ADL500 • Quick installation guide 3

Sommario

Information about this manual ....................................................................................................... 2

1 - Safety Precautions ..................................................................................................................... 4

1.1 Symbols used in the manual ............................................................................................................................................... 4

1.2 Safety precaution................................................................................................................................................................. 4

1.3 General warnings ................................................................................................................................................................ 5

1.4 Instruction for compliance with UL Mark (UL requirements), U.S. and Canadian electrical codes...................................... 6

1.5 Disclaimer............................................................................................................................................................................ 6

2 -................................................................................................................. 7

3 ............................................................................................................................... 8

3.................................................................................................................................................... 8

3.2 Standards ............................................................................................................................................................................ 8

3.3 Control modes ..................................................................................................................................................................... 8

3.4 Precision.............................................................................................................................................................................. 8

3.4.1 Speed control .......................................................................................................................................................................................8

3.4.2 Speed control limits..............................................................................................................................................................................8

3.4.3 Torque control.......................................................................................................................................................................................9

3.4.4 Current rating .......................................................................................................................................................................................9

3.5 Input electrical data ............................................................................................................................................................. 9

3.6 Output electrical data......................................................................................................................................................... 10

3 ................................................................................................................................................10

3.............................................................................................................................................10

3.6.3 K: Ambient temperature reduction factor.......................................................................................................................................... 11

3.7

..................................................................................................................... 11

3.8

No-load consumption (Energy rating)...................................................................................................................................... 11

3.9 Cooling .............................................................................................................................................................................. 11

3.10 Weights and dimensions.................................................................................................................................................. 12

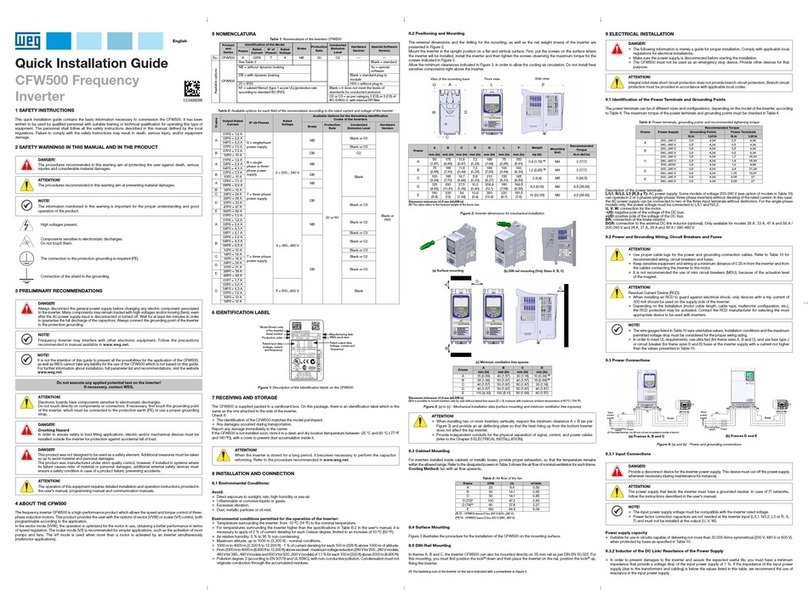

4 - Mechanical installation ............................................................................................................ 13

4.1 Maximum inclination and assembly clearances ................................................................................................................ 13

4.2 Fastening positions............................................................................................................................................................ 14

5 - ............................................................... 15

5.1 Power section .................................................................................................................................................................... 16

5.1.1 Power terminals and connection ........................................................................................................................................................16

5.1.2 Cable cross-sections..........................................................................................................................................................................16

5.1.3 Connection of shielding (recommended)............................................................................................................................................16

5.2 Regulation section ............................................................................................................................................................. 17

5.2.1 Cable cross-sections..........................................................................................................................................................................17

5.2.2 I/O and Relays connection .................................................................................................................................................................17

5.2.3 Feedback Connection ........................................................................................................................................................................18

5.2.4 +24V supply connection .....................................................................................................................................................................18

5.2.5 Safety STO connection (SFTY-STO)..................................................................................................................................................19

5.2.6 Led .....................................................................................................................................................................................................19

5.3 Typical connection diagram ............................................................................................................................................... 20

6 - Use of the optional keypad (KB-ADL500)............................................................................... 22

6.1 Description......................................................................................................................................................................... 22

6.1.1 Membrane keypad..............................................................................................................................................................................22

6.1.2 Meaning of LEDs................................................................................................................................................................................22

6 .................................................................................................................................. 23

6......................................................................................................................................23

6.2.2 Display of a parameter ......................................................................................................................................................................23

6.3.................................................................................................................................................... 24

6.4 Alarms................................................................................................................................................................................ 24

6.4.1 Alarm reset .........................................................................................................................................................................................24

6.5 ............................................................................................................... 24

6.6 .................................................................................................. 24

7 - Startup wizard for Asynchronous motor ................................................................................ 26

8 - Startup wizard for Brushless motors...................................................................................... 33

9 - Optimization wizard.................................................................................................................. 39

10 - Troubleshooting...................................................................................................................... 41

10.1 Alarms.............................................................................................................................................................................. 45

10.1.1 EFC application alarms ....................................................................................................................................................................48

10.2 Speed fbk loss alarm according to the type of feedback ................................................................................................. 49

10.2.1 Reset Speed fbk loss alarm .............................................................................................................................................................51

10.2.2 Encoder error alarm .........................................................................................................................................................................51

10.3 Messages ........................................................................................................................................................................ 52