Epiroc SB 102 Maintenance and service guide

Safety and operating instructions

Hydraulic breakers

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, 552

© Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

Contents

Introduction .................................................................................................................................................... 5

About the Safety and operating instructions .............................................................................................. 5

Safety instructions ......................................................................................................................................... 5

Safety signal words .................................................................................................................................. 5

Personal precautions and qualifications ................................................................................................ 5

Transport ............................................................................................................................................... 5

Installation, storage, maintenance and disposal .................................................................................... 5

Operation ............................................................................................................................................... 5

Testing ................................................................................................................................................... 6

Personal protective equipment .............................................................................................................. 6

Drugs, alcohol or medication ................................................................................................................. 6

Carrier, precautions .................................................................................................................................. 6

Installation, precautions .......................................................................................................................... 6

Hydraulic system ................................................................................................................................... 6

Assembly or disassembly ...................................................................................................................... 6

Operation, precautions ............................................................................................................................ 7

Maintenance, precautions ........................................................................................................................ 8

Storage, precautions ................................................................................................................................ 9

Overview ....................................................................................................................................................... 10

Design and function ............................................................................................................................... 10

Main parts ................................................................................................................................................ 10

Labels ...................................................................................................................................................... 10

Data plate ............................................................................................................................................. 11

Noise level label ................................................................................................................................... 11

Labels on the accumulator ................................................................................................................... 11

Guarantee ................................................................................................................................................ 11

Transport ....................................................................................................................................................... 11

Lifting the hydraulic breaker .................................................................................................................. 11

Transport using a forklift ....................................................................................................................... 12

Transport using a lorry ........................................................................................................................... 12

Installation .................................................................................................................................................... 12

Hoses and connections ......................................................................................................................... 12

Hydraulic oil ............................................................................................................................................ 13

Assembly ................................................................................................................................................. 13

Pressure adjustment .............................................................................................................................. 15

Water flushing ......................................................................................................................................... 15

Working tool ............................................................................................................................................ 15

Selecting the right working tool ............................................................................................................ 15

Conical moil point ........................................................................................................................... 15

Chisels and spades ........................................................................................................................ 15

Blunt tool ......................................................................................................................................... 15

Changing the working tool ................................................................................................................... 15

Operation ...................................................................................................................................................... 17

Preparation before breaking .................................................................................................................. 17

Operating temperatures ....................................................................................................................... 17

Engine rpm .......................................................................................................................................... 17

Operating ................................................................................................................................................. 17

Risk area .............................................................................................................................................. 17

Breaking ............................................................................................................................................... 17

Breaking under water ........................................................................................................................... 19

Heavy duty operation ........................................................................................................................... 19

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

Contents

© Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

3

Special applications ............................................................................................................................. 19

Maintenance ................................................................................................................................................. 19

Cleaning ................................................................................................................................................... 20

Every second hour ................................................................................................................................. 20

Lubricating with a grease gun .............................................................................................................. 20

Central lubrication system ................................................................................................................... 20

Every day ................................................................................................................................................. 20

Every week .............................................................................................................................................. 20

Wear limits ........................................................................................................................................... 21

Replacing the working tool bushing ..................................................................................................... 21

Every year ................................................................................................................................................ 21

Storage .......................................................................................................................................................... 21

Disposal ........................................................................................................................................................ 22

Troubleshooting ........................................................................................................................................... 23

Hydraulic breaker does not start ........................................................................................................... 23

Impact force too low ............................................................................................................................... 23

Oil leaks ................................................................................................................................................... 23

Hydraulic breaker operates too slow .................................................................................................... 24

Operating temperature too high ............................................................................................................ 24

Technical data .............................................................................................................................................. 25

Machine data ........................................................................................................................................... 25

Capacities ................................................................................................................................................ 26

Noise declaration statement .................................................................................................................. 27

Flow diagrams for the correct operating pressure .............................................................................. 28

SB 52: 100–150 bar ............................................................................................................................. 28

SB 102: 100–150 bar ........................................................................................................................... 29

SB 152: 100–150 bar ........................................................................................................................... 29

SB 202: 100–150 bar ........................................................................................................................... 30

SB 302: 100-150 bar ............................................................................................................................ 30

SB 452: 100–150 bar ........................................................................................................................... 31

SB 552: 100–150 bar ........................................................................................................................... 31

EC Declaration of Conformity ..................................................................................................................... 32

EC Declaration of Conformity (EC Directive 2006/42/EC) ................................................................... 32

Contents SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

4 © Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

Introduction

Epiroc is a leading productivity partner for the

mining, infrastructure and natural resources

industries. With cutting-edge technology, Epiroc

develops and produces innovative drill rigs, rock

excavation and construction equipment, and

provides world-class service and consumables.

The company was founded in Stockholm, Sweden,

and has passionate people supporting and

collaborating with customers in more than 150

countries.

Construction Tools PC AB

Box 703

391 27 Kalmar

Sweden

About the Safety and

operating instructions

The aim of the instructions is to provide you with

knowledge of how to use the hydraulic breaker in

an efficient, safe way. The instructions also give

you advice and tell you how to perform regular

maintenance on the hydraulic breaker.

Before using the hydraulic breaker for the first time

you must read these instructions carefully and

understand all of them.

