Epiroc LPHB-M Maintenance and service guide

Safety and operating instructions

Posthole borer

LPHB-M

© Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

Contents

Introduction .................................................................................................................................................... 5

About the Safety and operating instructions .............................................................................................. 5

Safety instructions ......................................................................................................................................... 5

Safety signal words .................................................................................................................................. 5

Personal precautions and qualifications ................................................................................................ 5

Transport ............................................................................................................................................... 5

Installation, storage, maintenance and disposal .................................................................................... 5

Operation ............................................................................................................................................... 5

Testing ................................................................................................................................................... 6

Personal protective equipment .............................................................................................................. 6

Drugs, alcohol or medication ................................................................................................................. 6

Carrier, precautions .................................................................................................................................. 6

Installation, precautions .......................................................................................................................... 6

Operating, precautions ............................................................................................................................ 7

Maintenance, precautions ........................................................................................................................ 9

Storage, precautions ................................................................................................................................ 9

Overview ....................................................................................................................................................... 10

Design and function ............................................................................................................................... 10

Main parts ................................................................................................................................................ 10

Labels ...................................................................................................................................................... 10

Data plate ............................................................................................................................................ 10

Safety label .......................................................................................................................................... 10

RPM label ............................................................................................................................................ 11

Transport ....................................................................................................................................................... 11

Lifting the machine ................................................................................................................................. 11

Installation .................................................................................................................................................... 11

Hoses ....................................................................................................................................................... 11

Quick-release couplings ......................................................................................................................... 11

Hydraulic oil ............................................................................................................................................. 11

Pressure adjustment .............................................................................................................................. 12

Insertion tool ........................................................................................................................................... 12

Fitting and removing the insertion tool ................................................................................................. 12

Operation ...................................................................................................................................................... 13

Operating temperatures ......................................................................................................................... 13

Risk area .................................................................................................................................................. 13

Assembly ................................................................................................................................................. 13

Connecting the posthole borer to the carrier ....................................................................................... 13

Disassembly ............................................................................................................................................ 13

Maintenance ................................................................................................................................................. 14

Every day ................................................................................................................................................. 14

Periodic maintenance ............................................................................................................................. 14

Storage .......................................................................................................................................................... 14

Disposal ........................................................................................................................................................ 14

Technical data .............................................................................................................................................. 15

Machine data ........................................................................................................................................... 15

Noise declaration statement .................................................................................................................. 15

EC Declaration of Conformity ..................................................................................................................... 16

EC Declaration of Conformity (EC Directive 2006/42/EC) ................................................................... 16

LPHB-M Contents

© Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

3

Introduction

Epiroc is a leading productivity partner for the

mining, infrastructure and natural resources

industries. With cutting-edge technology, Epiroc

develops and produces innovative drill rigs, rock

excavation and construction equipment, and

provides world-class service and consumables.

The company was founded in Stockholm, Sweden,

and has passionate people supporting and

collaborating with customers in more than 150

countries.

Construction Tools PC AB

Box 703

391 27 Kalmar

Sweden

About the Safety and

operating instructions

The aim of the instructions is to provide you with

knowledge of how to use the posthole borer in an

efficient, safe way. The instructions also give you

advice and tell you how to perform regular

maintenance on the posthole borer.

Before using the posthole borer for the first time

you must read these instructions carefully and

understand all of them.

Safety instructions

To reduce the risk of serious injury or death to

yourself or others, read and understand the Safety

and operating instruction before installing,

operating, repairing, maintaining, or changing

accessories on the machine.

Post this Safety and operating instruction at work

locations, provide copies to employees, and make

sure that everyone reads the Safety and operating

instruction before operating or servicing the

machine. For professional use only.

In addition, the operator or the operator's employer

must assess the specific risks that may be present

as a result of each use of the machine.

Safety signal words

The safety signal words Danger, Warning and

Caution have the following meanings:

DANGER Indicates a hazardous

situation which, if not avoided,

will result in death or serious

injury.

WARNING Indicates a hazardous

situation which, if not avoided,

could result in death or

serious injury.

CAUTION Indicates a hazardous

situation which, if not avoided,

could result in minor or

moderate injury.

Personal precautions and

qualifications

Only qualified and trained persons may operate or

maintain the machine. They must be physically

able to handle the bulk, weight, and power of the

machine. Always use your common sense and

good judgement.

Transport

Transport of the machine may only be undertaken

by persons who:

◆are authorised to operate a crane or fork-lift

truck in conformity with the applicable national

directives,

◆are aware of all the relevant national safety

instructions and accident prevention

instructions

◆and have read and understood the sections

"Safety instructions" and "Transport" in this

manual.

Installation, storage, maintenance and

disposal

Installation, storage, maintenance and disposal of

the machine may only be undertaken by persons

who:

◆are aware of all the relevant national safety

instructions and accident prevention

instructions

◆and have read and understood the Safety and

operating instructions.

Operation

Operation of the machine may only be undertaken

by qualified carrier operators. Carrier operators are

qualified if they:

◆are trained to operate a carrier in conformity

with national directives,

◆are aware of all the relevant national safety

instructions and accident prevention

instructions

◆and have read and understood the Safety and

operating instructions.

LPHB-M Safety and operating instructions

© Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

5

Testing

Testing of the hydraulic installation must only be

carried out by professional technicians. The

technicians must be authorised to approve a

hydraulic installation in accordance with national

directives.

Personal protective equipment

Always use approved protective equipment.

Operators and all other persons in the working

area must wear protective equipment, including at

a minimum:

•Protective helmet

•Hearing protection

•Impact resistant eye protection with side

protection

•Respiratory protection when appropriate

•Protective gloves

•Proper protective boots

•Appropriate work overall or similar clothing (not

loose-fitting) that covers your arms and legs.

Drugs, alcohol or medication

WARNING Drugs, alcohol or medication

Drugs, alcohol or medication may impair your

judgment and powers of concentration. Poor

reactions and incorrect assessments can lead to

severe accidents or death.

