E+E Elektronik EE072 User manual

BA_EE072 // v2.0 // Modification rights reserved

User Manual

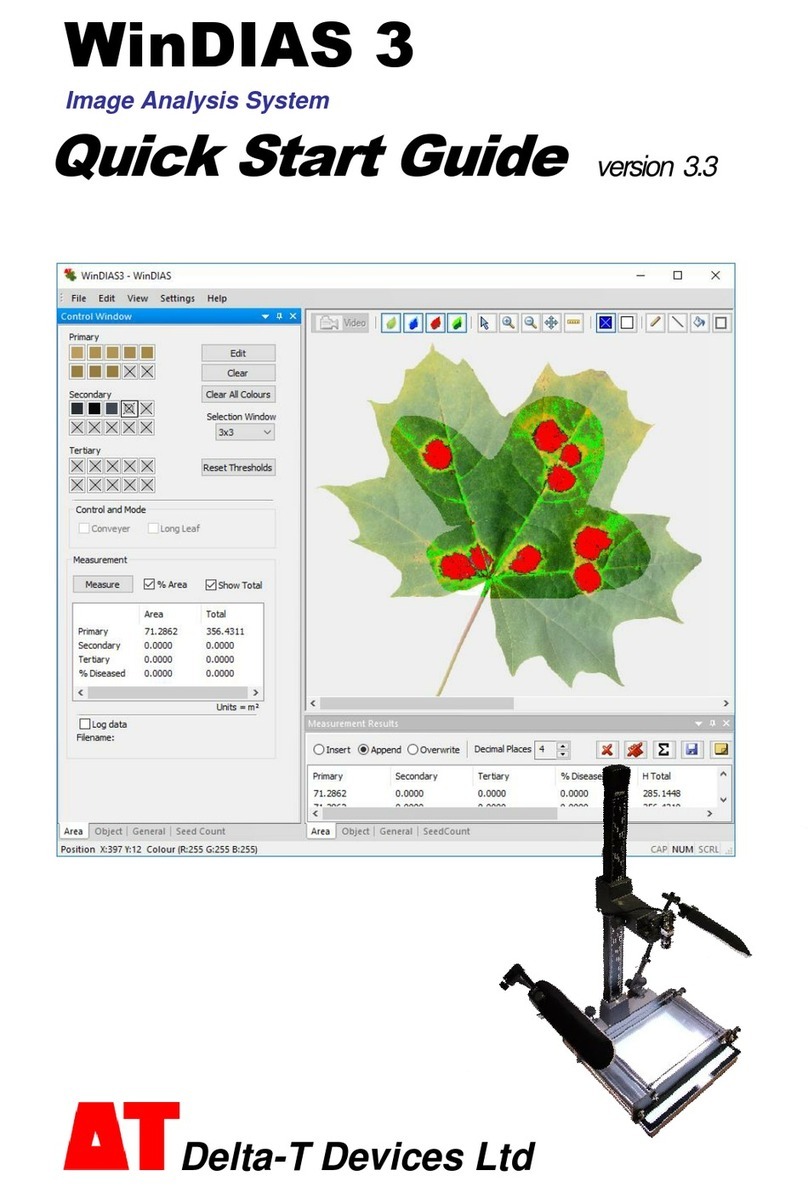

EE072

Humidity and Temperature Probe

with Digital Interface

E+E Elektronik Ges.m.b.H. doesn‘t accept warranty and liability claims neither upon this publication nor in case of

improper treatment of the described products.

The document may contain technical inaccuracies and typographical errors. The content will be revised on a

regular basis. These changes will be implemented in later versions. The described products can be improved and

changed at any time without prior notice.

© Copyright E+E Elektronik Ges.m.b.H. All rights reserved.

EMC note USA (FCC):

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

EMC note Canada (ICES-003):

CAN ICES-3 (A) / NMB-3 (A)

CONTENT

1 General .................................................................................................................................................4

1.1 Explanation of Symbols.................................................................................................................................4

1.2 Safety Instructions.........................................................................................................................................4

1.2.1 General Safety Instructions..................................................................................................................................4

1.2.2 Intended Use........................................................................................................................................................4

1.2.3 Mounting, Start-up and Operation........................................................................................................................4

1.3 Environmental Aspects..................................................................................................................................5

2 Scope of Supply ..................................................................................................................................5

3 Product Description ............................................................................................................................5

3.1 General..........................................................................................................................................................5

3.2 Dimensions....................................................................................................................................................6

3.3 Electrical Connection.....................................................................................................................................6

3.3.1 Modbus Version ...................................................................................................................................................6

3.3.2 CANopen Version ................................................................................................................................................7

