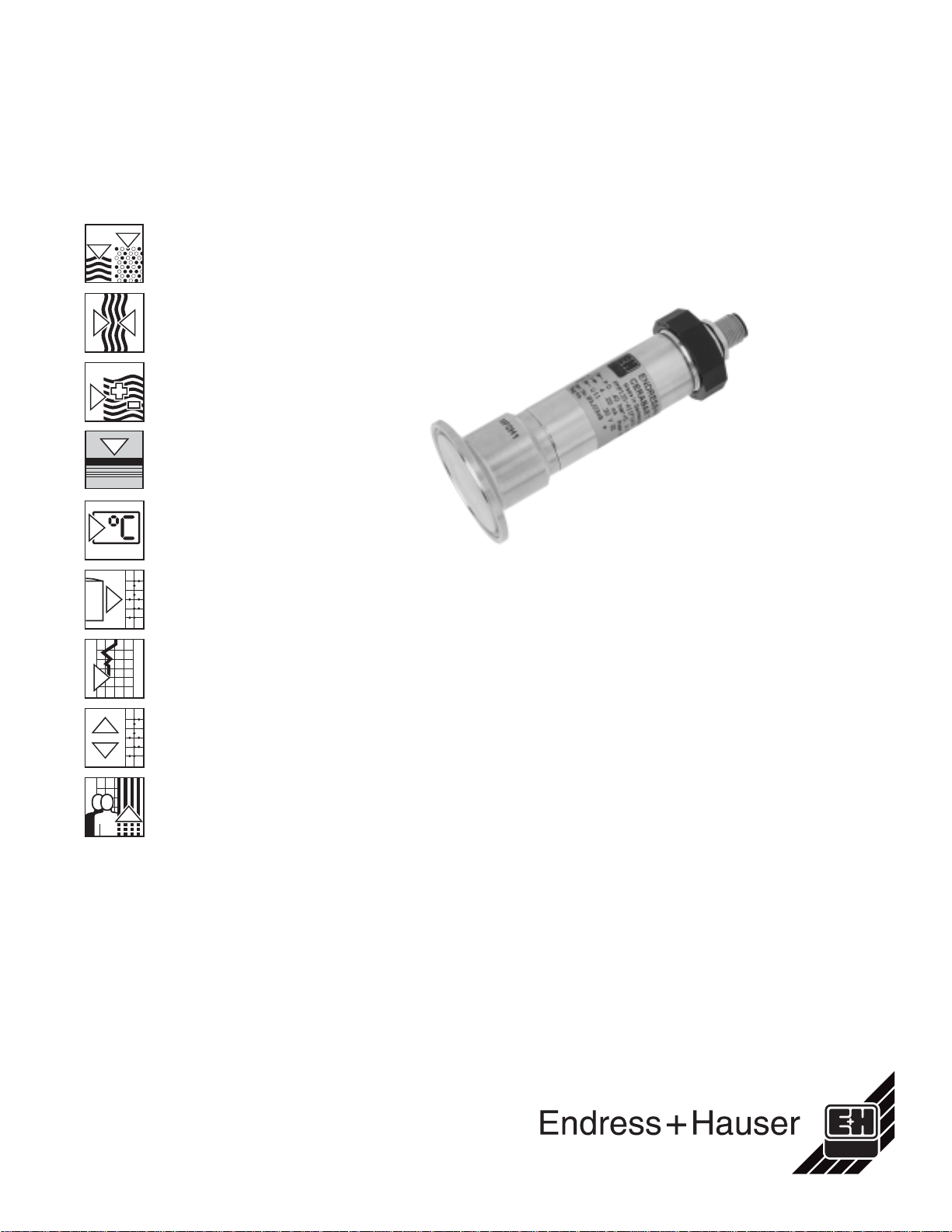

E+H Cerabar T PMP 135 Manual

Technical

Information

TI 372P/24/ae Pressure Transmitter

cerabar T PMP 135

Pressure transmitter for hygienic processes

For absolute and gauge pressures up to 500 psi

Flush-mounted process connections with

metal diaphragm

The Power of Know How

Application

The Cerabar T PMP 135 is a pressure

transmitter for hygienic applications, e.g.

in the food processing and pharmaceuti-

cal industries. It is designed for measur-

ing absolute and gauge pressures in

gases, vapors, liquids and dust.

