PIT. THE WALL BLOCK AND CAPS OF THE

EP HENRY FIRE PIT ARE NOT FIRE RATED.

DO NOT ALLOW FLAMES TO COME IN

DIRECT CONTACT WITH THE BLOCKS OR CAPS.

COMPONENTS

Please check and make sure all components

are in place before you begin to assemble.

Your EP Henry Fire Pit Kit should contain the

following items:

• 12 single sided Cast Stone Wall™ corner units

• 12 – 16″ Double Sided Cast Stone Wall

stretcher units

• 12 – 10″ Double Sided Cast Stone Wall units

• 4 – cap units (2″h x 9″w x 45″l)

• 1 – 3/16″ steel insert, (18″h x 32″w x 32″l)

• 1 – Stainless steel ange collar 2″x 6″

• 2 – Half-size cooking grills

Contact your EP Henry Authorized Hardscaping

Distributor® immediately if any components are

missing or damaged upon opening. Proof of

purchase required.

PLEASE NOTE: The wall block and caps are not

re rated. Never allow ame to come in direct

contact with them.

CALL BEFORE YOU DIG!

It is your responsibility to notify the utility companies a few days prior

to digging so that they can mark out any underground lines. For your

convenience, dial 8-1-1 nationwide and be prepared to describe the scope of

your project. Avoid injury, expense and possibly a day in the dark.

For more info, visit www.call811.com.

800.44.HENRY ephenry.com EPHenryUSA

PLANNING THE CONSTRUCTION

Establish the location where the re pit is to be built. Mark

the center of that location. Then mark out the 50″ x 50″

square footprint of the re pit. If you are building your re pit

in an open area the excavation and compacted stone base

needs to exceed the exterior dimensions of the re pit by 6″

on all sides.

If you are building the re pit within a paver installation,

construct the re pit walls laying the rst course of block

directly on the sand setting bed of the paver installation.

Make sure to install an expansion joint between the

interfacing sides of the surrounding pavers that butt against

the bottom of the rst course of block.

Make sure all units are dry and dust free before applying

adhesives. Adhesive should be applied toward the outside

of the units on each course of block to prevent it from over-

heating. It is recommended that any adhesive be allowed to

cure for at least 48 hours before lighting a re in the re pit.

DENSE-GRADED AGGREGATE BASE CONSTRUCTION

After marking out the area of the re pit and excavating

7″ deep (to accommodate 6″ of dense-graded aggregate

stone and a 1″ layer of setting bed sand). Make sure the

excavated sub-grade soil surface is smooth and level and

well compacted.

A geotextile fabric (Mira 500x or Mira 140n) is

recommended as a separation membrane on top of the soil

surface and up the sides of the excavation to help maintain

the integrity of the dense-graded aggregate stone base,

especially when clay soils are present.

NOTE:

Excavate and remove all sod and organic soils in the

interior of the footer excavation to the depth required.

Shovel in the stone for the base and spread it evenly in

layers 2″ or 3″ thick. Carefully compact the stone base as

evenly as possible. For best results, use of a vibratory plate

compactor is recommended. Repeat this process until the

stone base is 6″ deep. Before compacting the nal layer

of stone, use a straight edge and level to see if the surface

is smooth and level, then compact and check again. If the

surface is not level and smooth, scratch the surface with

a rake, smooth and level it. Use coarse washed concrete

sand to ll in any remaining depressions. Then make a nal

compaction.

Lay two pipes with an outside diameter of 1″ parallel to the

length of the footer trench. Place a few shovels of coarse-

washed concrete sand on the compacted stone surface

between the pipes and over them. Then using a straight

edge, such as a 2″ x 4″, drag it across the length of the

pipes smoothing the sand. Repeat this process until the

entire surface of the footer is covered with a uniform layer

of coarse concrete sand 1″ thick. Pick up the pipes and ll

in the voids left by the pipes with sand, smoothing it with a

broom or mason’s trowel.

CALL BEFORE YOU DIG! Dial 8-1-1 or visit www.call811.com

800.44.HENRY | ephenry.com

INSTALLING THE FIRE PIT BLOCK

Install the rst course of block using the Construction Detail

as a guide. Seat the blocks into the sand using a dead blow

hammer or rubber mallet. Check the top surface of the blocks

to make sure they are level from front to back, side to side,

and from block to block across the base course spanning

from one side of the base course to the other side. The block

should settle into the sand about 3/8″. Install the remaining

block as shown in the Construction Details.

High strength exible concrete adhesive must be used

between all courses of the re pit block. Apply the adhesive

toward the outside edge of the exposed, horizontal, at

surface of each course of block as the block being placed

on top of it is set in the correct position. Use a level to align

the block vertically on the inside face of the wall. The outside

re pit face prole will vary due to the stone face and deeply

textured surface of the blocks.

It is important to cover the exposed compacted stone base

surrounding the re pit with stone. Wood chips, mulch, grass

or other ammable materials should not be used in or around

the re pit to cover disturbed soil or the excavation overdig.