3.4 Specification of the CAN Lines......................................................................................................................7

4 Installation ...........................................................................................................................................7

4.1 Wall and Ceiling Mount..................................................................................................................................7

4.2 Duct Mount ....................................................................................................................................................8

4.3 Recommendations for accurate Humidity and Temperature

Measurement ................................................................................................................................................8

5 Modbus.................................................................................................................................................9

5.1 Modbus Setup ...............................................................................................................................................9

5.2 Modbus Register Map .................................................................................................................................10

5.3 Modbus RTU Example ................................................................................................................................11

6 CANopen ............................................................................................................................................12

6.1 CANopen Setup ..........................................................................................................................................12

6.2 Function overview .......................................................................................................................................12

6.3 Electronic Datasheet (EDS) ........................................................................................................................13

6.4 Layer Setting Services (LSS) ......................................................................................................................13

7 Maintenance and Service .................................................................................................................13

7.1 Cleaning ......................................................................................................................................................13

7.2 Filter Cap Replacement...............................................................................................................................13

7.3 Protection during Site Cleaning Operations ................................................................................................14

7.4 Repairs ........................................................................................................................................................14

7.5 Configuration Interface ................................................................................................................................14

7.6 RH / T Adjustment and Calibration ..............................................................................................................14

7.7 Spare Parts .................................................................................................................................................15

8 Accessories .......................................................................................................................................15

9 Technical Data ...................................................................................................................................16

4User Manual EE072 Humidity and Temperature Probe with Digital Interface

1 General

This user manual serves for ensuring proper handling and optimal functioning of the device. The user

manual shall be read before commissioning the equipment and it shall be provided to all staff involved

in transport, installation, operation, maintenance and repair. The user manual may not be used for the

purposes of competition without the written consent of E+E Elektronik® and may not be forwarded to

third parties. Copies may be made for internal purposes. All information, technical data and diagrams

included in these instructions are based on the information available at the time of writing.

1.1 Explanation of Symbols

This symbol indicates safety information.

It is essential that all safety information is strictly observed. Failure to comply with this information can

lead to personal injuries or damage to property. E+E Elektronik® assumes no liability if this happens.

This symbol indicates instructions.

The instructions shall be observed in order to reach optimal performance of the device.

1.2 Safety Instructions

1.2.1 General Safety Instructions

■ Avoid any unnecessary mechanical stress and inappropriate use.

■ When replacing the filter cap make sure not to touch the sensing elements.

■ The device must be operated with the filter cap on at all times.

■ Installation, electrical connection, maintenance and commissioning shall be performed by qualified

personnel only.

■ Use the EE072 only as intended and observe all technical specifications.

■ Do not use EE072 in explosive atmosphere or for measurement of aggressive gases.

■ Do not apply the nominal voltage to the data lines.

1.2.2 Intended Use

The EE072 is intended for highly accurate humidity (RH) and temperature (T) measurement in

demanding process applications. The measured values and the calculated parameters are availabe on

Modbus RTU or CANopen.

The use of the EE072 in any other way than described in this manual bears a safety risk for people and

the entire measurement installation and is therefore not allowed.

The manufacturer cannot be hold responsible for damages as a result of incorrect handling, installation,

and maintenance of the equipment.

In order to avoid damage to the instrument or health hazards, the measuring equipment must never be

manipulated with tools that are not specifically described in this manual.

The sensor may only be utilized in accordance with the conditions defined in the technical data.

Otherwise, measurement inaccuracies will occur and equipment failures cannot be ruled out.

The steps recommended by the manufacturer for installation, inspections and maintenance work must

be observed and carried out for the safety of the user and for the functionality of the equipment.

Unauthorized product modification leads to loss of all warranty claims. This may be accomplished only

with an explicit permission of E+E Elektronik®!

1.2.3 Mounting, Start-up and Operation

The EE072 humidity and temperature probe has been produced under state of the art manufacturing

conditions, has been thoroughly tested and has left the factory fulfilling all safety criteria. The

manufacturer has taken all precautions to ensure safe operation of the device. The user must ensure

5

User Manual EE072 Humidity and Temperature Probe with Digital Interface

that the device is set up and installed in a manner that does not have a negative effect on its safe

use. The user is responsible for observing all applicable safety guidelines, local and international, with

respect to safe installation and operation on the device. This user manual contains information and

warnings that must be observed by the user in order to ensure safe operation.

■ Mounting, start-up, operation and maintenance of the device may be performed by qualified staff

only. Such staff must be authorized by the plant operator to carry out the mentioned activities.

■ The qualified staff must have read and understood this user manual and must follow the

instructions contained within.