• Finely graduated measuring ranges

up to 500 psi

• Electronic versions include:

- 4 to 20 mA analog output

- Switch output (PNP)

Features and benefits

The PMP 135 is a compact, low cost

pressure transmitter, engineered for

hygienic processes.

• Flush-mounted process connections

with metal diaphragm

• Hygienic design as per 3-A guidelines

• Analog output accuracy ≤0.5%, PNP

switch point deviation ≤1%

• Up to 5 times overload resistant and

excellent longterm stability (0.15%

per year)

• Process temperature, -13° to +212°F;

maximum temperature 275°F (1 hour)

• Optional 3.1.B inspection certificate

• Wetted materials made of 316L SS

with a surface quality of Ra≤0.8 µm

(better than 150 grit)

Cerabar T PMP 135

Endress+Hauser

Function and system design

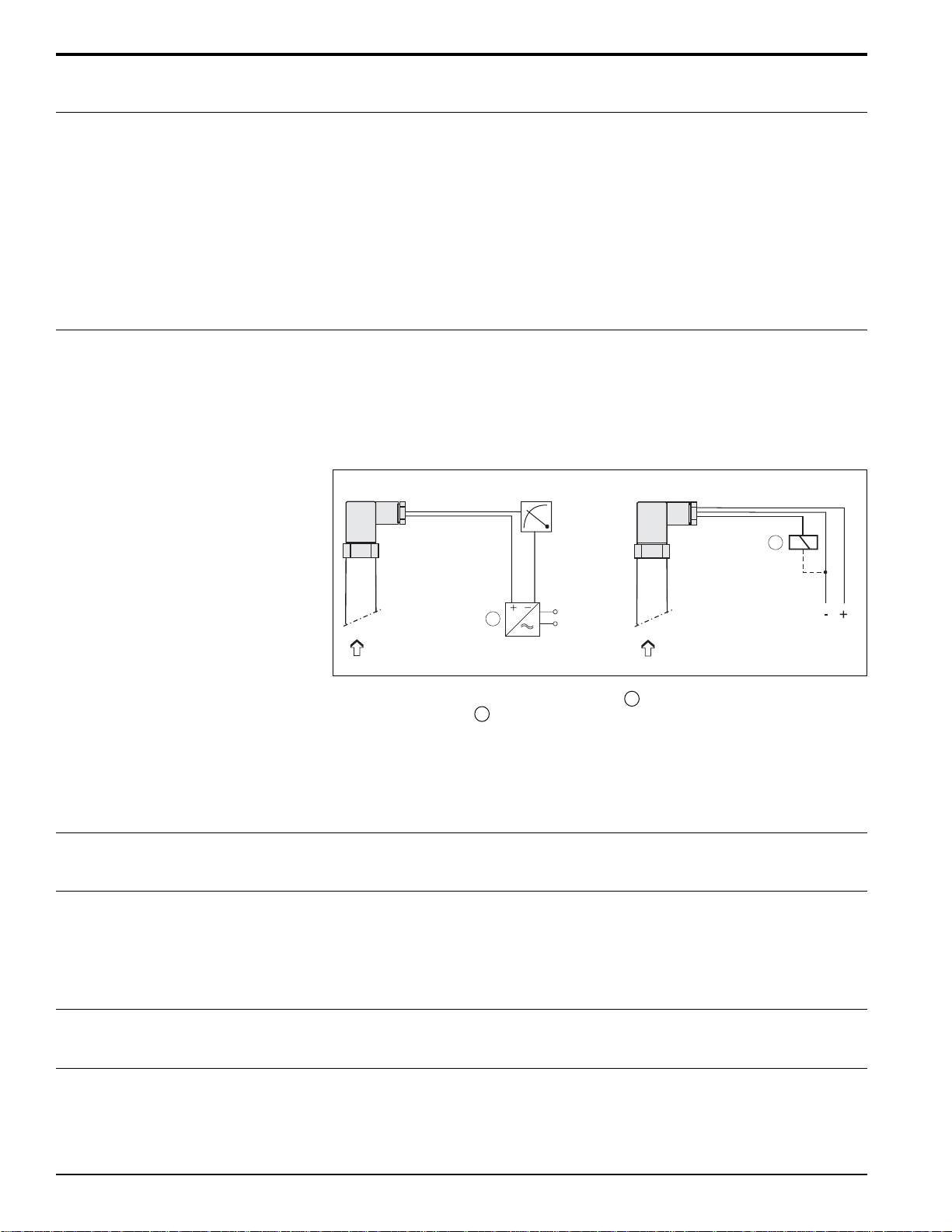

Measuring principle PMP 135 with analog output

The process pressure acting on the metallic separating diaphragm of the sensor is

transmitted to a resistance bridge via a fill fluid. The change in the output voltage of

the bridge is proportional to the pressure and can be measured directly.

PMP 135 with PNP switch output

The process pressure acting on the metallic separating diaphragm of the sensor is

transmitted to a resistance bridge via a fill fluid. A differential amplifier creates a

standard signal from the pressure-proportional change in the output voltage of the