►Never use the machine when you are tired or

under the influence of drugs, alcohol or

medication.

►No person who is under the influence of drugs,

alcohol or medication may operate the

machine.

Carrier, precautions

Before using or transporting the carrier with the

machine attached, carefully read the carrier

manufacturer's safety regulations and operating

instructions.

Make sure that the carrier is equipped with

adequate protective features, including a protective

screen in front of the operator.

The machine is to be mounted on the shovel or on

the arm of small skid-steer loaders or excavators

with sufficient load capacity.

Carriers without sufficient load capacity will not

provide the required degree of stability and could

even fall over during machine use, causing injury

and damage.

Installation, precautions

WARNING Ejected working tool

If the tool retainer on the machine is not in a locked

position, the working tool can be ejected with force,

which can cause personal injury.

►Always stop the machine before changing the

working tool or accessories.

►Never point the working tool at yourself or

anyone else.

►Make sure that the working tool is fully inserted

and the tool retainer is in a locked position

before the machine is started.

►Check the lock function by pulling the working

tool outwards powerfully.

WARNING Hydraulic oil at high pressure

Thin jets of hydraulic oil under high pressure can

penetrate the skin and cause permanent injury.

►Immediately consult a doctor if hydraulic oil has

penetrated the skin.

►Never use your fingers to check for hydraulic

fluid leaks.

►Keep your face away from any possible leaks.

WARNING Hydraulic oil

Spilled hydraulic oil can cause burns, accidents

due to slippery conditions and will also harm the

environment.

►Take care of all spilled oil and handle it

according to your safety and environmental

regulations.

►Never dismount the hydraulic machine when

the hydraulic oil is hot.

►Never run any hydraulic lines for attachment of

the hydraulic machine through the drivers cab.

CAUTION Skin eczema

Hydraulic oil can cause eczema if it comes in

contact with the skin.

►Avoid getting hydraulic oil on your hands.

►Always use protective gloves when working

with hydraulic oil.

►Wash hands after contact with hydraulic oil.

CAUTION Moving parts

Risk for crushed hands and fingers.

►Never check bores or passages with hands or

fingers.

Safety and operating instructions LPHB-M

6 © Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

Operating, precautions

WARNING Operating pressure

If the maximum operating pressure for the

hydraulic machine is exceeded, it can result in

material damage and personal injury.

►Always run the hydraulic machine with the

correct operating pressure. See "Technical

data".

DANGER Explosion hazard

If an working tool comes into contact with

explosives or explosive gases, an explosion could

occur. When working on certain materials and

when using certain materials in machine parts,

sparks and ignition can occur. Explosions will lead

to severe injuries or death.

►Never operate the machine in any explosive

environment.

►Never use the machine near flammable

materials, fumes or dust.

►Make sure that there are no undetected

sources of gas or explosives.

WARNING Trapping hazard

There is risk of neck ware, hair, gloves and clothes

getting dragged into or caught by a rotating

insertion tool or accessories. This may cause

choking, scalping, lacerations or death. To reduce

the risk:

►Never grab or touch a rotating drill steel.

►Avoid wearing clothing, neck ware or gloves

that may get caught.

►Cover long hair with a hair net.

WARNING Projectiles

Failure of the work piece, of accessories, or even

of the machine itself may generate high velocity

projectiles. During drilling, splinters, or other

particles may become projectiles and cause bodily

injury by striking the operator or other persons.

Also, breakage of the work piece, accessories, or

the insertion tool may generate high velocity

projectiles that can cause bodily injury. In addition,

objects falling from a height can cause bodily

injury. To reduce risks:

►Close off the working area.

►Before starting, make sure that no persons are

in the danger area, 5 meters both horizontally

and vertically from the machine.

►Immediately switch off the machine when

persons are present in the danger area.

►Never operate unless the inserted tool is

retained in the machine with a proper tool

retainer.

WARNING Slipping, tripping and falling

hazards

There is a risk of slipping or tripping or falling, for

example tripping on the hoses or on other objects.

Slipping or tripping or falling can cause injury. To

reduce this risk:

►Always make sure that no hose or other object

is in your way or in any other person's way.

WARNING Dust and fume hazard

Dusts and/or fumes generated or dispersed when

using the machine may cause serious and

permanent respiratory disease, illness, or other

bodily injury (for example, silicosis or other

irreversible lung disease that can be fatal, cancer,

birth defects, and/or skin inflammation).

Some dusts and fumes created by drilling,

breaking, hammering, sawing, grinding and other

construction activities contain substances known to

the State of California and other authorities to

cause respiratory disease, cancer, birth defects, or

other reproductive harm. Some examples of such

substances are:

•Crystalline silica, cement, and other masonry

products.

•Arsenic and chromium from chemically-treated

rubber.

•Lead from lead-based paints.

Dust and fumes in the air can be invisible to the

naked eye, so do not rely on eye sight to

determine if there is dust or fumes in the air.

To reduce the risk of exposure to dust and fumes,

do all of the following:

►Perform site-specific risk assessment. The risk

assessment should include dust and fumes

created by the use of the machine and the

potential for disturbing existing dust.

►Use proper engineering controls to minimize the

amount of dust and fumes in the air and to

minimize build-up on equipment, surfaces,

clothing, and body parts. Examples of controls

include: exhaust ventilation and dust collection

systems, water sprays, and wet drilling. Control

dusts and fumes at the source where possible.

Make sure that controls are properly installed,

maintained and correctly used.

►Wear, maintain and correctly use respiratory

protection as instructed by your employer and

as required by occupational health and safety

regulations. The respiratory protection must be

LPHB-M Safety and operating instructions

© Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

7

effective for the type of substance at issue (and

if applicable, approved by relevant

governmental authority).

►Work in a well ventilated area.

►If the machine has an exhaust, direct the

exhaust so as to reduce disturbance of dust in a

dust filled environment.

