Epcos BR 7000 User manual

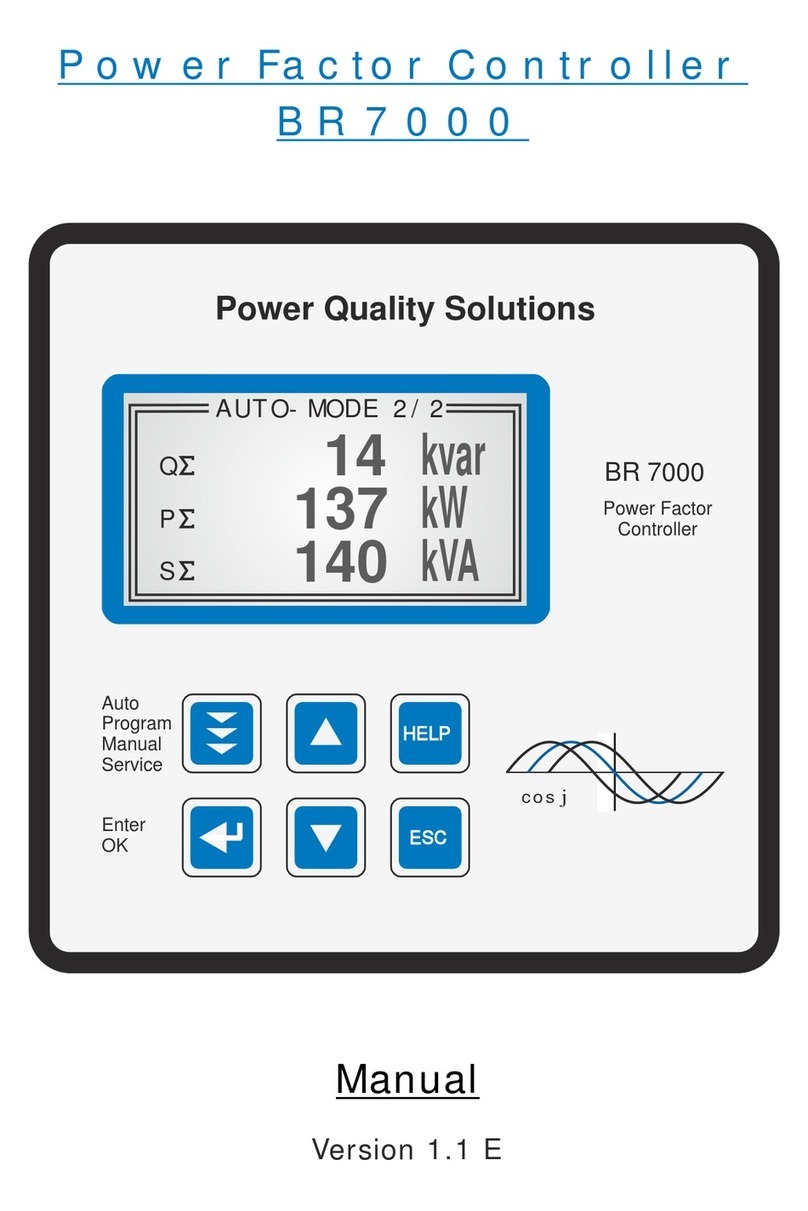

PowerFactorController

BR7000

Manual

Version 4.0 E

Power Factor

Controller

BR 7000

Auto

Program

Manual

Service

Enter

OK

Power Quality Solutions

HELP

ESC

0.869 IND

0.869 IND

0.869 IND

L1

L2

L3

1 2 3 4

AUTO-MODE cos ϕ

PC-Software „BR7000-Soft“ (enclosed with delivery)

Windows-Software for programming of the PF-controller BR7000 and for visualization,

storageandanalysis ofgrid parameters.

RConnection to RS485-Bus

RAdministration of several controllers possible

RDirect connection to USB-port of PC via accessory USB-adapter

It allows a comfortable visualization and analysis of grid parameters during online-

operation. At the same time, the storage and graphical analysis of all recorded data incl.

the export- and printing function can be performed. The spectrum of harmonics can

promptlybe displayedas bar chart.

The display and recording mode allows a convenient online-display of different grid

parameters. 3 display arrangements with each up to 12 different parameters can be

shownsimultaneously.All values displayed can be recorded for a later processing.

The step display deliversdetailed informationabout thesingle switchingsteps.

With the configuration manager all parameters of the BR7000 can completely be read

out, edited and stored and can be delivered back to the device. All values can be recorded

ina configurationfile.

The graphic mode allows the graphical display of recorded grid parameters for a

congruent evaluation. All values can be freely configured. Copy and print function are

possible.

A graphic bar diagram in the online-mode allows the display of voltage and current

harmonicsat oneglance.

A detailed description of all software functions can be found in the brochure resp. in the

online-help-functionof thesoftware.

CONTENTS

Section1 General p.3

Section2 Installation andinstructions forusage p.4

Section3 Connection alternativesmeasuring voltage p.6

andmeasuring current

Section4 Display functions p.8

Section5 Display ofgrid parameters p.9

Section6 PROGRAM-MODE /Manual programming p.11

6.1Programminglock p.18

Section7 HELP-function /actual assignmentof outputs p.19

Section8 Alarm relay/ Errormessages p.19

Section 9 MANUAL OPERATION p.21

Section10 SERVICE MENU/ Fault memory p.22

Section11 EXPERTMODE

11.1 Expert-Mode1 p.23

11.2 Expert-Mode2 p.25

Section12 OSCI-MODE p.26

Section13 DISPLAY-editor p.26

Section14 Maintenance andwarranty p.26

Section15 INTERFACES p.27

Section16 C-TEST MODE and TEST-RUN p.29

Controlprinciple p.30

ASCII-protocol p.31

Application:Controller coupling p.31

Appendixes/Tables:

Annex1 Controlseries table/ editor p.32

Annex2 Troubleshooting p.33

Annex3 Technicaldata p.35

Annex4 Factory settings p.37

Annex5 Operationdiagram p.39

CAUTIONS: 1. High voltage !