bridge. A comparator with an adjustable hysteresis compares this signal with the

pre-set switch point and then activates the transistor output and LED display.

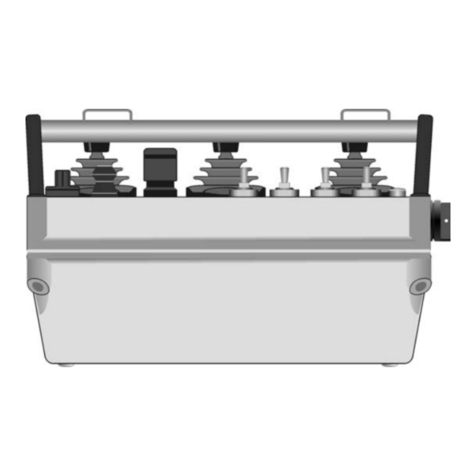

Cerabar T PMP 135 pressure transmitter with:

• 4 to 20 mA analog output

Power supply, e.g. RN 221N transmitter power supply unit from Endress+Hauser

• Switch output

Preferably in connection with a programmable logic controller (PLC). Positive

signal at electronics switch (PNP).

Measuring system

Input

The measured variable for the Cerabar T PMP 135 pressure transmitter can be

selected as either gauge or absolute pressure.

Measuring ranges up to 500 psi (40 bar) can be selected (refer to Ordering Informa-

tion).

Measured variable

Measuring range

Output

Output signal 4 to 20 mA

RB≤(US- 12 V) / 0.02 A (US= power supply)

Analog output

Load

2

4 to 20 mA

pp

1

2

AB

A = analog output with transmitter power supply unit 1

B = PNP output with load 2 , e.g. PLC, DCS, relay

Cerabar T PMP 135

Endress+Hauser 3

Output signal Positive voltage signal (rate depends on power supply voltage) at electronics switch

output (PNP)

Switch status ON: Ia≤500 mA

Switch status OFF: Ia≤1 mA

Maximum 6 W

Maximum 10 Hz

Input resistance Ri≤2 kΩ

Input current Ii≥10 mA

To prevent electrical interference, only operate an inductive load (relays, contactors,

solenoid valves) when directly connected to a protective circuit (diode or capacitor).