Safety instructions

To reduce the risk of serious injury or death to

yourself or others, read and understand the Safety

and operating instruction before installing,

operating, repairing, maintaining, or changing

accessories on the machine.

Post this Safety and operating instruction at work

locations, provide copies to employees, and make

sure that everyone reads the Safety and operating

instruction before operating or servicing the

machine. For professional use only.

In addition, the operator or the operator's employer

must assess the specific risks that may be present

as a result of each use of the machine.

Save all warnings and instructions for future

reference.

Safety signal words

The safety signal words Danger, Warning and

Caution have the following meanings:

DANGER Indicates a hazardous

situation which, if not avoided,

will result in death or serious

injury.

WARNING Indicates a hazardous

situation which, if not avoided,

could result in death or

serious injury.

CAUTION Indicates a hazardous

situation which, if not avoided,

could result in minor or

moderate injury.

Personal precautions and

qualifications

Only qualified and trained persons may operate or

maintain the machine. They must be physically

able to handle the bulk, weight, and power of the

tool. Always use your common sense and good

judgement.

Transport

Transport of the hydraulic breaker may only be

undertaken by persons who:

•are authorised to operate a crane or fork-lift

truck in conformity with the applicable national

directives,

•are aware of all the relevant national safety

instructions and accident prevention

instructions

•and have read and understood the safety and

transport chapters of this manual.

Installation, storage, maintenance and

disposal

Installation, storage, maintenance and disposal of

the hydraulic breaker may only be undertaken by

persons who:

•are aware of all the relevant national safety

instructions and accident prevention

instructions

•and have read and understood the Safety and

operating instructions.

Operation

Operation of the hydraulic breaker may only be

undertaken by qualified carrier operators. Carrier

operators are qualified if they:

•are trained to operate a carrier in conformity

with national directives,

•are aware of all the relevant national safety

instructions and accident prevention

instructions

•and have read and understood the Safety and

operating instructions.

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

Safety and operating instructions

© Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

5

Testing

Testing of the hydraulic installation must only be

carried out by professional technicians. The

technicians must be authorised to approve a

hydraulic installation in accordance with national

directives.

Personal protective equipment

Always use approved protective equipment.

Operators and all other persons in the working

area must wear protective equipment, including at

a minimum:

•Protective helmet

•Hearing protection

•Impact resistant eye protection with side

protection

•Respiratory protection when appropriate

•Protective gloves

•Proper protective boots

•Appropriate work overall or similar clothing (not

loose-fitting) that covers your arms and legs.

Drugs, alcohol or medication

WARNING Drugs, alcohol or medication

Drugs, alcohol or medication may impair your

judgment and powers of concentration. Poor

reactions and incorrect assessments can lead to

severe accidents or death.

►Never use the machine when you are tired or

under the influence of drugs, alcohol or

medication.

►No person who is under the influence of drugs,

alcohol or medication may operate the

machine.

Carrier, precautions

Before using or transporting the carrier with the

hydraulic breaker attached, carefully read the

carrier manufacturer's safety regulations and

operating instructions.

Make sure that the carrier is equipped with

adequate protective features, including a protective

screen in front of the operator.

The hydraulic breaker must only be mounted on a

carrier with sufficient load capacity.

Carriers without sufficient load capacity will not

provide the required degree of stability and could

even fall over during hydraulic breaker use,

causing injury and damage.

Installation, precautions

Hydraulic system

DANGER Compressed gas, explosion

hazard

The integrated piston accumulator is pressurized

even when the hydraulic system is shut off. To

dismount the accumulator without first releasing

the nitrogen gas can cause serious personal injury

or death.

►Fill the integrated piston accumulator with

nitrogen (N2) only.

►Only authorised personnel are qualified to work

with the accumulator.

WARNING Hydraulic oil at high pressure

Thin jets of hydraulic oil under high pressure can

penetrate the skin and cause permanent injury.

►Immediately consult a doctor if hydraulic oil has

penetrated the skin.

►Never use your fingers to check for hydraulic

fluid leaks.

►Keep your face away from any possible leaks.

WARNING Hydraulic oil

Spilled hydraulic oil can cause burns, accidents

due to slippery conditions and will also harm the

environment.

►Take care of all spilled oil and handle it

according to your safety and environmental

regulations.

►Never dismount the hydraulic machine when

the hydraulic oil is hot.

►Never run any hydraulic lines for attachment of

the hydraulic machine through the drivers cab.

CAUTION Skin eczema

Hydraulic oil can cause eczema if it comes in

contact with the skin.

►Avoid getting hydraulic oil on your hands.

►Always use protective gloves when working

with hydraulic oil.

►Wash hands after contact with hydraulic oil.

Assembly or disassembly

WARNING Moving parts

Risk for leaking oil and personal injury, such as

crushed hands and fingers.

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

6 © Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

►Never check bores or passages with hands or

fingers.

►Any boom movements must only be done in

cooperation with the personnel mounting the

hydraulic breaker.

►If the hydraulic breaker is mounted on a quick

hitch coupling, make sure it is locked securely

and all risks of the hydraulic breaker coming

loose are eliminated.

Operation, precautions

DANGER Explosion hazard

If a working tool comes into contact with explosives

or explosive gases, an explosion could occur.

When working on certain materials and when using

certain materials in machine parts, sparks and

ignition can occur. Explosions will lead to severe

injuries or death.