►Operate and maintain the machine as

recommended in the operating and safety

instructions

►Select, maintain and replace consumables/

working tools/ other accessories as

recommended in the operating and safety

instructions. Incorrect selection or lack of

maintenance of consumables/ inserted tools/

other accessories may cause an unnecessary

increase in dust or fumes.

►Wear washable or disposable protective clothes

at the worksite, and shower and change into

clean clothes before leaving the worksite to

reduce exposure of dust and fumes to yourself,

other persons, cars, homes, and other areas.

►Avoid eating, drinking, and using tobacco

products in areas where there is dust or fumes.

►Wash your hands and face thoroughly as soon

as possible upon leaving the exposure area,

and always before eating, drinking, using

tobacco products, or making contact with other

persons.

►Comply with all applicable laws and regulations,

including occupational health and safety

regulations.

►Participate in air monitoring, medical

examination programs, and health and safety

training programs provided by your employer or

trade organizations and in accordance with

occupational health and safety regulations and

recommendations. Consult with physicians

experienced with relevant occupational

medicine.

►Work with your employer and trade organization

to reduce dust and fume exposure at the

worksite and to reduce the risks. Effective

health and safety programs, policies and

procedures for protecting workers and others

against harmful exposure to dust and fumes

should be established and implemented based

on advice from health and safety experts.

Consult with experts.

►Residues of hazardous substances on the

machine can be a risk. Before undertaking any

maintenance on the machine, clean it

thoroughly.

DANGER Electrical hazard

The machine is not electrically insulated. If the

machine comes into contact with electricity, serious

injuries or death may result.

►Never operate the machine near any electric

wire or other source of electricity.

►Make sure that there are no concealed wires or

other sources of electricity in the working area

or in the ground where the drilling is performed.

WARNING Concealed object hazard

During operating, concealed wires and pipes

constitute a danger that can result in serious injury.

►Check the composition of the material before

operating.

►Watch out for concealed cables and pipes for

example electricity, telephone, water, gas and

sewage lines etc.

►If the inserted tool seems to have hit a

concealed object, switch off the machine

immediately.

►Make sure that there is no danger before

continuing.

WARNING Involuntary start

An involuntary start of the machine can lead to

severe injuries.

►Follow the instructions in the carrier manual to

prevent involuntary start of the machine.

►Installation of a start circuit on the hydraulic

attachment must be made in a way that avoids

any unintentional starts.

►A foot pedal on the carrier must be equipped

with a protection cover.

WARNING Noise hazard

High noise levels can cause permanent and

disabling hearing loss and other problems such as

tinnitus (ringing, buzzing, whistling, or humming in

the ears). To reduce risks and prevent an

unnecessary increase in noise levels:

►Risk assessment of these hazards and

implementation of appropriate controls is

essential.

►Operate and maintain the machine as

recommended in these instructions.

►Select, maintain and replace the working tool as

recommended in these instructions.

►If the machine has a silencer, check that it is in

place and in good working condition.

►Always use hearing protection.

Safety and operating instructions LPHB-M

8 © Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

►Use damping material to prevent work pieces

from 'ringing'.

Maintenance, precautions

CAUTION Hot machine

The machine can become hot when used.

Touching it can lead to burns.

►Never touch a hot machine.

►Wait until the machine has cooled down before

carrying out maintenance work.

WARNING Machine modification

Any machine modification may result in bodily

injuries to yourself or others.

►Never modify the machine. Modified machines

are not covered by warranty or product liability.

►Always use original parts, working tools and

accessories.

►Change damaged parts immediately.

►Replace worn components in good time.

CAUTION Hot working tool

The tip of the working tool can become hot and

sharp when used. Touching it can lead to burns

and cuts.

►Never touch a hot or sharp working tool.

►Wait until the working tool has cooled down

before carrying out maintenance work.

WARNING Working tool hazards

Accidental engagement of the start and stop

device during maintenance or installation can

cause serious injuries, when the power source is

connected.

►Never inspect, clean, install, or remove the

working tool while the power source is

connected.

Storage, precautions

◆Keep the machine and tools in a safe place, out

of the reach of children and locked up.

LPHB-M Safety and operating instructions

© Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

9

Overview

To reduce the risk of serious injury or death to

yourself or others, read the Safety instructions

section found on the previous pages of this

manual before operating the machine.

Design and function

The mounted posthole borer is a robust and

flexible hydraulic attachment suitable for all jobs in

connection with setting up of poles, piles, fences

etc. and where there is a need of drilling holes

down to a maximum depth of 1.5 m (59 in.) with

standard Epiroc insertion tools in sizes from ø90 to

ø350 mm (3.54 - 13.78 in.). The posthole borer is

to be mounted on the shovel or on the arm of a

small skid-steer, excavator or tractor weighing

800-3,500 kg (1,800 - 7,700 lbs) . No other use is

permitted.

The post hole borer has a clockwise rotation when

it is correctly connected to the carrier's hydraulic

system. The pressure provided by the carriers

hydraulic system must be at maximum 160 bar.

Never use the posthole borer as a rotation

movement supplier for other equipments. The

mounted posthole borer or the inserted tool must

never be used as a lifting device.

To choose the correct insertion tool, see the spare

parts list or the accessories catalogue.