Switch (PNP) output

Output current

Power

Switch frequency

Input PLC

Inductive loads

Power supply

Cable entry

1/2” NPT or PG 11 M 12 x 1 plug 15 ft cable, analog output only

1 Plug-in housing 1 Coupling nut 1 Reference pressure line

2 Plug-in jack with gasket 2 Connector with gasket

3 Coupling nut 3 Operating potentiometer (inner)

4 Plug with o-ring

5 Operating potentiometer (inner)

1

2

11

2

3

3

4

5

1/2" NPT / Pg 11 M 12x1 16 ft (5 m) cable

Cerabar T PMP 135

Endress+Hauser

4

Electrical connection

Analog output connection

Supply voltage 12 to 30 VDC

Maximum 5%

Plug with 1/2” NPT, Pg 11, M 12 x 1 or cable

Residual ripple

Cable entry

1 Plug with 1/2” NPT or Pg 11

2 M 12 x 1 ;lug

3 Cable (rd = red, wh = white, gn = green

1 Plug with 1/2” NPT or Pg 11

2 M 12 x 1 ;lug

R: External load, e.g. relay, programmable logic controller, distributed control system

PNP switch connection

Supply voltage

Residual ripple

Cable entry

Current consumption

12 to 32 VDC

Without load, < 20 mA, with reverse polarity protection

Maximum 10%

Plug with 1/2” NPT, PG 11 or M 12 X 1

––

–

++

+

+

GND

–

12

3

rd

wh

gn

3

3

2

1

12 to 30 V

12 to 30

V

12 to 30 V

4 to 20 mA

4 to 20 mA

4 to 20 mA

2 –

1 +

–

–

+

+

2 –1+ 3+

R

R

12

18 to 32 V

3

2

1

Cerabar T PMP 135

Endress+Hauser 5

Performance characteristics

Note: Percentages listed below refer to the measuring range

As per DIN IEC 60770, T = 77°F (25°C)

≤0.5% including hysteresis and non-reproducibility (limit point method as per

DIN IEC 60770)

≤1%

≤0.5%

2 to 4 ms

≤0.15% per year

• Zero: typical 0.2% / 10K, maximum 0.5% / 10K. Values are 0.1% / 10K higher for

measuring spans ≤87 psi (6 bar)

• Span: typical 0.2% / 10K, maximum 0.5% / 10K

• Switch point: typical 0.2% / 10K, maximum 0.5% / 10K

Reference operating conditions

Analog output non-linearity

Switch point deviation

Switch point non-reproducibility

Settling time

Long-term drift

Influence of temperature

Operating conditions, installation

Any orientation. Orientation dependent zero shift can be corrected using potentiom-

eter adjustments

Mounting position

Operating conditions, environment

-13° to +158°F (-25° to +70°C)

-40° to +185°F (-40° to +85°C)

4 Z: with Z = 158°F (70°C) as per VDI/VDE 3540

• NEMA 4X (IP 65) with 1/2” NPT or Pg 11 cable entry

• NEMA 4X (IP 65) with M 12 x 1 plug, when using gauge pressure sensors

NEMA 6P (IP 68), 1 m water column, with 12 x 1 plug, when using absolute

pressure sensors

• NEMA 6P (IP 68), 1 m water column, with cable

4M5 as per DIN EN 60721-3

Interference emission as per EN 61326 electrical device B

Interference immunity as per EN 61326 appendix A (industrial use) and NAMUR

recommendation NE 21

Ambient temperature

Storage temperature

Climate class

Degree of protection

Vibration resistance

Electromagnetic compatibility

Operating conditions, process

-13° to +212°F (-25° to +100°C), maximum 275°F (135°C) for maximum 1 hour

Maximum overload resistance, refer to “Ordering information”

Vacuum resistance up to 0.14 psia (10 mbarabs)