►Never operate the machine in any explosive

environment.

►Never use the machine near flammable

materials, fumes or dust.

►Make sure that there are no undetected

sources of gas or explosives.

WARNING Operating pressure

If the maximum operating pressure for the

hydraulic machine is exceeded, the accumulator

can be over charged which can result in material

damage and personal injury.

►Always run the hydraulic machine with the

correct operating pressure. See "Technical

data".

WARNING Dust and fume hazard

Dusts and/or fumes generated or dispersed when

using the machine may cause serious and

permanent respiratory disease, illness, or other

bodily injury (for example, silicosis or other

irreversible lung disease that can be fatal, cancer,

birth defects, and/or skin inflammation).

Some dusts and fumes created by drilling,

breaking, hammering, sawing, grinding and other

construction activities contain substances known to

the State of California and other authorities to

cause respiratory disease, cancer, birth defects, or

other reproductive harm. Some examples of such

substances are:

•Crystalline silica, cement, and other masonry

products.

•Arsenic and chromium from chemically-treated

rubber.

•Lead from lead-based paints.

Dust and fumes in the air can be invisible to the

naked eye, so do not rely on eye sight to

determine if there is dust or fumes in the air.

To reduce the risk of exposure to dust and fumes,

do all of the following:

►Perform site-specific risk assessment. The risk

assessment should include dust and fumes

created by the use of the machine and the

potential for disturbing existing dust.

►Use proper engineering controls to minimize the

amount of dust and fumes in the air and to

minimize build-up on equipment, surfaces,

clothing, and body parts. Examples of controls

include: exhaust ventilation and dust collection

systems, water sprays, and wet drilling. Control

dusts and fumes at the source where possible.

Make sure that controls are properly installed,

maintained and correctly used.

►Wear, maintain and correctly use respiratory

protection as instructed by your employer and

as required by occupational health and safety

regulations. The respiratory protection must be

effective for the type of substance at issue (and

if applicable, approved by relevant

governmental authority).

►Work in a well ventilated area.

►If the machine has an exhaust, direct the

exhaust so as to reduce disturbance of dust in a

dust filled environment.

►Operate and maintain the machine as

recommended in the operating and safety

instructions

►Select, maintain and replace consumables/

working tools/ other accessories as

recommended in the operating and safety

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

Safety and operating instructions

© Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

7

instructions. Incorrect selection or lack of

maintenance of consumables/ inserted tools/

other accessories may cause an unnecessary

increase in dust or fumes.

►Wear washable or disposable protective clothes

at the worksite, and shower and change into

clean clothes before leaving the worksite to

reduce exposure of dust and fumes to yourself,

other persons, cars, homes, and other areas.

►Avoid eating, drinking, and using tobacco

products in areas where there is dust or fumes.

►Wash your hands and face thoroughly as soon

as possible upon leaving the exposure area,

and always before eating, drinking, using

tobacco products, or making contact with other

persons.

►Comply with all applicable laws and regulations,

including occupational health and safety

regulations.

►Participate in air monitoring, medical

examination programs, and health and safety

training programs provided by your employer or

trade organizations and in accordance with

occupational health and safety regulations and

recommendations. Consult with physicians

experienced with relevant occupational

medicine.

►Work with your employer and trade organization

to reduce dust and fume exposure at the

worksite and to reduce the risks. Effective

health and safety programs, policies and

procedures for protecting workers and others

against harmful exposure to dust and fumes

should be established and implemented based

on advice from health and safety experts.

Consult with experts.

►Residues of hazardous substances on the

machine can be a risk. Before undertaking any

maintenance on the machine, clean it

thoroughly.

WARNING Electric shock

The hydraulic breaker is not insulated against

electric current. If the hydraulic breaker come in

contact with electric circuits or other electrical

power sources, there is a risk of severe injury or

death.

►Never work in the proximity of electric circuits or

other electrical power sources.

►Make sure there are no hidden electric circuits

in your working area.

WARNING Projectiles

Failure of the work piece, of accessories, or even

of the hydraulic breaker itself may generate high

velocity projectiles. During breaking, splinters, or

other particles may become projectiles and cause

bodily injury by striking the operator or other

persons. Also, breakage of the work piece,

accessories, or the working tool may generate high

velocity projectiles that can cause bodily injury. In

addition, objects falling from a height can cause

bodily injury. To reduce risks:

►Close off the working area.

►Before starting, make sure that no persons are

in the danger area, 20 meters both horizontally

and vertically from the hydraulic breaker.

►Immediately switch off the hydraulic breaker

when persons are present in the danger area.

►Press the working tool against the working

surface before you start.

►Never operate unless the working tool is

retained in the hydraulic breaker with a proper

tool retainer.

WARNING Noise hazard

High noise levels can cause permanent and

disabling hearing loss and other problems such as

tinnitus (ringing, buzzing, whistling, or humming in

the ears). To reduce risks and prevent an

unnecessary increase in noise levels:

►Risk assessment of these hazards and

implementation of appropriate controls is

essential.

►Operate and maintain the machine as

recommended in these instructions.

►Select, maintain and replace the working tool as

recommended in these instructions.

►If the machine has a silencer, check that it is in

place and in good working condition.

►Always use hearing protection.

►Use damping material to prevent work pieces

from 'ringing'.