2. BR7000 may only be used indoor !

3. Make sure that the discharge time set in the controller matches

the capacitor discharge time !

- 2 -

!

Section 1: GENERAL

The power factor controller BR7000 is the consequent follow-up development of the well

provenseriesBR6000.

The main distinctive feature is the new 3-phases measuring system. Due to the 3-phases

recording of voltage and current the device allows a convenient usage as grid measuring

deviceand aspower factorcontroller.

All measuring values can be edited and may be displayed in big letters for easier

readability.

2 interfaces are standard. By means of the comfortable windows-software that is included

in the delivery and by using one interface for a connection to a PC the execution and

evaluation of grid measurements is possible. The second interface can be used for

customerspecific purposes.

Used as PF-controller various control modes are available. They allow not only to control

according to the phase with the highest load or the average demand of the phases, but

also to realize a real single-phase control (balancing) or a mix of balancing and

conventionalthree-phases-control.

All well proven functions of the BR6000-series are available for the BR7000; for example

the control series editor, the test-run etc. For an easy usage the concept of graphic menu

navigation has mainly been adapted. New are amongst others an integrated help (HELP-

button) and the possibility to jump back in the programming menu by an additional

ESCape-button.

The usage of a fully graphic support display allows an additional Oscilloscope-Mode where

thephases (halfwaves)of voltageandcurrent cangraphicallybe displayed.

R3 x 5 free programmable switching outputs

R1 alarm relay, 1 programmable message relay, 1 relay for the cabinet fan

ROperating voltage: 110 ... 440VAC (+/-10%)

RMeasuring voltage: 3 x 30 ... 440 VAC (L-N) / 50...760 V (L-L)

RMeasuring current: 3 x 5A / 1A

RPre-programmed control series and control series editor

RIlluminated graphic display 128 x 64 dot, graphical menu navigation

R4-quadrant-operation

RAutomatic test-run possible

RMeasuring of capacitor current possible

RThree-phase display of various grid parameters ( U, I, F, Q, P, S Delta Q ... )

RDisplay up to 31st harmonic of voltage and current

RSimultaneous graphical display 1 period of voltage and current in Osci-mode

RMonitoring of temperature and particular capacitor output

RStorage of maximum grid parameters and switching operations/switch on times of

capacitors with time stamp

RManual/automatic operation

RProgramming of fixed steps or mascing of particular outputs possible

RControl possible as 3-phase, 1-phase or mixed-mode

RDisplay of different error messages, error storage

RComplete 2nd parameter set programmable

R2 integrated separate interfaces

RFirmware update possible, controller coupling possible

RIntegrated clock, several timers possible

RIntegrated help-function/plain text

RPanel-mounted instrument 144 x 144 x 50 mm

- 3 -

- 4 -

Section 2: INSTALLATION AND INSTRUCTIONS FOR USAGE

The BR7000 is designed as panel mounting instrument in PFC-systems. This requires a

cut out of 138 x 138 mm according to DIN 43700 / IEC 61554. The controller has to be

inserted from the front and fixed with the clamps (included in delivery). The device may

only be installed by qualified personnel and may only be operated according the given

safety regulations. In addition the relevant legal and safety instructions have to be

obeyed.

The measuring input is designed for 1- and 3-phase grids with or without neutral

conductor.Themaximum measuringvoltage is440V~ (L-N) / 760V ~ (L-L).

Thesupply voltageis 110...440V +/-10%.

Wiring connections must be suitable for the particular voltages. Input leads have to be

protected by over-current-protection devices. The supply voltage must be protected by a

fuse;it mustbe possibleto switch off the supply voltageby aseparator.

Thedevice mustnot beoperatedwithout protectiveearth contactorconnected!

Before connecting the BR7000, it has to be checked that all connections are at zero

potential; current transformers have to be short circuited. Correct phasing of measuring

voltage and measuring current have to be checked. The measuring current circuits must

2

bewired with minimum 2.5mm Cu.

Terminals mayonly beplugged whende-energized!

Attention!

During single-phase operation the coil voltage for the capacitor contactors must be drawn

from the same phase as the measuring voltage as only the measuring voltage is

monitored. (Protection against direct re-switching of contactors during a short-term

single-phasevoltage drop.)

The controller may only be operated when installed. The complete programming of all

application-specific parameters is done according chapter programming. Then the device

is set to automatic operation by pushing the operation mode button. The controller is now

readyfor operation.

Operating the controller without following to these operating instructions may be harmful

anddangerous!

!

!

!

Rear view

Operating mode:

- Automatic

- Program.

- Manual oper.

- Service

- Expert Mode

- Osci - Mode

- Display Editor

ENTER/ OK

Confirmation

storage of

values

Increase

selected

parameter

HELP

opens

Help pages

Reduce

selected

parameter

Escape

previous

page/value

in the display

- 5 -

Front view

The controller is supplied for a standard operating voltage of 110...440VAC (+/-10%), a

measuring voltage of 30...440 V~ (L-N) resp. 50...760V~ (L-L), 50/60Hz, and a

measuring current of 5A or 1A (programmable). A voltage converter is required for

differentoperatingvoltages.

Caution!

Voltages which exceed the allowed voltage range can damage the

device !