SETTING THE FIRE BOX AND BACKFILLING

CRUSHED STONE

After the re pit walls have been constructed, place the

steel re box in the center of the re pit opening. Due to

the excavation of sod and/or organic soils the top edge of

the re box will be lower than it needs to be. Measure the

distance from the top edge of the re box to the top of the re

pit walls. Then remove the re box and back ll the bottom

of the re pit with enough 1/2″ clean crushed stone to raise

the elevation of the re box so the top edge is even with the

top of the re pit walls. Make sure to tamp the crushed stone

before measuring for the required nished elevation.

Then reset the re box and back ll the 1.5″ (+/-) gap between

the back of the re pit walls and the steel re box with more

1/2″ clean crushed stone to an elevation that is 2″ below the

top of the re box and re pit walls.

The two piece grilling rack may be inserted at this time or

held out and installed later when needed for cooking.

NOTE:

Long term exposure to the weather will accelerate the

development of rust on the grilling racks. When not in use

storing the grilling racks indoors is advised.

CAPPING THE FIRE PIT WALL

After aligning the cap units, lift each unit individually leaving

the three others in place to act as a guide and apply high

strength exible adhesive on the top of the re pit walls.

Place daubs of adhesive the size of a quarter 6″ apart, near

the outside edge of the re pit wall block. Carefully lower the

cap unit back into place until it touches the adhesive. Use a

square on the inside back face of the caps to make the nal

cap alignment. Tap the caps in place with a rubber mallet,

dead blow hammer, or your hand. Do not use a steel hammer

to align them. It will chip the caps or leave marks on the

cap surface.

DO NOT LIGHT A FIRE IN THE FIRE PIT FOR AT LEAST 48

HOURS to allow any adhesive to cure properly and potentially

ammable fumes to dissipate.

SETTING THE CAP FLANGE

The nal step of the square re pit construction is to set

the protective cap ange in place. Carefully lower it on to

the inner cap surfaces so it extends down inside the re pit

protecting the inner edge of the wall caps. Always maintain

the protective cap rim in place when preparing to burn a

re, while a re is burning, and when hot ash or embers are

cooling o.

LIGHTING FIRES

IMPORTANT: Please review and become familiar with the

safety guidelines that accompany these instructions. Your

EP Henry Square Fire Pit is not designed for huge bon res.

Make sure that the res you light are kept relatively small for

the rst several res. Except in case of emergency, always

allow res to burn out on their own. Extinguishing res with

water may cause the cap or wall units to crack or spall. Do

not burn lumber, plywood, trash, leaves, or other debris in

your re pit. Only burn dry hardwoods. Do not use lighter

uid, gasoline, or other re accelerants to start or maintain

res. Always monitor a re to make sure sparks do not y

out and start a re outside of the re pit. Wear re resistant

gloves when maintaining the re and adding fuel.

NOTE:

The unit concrete block and wall caps of the EP Henry

Square Fire Pit are not re rated and designed for direct

contact with ame or excessive heat. Exposure to such

will damage the unit concrete causing it to crack, break, or

change color.

EP Henry accepts no responsibility for damage resulting from

non-conforming use of the re pit.

See back cover for further safety guidelines.