Medium temperature

Limiting medium pressure range

Cerabar T PMP 135

Endress+Hauser

Mechanical construction

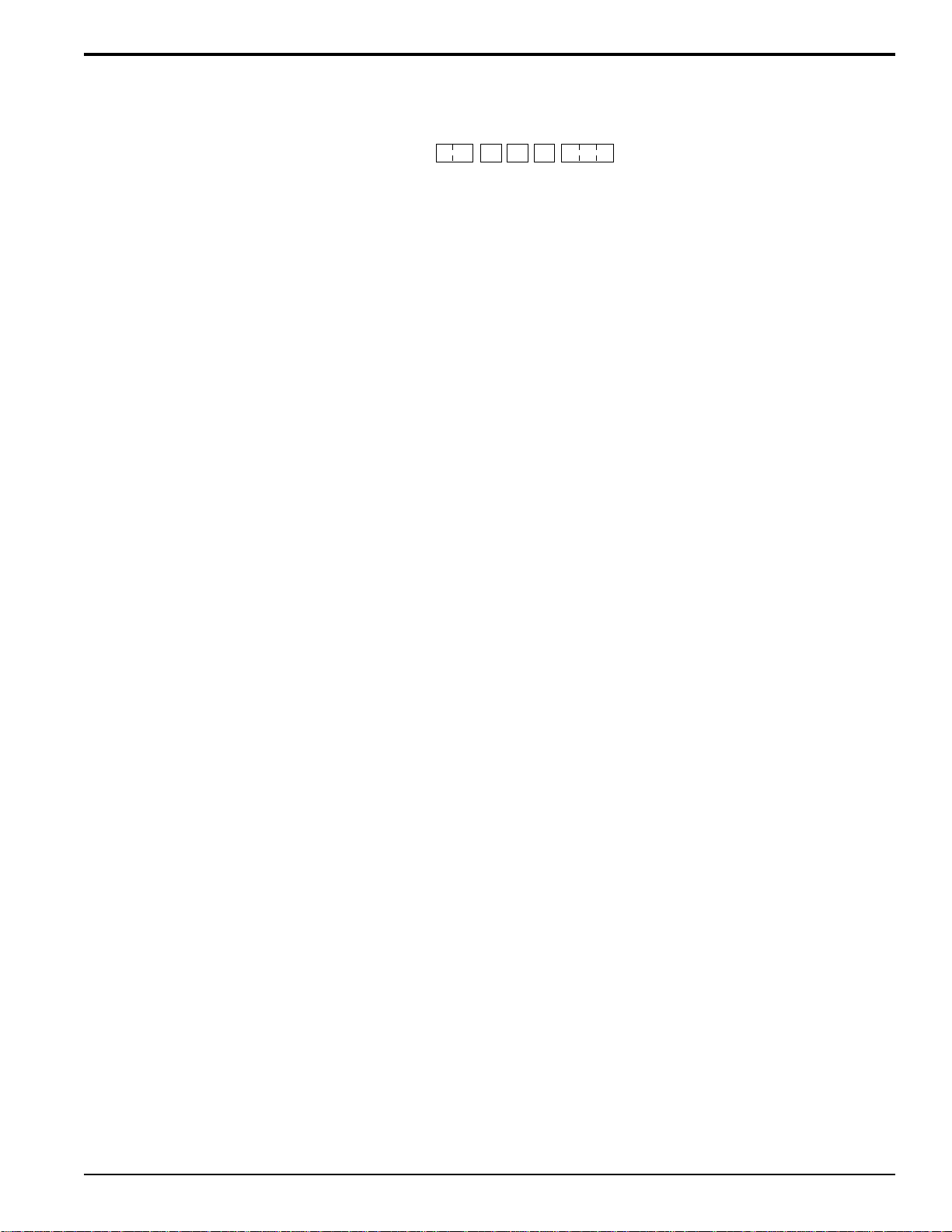

PMP 135 dimensions

A = height dimension of process connector (see process connection drawings below)

• Plug version with 1/2” NPT or Pg 11 cable connection per DIN 43650A/ISO 4400

• M 12 x 1 plug version

• Cable version , with 16 ft. (5 m) fixed cable including pressure compensation

tube.