!

Power Factor

Controller

BR 7000

Auto

Program

Manual

Service

Enter

OK

Power Quality Solutions

HELP

ESC

HELP

ESC

The allocation of switching outputs K1…K15

to the capacitors complies to the selected

connection variant and the desired

CONTROL-MODE

(Programming/point2)

Especially in ”Mixed Mode“ where some

outputs are used for single phase capacitors,

others for 3-phase-capacitors the proper

connectionmust beassured!

In the “HELP”-menu the BR7000 directly

displays the actual correct allocation of

outputs(AUTO-MODE:Help-page 7-9).

Forexamplesalso see page20

Power factor regulator BR7000

P3 K11 K12 K13 K14 K15 K23

Meßstrom

l L3 k

Betriebs.spg

110...440V~ Meßspannung

30 ... 440V L-N

Output 11-15 Fan relay

Meßstrom

l L2 k Meßstrom

l L1 k

Interface COM1

connection of 2nd connector-line

Switch.input

230V~

N L3 L2 L1

1 2

on

Termination

On top:

Interface

COM2

P1

P2

K1

K6

K2

K7

K3

K8

K4

K9

K5

K10

K21

K22

Output 6-10

Output 1-5

Message relay

Alarm relay

Type: BR7000

Meas. Voltage: 50 - 690VAC 50/60Hz

Supply voltage: 110 - 440VAC 50/60Hz

Ser.No.:

0.869 IND

0.869 IND

0.869 IND

L1

L2

L3

1 2 3 4

AUTO-MODE cos ϕ

Section 3: CONNECTION ALTERNATIVES MEASURING VOLTAGE

AND MEASURING CURRENT

According to the existing grid and the desired operating mode (CONTROL-MODE

Programming)theBR7000 hasto beconnected accord.one ofthe followingalternatives.

In grids without neutral conductor the connector N from meas.voltage at the

controller has to be open.

Program the ExpertMode 1 as: 13 U-connection: -- L1 - L2 - L3

Alternative1: measuringperformedineachphase-3currenttransformersneeded

Use: CONTROL-MODE:1-4

BR7000

Alternative2: single-phasemeasuringviacurrenttransformerinL1 Valuesextrapolated(balanceassumed).

Measuring complies with conventional measuring for switching of three-phase capacitors.

Use:CONTROL-MODE5

BR7000

Alternative 3: single-phase measuring as alternative 2 , but with capacitor current measuring in the compensation

systemforcollectionofrealcapacitorcurrents.

Use:CONTROL-MODE6

BR7000

Reserve

PE

N

L2 (S)

L3 (T)

L1 (R)

( L1) ( N ) L1 L2 L3 N(PE)*

Supply voltage

110-230V~ Measuring voltage Um Meas.current

L3

Meas.current

L2

Meas.current

L1

Load site

( L1) ( N ) L1 L2 L3 N(PE)*

Supply voltage

110-230V~ Measuring voltage Um Meas.current

L3

Meas.current

L2

Meas.current

L1

L1 (R)

L2 (S)

L3 (T)

PE

N

Load site

- 6 -

( L1) ( N ) L1 L2 L3 N(PE)*

Supply voltage

110-230V~ Measuring voltage Um Meas.current

L3

Meas.current

L2

Meas.current

L1

L1 (R)

L2 (S)

L3 (T)

PE

N

L1 L2 L3 N

PF C- system

- 7 -

kK k K

lL l L

Feed 1 Feed 2

K L K L

Measurement via sum current converter

P.F.Controller

Current

measurement

k l

k l

Example:

C.converter 1: 1000/5A

C.converter 2: 1000/5A

Sum-current converter: 5A+5A / 5A

C.converter ratio is: 2000 /5A

Connection of current transformer / sum current transformer

When installing the current converter, care should be taken to ensure that the load

current flows through it. The outputs of the compensation network must be installed

behind the current converter (in the direction of current flow). If the is connected

upvia sum-current converters,theoverallconversionratioisentered.

Caution!

Thesecondary clampsof theCT

havetobe shortcircuited before

currentleads areiterrupted !

BR7000

!

BR7000 in High Voltage Application

Theexample showsthe connectionof BR7000in HV-application.

The measuring current is taken off primary via X/1A transformer. Measuring voltage

produced via transformer 20000/100 V. In this case, the BR7000 has to be programmed

asfollows:

4 I-CONVERTER sek: X/ 1A

14 MEASUR.VOLTAGE (L-N): 100V:1,73= 58V

15 V-CONVERTER: 20kV/ 100V

L1 (R) L1 (R)

L2 (S) L2 (S)

L3 (T) L3 (T)

N

Meas.current

Im (X/1A) supply

voltage

Ub

Meas-

voltage

Um

BR 7000

PE

Meas.current Meas. voltage Um Supply voltage Ub

L1 L2 L3 L1 L2 L3 N L1 N

HIGH VOLTAGE LOW VOLTAGE

20 kV / 400 V

20000

100

Section 4: DISPLAY - FUNCTIONS

After the operating voltage has been switched on, the BR7000 briefly indicates with

descriptionand software-versionbefore changingto automaticoperation.

Actualvaluesand symbolsof theparticular operationstateare shownin thedisplay.

In the automatic operation (standard) capacitor steps are automatically switched on or

off to reach the pre-set target cos-phi. This happens when the required reactive power is

higherthan thevalueof thesmallest capacitorstep.

Example1: Automaticoperation

L1...L3:Individual compensationby single-phasecapacitors

- 8 -

Number of switching outputs until end stop.