Maintenance, precautions

WARNING Involuntary start

An involuntary start of the hydraulic breaker can

lead to severe injuries.

►Follow the instructions in the carrier manual to

prevent involuntary start of the hydraulic

breaker.

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

8 © Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

►Installation of a start circuit on the hydraulic

breaker must be made in a way that avoids any

unintentional starts.

►A foot pedal on the carrier must be equipped

with a protection cover.

WARNING Hydraulic system under high

pressure

Maintenance work on a hydraulic breaker under

pressure can lead to severe injuries. Connections

can loosen suddenly, parts can suddenly move and

hydraulic oil can be ejected.

►Depressurise the hydraulic system before

performing maintenance on the hydraulic

breaker or the carrier.

WARNING Machine modification

Any machine modification may result in bodily

injuries to yourself or others.

►Never modify the machine. Modified machines

are not covered by warranty or product liability.

►Always use approved original parts, tools, and

accessories.

►Change damaged parts immediately.

►Replace worn components in good time.

CAUTION Hot working tool

The tip of the working tool can become hot and

sharp when used. Touching it can lead to burns

and cuts.

►Never touch a hot or sharp working tool.

►Wait until the working tool has cooled down

before carrying out maintenance work.

WARNING Working tool hazards

Accidental engagement of the start and stop

device during maintenance or installation can

cause serious injuries, when the power source is

connected.

►Never inspect, clean, install, or remove the

working tool while the power source is

connected.

Storage, precautions

WARNING Heavy hydraulic breaker and

working tool

The hydraulic breaker and the working tool are

heavy equipment. If the breaker or working tool

topple over or fall down from where they are

stored, it can result in material damage and

personal injury.

►Store the hydraulic breaker and the working tool

so that falling or rolling down is prevented.

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

Safety and operating instructions

© Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

9

Overview

To reduce the risk of serious injury or death to

yourself or others, read the Safety instructions

section found on the previous pages of this

manual before operating the machine.

Design and function

SB is a range of rig mounted hydraulic breakers

designed for all kinds of demolition works. No other

use is permitted.

SB has a solid body which means that the breaker

body is made in one piece. The accumulator is

integrated with the body.

The hydraulic breaker is operated from the driver's

cab of the carrier using the carrier's hydraulic

system. The breaker frequency is controlled by the

oil flow from the carrier.

Recommended working tools are listed in the

spare parts list.

Main parts

A

B

C

D

G

E

H

I

F

J

K

A. Restrictor

B. Hammer body

C. Lock pin

D. Pressure relief valve

E. Accumulator

F. Oil drainage plug

G. Lock buffer

H. Tool retainer

I. Bushing

J. Scraper ring

K. Wear plate (only valid for SB 302 Tunnel and

SB 452 Tunnel)

Labels

The machine is fitted with labels containing

important information about personal safety and

machine maintenance. The labels must be in such

condition that they are easy to read. New labels

can be ordered from the spare parts list.

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

10 © Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

Data plate

A

BCDE

F

A. Machine type

B. Maximum hydraulic pressure

C. Serial number

D. The warning symbol together with the book

symbol means that the user must read the

safety and operating instructions before the

machine is used for the first time.

E. The CE symbol means that the machine is EC-

approved. See the EC Declaration of

Conformity which is delivered with the machine

for more information.

F. The EAC symbol means that the machine is

EAC approved.

Noise level label

WA

xxx

dB

The label indicates the guaranteed noise level

corresponding to EC-directive 2000/14/EC. See

"Technical data" for accurate noise level.

Labels on the accumulator

Read through the overhaul instructions carefully

before servicing or charging.

2

N

The accumulator must only be charged with

Nitrogen.

NOTICE Only certified personnel are allowed to

work with the accumulator.

Guarantee

The guarantee or product liability will be

invalidated by the following:

•Use other than intended

•Maintenance work not being carried out or

being carried out incorrectly

•The use of the wrong consumables

•The use of non-approved parts

•Damage due to wear

•Special applications without the required safety

facilities

•Damage due to improper storage

•Changes not carried out by or in consultation

with the manufacturer

Transport

WARNING Falling hydraulic breaker

If the hydraulic breaker is tipping over and falling, it

may cause serious injury.

►Place the hydraulic breaker in a safe position

where it cannot fall over and cause damage.

Lifting the hydraulic breaker

Carefully check that the carrier is stable enough

when transporting, performing maintenance, or

other kinds of work with the hydraulic breaker.

The hydraulic breaker is delivered in a box. To lift

the hydraulic breaker in a safe way, fit the lifting

strap in the manner shown in the illustration below.

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

Safety and operating instructions

© Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

11

Transport using a forklift

When using a forklift. Place the hydraulic breaker

at a pallet. Use wedges and strapping to secure it.

Slowly lift and transport the hydraulic breaker to its

intended destination.

Transport using a lorry

Put the hydraulic breaker on an anti-slip mat at the

lorry. Secure the machine to the loading surface

with straps.

Observe all the applicable national and regional

regulations on securing loads.

Installation

Before installing the hydraulic breaker on the

carrier or operating it, read the operation manual

and safety instructions provided by the carrier

manufacturer. Follow all instructions.

The carrier must have the appropriate hydraulic

system for operation of the breaker.

If the carrier is too large for the hydraulic breaker it

may lead to broken working tools and increased

wear. See "Technical data" for choosing suitable

carrier.