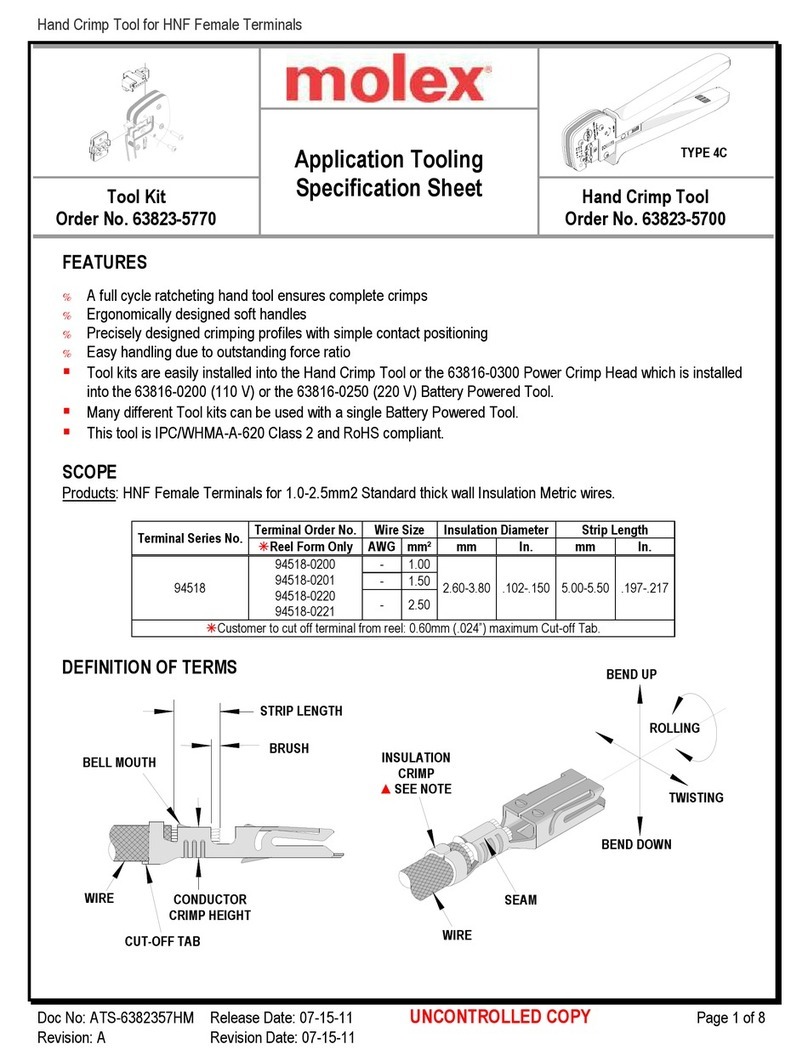

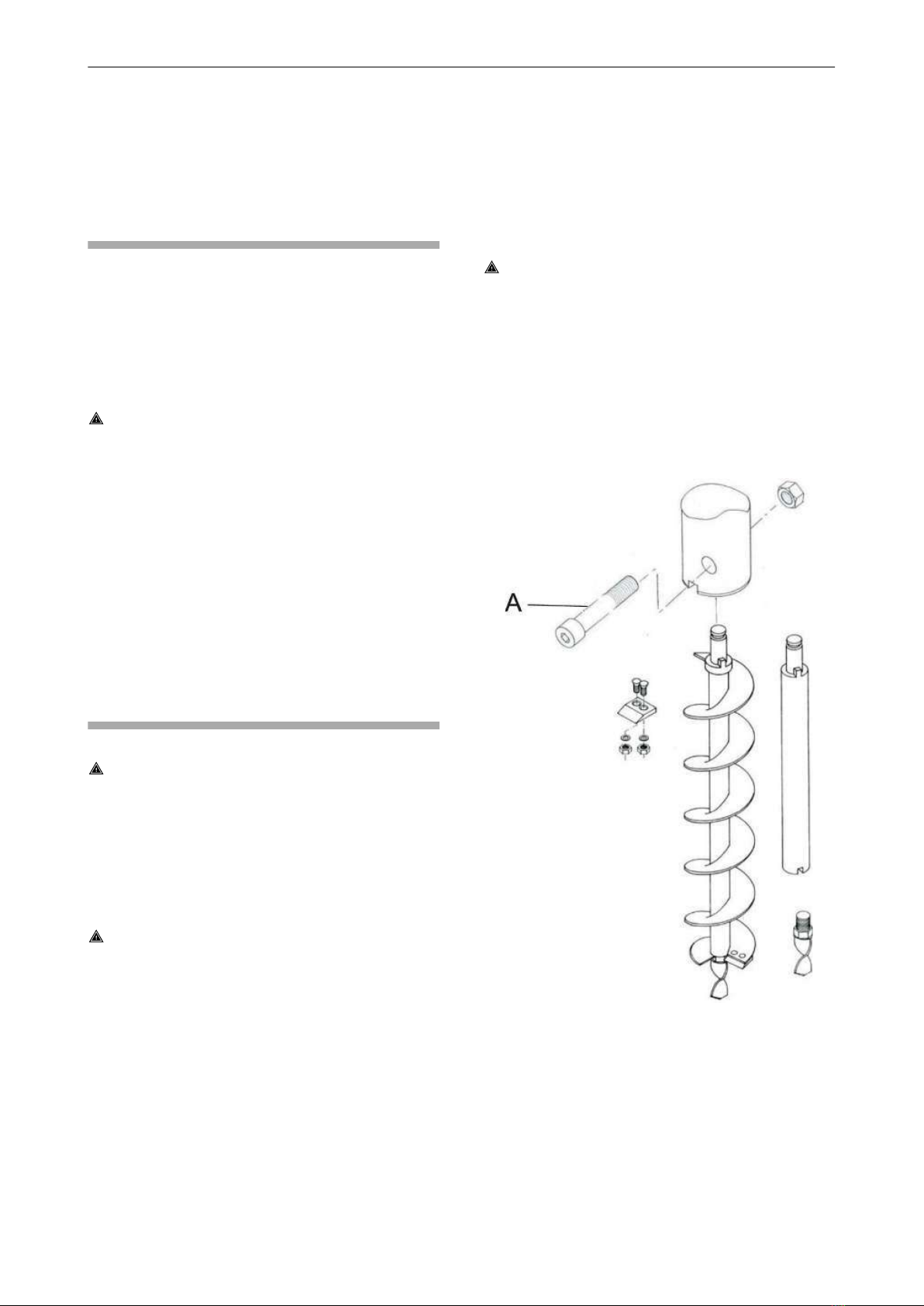

Main parts

A

G

B

F

C

H

E

D

A. Cradle link

B. Pin

C. Fixture

D. Connectors P and T

E. Grease nipple

F. Drive shaft

G. Motor OMR 250

H. Tool retaining screw

Labels

The machine is fitted with labels containing

important information about personal safety and

machine maintenance. The labels must be in such

condition that they are easy to read. New labels

can be ordered from the spare parts list.