Here: 15 three-phase capacitors, end-stop: 15

Control direction is symbolized by a

compact arrow:

Connecting-in

Connecting-out

The connecting-in arrow is always

located after the maximum possible

number of stages (end stop)

An open arrow indicates that the

required blocking time (Discharge time)

is running before an impending

switching step

A double arrow symbolizes switching of

several branches

The sigma-sign indicates the three-

phase-value (mean-value) resp.

activated three-phase-capacitors

Alarm relay activated

(declines in case of error)

Message relay activated: “SUPPLY”

Message relay activated:“Undercurrent”

Message relay aktivated: “Harmonics”

FAN-relay: ON

The particular capacitor outputs are

permanently monitored. Inverse display

= capacitor out of range

Display of 2nd parameter-set

Supply display (i.e.generator operation)

nd

2 Target-cos phi activated by timer

nd

2 Target-cos phi activated by supply

nd

2 Target-cos phi activated by supply

a

ERROR COM

nd low load operation

S

A

U

H

F

2

T

L

E

é

é

Example2: Automaticoperation(MixedMode)

L1...L3: phasewise compensationby

singlephase capacitors

Σ: Three-phasecapacitors activated

Example3: Automaticoperation

Measuringin onephase

Controllingof 15three-phase-capacitors

Σ

0.869 IND

0.869 IND

0.869 IND

0.917 CAP

L1

L2

L3

1 2 3 4

Σ

Σ

Σ

AUTO-MODE cos ϕ

AUTO-MODE cos ϕ

AUTO-MODE cos ϕ

L1

L2

L3

1 2 3 4

123456789

10 11 12 13 14 15

control direction

(here: connected-in)

active capacitor

branches

Section 5: DISPLAY OF GRID PARAMETERS

5.1 Display of 3 selected grid parameters

In Auto-Mode, button éleads to display mode 1. Here 3 (free selectable) grid parameters

are displayed in large letters. The selection and storage of these values is done in the

Display- Editor.

Example: Displaymode 1:

Desiredvaluesselected inthe

DisplayEditor (seesection 13)

5.2 Display of particular grid parameters (from AUTO-MODE by pressing ENTER)

By repeated activation of the “ENTER”-button (in automatic operation) several grid

parameterscanbe displayed(s.table below):

Action Display Unit in% Bargraph 3-phase

possible

ENTER 1 LINEVOLTAGE V x

ENTER 2 CURRENT A (apparent-,active-,reactive) x

ENTER 3 REACTIVEPOWER kvar x

ENTER 4 ACTIVEPOWER kW x

ENTER 5 APPARENT POWER kVA x

ENTER 6 DIFF. kvar to target kvar x

ENTER 7 FREQUENCY Hz

ENTER 8 TEMPERATURE °C/ °F

ENTER 9 3.-31. HARMONICS V/ I x x x

ENTER 10 HARMONICSTHD-V/I x x x

ENTER 11 Comp.- power (onlyat realcapacitor currentmeasurement)

ENTER 12 ENERGY kvarh /kWh (+),(-)

ENTER 13 TIME/ DATE é/êchange thedate format

ENTER 14 Softwareversion é/êmore information

ENTER returnto: 1

Buttons é/êchange thedisplay format:

Thevaluescan bedisplayedin theirunit, in% or as bar chart.

Examples,see nextpage.

- 9 -

14

137

140

kvar

kW

kVA

Q

P

S

=== DISPLAY ===

Examplesof differentdisplays:

VOLTAGE 3-phas. CURRENT: 3-phas. REACTIVE PWR 3-phas.

HARMONICSin % TEMPERATURE °C DIFF.REACTIVE PWRin %

HARMONICSdiagram THDV/I asbar diagram ENERGY

- 10 -

Repeated pressingof the"OperatingMode” keyactivatesthevariousmenus insequence:

- Automaticoperation

- Programming

- Manual Mode

- Service

- Expert-Mode 1 and 2

- Osci-Mode

- Display-Editor

- INTERFACE Mode

- C-TEST MODE

and backto Auto.

L1 V 0.4% I 0.5%

L2 V 1.4% I 0.8%

L3 V 1.4% I 0.7%

L1-N 233 V

L2-N 233 V

L3-N 233 V

2 CURRENT

8 TEMPERATURE

29°C

1 LINE VOLTAGE

9 HARMONICS [3]

2 STROM

2 STROM

12 ENERGY

L1 235 A

L2 133 A

L3 133 A

L1 71 kvar

L2 23 kvar

L3 22 kvar

116 kvar

L1 52 kvar

40.4 kWh (+)

0.4 kWh (-)

20.4 kvarh(+)

0.0 kvarh(-)

L2 50 kvar

L3 46 kvar

1.0%

0.5%

0% 3579

11 13 15 17 19 21 23 25 27 29 31

20%

10%

0%THD V 1 2 3 THD I 1 2 3

DISPLAY [ 1]

DISPLAY [ 1]

DISPLAY [ 1] - THD

DISPLAY

DISPLAY [ 7]

DISPLAY

DISPLAY

DISPLAY

3 REACTVE POWER

6 DIFF-REACTIVE POWER

9 HARMONICS I-1 [4]

Section 6: PROGRAM-MODE (manual programming)

Pressing the button “Operation Mode“ one time switches from automatic operation to the

programmode.

The upper part of the display always shows the parameter, the adjustable values are

shown in the lower part. Editable values are generally given in square brackets. Changes

of these values can be done by the buttons é/ ê. By pressing the “ENTER-button” the

valueisstored. Pressingthe “ESC”-buttonallows togo onestep back(without storing).