The safety equipment in the hydraulic system must

be checked for quality (CE mark, etc.), suitability

and functionability by a professional or authorised

supervisor before use.

Hoses and connections

WARNING Whipping hydraulic hose

Hydraulic hoses under pressure can whip

uncontrollably if screws loosen or are loosened. A

whipping hydraulic hose can cause severe injuries.

►Depressurize the hydraulic system before

loosening the connection of a hydraulic hose.

►Tighten the nuts on the connections of the

hydraulic hoses to the required torque.

Type of nipple: ORFS standard nipple. The nipple

dimensions can be found in the Spare parts list.

The quality of the hydraulic hoses should be 2SC

(according to EN 857) or better when connecting

the breaker to the carrier. If quick couplings are to

be used, we recommend using the 'Flat Face'

quick coupling. This type is sturdy and easy to

clean. The quick coupling pressure class must

agree with the carrier's working pressure.

Always clean the quick couplings before mounting

or dismounting. Always plug hoses and hose

nipples with tight and clean end caps when

dismounting.

Hose connections

Right (As seen from operator’s seat)

Air flushing Central

lubrication

Tank, return

line

Symbol

SB 52 G 1⁄4 in. G 1⁄4 in. G 3⁄8 in.

SB 102 G 1⁄4 in. G 1⁄4 in. G 1⁄2 in.

SB 152 G 1⁄4 in. G 1⁄4 in. G 1⁄2 in.

SB 202 G 1⁄4 in. G 1⁄4 in. G 1⁄2 in.

SB 302 G 1⁄4 in. G 1⁄4 in. G 3⁄4 in.

SB 302

Tunnel

G 1⁄4 in. G 1⁄4 in. G 3⁄4 in.

SB 452 G 1⁄4 in. G 1⁄4 in. G 3⁄4 in.

SB 452

Tunnel

G 1⁄4 in. G 1⁄4 in. G 3⁄4 in.

SB 552 G 1⁄4 in. G 1⁄4 in. G 1 in.

Hose connections

Left (As seen from operator's seat)

Water Pressure to

breaker

Pressure for

ContiLube II

micro

Symbol

SB 52 - G 3⁄8 in. G 1⁄4 in.

SB 102 - G 1⁄2 in. G 1⁄4 in.

SB 152 G 1⁄4 in. G 1⁄2 in. G 1⁄4 in.

SB 202 G 1⁄4 in. G 1⁄2 in. G 1⁄4 in.

SB 302 G 1⁄4 in. G 3⁄4 in. G 1⁄4 in.

SB 302

Tunnel

G 1⁄4 in. G 3⁄4 in. G 1⁄4 in.

SB 452 G 1⁄4 in. G 3⁄4 in. G 1⁄4 in.

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

12 © Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

Hose connections

Left (As seen from operator's seat)

SB 452

Tunnel

G 1⁄4 in. G 3⁄4 in. G 1⁄4 in.

SB 552 G 1⁄4 in. G 1 in. G 1⁄4 in.

Tightening torque for pressure and return hoses

SB 52 60 Nm

SB 102 150 Nm

SB 152 150 Nm

SB 202 150 Nm

SB 302 210 Nm

SB 302 Tunnel 210 Nm

SB 452 210 Nm

SB 452 Tunnel 210 Nm

SB 552 300 Nm

NOTICE The tightening torques in the table

above are valid when the pressure and return hose

are mounted directly on the hydraulic breaker's

connection nipple. If the pressure and return hose

are connected with an additional connection

nipple, another tightening torques must be used.

Hydraulic oil

Normally the type of hydraulic oil the carrier is

using also works for the hydraulic breaker. When a

hydraulic breaker is connected to the carrier, the

hydraulic oil will get dirty faster. Check and follow

the carrier's instructions for changing oil and oil

filter. It is common to change the oil filter more

frequent when a hydraulic breaker is installed.

SB hydraulic breakers are equipped with an oil

drainage plug to drain all oil before dismounting.

This is to reduce the risk of spilling oil.

NOTICE When the SB breaker is delivered it

contains some mineral based hydraulic oil. Before

connecting to the carrier's hydraulic system, check

which type of hydraulic oil the carrier is using.

Mixing different types of hydraulic oil may destroy

the lubrication quality which can lead to machine

damage.

In order to protect the environment we recommend

the use of biologically degradable hydraulic oil.

Viscosity

Viscosity (permitted) 15-100 cSt

NOTICE Always use clean oil and filling

equipment.

Assembly

Circulate the hydraulic oil before connecting the

hydraulic breaker. This is to make sure that the

hydraulic oil is clean. Use the same routine when

changing the hydraulic oil hose. For further

information see section "Hydraulic oil".

1. Connect the pressure and return hoses.

2. Run the hydraulic oil through the carrier's oil

filter for approximately 3 minutes to make sure

that the hoses are clean.

WARNING Falling breaker can cause

injuries

►Place the breaker in a safe position where it

can not fall over and cause damage.

Preparation

1. Place the breaker in a position where it is easy

and safe to mount the adapter plate.

NOTICE Mount the breaker so that the

accumulator faces the operator's cabin, to

reduce the risk of accumulator damage.

Mounting the adapter plate

1. Place the adapter plate on the hydraulic

breaker.