■ All process and electrical connections shall be thoroughly checked by authorized staff before putting

the device into operation.

■ Do not install or start-up a device supposed to be faulty. Make sure that such devices are not

accidentally used by marking them clearly as faulty.

■ A faulty device may only be investigated and possibly repaired by qualified, trained and authorized

staff. If the fault cannot be fixed, the device shall be removed from the process.

■ Service operations other than described in this user manual may only be performed by the

manufacturer.

Disclaimer of Liability

The manufacturer or their delegated representative is only liable in case of intent or gross negligence.

The accountability is limited to the value of the order issued at the time to the manufacturer. The

manufacturer is not liable for damages, originated from disregarding the safety instructions or violating

the instructions of the manual or operating conditions. Consequential damages are excluded from any

liability.

1.3 Environmental Aspects

Products from E+E Elektronik® are developed and manufactured observing of all relevant requirements

with respect to environment protection. Please observe local regulations for the device disposal.

For disposal, the individual components of the device must be separated according to local recycling

regulations. The electronics shall be disposed of correctly as electronics waste.

2 Scope of Supply

■ EE072 – Humidity and Temperature Probe with Digital Interface according to ordering code

■ Inspection certificate according to DIN EN 10204-3.1

■ Quick guide (for Modbus version only)

3 Product Description

3.1 General

The EE072 is a robust probe for relative humidity and temperature measurement. Its IP65 rating and

the E+E proprietary protective sensor coating make it ideal for highest requirements. This is also

underlined by the wide humidity and temperature working ranges of 0...100 %RH and -40...80 °C.

The EE072 is typically implemented in demanding process and climate control applications like in

agriculture, life stock, food, pharma or clean rooms. A wide choice of filter caps allow for versatile

options in challenging industrial applications. Installation is simplified by various mounting options which

are supported by E+E accessories.

The EE072 is available with two different interface versions, either with CANopen/CAN or with Modbus

RTU over RS485. The M12x1 connector links the probe to the digital infrastructure.

6User Manual EE072 Humidity and Temperature Probe with Digital Interface

3.2 Dimensions

L

101.5 (4)

99.5 (3.92)

M12x1

11

(0.43)

Ø12 (0.47)

L = Filter length; refer to data sheet "Accessories"

Fig. 1 Dimensions of EE072 in mm (inch)

5

1.5

20 Ø5

20

1.5

122

Ø105

174

44

94

Fig. 2 Dimensions of optional radiation shield (ordering code HA010502) in mm

3.3 Electrical Connection

The relations of electrical potential between a bus system and an EE072 humidity/temperature sensor

are characterized by the following properties:

■ The bus connection is not electrically isolated from the supply connection

■ The individual EE072 node is not electrically isolated from the supply voltage

■ Each EE072 humidity/temperature sensor can be supplied separately

3.3.1 Modbus RTU Version

Pin number Function Wire colors for accessories:

- Coupling flange HA010705

- Connection cable HA010819/820/821

1Supply voltage brown

2B RS485 (D-) white

3GND blue

4A RS485 (D+) black

front view

M12 device plug

front view

1 2

34

5

front view

1 2

34

Tab. 1 Connection to the EE072 Modbus RTU version

7

User Manual EE072 Humidity and Temperature Probe with Digital Interface

3.3.2 CANopen Version

Pin number Function Wire colors according to ISO 11898:

1CAN_SHLD Not in use

2CAN_V+ brown

3CAN_GND white

4CAN_H green

5CAN_L yellow

front view

M12 device plug

front view

1 2

34

5

front view

1 2

34

Tab. 2 Connection to the EE072 CANopen version, in accordance with CiA-303-1

In order to ensure a stable CANopen communication, the supply voltage must exceed the lower supply

voltage limit of 10 V DC within two seconds after power-on.

The EE072 triggers an alarm message if the supply voltage is outside the supply limits. The lowest

detectable voltage is 9 V and the highest 35 V.

3.4 Specification of the CAN Lines

The cables used for connecting the CAN bus nodes must comply with ISO 11898. Therefore, the lines

must have the following characteristics:

Bus system overall length

Parameter

< 300 m < 1000 m

Cable type LIYCY 2 x 2 x 0.5 mm2

twisted pair with shielding

CYPIMF 2 x 2 x 0.5 mm2

twisted pair with shielding

Line resistance 40Ω/km 40Ω/km

Line capacitance 130 nF/km 60 nF/km

Connection Pair 1 (white / brown): CAN_GND and CAN_V+

Pair 2 (green / yellow): CAN_H and CAN_L

Tab. 3 CAN cable specification

■ Only use cables that have an additional pair of wires for CAN_GND.