1 LANGUAGE

Thisselects thelanguage ofthe operatingmenu

[GERMAN, ENGLISH, SPANISH, RUSSIAN, TURKISH]

2 CONTROL-MODE [1...12]

CONTROL-MODE [1]:

3-phase measuring / max. 3x5 single phase capacitors L-N

(3 current transformers needed), values displayed and calculated per phase.

Connection of measuring current and measuring voltage (refer to page 6).

Controlling is done with max. 5 outputs per phase in case of switching of single-

phasecapacitors L-N.

Allocation of switching outputs K1…K15 to the capacitors according to the selected

connectionvariantand thedesired CONTROL-MODE.

Especially in ”Mixed Mode“ where some outputs are used for single phase

capacitors, and others for 3-phase-capacitors the proper connection must be

assured!

In the HELP-function the BR7000 directly displays the correct allocation of outputs

(AUTO-MODE: Help-page7-9).

!

- 11 -

Example :

3x 5 single-phase capacitors (L-N)

Output assignment

L1 (R)

L2 (S)

L3 (T)

P1 1 2 3 4 5 P2 6 7 8 9 10 P3 11 12 13 14 15

Output 1-5 Output 6-10 Output 11-15

meas.voltage L1 meas.voltage L2 meas.voltage L3

PE

N

F1: 6,3AT F1: 6,3AT F1: 6,3AT

C1.1 (C1 at L1-N)

C1.2 (C1 at L2-N)

C1.3 (C1 at L3-N)

C2.1 (C2 at L1-N)

C2.2 (C2 at L2-N)

C2.3 (C2 at L3-N)

C3.1 (C3 at L1-N)

C4.1 (C4 at L1-N)

C5.1 (C5 at L1-N)

C3.2 (C3 at L2-N)

C4.2 (C4 at L2-N)

C5.2 (C5 at L2-N)

C3.3 (C3 at L3-N)

C4.3 (C4 at L3-N)

C5.3 (C5 at L3-N)

K1

(K2)

(K3)

(K4)

(K5)

K6

(K7)

(K8)

(K9)

(K10)

K11

(K12)

(K13)

(K14)

(K15)

C1.1

(C2.1)

(C3.1)

(C4.1)

(C5.1)

C1.2

(C2.2)

(C3.2)

(C4.2)

(C5.2)

C1.3

(C2.3)

(C3.3)

(C4.3)

(C5.3)

=== PROGRAM-MODE ===

CONTROL-MODE [2]: MIXED-MODE 3-phasige measuring

3 current transformers required. Values displayed and calculated per phase. Connection of

measuringcurrentandmeasuring voltage seepage6.

Controllingdonewithmax.4 outputs per phase for switching of single phase capacitors L-N.

The rest of the outputs (min. 3, max. 12) are used for switching of three-phase capacitors

tocontrol the base load.

Partitioninginto single-phase / three-phase capacitors is done at

Programming:4ENDSTOP!

The allocation of the switching outputs to the particular capacitors can be retrieved in AUTO-

MODEon HELP-pages 7…9.

CONTROL-MODE [3]:

3-phase measuring / max. 3x5 single-phase capacitores L-L

3current transformersrequired. Values displayedand calculated per phase.

Controllingdone with max.5 outputs per phase, switching of single phase capacitors L-L

L1 (R)

L2 (S)

L3 (T)

Example:

3x 4 single-phase-capacitors +

3 standard 3-phase capacitors

Output assignment

3 x 4 Single-phase steps

3 Three-phase-

capacitors

P1 1 2 3 4 5 P2 6 7 8 9 10 P3 11 12 13 14 15

Output 1-5 Output 6-10 Output 11-15

meas.voltage L1 meas.voltage L2 meas.voltage L3

PE

N

K 5

(K10)

(K15)

F1: 6,3AT F1: 6,3AT F1: 6,3AT

C1.1 (C1 at L1-N)

C1.2 (C1 at L2-N)

C1.3 (C1 at L3-N)

C2.1 (C2 at L1-N)

C2.2 (C2 at L2-N)

C2.3 (C2 at L3-N)

C3.1 (C3 at L1-N)

C4.1 (C4 at L1-N)

C3.2 (C3 at L2-N)

C4.2 (C4 at L2-N)

C3.3 (C3 at L3-N)

C4.3 (C4 at L3-N)

C1Σ(C1 3-phas.)

C2Σ(C2 3-phas.)

C3Σ(C3 3-phas.)

C1Σ

( C2Σ)

( C3Σ)

K1

(K2)

(K3)

(K4)

K6

(K7)

(K8)

(K9)

K11

(K12)

(K13)

(K14)

C1.1

(C2.1)

(C3.1)

(C4.1)

C1.2

(C2.2)

(C3.2)

(C4.2)

C1.3

(C2.3)

(C3.3)

(C4.3)

L1 (R)

L2 (S)

L3 (T)

Example:

3x 5 single-phase capacitors (L-L)

Output assignment

P1 1 2 3 4 5 P2 6 7 8 9 10 P3 11 12 13 14 15

Output 1-5 Output 6-10 Output 11-15

meas.voltage L1 meas.voltage L2 meas.voltage L3

PE

N

F1: 6,3AT F1: 6,3AT F1: 6,3AT

C1.1 (C1 at L1-L2)

C1.2 (C1 at L2-L3)

C1.3 (C1 at L3-L1)

C2.1 (C2 at L1-L2)

C2.2 (C2 at L2-L3)

C2.3 (C2 at L3-L1)

C3.1 (C3 at L1-L2)

C4.1 (C4 at L1-L2)

C5.1 (C5 at L1-L2)

C3.2 (C3 at L2-L3)

C4.2 (C4 at L2-L3)

C5.2 (C5 at L2-L3)

C3.3 (C3 at L3-L1)

C4.3 (C4 at L3-L1)

C5.3 (C5 at L3-L1)

K1

(K2)

(K3)

(K4)

(K5)

K6

(K7)

(K8)

(K9)

(K10)

K11

(K12)

(K13)

(K14)

(K15)

C1.1

(C2.1)

(C3.1)

(C4.1)

(C5.1)

C1.2

(C2.2)

(C3.2)

(C4.2)

(C5.2)

C1.3

(C2.3)

(C3.3)

(C4.3)

(C5.3)

=== PROGRAM-MODE ===

CONTROL-MODE [4]: 3-phase measuring / max. 15 three-phase capacitors

Connectionof measuring current and measuring voltage referto page 6.