2. Place NYLOK BLUE PATCH™ (Known as

TUF-LOK® in Europe) screws through all bore

holes and fit nuts to the screws.

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

Safety and operating instructions

© Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

13

If NYLOK BLUE PATCH™ (Known as TUF-

LOK® in Europe) screws are not available we

recommend using NORD-LOCK® washers

under bolts and nuts. (NYLOK BLUE PATCH is

a trademark of Nylok Corporation. TUF-LOK is

a registered trademark of Nylok Corporation in

Europe. NORD-LOCK is a registered

trademark of Nord-Lock International AB.)

3. Tighten the nuts, see the tightening torque in

the table below.

Adapter plate Tightening torque

SB 52 240 Nm

SB 102 170 Nm

SB 152 170 Nm

SB 202 170 Nm

SB 302 170 Nm

SB 302 Tunnel 170 Nm

SB 452 400 Nm

SB 452 Tunnel 400 Nm

SB 552 400 Nm

Connecting the breaker to the carrier

1. Position the breaker in a safe way during

installation.

The pressure inlet on the hydraulic breaker is

on the left side when you are facing the

accumulator. If the pressure hose is on the

other side of the boom you can cross the hoses

or turn the hydraulic breaker.

2. Carefully lower the stick of the boom into the

adapter.

WARNING Moving parts can crush and

cut

►Never check bores or passages with hands

or fingers.

An assistant must direct the movement of the

boom until the bores in the boom are flush with

those in the adapter.

Agree with the assistant on clear hand signals

for use during the mounting procedure.

3. Insert the pin and lock.

4. Lift up the hydraulic breaker using the boom.

5. Extend the bucket cylinder until the bore in the

toggle is flush with those in the adapter. Insert

toggle pin and lock.

6. After mounting the breaker, carefully extend

and retract the bucket cylinder to its full extent

in each direction. It is important that the

cylinder can be fully extended and retracted

without any difficulty.

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

14 © Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

Pressure adjustment

The hydraulic breaker is equipped with a pressure

relief valve which secures the breaker. The

operating pressure of the machine (max 150 bar)

is checked and adjusted by a pressure gauge

while operating the hydraulic breaker.

◆If the operating pressure is more than 150 bar

the pressure must be decreased. Reduce the

oil flow from the carrier until the pressure is

down to 150 bar. This adjustment is important

to ensure that the built in pressure relief valve in

the breaker does not open and leak oil back to

the tank and create heating problems.

◆If the operating pressure is between 130–150

bar, normally no adjustment is needed.

◆If the carrier's oil flow is too low to retain an

acceptable operating pressure the restrictor in

the breaker needs to be changed. See flow

diagrams in "Technical data" to choose the best

restrictor for your application.

Position the hydraulic breaker vertically towards

solid bedrock or similar to adjust the pressure

using a pressure gauge.

Water flushing

The hydraulic breaker is prepared for water

flushing, this function is to bind the dust when

performing demolition operations.

When connecting water flushing the plug in the

front of the breaker must be exchanged with a

water nozzle. See the Spare parts list for ordering

a new water nozzle.

Use a ¼ in. hydraulic hose with a JIC connection

as a proper water hose. Contact your nearest

authorised workshop for further instructions.

NOTICE It is recommended to use water flushing

to reduce the wear on the hydraulic breaker during

tunnel and dust-intensive applications.

Working tool

Selecting the right working tool

Conical moil point

•Very good

penetration

•Regular spread of

wedge action

•No torsion effect

Chisels and spades

•Very good spread of

wedge action

•Good penetration

•Torsion effect

Blunt tool

•Very good energy

application

•Optimum breaking

effect

•No torsion effect

Changing the working tool

WARNING Running engine

Changing the inserted tool or accessories while the

carrier's engine is running can cause serious injury.

►Secure the carrier against involuntary

activation.

1. Shut the carrier's engine off.

2. Dismount the working tool, use a lifting strap to

reduce the risk of personal injury.

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

Safety and operating instructions

© Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

15

3. Remove and check the lock buffer. Change

worn or damaged parts.

NOTICE The lock buffer in the tool retainer

lock is made of plastic and can melt when

operating in a hot environment. If this occurs,

change the standard lock pin. Find optional

spring pin in the spare parts list.

4. Clean and lubricate the bushing plentifully.

NOTICE When mounting a new working tool,

it is especially important to lubricate plentifully.

5. Mount the working tool, use a lifting strap to

reduce the risk of personal injury

6. Rotate the working tool to spread the grease.

7. Mount the tool retainers, one at the time.

8. Drive in the lock pin until the lock buffer

attaches in the lock pin groove.

Tunnel versions:

A

C

B

..

For Tunnel versions, dismount the working tool (A),

front shield (B) and dust cover (C). Use a lifting

strap to reduce the risk of personal injury.

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

16 © Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

If front shield or dust cover is worn out, change to

new ones, otherwise reuse them.

Mount the front shield and dust cover on the

working tool. Mount the working tool in accordance

with step 4 - 8.

Operation

NOTICE The hydraulic breaker or the working

tool is not to be used as a lifting device. When

lifting heavy components use the hook on the

carrier arm.

Preparation before breaking

Operating temperatures

The operating temperatures of the hydraulic

breaker are between -20ºC (-4ºF) and +80ºC

(+176ºF).