Process connections

Tri-clamp, 1/2” or 3/4” (ISO 2852)

Tri-clamp, 1” or 1-1/2” (ISO 2852)

Tri-clamp, 2” (ISO 2852)

G 1A (ISO 228), with tapered metallic seal

G 1A (ISO 228), with sealing surface for flush-mounted installation

SMS 1-1/2”

1

2

3

4

5

6

6

1/2" NPT / Pg 11 M 12 16 ft

(5 m) cable

3.11"

(79)

1.46"

(37)

2.05"

(52)

3.11"

(79)

0.59"

(15)

2.72"

(69)

2.13"

(54)

1.53"

(39)

AAA

Ø 1.08"

(27.5) Ø 1.08"

(27.5) Ø 1.08"

(27.5)

123

456

G1A

G1A Ø 2.17"

(55)

1.30"

(33) * 1.30"

(33) * 1.30"

(33) *

1.30"

(33) *

1.54"

(39) * 1.61"

(41) *

1.06"

(27) 0.91"

(23)

Ø 1.08"

(27.5)

Ø 1.34"

(34)

Ø 1.71"

(43.5)

Ø 1.99"

(50.5)

Ø 2.22"

(56.5)

Ø 2.52"

(64)

MMM

M

M

M = diaphragm diameter,0.68" (17.2 mm)

* = "A" dimension height added for overall unit length (refer to graphic at top of page).

M

Cerabar T PMP 135

Endress+Hauser

Human interface

Materials • Process connections and diaphragm: 316L SS

Wetted surface smoothness: Ra≤0.8 µm (≥150 grit)

• Transitter housing: 304 SS

• Plug: polyamide (PA)

• Cable outer covering: polyurethane (PUR)

• Fill fluid: Neobee M20 (FDA-no. 21CFR172.856)

Operating elements location

The potentiometer for operating the

Cerabar T with analog or PNP switch

output is located beneath the plug base.

Operating elements

Adjustments Analog output: zero point adjustment

The zero point can be adjusted for the Cerabar T with analog output and plug

version.

PNP switch output: switch point and hysteresis adjustment

The Cerabar T with PNP switch output allows adjustment of both the switch point and

hysteresis. Adjustment can be made at atmospheric pressure using the enclosed

test cables and voltmeter.

1

Potentiometer for zero point correction by ± 5% of the measuring range

1

Hysteresis adjustment, 1.5 to 20%; factory setting 10%

2

Switch point adjustment, 0 to 100%; factory setting 50%

3

LED color code for checking switch status: green = OFF; red = ON

4

Connect voltmeter to test points: 0 to 1 V corresponds to 0 to 100%

Percentages refer to the measuring range.

7

1

+

–

1

2

3

4

Cerabar T PMP 135

Endress+Hauser

8

Instructions for switch point and hysteresis

U

out

= output voltage

p = acting pressure

The percentages refer to the measuring range

Hysteresis

1.5 to 20 %

Switch point

0 to 100 %

ON = red LED

OFF = green LED

Switch

on Switch

off

p

Uout

on

off

Certificates and approvals

CE mark By attaching the CE mark, Endress+Hauser confirms that the instrument fulfills all the

requirements of the relevant EC directives.

This device conforms to Article 3 (3) of EC Directive 97/23/EC (pressure equipment

directive) and is developed and produced in sound engineering practice.

Pressure equipment directive

Cerabar T PMP 135

Endress+Hauser 9

Ordering information

Cerabar T PMP 135 PMP 135 -

1 Electrical connection

A1 Plug with Pg 11 cable gland, NEMA 4X (IP 65)

A2 Plug with 1/2” NPT conduit entry, NEMA 4X (IP 65)

A3 Cable, 16 ft. (5 m), NEMA 6P (IP 68)

A4 M 12 x 1 plug, NEMA 4X (gauge) / NEMA 6P (absolute) (IP 65 / 68)

2 Process connection

F Tri-clamp, 1/2” to 3/4”

G Tri-clamp, 1” to 1-1/2”

H Tri-clamp,2”

M G 1A, with metallic sealing, tapered

N G 1A with sealing surface for flush-mounted installation

S SMS1-1/2”