800.44.HENRY | ephenry.com

CAST STONE WALL SQUARE FIRE PIT KIT INSTALLATION DETAIL

CAST STONE WALL SQUARE FIRE PIT KIT CROSSSECTION

CAST STONE WALL SQUARE FIRE PIT KIT

INSTALLATION GUIDELINE

800.44.HENRY ephenry.com EPHenryUSA

© 2018 EP Henry. All rights reserved. Rev818

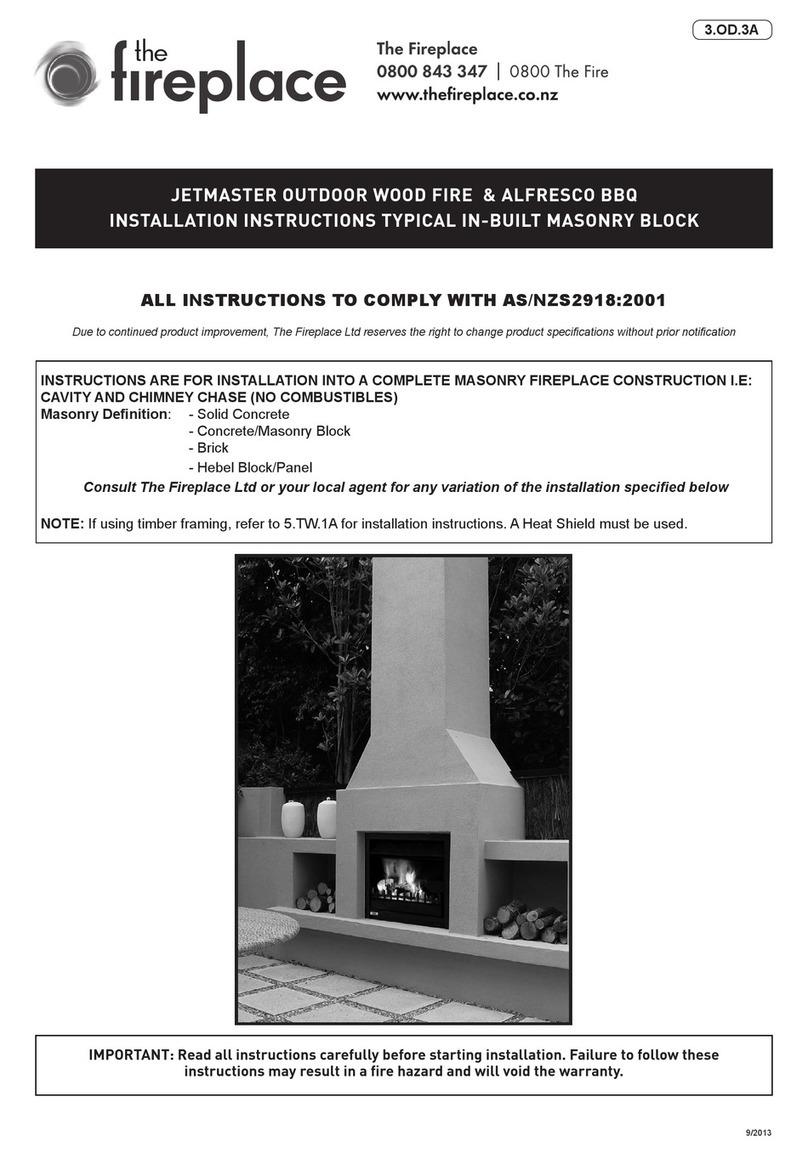

EP HENRY FIRE PIT SAFETY GUIDELINES

Read all safety recommendations carefully. Before

assembling your EP Henry Fire Pit read all of the instructions

and installation guidelines.

Contact your local building code or fire safety code ocials

to obtain any regulations regarding the construction and use

of fire pits in your community. Make sure you comply with

those regulations.

SELECTING THE LOCATION OF YOUR FIREPIT

Choose a location that is at least 20 feet away from any

structures.

Make sure that there are no overhanging objects such as tree

branches, canopies, cantilevered roof structures, or other

elements that are ammable and could catch on re.

Never build a re pit for use indoors in a house, warehouse,

gazebo, garage, or any other indoor setting.

Make sure that combustible materials such as wood chips,

mulch, ornamental grasses, propane tanks, barbeque grills and

other ammable materials are a safe distance away.

Never use re accelerants such lighter uid, kerosene,

gasoline, etc. to start or maintain res.

Keep children away from the re pit while burning res. Never

leave children unsupervised around a re.

Always burn res in the right weather conditions. Strong winds

may blow sparks or embers out of the re pit creating a re

hazard

Always use a long re tool to manage the re.

Never touch the grilling racks while a re is lit. The grilling

racks will become extremely hot and burn skin on contact.

Never use the re pit to dry cloths, laundry, or other damp

items.

Never sit too close to the re. Establish seating positions at

least three feet away from the re pit.

Always use re resistant gloves when placing wood into the

re, or cooking on the grilling racks.

Always have a source of water or re extinguisher available in

case of emergencies.

Always burn dry hardwoods in your re pit. Do not burn

lumber, plywood, trash, leaves, or other debris in your

re pit.

Never stack too much wood in the re pit. Make sure the re

wood being burned is kept well below the top of the re pit (1’

or more) and held away from the walls of the re box.

Unless there is an emergency, never extinguish the re with

water. It may cause the wall caps or re pit block to crack

or spall.

Do not light res if the wind is blowing toward structures or if

the wind is strong allowing sparks to carry any distance away

from those maintaining the re.

Do not allow ash to build up in the re box. Never throw out

embers. Make sure that all ash is completely cold before

disposing of it.

EP HENRY IS NOT RESPONSIBLE FOR:

Damages, injuries, or expenses caused by use of the re pit

or its use in areas where there are hazardous or ammable

materials, ammable gases, reworks, or any sources of

collateral combustion or explosion.

Damages, injuries, or expenses caused by improper use or use

not compliant with the safety guidelines.

Damages, injuries, or expenses resulting from the misuse,

accidents, negligence, delinquent behavior, or secondary res

resulting from use of the re pit.

Damages, injuries, and expenses caused by insucient

maintenance of the re pit, re box, grilling racks, or any other

element of the re pit.

Other EP HENRY Outdoor Fireplace manuals

Popular Outdoor Fireplace manuals by other brands

The Fireplace

The Fireplace JETMASTER 700 D installation instructions

Superior

Superior VRE4543EN Installation and operation instructions

Napoleon

Napoleon PATIOFLAME GPFN Installation and operation instructions

Endless Summer

Endless Summer Dakota GAD19101ES owner's manual

Vermont Castings

Vermont Castings ODGSR36A Homeowner's installation and operating manual

FEUERHAND

FEUERHAND PYRON user manual