CAUTION Temperature hazard

The hydraulic breaker and the hydraulic oil system

of the carrier can be damaged if the hydraulic

breaker is used at higher or lower temperatures.

►Only start the hydraulic breaker when the

hydraulic oil has reached the proper operating

temperature.

►If the ambient temperature is below –20ºC

(-4ºF), you must warm up the working tool and

the hydraulic breaker before use.

►If the oil temperature exceeds +80ºC (+176ºF),

you must not use the hydraulic breaker as the

oil quality becomes inadequate which severely

shortens the life time of seals and O-rings.

Engine rpm

Too high engine rpm only results in increased fuel

consumption and increased oil temperature. Adapt

the engine rpm to the recommended value to give

the correct operating oil flow.

Operating

Risk area

Before starting the hydraulic breaker, make sure

that no persons are in the risk area, 20 meters

both horizontally and vertically from the hydraulic

breaker.

20 m

Breaking

CAUTION Machine and tool hazard

Continuous operation at full extension and/or

retraction can result in damage to the hydraulic

cylinders.

►Always avoid operating the breaker with the

cylinders fully extended or retracted.

►Reposition the carrier and/or boom to avoid fully

extended or retracted cylinders.

►Pay attention and look at what you are doing.

Never start the hydraulic breaker until both carrier

and the hydraulic breaker are in the correct

position.

◆Direct the hydraulic breaker in a position 90°

towards the object.

◆Start near the edge and work your way in

towards the middle. Never start in the middle of

large objects.

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

Safety and operating instructions

© Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

17

◆Never run the hydraulic breaker longer then 15

seconds on the same spot. Move the working

tool to a new position if the object does not

break.

◆Never bend with the working tool.

◆Use the correct feed pressure. When the feed

pressure is correct the hydraulic breaker is

working at its best and the vibrations are at a

minimum. Also the wear on the bushing and

inserted tool is kept to a minimum.

◆Listen to the sound from the hydraulic breaker.

The sound changes if there is any bending

between the working tool and bushing.

◆Never run the breaker with the boom cylinders

at their end positions. It may cause damage to

the carrier.

◆Avoid idling strokes; it causes wear on both

working tool and tool retainers.

◆The hydraulic breaker or the working tool is not

to be used as a lifting device. When lifting

heavy components use the hook on the carrier

arm.

◆Never use the hydraulic breaker as a sledge

hammer to demolish material.

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

18 © Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

◆Never use the hydraulic breaker to move

debris.

Breaking under water

Hydraulic breakers can be used for operating

under water.

bar

1.5-2

NOTICE When operating under water the

hydraulic breaker must be fed with compressed air

to keep the area between the piston and the

inserted tool free from water. If the area between

the piston and the inserted tool gets filled with

water, it may penetrate into the hydraulic oil system

when the hydraulic breaker is started.

The air pressure must be 1.5-2 bar at the air inlet

on the breaker and the air consumption can be

found in "Technical data". Suitable air hose is a 1⁄4

in. hydraulic hose with JIC connection. Contact

your nearest authorised workshop for further

instructions.

Heavy duty operation

The hydraulic breakers SB 302 Tunnel and SB 452

Tunnel are specially suited for heavy duty

operations such as scaling in tunnelling and

underground applications. The Tunnel breakers

are equipped with water nozzles (A).

A

Use a permanent water flushing and air supply as

standard to minimize wear and enable dust binding

during operation. See "Hoses and connections" for

information about connecting utilities.

Other breakers in the SB series, with the exception

of SB 52 and SB 102, can be retrofitted with water

nozzles. More information about water nozzles can

be found in the Spare parts list.

Special attention should be taken to ensure proper

lubrication and maintenance during heavy duty

operation. The use of a permanent lubrication

system or the ContiLube™ II micro is

recommended.

Special applications

NOTICE Always consult the Customer Center /

Dealer in your area in case of special applications-

tunnelling, high thermal load and underwater

application.

You can contact your nearest authorised workshop

for further instructions.

Maintenance

It is essential that regular maintenance is

performed to maintain the breakers maximum

efficiency.

Equipment that is insufficiently maintained can be

dangerous for both the operator and persons near

the breaker. Make sure that regular maintenance

routines with lubrication are followed to keep the

equipment safe and efficient.

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

Safety and operating instructions

© Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

19

Cleaning

NOTICE Environmental damage due to polluted

water

Hydraulic oil and chisel paste are environmentally

harmful and must not penetrate the ground or

enter the water table or water supplies.

◆Collect the water used for cleaning if it has

been contaminated by hydraulic oil and chisel

paste.

◆Dispose of the water in accordance with the

applicable regulations to avoid environmental

hazards.

Every second hour

Regularly lubricate the working tool, the tool

retainer and the bushings.

Lubricating with a grease gun

WARNING Hot working tool during

operation and a period of time after use.

►Avoid contact with the working tool.

WARNING Hot hydraulic breaker during

operation and a period of time after use.

►Avoid contact with the hydraulic breaker.

CAUTION Skin eczema

Grease can cause eczema if it comes in contact

with the skin.

►Avoid getting grease on your hands. Wash

thoroughly after contact.

1. Press the working tool all the way into the

breaker up to the stop (A). Otherwise the space

between the top of the working tool and the

piston will be filled with grease, and damage

can occur to seals, piston, and cylinder.