3 Output signal, certificate

0 4 to 20 mA analog, 2-wire

2 PNP switch output, 3-wire

4 Additionalequipment

1 Withoutadditionalequipment

C 3.1.B inspection certificate per EN 10204

2 Linearity protocol

5 Measuringrange(permitted overload)

Gaugepressure

Q4H 0 to 15 psi (60 psi)

Q4K 0 to 30 psi (150 psi)

Q4N 0 to 50 psi (240 psi)

Q4R 0 to 150 psi (600 psi)

Q4S 0 to 300 psi (1500psi)

Q4T 0 to 500 psi * (2400 psi)

A1G 0 to 1 bar / 0 to 100 kPa (4 bar)

A1H 0 to 1.6 bar / 0 to 160 kPa (6.4 bar)

A1N 0 to 2.5 bar / 0 to 25 kPa (10bar)

A1Q 0 to 4 bar / 0 to 400 kPa (16bar)

A1R 0 to 6 bar / 0 to 600 kPa (24 bar)

A1S 0 to 10 bar / 0 to 1000 kPa (40bar)

A1T 0 to 16 bar / 0 to 1600 kPa (64bar)

A1W 0 to 25 bar / 0 to 2500 kPa (100 bar)

A1X 0 to 40 bar * / 0 to 4000 kPa * (160bar)

* absolute pressure transmitter

Absolutepressure

R4H 0 to 15 psi (60 psi)

R4K 0 to 30 psi (150 psi)

R4N 0 to 50 psi (240 psi)

R4R 0 to 150 psi (600 psi)

R4S 0 to 300 psi (1500 psi)

R4T 0 to 500 psi (2400 psi)

A2G 0 to 1 bar / 0 to 100 kPa (4 bar)

A2H 0 to 1.6 bar / 0 to 160 kPa (6.4 bar)

A2N 0 to 2.5 bar / 0 to 25 kPa (10bar)

A2Q 0 to 4 bar / 0 to 400 kPa (16bar)

A2R 0 to 6 bar / 0 to 600 kPa (24 bar)

A2S 0 to 10 bar / 0 to 1000 kPa (40bar)

A2T 0 to 16 bar / 0 to 1600 kPa (64bar)

A2W 0 to 25 bar / 0 to 2500 kPa (100 bar)

A2X 0 to 40 bar / 0 to 4000 kPa (160bar)