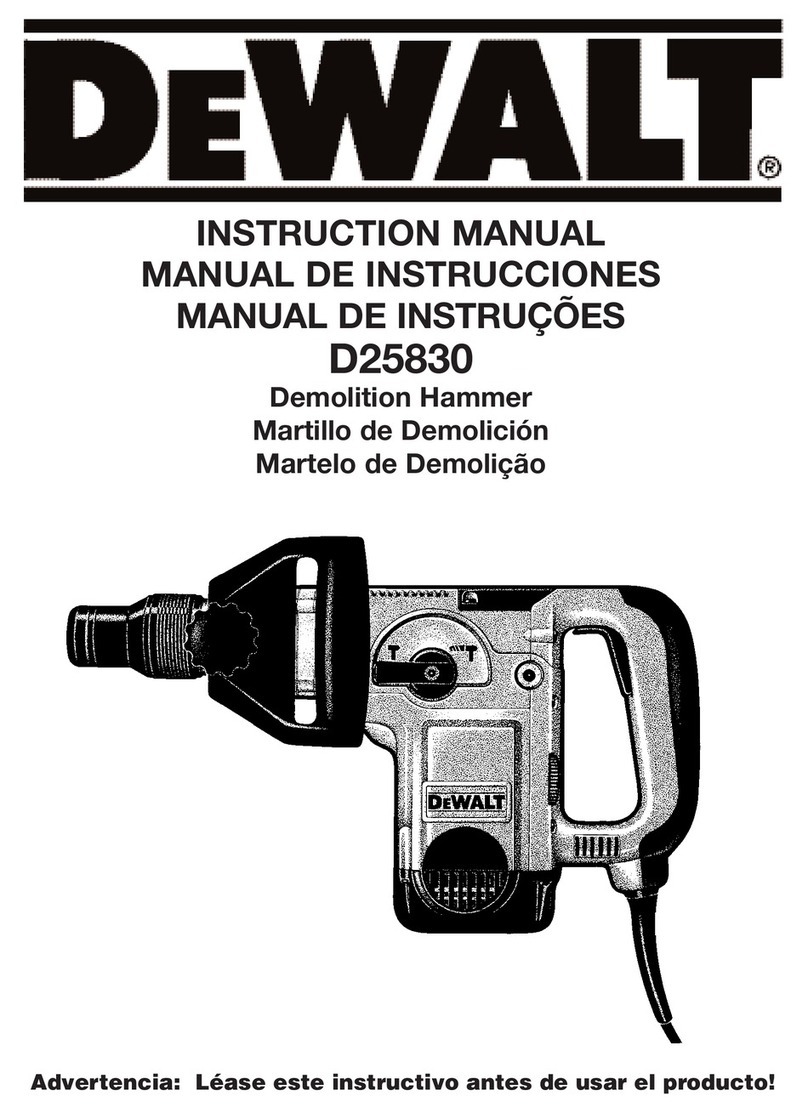

Data plate

A

BCDE

F

A. Machine type

B. Maximum hydraulic pressure

C. Serial number

D. The warning symbol together with the book

symbol means that the user must read the

safety and operating instructions before the

machine is used for the first time.

E. The CE symbol means that the machine is EC-

approved. See the EC Declaration of

Conformity which is delivered with the machine

for more information.

F. The EAC symbol means that the machine is

EAC approved.