■ Trouble-free operation of the CAN bus is only possible with correctly connected CAN_GND.

■ Connectthebusterminationresistors.A120Ωterminatingresistormustbeconnectedateach

physical end of the bus system (main trunk).

4 Installation

4.1 Wall and Ceiling Mount

Best measurement performance is achieved when the entire probe is located inside the environment to

be monitored.

In such a case, the EE072 may be for instance fixed onto a wall with the mounting clip HA010211 (not

included in the scope of supply, see data sheet “Accessories”), or freely hang from the ceiling on the

connection cable.

Fig. 3 Optional wall and ceiling mount (ordering code HA010211)

8User Manual EE072 Humidity and Temperature Probe with Digital Interface

4.2 Duct Mount

The probe also can be installed into a duct using the plastic flange HA010202 or the stainless steel

flange HA010201 (not included in the scope of supply, see data sheet “Accessories”).

Fig. 4 Optional plastic flange (ordering code

HA010202)

Fig. 5 Optional stainless steel flange

(ordering code HA010201)

4.3 Recommendations for accurate Humidity and Temperature

Measurement

■ In case the EE072 probe is not entirely located in the environment to be monitored, large

temperature differences along the probe will lead to temperature gradients. These will have an

influence on the accuracy. Therefore, it is of paramount importance to minimize the temperature

gradients. The biggest part of the probe shall be located in the target environment and the rest shall

be thermally well insulated.

■ For outdoor applications the EE072 shall be equipped with a radiation shield (HA010502) which

provides protection from rain, snow and ice. This also causes a natural ventilation which largely

prevents overheating of the probe in the sun and thus a distortion of the measured values.

■ For highest accuracy of the measured humidity and the calculated parameters (e.g. wet bulb

temperature, dew point and others), the user can set the barometric pressure at the operating point,

using the EE-PCS Product Configuration Software (see „7.5 Configuration Interface“), via Modbus

protocol (see „5.1 Modbus Setup“) or via CANopen protocol. The factory setting is 1013.25 mbar.

■ Best accuracy is achieved with a velocity of min. 0.2 m/s of the air surrounding the probe. Depending

on the installation position, flow direction and flow velocity, the accuracy may decline. The following

table gives a concise overview. Please note that the vertical positioning with the sensing element

upside is the most sensitive one concerning accuracy. Because of possible self heating due to the

sensor electronics, it is crucial to have the indicated air flow velocity.

Flow direction of medium

> 0.2 m/s > 0.2 m/s

Polycarbonate > 0.2 m/s

Stainless steel > 2 m/s > 0.2 m/s

> 0.2 m/s Polycarbonate > 0.2 m/s

Stainless steel > 2 m/s

> 0.2 m/s > 0.2 m/s

Tab. 4 Mounting position, air velocity and accuracy

9

User Manual EE072 Humidity and Temperature Probe with Digital Interface

5 Modbus

5.1 Modbus Setup

Factory settings Selectable values (via EE-PCS)

Baud rate 9600 9600, 19200, 38400, 57600, 76800, 115200

Data bits 8 8

Parity Even None, odd, even

Stop bits 1 1, 2

Slave address 234 1...247

Tab. 5 Modbus default settings

Device address, baud rate, parity and stop bits can be set via:

1. EE-PCS, Product Configuration Software and the Modbus configuration adapter HA011018.

The EE-PCS can be downloaded free of charge from www.epluse.com/configurator

2. Modbus protocol in the register 60001 (0x00) and 60002 (0x01).

See Application Note Modbus AN0103 (available on www.epluse.com/EE072)

The serial number as ASCII-code is located at read register address 30001-30008 (16 bits per address).

The firmware version is located at register address 30009 (bit 15...8 = major release; bit 7...0 = minor

release). The sensor name is located at register address 30010.

Please note: When reading the serial number or the sensor name, it is always necessary to read all 8

registers, even if the desired information requires less.

Please note: For obtaining the correct floating point values, both registers have to be read within

the same reading cycle. The measured value can change between two Modbus requests, therefore

exponent and mantissa may get inconsistent.

Communication settings (INTEGER 16 bit)

Parameter Register number1) [DEC] Protocol address2) [HEX]

Write register: function code 0x06

Slave-ID Modbus address 0001 0x00

Modbus protocol settings3) 0002 0x01

1) Register number starts from 1.

2) Protocol address starts from 0.

3) For Modbus protocol settings see Application Note Modbus AN0103 (available on www.epluse.com/EE072).

INFO (read register)

Parameter Register number1) [DEC] Protocol address2) [HEX]

Read register: function code 0x03 / 0x04

Serial number (as ASCII) 0001 0x00

Firmware version 0009 0x08

Sensor Name 0010 0x09

1) Register number starts from 1.