Values displayedand calculated per phase. Controlling done with max. 15 outputs according

tomaximum or mean-value of the reactivepower

CONTROL-MODE [5]: 1-phase measuring / max. 15 three-phase capacitors

Onlycurrent transformerin L1 required

Connectionof measuring current and measuring voltage see page 6

Values extrapolatedto all phases (balance assumed)

Measuringcomplies with conventional measuring for switching of three-phase capacitors.

CONTROL-MODE [6]: 1-phase measuring / max. 15 three-phase capacitors

with internal capacitor current measurement

According variant 5, but the free current inputs (L2 or L3) are used for internal capacitor

current measurementfor real monitoring of capacitors.

Connectionof measuring current and measuring voltage see page 6 -pict. 3!

CONTROL-MODE [7]: 3-phase measuring / max. 15 three-phase capacitors

Externalmeasurement for real monitoring of capacitors via 1...6 pcs. devices „MMI6000”

Programmingof numbers of MMI in C-TEST MODE

Canbe used for 1...6 cabinet-parts

Connectionof MMI6000 via LAN-cables (COM2 at BR7000)

Connectionof BR7000: compare Control-Mode 4

CONTROL-MODE [8]: 1-phase measuring / max. 15 three-phase capacitors

Externalmeasurement for real monitoring of capacitors via 1...6 pcs. devices „MMI6000”

Programmingof numbers of MMI in C-TEST MODE

Canbe used for 1...6 cabinet-parts

Connectionof MMI6000 via LAN-cables (COM2 at BR7000)

Connectionof BR7000: compare Control-Mode 5

CONTROL-MODE [9]: 3-phase measuring / max. 3x5 single phase capacitors L-N

correspondto Control-Mode 1, but remote measurement via „MMI7000"

Canbe used if CT is far awayfrom thecontroller or MMI7000 already exists in the system

Connectionof MMI7000 is done via LAN-cable to COM2 at BR7000

Connectionof MMI7000: compare connection of BR7000 at page6 / pict.1

Connectionof BR7000: 3-phase voltage only, no connection of CTs needed.

CONTROL-MODE [10]: 3-phase measuring / max. 15 three-phase capacitors

correspondto Control-Mode 4, but remote measurement via „MMI7000"

Connectionof MMI7000 is done via LAN-cable to COM2 at BR7000

Connectionof MMI7000: compare connection of BR7000 at page6 / pict.1

Connectionof BR7000: 3-phase voltage only, no connection of CTs needed.

CONTROL-MODE [11]: 3-phase measuring / max. 15 three-phase capacitors

Remote measurement and internal real monitoring of capacitors (L1...L3)

correspondto Control-Mode 6, but remote measurement via „MMI7000"

internalreal monitoring of capacitors via current inputs L1...L3

e.g.Monitoring for 1...3 cabinets

Connectionof MMI7000 is done via LAN-cable to COM2 at BR7000

Connectionof MMI7000: compare connection of BR7000 at page6 / pict.1

CONTROL-MODE [12]: 3-phase measuring / max. 15 three-phase capacitors

Remote measurement and internal real monitoring of capacitors (L1...L3)

correspondto Control-Mode 6, but remote measurement via „MMI7000"

internalreal monitoring of capacitors via current inputs L1...L3

-->Single-phase monitoring for 1 cabinet

Connectionof MMI7000 is done via LAN-cable to COM2 at BR7000

Connectionof MMI7000: compare connection of BR7000 at page6 / pict.1

- 13 -

=== PROGRAM-MODE ===

3 I-CONVERTER PRIM [1000] A/ X (5 ...13000) A

Selectsthe primarycurrent ofthe currentconverter.

Sequentialadjustment ofL1...L3.

viathe é/ êkeys. Save andcontinue withENTER

4 I-CONVERTER SEC 1000A /[5 ]A (1 /5 A )

Thissets thesecondary currentof thecurrent converter.

Selection via é/ê. Saveand continuewith ENTER

5 END STOPP

Programming of the maximum number of active

capacitorbranches.

Depending on the selected operation mode the

maximum number of connected capacitors at the output

groups L1…L3 and (if available) for the output groups Σ

(three-phasecapacitors) areset.

The visible symbols of the capacitors correspond to the

connectedoutputs.

Inputvia é/ ê.Saveand continuewith ENTER

6 CONTROL SERIES [1] (1...20 +ED )

The ratio of the capacitor branch powers determines the

control series, the power of the first capacitor always

beingassigned thevalue1.

Selection of desired control series consecutively for

L1…L3and for Σ(three-phaseoutputs).

If the required control series should not be present, the

user may define a special one in control series “ED” ( see

Annex4: Control-serieseditor )

7 CONTROL PRINCIPLE

The controlpreference maybe selected here:

SEQUENTIAL connection

LOOP connection

INTELLIGENT loop connection (defaultsetting)

COMBINED CHOKE

SeeSection 13for anexplanation ofthe control modes.

