EPI ENVIRO Cover Deployer 800 Operation manual

Enviro™Cover Deployer Model 800

Dispensing System

Operation and Service Manual

EPI Environmental Products Inc.

Tel: +1 (604) 738-6281

, EPI and Enviro™are registered marks of EPI Environmental Products Inc.

Enviro™Cover System is protected by composition, method and apparatus

patents and patent applications worldwide.

All rights reserved. No part of this Manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, including

photocopying, recording or by any information storage or retrieval system, without permission in writing from the publisher.

Doc #: EC501 / Rev. 1 / Effective Date: October 17, 2014

This Dispensing System Operation and Service Manual is an integral part of Enviro™ Cover

System. It provides important information and instructions on the equipment, loading,

dispensing, health and safety, operation, maintenance, lock-out procedure and information

on product warranty. This Manual is one of five Enviro™ Cover Deployer Model 800 manuals

(Morooka Track Carrier –Operation & Part and Engine –Operation & Part Manuals), which

should be kept easily accessible by Enviro™ Cover Deployer operator for reference.

The information presented in this literature is based on the best data available and is believed to be correct.

However, nothing stated herein is to be taken as warranty (unless specified), expressed or implied regarding the

accuracy of the information or the use of our product. Nor shall anything contained herein be construed to

constitute a permission or recommendation to practice any invention covered by a patent, patent application or

know-how owned by EPI Environmental Products Inc. or any subsidiaries of the Company.

Published and printed by:

EPI Environmental Products Inc.

#801 - 1788 West Broadway

Vancouver, B.C. Canada V6J 1Y1

Tel: +1 (604) 738-6281

Fax: +1 (604) 738-7839

Email: [email protected]

Website: www.envirocoversystem.com and www.epi-global.com

,, EPI and Enviro™are registered marks of EPI Environmental Products Inc. Enviro™Cover System is protected

by composition, method, and apparatus patents worldwide.

It is expressly understood and agreed that SELLER MAKES NO EXPRESS OR IMPLIED WARRANTIES OF FITNESS OR

OF MERCHANTABILITY OR OF ANY OTHER KIND WHATSOEVER except that the goods sold hereunder shall be of the

quality warranted in the Company’s Product Specifications. Buyer assumes all risk of liability whatsoever resulting

from the use of such goods, whether used singularly or in combination with others. Seller’s liability for non-

conforming goods is exclusively limited, at the seller’s option, to replacement of the defective goods or the

purchase price of such goods and under no circumstances shall Seller be liable for incidental or consequential

damages.

All rights reserved. No part of this Manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, including

photocopying, recording or by any information storage or retrieval system, without permission in writing from the publisher.

Doc #: EC501 / Rev. 1 / Effective Date: October 17, 2014

Things You Should Know about Using Model 800 Manuals:

This Dispensing System Operation and Service Manual contains important information and

instructions on the equipment, accessories, features, health and safety, loading, operating

procedure, lock-out procedure, maintenance checklists and know-how of EPI’s Enviro™ Cover

System.

Please read through this Manual and all Model 800 related manuals carefully

and have the personnel trained before commencing the operation of Enviro™

Cover System.

This Manual describes the specifications of the equipment that were in effect when this Manual

was prepared. EPI reserves the right to change the specifications or to discontinue the models

without any notice and without incurring any liability.

If you have any questions about Enviro™Cover System, please contact EPI or your local EPI

representative.

EPI Environmental Products Inc.

Tel: +1 (604) 738-6281

Toll Free: +1 (866) 738-6281

Fax: +1 (604) 856-8189

Email: [email protected]

Canadian Corporate Office

#801 - 1788 West Broadway

Vancouver, BC V6J 1Y1 Canada

US Corporate Office

#207 - 102 Grover Street

Lynden, WA 98264, USA

All rights reserved. No part of this Manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, including

photocopying, recording or by any information storage or retrieval system, without permission in writing from the publisher.

Doc #: EC501 / Rev. 1 / Effective Date: October 17, 2014

Table of Contents

Page

1

Enviro™ Cover System

1-2

2

Health and Safety Introduction

3-4

3

General Specifications

5

4

Off Loading Procedures

6

5

Decal Layout

7

6

Components Guide

8-13

7

Installation of EC Roll

14

8

Ground Attendant Operational Hand Signals

15-16

9

EC Deployment and Safety Decal

17-24

10

Daily Checklist

25

11

Pre-Delivery Checklist

26

12

Maintenance Checklist & Lock-Out Procedure

27

13

Electrical and Hydraulic Schematic Diagrams

28-29

14

Training Sign-off Record

30

15

Notes

31

All rights reserved. No part of this Manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, including

photocopying, recording or by any information storage or retrieval system, without permission in writing from the publisher.

Doc #: EC501 / Rev. 1 / Effective Date: October 17, 2014

1

Chapter 1 Enviro™Cover System

Enviro™Cover

Enviro™ Cover (EC) is a non-reusable engineered geosynthetic alternative daily cover as

classified by ASTM D6523. It is a plastic film meeting established and regulatory criteria for

landfill daily cover.

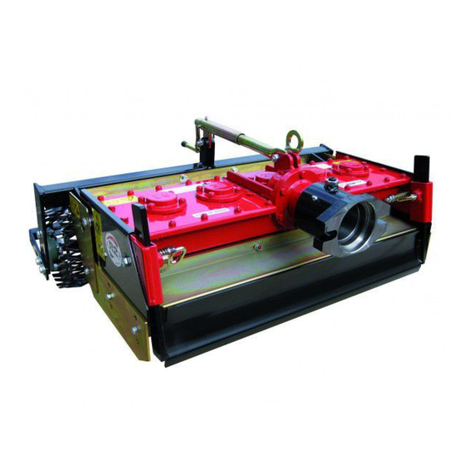

Enviro™ Cover Deployer

Enviro™ Cover Deployer Model 800 (ECD) is the equipment that applies EC and dispenses

ballast material onto the EC panel. It is a customized self propelled unit.

The equipment and the application method developed by EPI for laying film on the working face

of a landfill.

Figure 1: Enviro™ Cover Deployer Model 800

Table of contents