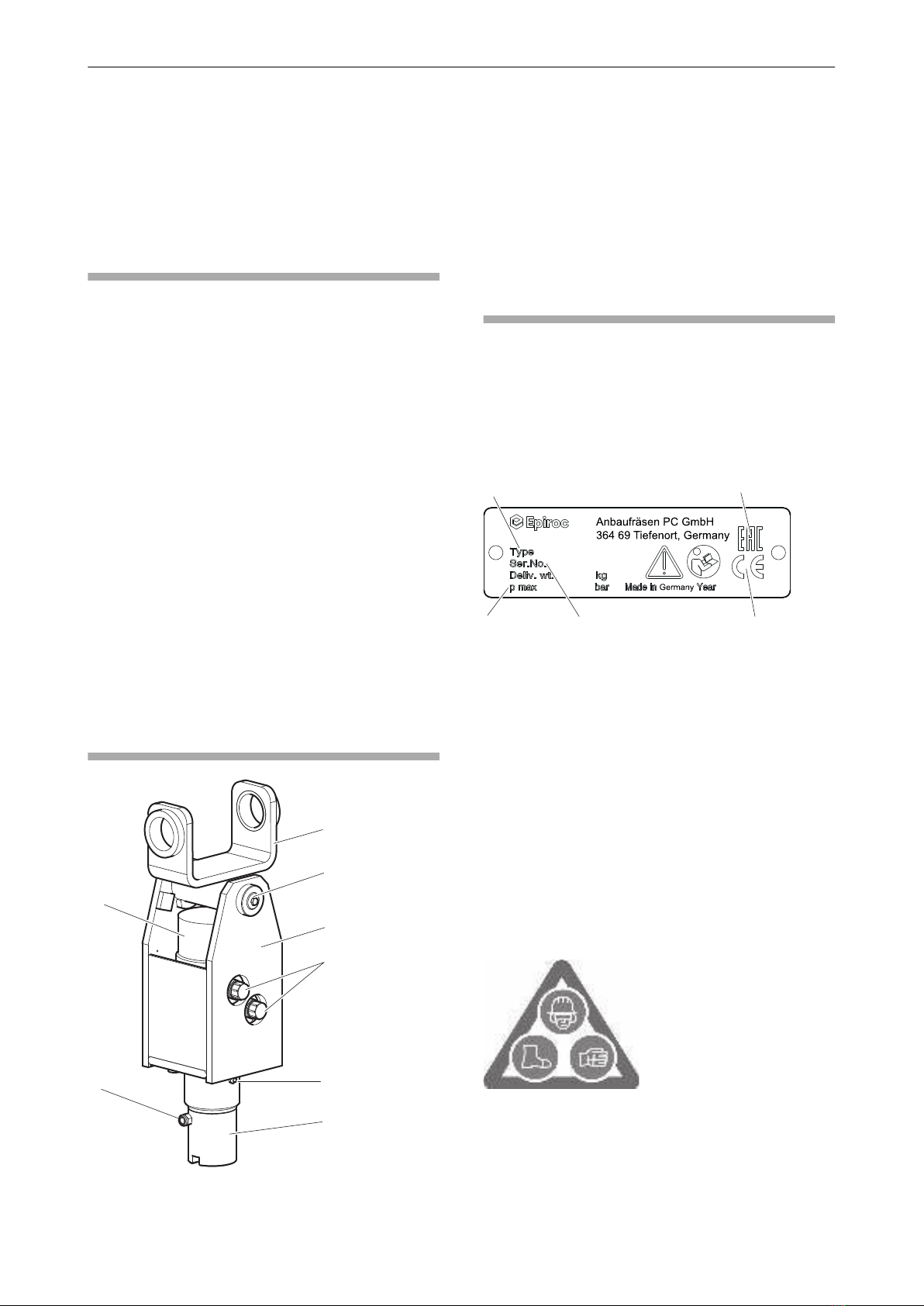

Safety label

Safety and operating instructions LPHB-M

10 © Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

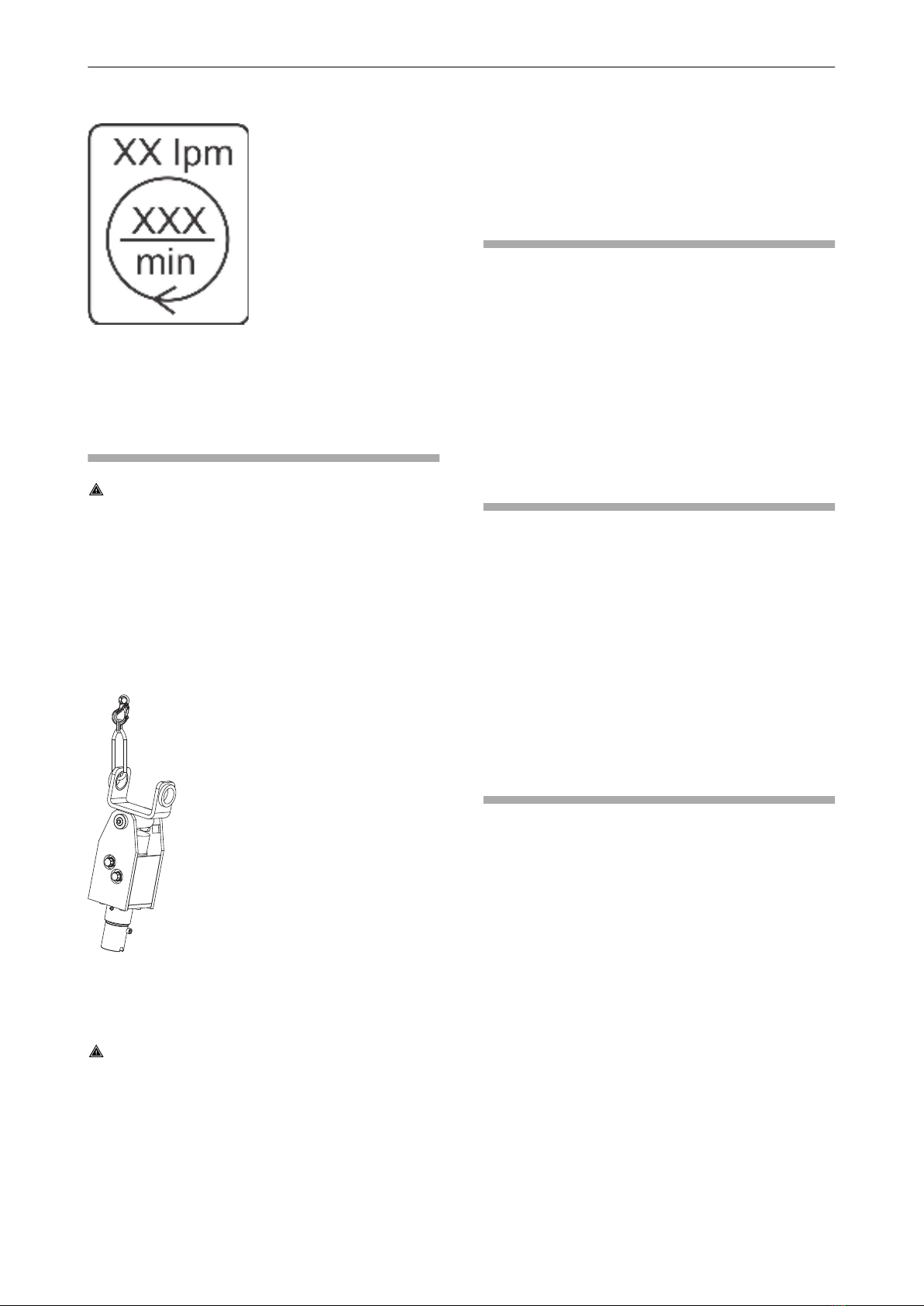

RPM label

Transport

Lifting the machine

WARNING Falling machine can cause

injuries

►Place the machine in a safe position where it

can not fall over and cause damage.

Carefully check that the carrier is stable enough

when transporting or doing maintenance or other

work on the machine.

The machine is delivered in a box. To lift out the

machine in a safe way, fit the lifting strap in the

manner shown in the picture below.

Installation

WARNING Whipping hydraulic hose

Hydraulic hoses under pressure can whip

uncontrollably if screws loosen or are loosened. A

whipping hydraulic hose can cause severe injuries.

►Depressurise the hydraulic system before

loosening the connection of a hydraulic hose.