Selectionwith é/êkeys.

Saveandcontinue with ENTER

8 POWER 1st STAGE [0.01... 255.99] / [10...2550]kvar

To determine the controller's response sensitivity, the

dimensions of the smallest capacitor (stage 1) must be

known. They are entered in two steps in kvar. The

integral kvar values (before the comma) are initially

selectedvia theé/ êkeysand saved withENTER.

The positions after the comma are then selected, again

viathe é/êkeys.

If the capacitor value is below the response sensitivity, a

warning will occur ( indication of “!” in thedisplay )

- 14 -

7 CONTR.PRINCIPLE

[ INTELLIGENT ]

PROGRAM-MODE

3 I-CONVERTER PRIM

[ 1000]A / 5 A

1000]A / 5 A

1000]A / 5 A

L1

L2

L3

8 POWER 1.STAGE

[ 25].00 kvar

25 .00 kvar

25 .00 kvar

L1-N

L2-N

L3-N

6 CONTR.SERIES L1-N

12333

12333

12333

[ 3]

3

3

L1-N

L2-N

L3-N

1 2 3 4 5

5 END STOP L1-N

[ 5]

5

5

L1-N

L2-N

L3-N

1 2 3 4 5

PROGRAMM-MODE [5]

PROGRAM-MODE [1]

PROGRAM-MODE [3]

PROGRAM-MODE

- 15 -

=== PROGRAM-MODE ===

9 TARGET COS PHI [0.98 ind] ( 0.1ind ...0.1 cap)

By setting the target cos phi, the power factor to be

attainedvia thePF correctionis defined.

Sequentialsetting ofL1 ...L3 viaé/ ê,

Saveandcontinue withENTER.

10 TARGET 2nd cosPhi [NO ] (1...4 )

1:NO (no 2nd targetcosPhi,

continuewith 14)

2:Timer (2nd cosPhi -activatedby timer,

schedulerwith 12,13)

3:Energy supply (2ndtarget cos-phi- activatedby

Energy-supply)

4:Low load (2ndtarget cosPhi - activatedby

lowload (smaller than 3x1st stage)

11 TARGET 2nd cosPhi [ 0.9IND ] (0.1 ind ...0.1 cap )

Setpoint forthe 2ndtarget cosPhi

(onlyavailableif selectedunder 10)

12 SWITCH ON TIME ϕ2 [ HH:MM:SS]

Switch-ontime ofthe timerfor the2nd target-cos phi

(only available ifselected under10 )

13 SWITCH OFF TIME ϕ2 [ HH:MM:SS]

Switch-offtime ofthe timerfor the2nd target-cos phi

(only available ifselected under10 )

14 MEASURING VOLTAGE L-L[400]V ( 50...760)V

Programmingof measuring voltage.

The values programmed here always refer to the

voltage at the clamps of the controller !

Selectionvia é/ ê. Save/ continue with ENTER

15 V-CONVERTER [NO ] (300V-380kV/ 440V)

When a measuring-voltage converter (e.g. for HV-

measurement) is used, its conversion ratio is to be

programmedhere.

Selectionvia é/ ê. Save/ continue with ENTER

16 FREQUENCY [40...90]Hz (50Hz, 60Hz,16,7Hz)

Usefix-frequencyin gridswith difficultvoltage form

(harmonics)

17 CONNECTING TIME:[ 40 ] sec. (1 sec.... 130min.)

The time between connecting the capacitors to increase

the momentary network capacitance. It should be noted

that in practical operation the real connection time is

affectedby thedischarge time(locking time).

Selectionvia é/ ê. Save/ continue with ENTER

12 SWITCH ON TIME ϕ2

ON [16]: 00 MO-FR

OFF 07 : 00 MO-FR

15 V-CONVERTER

[NO]

PROGRAM-MODE [3]

PROGRAM-MODE

PROGRAM-MODE

10 TARGET 2nd cos ϕ

[ SUPPLY ]

PROGRAM-MODE

9 TARGET cos ϕ

[ 0.980 IND]

=== PROGRAM-MODE ===

18 DISCONNECT TIME: [ 40] sec. (1 sec.... 130min.)

The time between disconnecting the capacitors to reduce the momentary

networkcapacitance.

Selectionvia é/ ê. Save/ continue with ENTER

19 DISCHARGE TIME: [60 ]sec. ( 1 sec. ... 130min.)

This is the time for which an individual output is blocked between disconnecting

and connecting. It depends on the discharge device of the capacitor. The

discharge time of a conventional system without fast discharge resistors or

reactors should not be adjusted to less than the data sheet value of the used

capacitor.

Selectionwith buttons é/ê. Save /Continue with ENTER

20 ALARM TEMPERATURE [ 55 ] °C ( 20...80 )°C

The alarm temperature programmed here is the temperature at which a

stepwise disconnection of the capacitors is performed. After 10 min. the

standard alarm relay of the controller (K21) will respond. At the same time,

thedisplay showsthe causeof thealarm (over temperature).

When the temperature drops again, the required branches are automatically re-

connectedin steps.

Selectionwith é/ ê.Save/ Continue with ENTER

21 FAN TEMPERATURE [ 30 ] °C ( 15...70 )°C

Thresholdfor thefan relay (K23) forcontrol ofa cabinetfan.

22 MESSAGE RELAY [OFF ] (1...9 )

The message relay (K22) can be programmed for one of the following options

asrequired:

1 - OFF

2 - Supply: Messagewhen activepower issupplied.

3- Under current:

Messagewhen themeasuring currentis notmet.

Signalis generatedwhenthe currentvalue

dropsbelow theresponse sensitivityof thecontroller.