A

2. Lubricate the working tool's shank plentifully

during all upward operations. The bushing and

the working tool must be lubricated so

frequently that dirt cannot penetrate into the

hydraulic breaker.

When the working tool is exposed to high pressure

and high temperatures a standard type of grease

will melt and run. To avoid this always use Epiroc

chisel paste.

Central lubrication system

We recommend Epiroc's central lubrication

system. When this system is fitted on the carrier,

grease is pumped continuously from a lubrication

container on the carrier to the hydraulic breaker

when the hydraulic breaker is activated. This

increases the life of the tool bushings and working

tools considerably.

Every day

◆Check tool retainers and lock pins for damage,

change if necessary.

◆Check that hoses, couplings, and accumulator

are in a good condition, change if necessary.

◆Check that bolts and connections are free from

damage and properly tightened, change if

damaged. See tightening torques in the spare

parts list.

◆Refill the central lubricating system.

◆Check that wear plate and bolts are free from

damage, change if necessary.

Every week

◆Clean the hydraulic breaker carefully.

◆Check the wear bushing's wear and maximum

inner wear limits.

A

The wear bushing must be replaced when the

inner diameter (A) has reached its maximum

wear limit, see section "Wear limits" and

"Replacing the working tool bushing".

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel,

552

20 © Construction Tools PC AB | 9800 0648 01 | 2018-01-01

Original instructions

This manual suits for next models

8

Table of contents

Other Epiroc Power Tools manuals

Popular Power Tools manuals by other brands

Power Fist

Power Fist 8656860 user manual

Lumberjack

Lumberjack BJ1100 Safety and operating manual

Master cool

Master cool 70053 operating instructions

Tack life

Tack life PTR01A user manual

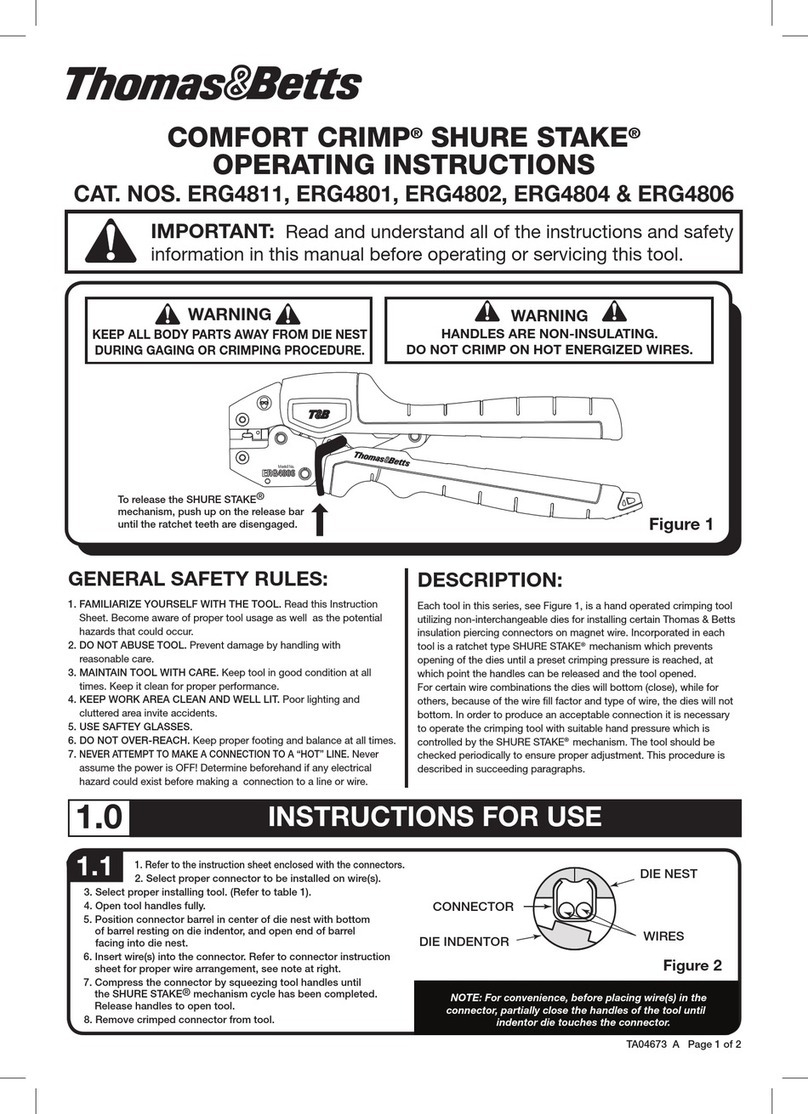

Thomas&Betts

Thomas&Betts COMFORT CRIMP SHURE STAKE ERG1802 operating instructions

FLORABEST

FLORABEST FSG 85 B1 translation of original operation manual

Pro's Kit

Pro's Kit SS-611A user manual

Central Pneumatic

Central Pneumatic 66874 Set up and operating instructions

Thomas&Betts

Thomas&Betts COMFORT CRIMP SHURE STAKE ERG4811 operating instructions

Delta

Delta DJ-15 instruction manual

Beveltools

Beveltools Bevel Mite ABIS-06 instruction manual

Power Fist

Power Fist 8654568 user manual