2) Protocol address starts from 0.

Air pressure

Parameter Register number1) [DEC] Register address2) [HEX]

Read and write register: function code 0x03 / 0x10

Air pressure3) 5001 0x1388

1) Register number starts from 1

2) Register address starts from 0

3) Ambient pressure in mbar, with 2 decimal digits (e.g. 1008.25), (Default value 1013.25 mbar)

10 User Manual EE072 Humidity and Temperature Probe with Digital Interface

5.2 Modbus Register Map

The measured data is saved as a 32 bit floating point values (data type FLOAT) and as 16 bit signed

integer values (data type INTEGER).

FLOAT (read register):

Parameter Unit Register number1) [Dec] Register address2) [HEX]

Read register: function code 0x03 / 0x04

Temperature T

°C 1003 0x3EA

°F 1005 0x3EC

°K 1009 0x3F0

Relative humidity RH, Uw % RH 1021 0x3FC

Water vapour partial pressure e mbar 1101 0x44C

psi 1103 0x44E

Dew point temperature Td

°C 1105 0x450

°F 1107 0x452

°K 1147 0x47A

Wet bulb temperature Tw

°C 1109 0x454

°F 1111 0x456

°K 1145 0x478

Absolute humidity dv g/m³ 1113 0x458

gr/ft³ 1115 0x45A

Mixing ratio r g/kg 1121 0x460

gr/lb 1123 0x462

Specific enthalpy h

kJ/kg 1125 0x464

ft lbf/lb 1127 0x466

BTU/lb 1129 0x468

Frost point temperature Tf

°C 1131 0x46A

°F 1133 0x46C

°K 1149 0x47C

Ice bulb temperature Ti

°C 1237 0x4D4

°F 1239 0x4D6

°K 1241 0x4D8

1) Register number starts from 1

2) Register address starts from 0

INTEGER (read register):

Parameter Unit Scale3) Register number1) [Dec] Register address2) [HEX]

Read register: function code 0x03 / 0x04

Temperature T

°C 100 4002 0xFA1

°F 50 4003 0xFA2

°K 50 4005 0xFA4

Relative humidity RH, Uw % RH 100 4011 0xFAA

Water vapour partial pressure e mbar 10 4051 0xFD2

psi 1000 4052 0xFD3

Dew point temperature Td

°C 100 4053 0xFD4

°F 100 4054 0xFD5

°K 100 4074 0xFE9

Wet bulb temperature Tw

°C 100 4055 0xFD6

°F 100 4056 0xFD7

°K 100 4073 0xFE8

Absolute humidity dv g/m³ 10 4057 0xFD8

gr/ft³ 10 4058 0xFD9

Mixing ratio r g/kg 10 4061 0xFDC

gr/lb 10 4062 0xFDD

Specific enthalpy h

kJ/kg 1 4063 0xFDE

ft lbf/lb 1 4064 0xFDF

BTU/lb 1 4065 0xFE0

Frost point temperature Tf

°C 100 4066 0xFE1

°F 100 4067 0xFE2

°K 100 4075 0xFEA

Ice bulb temperature Ti

°C 100 4119 0x1016

°F 100 4120 0x1017

°K 50 4121 0x1018

1) Register number starts from 1

2) Register address starts from 0

3) Examples: For scale 100, the reading of 2550 means a value of 25.5. For scale 50, the reading of 2550 means a value of 51.

11

User Manual EE072 Humidity and Temperature Probe with Digital Interface

5.3 Modbus RTU Example

Example of MODBUS RTU command for reading the temperature (float value) T = 26,953624 °C

from the register 0x3EA

■ Device EE072; slave ID 234 [0xEA]

Reference document, chapter 6.3: www.modbus.org/docs/Modbus_Application_Protocol_V1_1b.pdf

■ See Application Note Modbus AN0103 (available on www.epluse.com/EE072)

Modbus ID

address

Function

code

Starting

address Hi

Starting

address Lo

No. of

register Hi

No. of

register Lo CRC

Request [Hex]: EA 03 03 EA 00 02 F2 A0

Modbus ID

address

Function

code

Byte

count

Register 1

value Hi

Register 1

value Lo

Register 2

value Hi

Register 2

value Lo CRC

Response Hex]: EA 03 04 A1 06 41 D7 12 CE

Decoding of oating point values:

Floating point values are stored according IEEE754 standard. The byte pairs 1, 2 and 3, 4 are inverted

as follows:

MMMMMMMM MMMMMMMM SEEEEEEE EMMMMMMM

Byte 3 Byte 4 Byte 1 Byte 2

Example:

Response [Hex] Value in

decimal

Byte 1 (Register 2 - Hi) Byte 2 (Register 2 - Lo) Byte 3 (Register 1 - Hi) Byte 4 (Register 1 - Lo)

41 D7 A1 06 26.953624

12 User Manual EE072 Humidity and Temperature Probe with Digital Interface

6 CANopen

6.1 CANopen Setup

Factory settings Selectable parameters Configurable via

Baud rate 125 kBit/s 125 kBit/s, 250 kBit/s, 500 kBit/s, 800

kBit/s, 1MBit/s

EE-PCS or LSS

Node ID 64 1...127 EE-PCS or LSS

TPDO 1 T in [°C], Uw in [%] T, Uw, e, Td, Tw, dv, r, h, Tf, Ti CAN SDO

TPDO 2 e in [mbar],Td in [°C] T, Uw, e, Td, Tw, dv, r, h, Tf, Ti CAN SDO

TPDO 3 r in [g/kg], h in [kJ/kg] T, Uw, e, Td, Tw, dv, r, h, Tf, Ti CAN SDO

TPDO 4 Tf in [°C], Ti in [°C] T, Uw, e, Td, Tw, dv, r, h, Tf, Ti CAN SDO

TPDO data type REAL32 REAL32, INTEGER16 CAN SDO

Abbreviations: TPDO Transceive Process Data Object

EE-PCS E+EProductCongurationSoftware(seechapter7.5CongurationInterface)

LSS Layer Setting Services (see chapter 6.4 Layer Setting Services (LSS))

CAN SDO Service Data Object

Tab. 6 CANopen default settings

Parameter Symbol Condition Units

Temperature T [°C, °F, K]

Relative humidity Uw, RH [%]

Water vapour partial pressure e [mbar, psi]

Dew point temperature Td [°C, °F, K]

Wetbulb temperature Tw Tw 0 C [°C, °F, K]

Water vapour density

(absolute humidity)

dv [g/m³]

Mixing ratio r [g/kg]

Specific enthalpy h [kJ/kg]

Frost point temperature Tf Tf 0 °C [°C, °F, K]

Ice bulb temperature Ti Ti 0 °C [°C, °F, K]

Tab. 7 Selectable parameters

6.2 Function overview

The EE072 humidity/temperature probes have a standardised CANopen interface according to

CiA DS-301 and a device profile according to CiA DSP-404. All measured values and parameters

are accessible via the object directory (OD). The individual configuration can be saved in the internal

permanent memory (EEPROM).

The following CANopen functions are available:

■ Transceive Process Data Objects (TPDO1 - 4) in four possible operating modes:

– individual query via Remote Transmit Request (RTR)

– cyclic transmission by interval time

– event-controlled transmission on measurand change

– synchronized transmission after receipt of a SYNC telegram

■ Service Data Object (standard SDO)

■ Error messages via Emergency Object (EMCY) with support:

– the general error register (Error Register)

– the manufacturer-specific status register (Manufacturer Status)

– the error list (Pre-defined Error Field)

– supply range alarm

■ Monitoring mechanisms Heartbeat and Nodeguarding/Lifeguarding

■ Save and restore function for all parameters (Store and Load Parameter Field)

■ Setting the Node ID and the baud rate via LSS

■ In addition to the CiA DS-301 functionality, there are further manufacturer or profile specific features:

– Setting of pressure compensation parameter (object 2205h- default value 1013.25 mbar)

– Supply voltage monitoring

– Read calibration date (factory and customer)

13

User Manual EE072 Humidity and Temperature Probe with Digital Interface

6.3 Electronic Datasheet (EDS)

An electronic data sheet (EDS) is available for the EE072 CANopen (download free of charge at E+E‘s

EE072 webpage) .

It contains a complete description of the object dictionary and facilitates a convenient integration into a

CANopen engineering software.

6.4 Layer Setting Services (LSS)

In order to use the LSS functionality, LSS data is required which clearly identifies the sensor. This is the

Identity Object (Index 1018h).

Designation Object Sub-Index Value for EE072

Vendor ID 1018h01h000004C8h

Product code 1018h02h0x00h

Revision number 1018h03h0x00h

CANopen serial number 1018h04hdevice specific (LLS – 04h: 0x….)

The sensor specific identifier (LLS – 04h) is printed on each EE072.

Example of sensor labeling including LSS data:

EE072 TT2

CANopen / LSS – 04h: 0x20220503

Supply: 10 - 28 V DC

7 Maintenance and Service

EE072 does not require any special maintenance, nevertheless for high accurate measurements espe-

cially over wide RH and T ranges it is recommended to calibrate the probe every 12 months. If needed,

the enclosure may be cleaned and the device may be re-adjusted as described below.