►Tighten the nuts on the connections of the

hydraulic hoses to the required torque.

►Check that the hydraulic hose and the

connections are not damaged.

Hoses

For connection on the machine, the hydraulic hose

must be approved for a working pressure of at

least 172 bar (2,500 psi) and have a 12.7 mm (½

in.) inner diameter. To resist exterior wear and tear,

we recommend using a 2-layer hydraulic hose.

The machine connection marked P (pump) is the

oil inlet, and the connection marked T (tank) is the

oil outlet. Always connect both hoses and make

sure that all hose connections are tight. Never

carry the machine by the hose.

Quick-release couplings

The original hydraulic hoses are fitted with Flat-

Face quick-release couplings that are strong and

easy to clean. The quick-release couplings are

fitted so that the male connection supplies oil and

the female connection receives oil.

NOTICE Wipe all couplings clean before

connecting. Ensure that couplings are clean and

correctly engaged before operation. Failure to do

so may result in damage to the quick couplings

and cause overheating and cause foreign matter to

enter the hydraulic system.

Hydraulic oil

In order to protect the environment, use of

biologically degradable hydraulic oil is

recommended. No other fluids must be used.

◆Viscosity (preferred) 20-40 cSt.

◆Viscosity (permitted) 15-100 cSt.

◆Viscosity index minimum 100.

Standard mineral or synthetic oil can be used.

Make sure to only use clean oil and filling

equipment.

When the machine is used continuously, the oil

temperature will stabilise at a level which is called

the working temperature. This will, depending on

the type of work and the cooling capacity of the

hydraulic system, be between 20-40°C (68-104°F)

above the ambient temperature. At working

temperature, the oil viscosity must be within the

preferred limits. The viscosity index indicates the

connection between viscosity and temperature. A

high viscosity is therefore preferred, because the

LPHB-M Safety and operating instructions

© Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

11

oil can then be used within a wider temperature

range. The machine must not be used, if oil

viscosity fails to remain within the permitted area,

or if the working temperature of the oil does not fall

between 20°C (68°F) and 70°C (158°F).

Pressure adjustment

The maximum pressure of the power source is

important. The pressure created in case of an

incorrectly or unfitted return line coupling would

cause overloading. Which could harm the machine

and result in bodily injuries. The maximum

pressure of the power source is 172 bar (limited by

safety valve adjustment).

WARNING Operating pressure

If the maximum operating pressure for the

hydraulic machine is exceeded, it can result in

material damage and personal injury.

►Always run the hydraulic machine with the

correct operating pressure, see "Technical

data".

►Only readjust the pressure relief valve (torque

control) on the machine according to procedure

and values described under maintenance. Note

that higher settings might lead to a higher

torque, which could harm the machine and

result in serious injury or death.

Insertion tool

CAUTION Hot working tool

The tip of the working tool can become hot and

sharp when used. Touching it can lead to burns

and cuts.

►Never touch a hot or sharp working tool.

►Wait until the working tool has cooled down

before carrying out maintenance work.

WARNING Ejected insertion tool

If the tool retainer on the machine is not tightened,

the inserted tool can be ejected with force, which

can cause personal injury.

►Never start the carrier while changing the

insertion tool.

►Shut the carrier's engine off and secure the

carrier and machine against involuntary start

before changing the inserted tool or

accessories.

►Never point the inserted tool at yourself or

anyone else.

►Make sure that the insertion tool is fully inserted

and the tool retainer is tightened before the

machine is started.

►Check the locking function by pulling the

inserted tool outwards forcefully.

Fitting and removing the insertion tool

WARNING Running engine

Changing the inserted tool or accessories while the

carrier's engine is running can cause serious injury.

►Secure the carrier against involuntary

activation.

Whenever fitting or removing the insertion tool the

following instructions must be observed:

◆Close the tool retainer and check the lock

function by pulling the inserted tool outwards

forcefully.

1. Shut the carrier's engine off before changing

the inserted tool.

2. Unscrew the tool retaining screw (A).

3. Remove the inserted tool.

4. Insert the new insertion tool.

5. Screw in the tool retaining screw (A).

Safety and operating instructions LPHB-M

12 © Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

Operation

Operating temperatures

The operating temperatures of the hydraulic

attachment are between -20ºC (-4°F) and +80ºC

(+176°F).

CAUTION Temperature hazard

The hydraulic attachment and the hydraulic oil

system of the carrier can be damaged if the

hydraulic attachment is used at higher or lower

temperatures.

►Only start the hydraulic attachment when the

hydraulic oil has reached the proper operating

temperature.

►If the ambient temperature is below -20ºC

(-4°F), you must warm up the insertion tool and

the hydraulic attachment before use.

►If the oil temperature exceeds +80ºC (+176°F),

you must not use the hydraulic attachment as

the oil quality becomes inadequate which

severely shortens the life time of seals and O-

rings.

Risk area

Before starting the machine, make sure that no

persons are in the risk area, 5 meters both

horizontally and vertically from the machine.

5 m

5 m

5 m

Assembly

WARNING Falling machine can cause

injuries

►Place the machine in a safe position where it

cannot fall over and cause damage.

Circulate the hydraulic oil before connecting the

machine. This is to make sure that the hydraulic oil

is clean. Use the same routine when changing a

hydraulic oil hose.

1. Connect the pressure and return hose.

2. Run the hydraulic oil through the carrier's oil

filter for approximately 3 minutes to make sure

that the hoses are clean.

Connecting the posthole borer to the

carrier

1. Switch off the carrier and depressurise the

hydraulic system by releasing the carrier's

hydraulic tank pressure. If no quick-release

couplings are used, close all shut-off valves in

the installation at the boom.

2. Remove the protective caps from the nipples

and make sure that the connectors and hoses

are clean and not damaged. Replace if

damaged.

3. Connect the posthole borer to the machine

boom. After mounting the posthole borer,

carefully extend and retract the bucket cylinder

to its full extent in each direction. It is important

that the cylinder can be fully extended and

retracted without any difficulty.