4 - Harmonics:

Messagewhen thelimiting valueof the total harmonic

distortionfactor (THD-V) isexceeded. This valuecan

beparameterizedunder ”38Harmonics” (in%).

5 - ERROR - System current measuring

6 - ERROR - Com1 (interface error)

7 - ERROR - Com2 (interface error)

8 - ERROR - Com1/2 (interface error)

9 - C-DEFECT

- 16 -

S

U

H

E

E

Display:

Display:

Display:

Display:

Display:

=== PROGRAM-MODE ===

23 EXTERNAL INPUT [NO ] (1...8 )

Setting of the desired action upon applying a control voltage of 110...230V~ at

theexternal input.

1- NO (no action)

2- 2nd parameter set (switch over to2nd parameter set).

Thisselection simultaneouslyactivatesthe followingpoints 24…37

forprogrammingof thevaluesof the2nd parameterset.

3 - External error (Displayof anerror message)

4 - Remote - Switch ON

5 - Remote - Switch OFF

6 - Remote - Stopp

7 - Coupling operation parallel COM2

(Inputfor signalof couplingswitch)

8 - Coupling operation Master/Slave COM2

(Inputfor signalof couplingswitch)

Descriptionof couplingoperations.page 31

Programming of 2nd parameter set

(only active if 23 EXTERNAL INPUT is set to 2nd parameter set)

As a standard, the values of the 2nd parameter set equal the values of the normal

parameter set. Possible applications are for example: changing of target cos-phi, switch-

overof current transformeror switch-overthe switchingtimes.

By triggering a 110...230V~ signal at the external input, the 2nd parameter set is

activated with following values:

The programming of the 2nd parameter set is performed equivalent to the

programming of the 1st set parameters (3-19)

38 HARMONICS [ 7 ]% (--.-- ... 25.5)%

Threshold value THD-V (in%). In case this value is exceeded a message will be displayed.

THD-V ist the ratio of the geometric sum of unequal harmonics to the 1st harmonic. In any

case, a warning will be displayed. Warning via message relay will only be executed if

selectedin 22.

24. I-converter prim

25. I-converter sec

26. End stop

27. Control serie

28. Control principle

29. Power 1st stage

30. Target cos-Phi nominal value

31. 2nd target cos-Phi NO/supply/Timer

32. 2nd target cos-Phi nominal value

33. Switch on time target cos-Phi-2

34. Switch off time target cos-Phi-2

35. Connecting time

36. Disconnecting time

37. Discharge time

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

- 17 -

=== PROGRAM-MODE ===

39 HARMONICS [--,-- ]% (--.-- ...25.5)%

Threshold value THD-I (in%). In case this value is exceeded a message will be

displayed.

40 CLOCK [HH:MM ], DATE [DD.MM.YY]

Setsystem-time anddate

(Due to an internal battery the time will be kept even in case of power loss)

Selectionwith é/ ê.Save/continuewith ENTER

41 Q-OFFSET (L1-L3) [NO ] ( multiple of 1st stage)

H

42 CONTRAST [4 ] (0...10)

Adjustmentof displaycontrastfor bestreadability

40 BASIC SETTINGS [NO ] (YES/NO)

When selecting YES and confirmated with ENTER, all parameters are set back to

the basic settings of the panel builder (optimum values for the system if

thecontroller hasbeen deliveredtogether withthe PFC-system).

If the controller has been delivered ex works, this point corresponds to the

defaultsettings.

ATTENTION: All user settings get lost !

Section 6.1: PROGRAMMING LOCK

As a protection against unauthorized changes of the system parameters, the device is

equipped with a programming lock. This can be activated in the EXPERT MODE. When the

lockis active,all parameters canbe checkedbutnot changed.

Alternatives:

Lockactive /Not active/ Automatic activationafter 24 h

ere an additional capacitive power is switched on independent from target

cos-phiand controlling - e.g. transformerdirect compensation.

(value programmable via arrow-keys).

- 18 -

Section 7: HELP-Functions / actual output assignment

TheBR7000 featuresa contextrelated helpfunction.

For each menu item one or more help pages are available which can be accessed directly

with the HELP-button. Scrolling is done with "UP/DOWN" buttons, back retrace with

ESCape.

In automatic operation (= = =AUTO-MODE= = =) 9 help pages are available. The first

pagesexplain thegeneralmeaning ofused symbols.

On the help pages 7…9 the actual assignment of the internal relay outputs

K01…K15to thephases andto thecapacitors areshown directly.

This table depends on the CONTROL-MODE that is set and will change

automatically.

The assignment shown here is not trivial, especially in CONTROL-MODE 2

(MIXEDMODE) andmust beobeyed withoutexeption!

s.example nextpage

Section 8: ALARM RELAY / ERROR MESSAGES

The contact of the alarm relay (K21) is closed during normal operation and opens in

case of failure. At the same time, the respective error is indicated in plain text in the

display:

UNDERCOMPENSATED - displayand relay

missing reactive power

OVERCOMPENSATED - displayand relay

OVERCURRENT - displayand relay

MEASURING VOLTAGE ??? - displayand relay

OVERTEMPERATURE - displayand relay

OVERVOLTAGE -display andrelay

UNDERVOLTAGE -display andrelay

HARMONICS - display andrelay

Additionally, several messages for different operation states are generated. An individual

adjustmentresp. maskingof singlemessages ispossible inEXPERT-MODE2.

During masking, the display of message, the eventual output via alarm relay and possible

influcenceson thecontrol processare suppressed.

- 19 -

!

Other manuals for BR 7000

1

Table of contents

Other Epcos Controllers manuals