7.1 Cleaning

Use a damp soft cloth to remove deposits of dust or dirt from the exterior of the probe. Do not use any

solvents or abrasive cleaning agents.

In case of dusty, oily and polluted environment:

■ Use a damp soft cloth to remove deposits of dust or dirt from the exterior of the probe. Do not use

any solvents or abrasive cleaning agents.

■ The filter cap shall be replaced once in a while with an E+E original one (see below).

■ If needed, the sensing element of the humidity probe can be cleaned by the user (see cleaning inst-

ruction - www.epluse.com/cleaning-instructions)

7.2 Filter Cap Replacement

In a dusty or polluted environment it might be necessary to replace the filter cap once in a while. In most

of the cases, a clogged filter shows visible contamination or dirt. Longer response time of the humidity

measurement also indicates a clogged filter cap. In such cases, replace the filter by a new, original one,

see „7.7 Spare Parts“.

Procedure

■ Turn the filter cap counter-clockwise for removing it.

■ Install the new filter cap finger tight by turning it clockwise.

While replacing the filter cap take very good care to not touch or rub the sensing element.

14 User Manual EE072 Humidity and Temperature Probe with Digital Interface

7.3 Protection during Site Cleaning Operations

During site cleaning or sterilization process, if the EE072 remains on the measuring site the sensing

head can be protected with the optional protection cap for 12 mm (0.47") probe (HA010783, see

datasheet “Accessories”).

In case the probe is removed from the site, it is recommended to apply the protection cap for the M12

cable socket (HA010781) and the one for the EE072 M12 plug of (HA010782).

Fig. 6 Protection cap for

Ø12 mm (0.47") probe

(ordering code

HA010783)

Fig. 7 Protection cap M12

female connector

(ordering code

HA010781)

Fig. 8 Protection cap M12

female connector

(ordering code

HA010782)

7.4 Repairs

Repairs may be carried out by the manufacturer only. The attempt of unauthorized repair excludes any

warranty claims.

7.5 Configuration Interface

The EE072 is ready to use and does not require any configuration by the user. The user can change the

factory setup by using the configuration adapter (Modbus: HA011018 / CAN: HA011021) and the EE-

PCS Product Configuration Software.

With the EE-PCS, it is possible to change the digital communication settings and to perform a RH

and T adjustment in the form of an offset or as a 2-point adjustment. For the purpose of pressure

compensation, the barometric air pressure at the operating site may be set.

EE-PCS PRODUCT CONFIGURATION SOFTWARE

1. Download the EE-PCS Product Configuration Software from www.epluse.com/configurator and

install it on the PC.

2. Connect the E+E device to the PC using the appropriate configuration cable.

3. Start the EE-PCS software.

4. Follow the instructions on the EE-PCS opening page for scanning the ports and identifying the

connected device.

5. Click on the desired setup or adjustment mode from the main EE-PCS menu on the left and follow

the online instructions of the EE-PCS.

PC

HA011018/HA011021

7.6 RH / T Adjustment and Calibration

Definition

■ Adjustment

the specimen is brought in line with the reference.

■ Calibration

the specimen is compared with a reference and its deviation from the reference is documented.

15

User Manual EE072 Humidity and Temperature Probe with Digital Interface

Humidity calibration and adjustment

Depending on the application and the requirements of certain industries, there might arise the need for

periodical humidity calibration (comparison with a reference) or adjustment (bringing the device in line

with a reference).

Calibration and adjustment at E+E Elektronik

Calibration and/or adjustment can be performed in the E+E Elektronik calibration laboratory. For

information on the E+E capabilities in ISO or accredited calibration please see www.eplusecal.com.

Calibration and adjustment by the user

Depending on the level of accuracy required, the humidity reference can be:

■ Humidity calibrator (e.g. Humor 20), please see www.epluse.com/humor20.

■ Handheld device (e.g. Omniport 30), please see www.epluse.com/omniport30.

■ Humidity standards (e.g. Humidity Calibration Kit), please see www.epluse.com/EE072.