4. Connect the pressure hose and the tank hose.

5. Start the carrier and allow it to run for a few

minutes to warm up the hydraulic oil.

6. Make sure that the posthole borer is supplied

with the correct flow according to the technical

data.

Never exceed the maximum relief valve setting

stated on the tool.

Disassembly

1. Depressurise the hydraulic system by releasing

the carrier's hydraulic tank pressure. If no

quick-release couplings are used, close all

shut-off valves in the installation at the boom.

2. Stop the carrier.

3. Disconnect the hoses and refit the protective

caps to the nipples.

4. An assistant must remove the hydraulic

attachment. Agree with the assistant on clear

hand signals for use during the dismounting

procedure.

5. Remove the bolt locks from the stick and

linkage bolts.

LPHB-M Safety and operating instructions

© Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

13

6. Drive out the linkage bolt with a steel arbour

and a hammer.

7. Switch on the carrier and retract the bucket

cylinder.

8. Move the carrier stick out of the adaptor plate.

9. Loosen the fastening screws for the adaptor

plate. Store the screws and lock washers for

future use. Remove the adaptor plate.

Maintenance

Regular maintenance is a basic requirement for

the continued safe and efficient use of the

machine. Follow the maintenance instructions

carefully.

◆Before starting maintenance on the machine,

clean it in order to avoid exposure to hazard

substances.

◆Use only authorised parts. Any damage or

malfunction caused by the use of unauthorised

parts is not covered by warranty or product

liability.

◆When cleaning mechanical parts with solvent,

comply with appropriate health and safety

regulations and ensure there is satisfactory

ventilation.

◆For major service to the machine, contact your

nearest authorised workshop.

Every day

◆Clean and inspect the machine and its functions

each day before start working.

◆Conduct a general inspection for leaks,

damage, and wear.

◆Change damaged parts immediately.

◆Replace worn components in good time.

◆Make sure that all the attached and related

equipment, such as hoses and flow dividers are

properly maintained.

◆Clean the quick-release couplings before use.

Periodic maintenance

After each operating period of approximately 300

working hours or twice a year the machine must be

dismantled and all parts be cleaned and checked.

This work must be performed by authorised staff,

trained for this task.

Storage

WARNING Falling machine

Falling machine can cause injuries.

►Place the machine in a safe position where it

can not fall over and cause damage.

If the machine is not used for a long time, the

following points have to be considered to protect

the machine from corrosion:

◆Clean the machine carefully.

◆Store the machine in a dry place.

Disposal

A used machine must be treated and scrapped in

such a way that the greatest possible portion of the

material can be recycled and any negative

influence on the environment is kept as low as

possible.

Before a used machine is scrapped it must be

emptied and cleaned from all hydraulic oil. The

remaining hydraulic oil must be deposited and any

negative influence on the environment is to be kept

as low as possible.

Safety and operating instructions LPHB-M

14 © Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

Technical data

Machine data

LPHB-M

Weight, kg (lb) 31 (68)

Measurement, LxHxW, mm (in.) 555 x 175 x 209 (21.9 x 6.9 x 8.2)

Oil flow, l.p.m 20-60

Working pressure, bar 100-140

Maximum pressure, bar 160

Maximum back pressure in return line, measured at machine, bar 30

Maximum torque (Previous models equipped with OMR 250 motor: Maximum pressure

setting 80 bar, note that you can still have 160 bar on the pressure line), Nm at bar

450 at 140

Motor OMR 250

Revolutions, r.p.m 80-200

Connectors P and T, in. 1⁄2 BSP

Noise declaration statement

LPHB-M

Sound pressure 1 dB(A) <70

1 Sound pressure level according to EN ISO 3744 in accordance with directive 2000/14/EC at 10 metres

distance.

These declared values were obtained by laboratory type testing in accordance with the stated directive or

standards and are suitable for comparison with the declared values of other tools tested in accordance with

the same directive or standards. These declared values are not adequate for use in risk assessments and

values measured in individual work places may be higher. The actual exposure values and risk of harm

experienced by an individual user are unique and depend upon the way the user works, in what material the

machine is used, as well as upon the exposure time and the physical condition of the user, and the condition

of the machine.

We, Construction Tools EOOD, cannot be held liable for the consequences of using the declared values,

instead of values reflecting the actual exposure, in an individual risk assessment in a work place situation

over which we have no control.

LPHB-M Safety and operating instructions

© Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

15

EC Declaration of Conformity

EC Declaration of Conformity (EC Directive 2006/42/EC)

We, Anbaufräsen PC GmbH, hereby declare that the machines listed below conform to the provisions of EC

Directive 2006/42/EC (Machinery Directive) and the harmonised standards mentioned below.

Hydraulic posthole borer Pmax (bar)

LPHB-M 160

Following harmonised standards were applied:

EN ISO 11148-3

Technical Documentation authorised representative:

Roger Dähne

Anbaufräsen PC GmbH

364 33 Tiefenort

Germany

General Manager:

Martina Schierholz

Manufacturer:

Anbaufräsen PC GmbH

364 33 Tiefenort

Germany

Place and date:

Tiefenort, 2018-05-07

Safety and operating instructions LPHB-M

16 © Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

Original instructions

Anbaufräsen PC GmbH | 9864 0046 01 | 2018-05-15

©

Any unauthorized use or copying of the contents or any part thereof is prohibited. This

applies in particular to trademarks, model denominations, part numbers, and drawings.

epiroc.com

Other manuals for LPHB-M

1

Table of contents

Other Epiroc Power Tools manuals

Popular Power Tools manuals by other brands

Ingersoll-Rand

Ingersoll-Rand BXR-100H Operation & maintenance manual

Bosch

Bosch GOP 10,8 V-LI Professional operating instructions

Shop fox

Shop fox SHOP FOX W1829 owner's manual

CustomCrimp

CustomCrimp CC200 Operator's manual

Delta

Delta 23-675 instruction manual

Bosch

Bosch GSA18V-083 Operating/safety instructions