7.7 Spare Parts

Description Order code

Filter caps for probes with Ø 12 mm Please refer to the

datasheet “Accessories“

8 Accessories

General Order code

E+E Product Configuration Software (Download: www.epluse.com/configurator) EE-PCS

Protection cap for the M12 cable socket HA010781

Protection cap for the M12 plug of EE072 HA010782

Protection cap for 12 mm probe HA010783

Stainless steel mounting flange HA010201

Plastic mounting flange HA010202

T-coupler M12 - M12 HA030204

Wall mounting clip HA010211

Radiation shield for probes with Ø12mm HA010502

Drip water protection HA010503

Modbus Order code

M12 cable connector for self assembly, 4 pole HA010707

Modbus configuration adapter HA011018

Connection cable, 5 pole, M12x1 socket - free ends, PUR insulation

1.5 m (4.9 ft)

5 m (16.4 ft)

10 m (32.8 ft)

HA010819

HA010820

HA010821

CAN Order code

M12 cable connector for self assembly, 5 pole HA010708

CAN configuration adapter HA011021

16 User Manual EE072 Humidity and Temperature Probe with Digital Interface

9 Technical Data

Measurands

Relative humidity

Accuracy1) (incl. hysteresis, non-linearity and repeatability)

-15…40 °C (5…104 °F) ±(1.3+0.3%*mv)%RH forRH≤90%

± 2.3 % for RH >90 %

-40…80 °C (-40…176 °F) ± (1.5 + 1.5 % *mv) %RH mv = measured value

Response time < 15 s with stainless steel grid filter at 20 °C (68 °F) / t90

Resolution 0.01 %RH

Temperature

Accuracy1)

0.48

0.6

0.4

0.3

0.2

0.1

standard

high

Resolution 0.01 °C

General

Sensing element E+E HCT01 with E+E proprietary coating

Measuring interval 1 s

Supply 10 - 28 V DC

Current consumption, typ. 3 mA (RS485, without termination resistor)

8 mA (CAN)

Enclosure Polycarbonate RAL 7035 / Stainless steel 1.4404 / AISI 316

Protection class2) IP65

Electromagnetic compatibility EN 61326-1:2013 EN 61326-2-3:2013

Industrial Environment

Working range -40…80 °C (-40...176 °F) / 0…100 % RH

Storage conditions -40…80 °C (-40...176 °F) / 0…90 % RH, non-condensing

Configuration and adjustment EE-PCS (Product Configuration Software, free download) and

configuration adapter

Digital Communication

RS485

Protocol Modbus RTU

Connector M12x1, 4 poles

Default settings Baud rate 96003), parity even, 1 stop bit, slave ID 234

CAN

Protocol / Profile CANopen / device profile CiA 404

Connector M12x1, 5 poles, pin assignment according to CiA 303-1

Default settings Baud rate 125 kBit/s4), node ID 64

1) Traceable to international standards, administrated by NIST, PTB, BEV,... The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor

k=2 (2-times standard deviation). The accuracy was calculated in accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

For Modbus, the accuracy is defined at a 12 V DC supply, baud rate 9600, without termination resistor, a polling interval of >= 1 s and a flow velocity of > 0.2 m/s.

For CANopen, the accuracy is defined at a flow velocity of > 0.2 m/s.

2) The IP65 rating applies when plugged into an appropiate M12x1 female connector.

3) Supported baud rates: 9 600, 19 200, 38 400, 57 600, 76 800 and 115 200.

For more details about communication setting see User Manual and Modbus Application Note at www.epluse.com/ee072

4) Supported baud rates: 125 kBit/s, 250 kBit/s, 500 kBit/s, 800 kBit/s, 1 MBit/s.

For further information on the configuration see software instruction manual and the EDS file (Electronic Data Sheet).

HEADQUARTERS

E+E Elektronik Ges.m.b.H.

Langwiesen 7

4209 Engerwitzdorf

Austria

Tel.: +43 7235 605-0

E-mail: [email protected]

Web: www.epluse.com

SUBSIDIARIES

E+E Elektronik China

18F, Kaidi Financial Building,

No.1088 XiangYin Road

200433 Shanghai

Tel.: +86 21 6117 6129

E-mail: [email protected]

E+E Elektronik France

Le Norly III, 136 chemin du Moulin

69130 Ecully

Tel.: +33 4 74 72 35 82

E-mail: [email protected]

E+E Elektronik Germany

Schöne Aussicht 8 C

61348 Bad Homburg

Tel.: +49 6172 13881-0

E-mail: [email protected]

E+E Elektronik Italy

Via Alghero 17/19

20128 Milano (MI)

Tel.: +39 02 2707 86 36

E-mail: [email protected]

E+E Elektronik Korea

Suite 2001, Heungdeok IT

Valley Towerdong, 13,

Heungdeok 1-ro, Giheung-gu

16954 Yongin-si, Gyeonggi-do

Tel.: +82 31 732 6050

E-mail: [email protected]

E+E Elektronik USA

333 East State Parkway

Schaumburg, IL 60173

Tel.: +1 847 490 0520

E-mail: [email protected]

Other manuals for EE072

1

Table of contents