1 2 3 4 5

Cerabar T PMP 135

Endress+Hauser

10

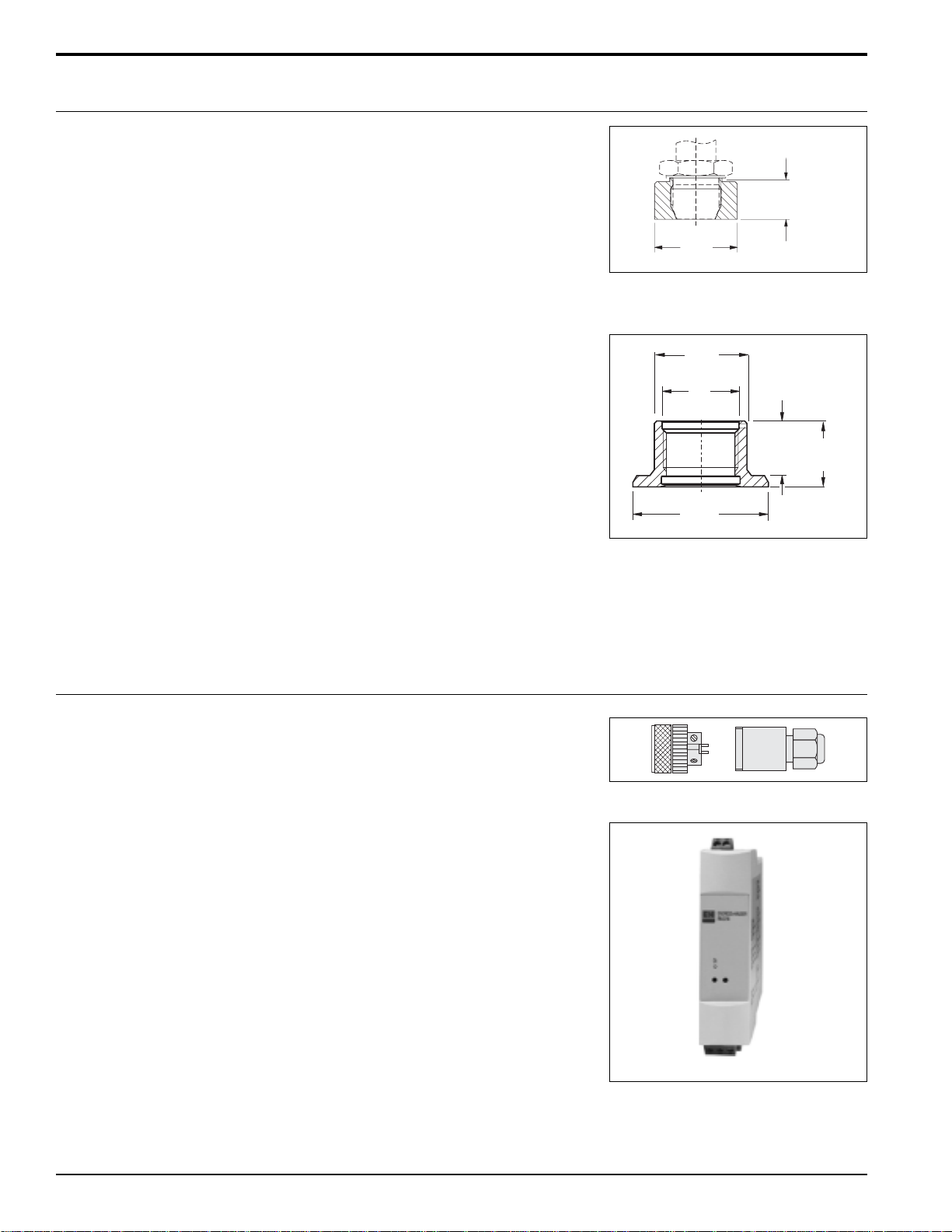

Accessories

Welding bosses • Welding boss for flush-mounted

installation of G1 A process

connection with metallic sealing

taper (used with process connection

M selection, order code).

Material: 316L SS

Order number: 52005087

• Optional with 3.1.B inspection

certificate

Order number: 52010171

1.97"

(50)

1.18"

(30)

• Welding boss for flush-mounted

installation of G1 A process

connection with sealing surface

(used with proces connection N

selection, order code).

Material: 316L SS

Gasket (enclosed): silicon o-ring

Order number: 52001051

• Optional with 3.1.B inspection

certificate

Order number: 52011196

• Welding aid (dummy plug) for welding

the boss (order numbers 52005087

and 52001051), prevents warping

of boss during welding.

Material: brass

Order number: 52005272

• M 12 x 1 plug-in jack, connection to

M 12 x 1 housing

Order number: 52006263

ø 2.36"

(60 )

-0 . 0 1 5

– 0 . 4

0.97"

(24.6) 1.17"

(29.6)

ø 1.61"

(41)

G1

ISO 228

Plug-in jack

Power supply / display units • RN 221 N transmitter power supply

unit. For safe galvanic isolation of the

4 to 20 mA analog signal and for

supplying power to the Cerabar T.

Refer to TI 073R/09/en

Cerabar T PMP 135

Endress+Hauser 11

• RIA 251 process display unit, digital

display unit for indicating the analog

signal through the 4 to 20 mA current

loop.

Refer to TI 063R/24/ae

Supplemental documentation

Cerabar T PMP 131, pressure transmitter with

polysilicon sensor: TI 291P/24/ae

Cerabar T PMC 131, pressure transmitter with

capacitive ceramic sensor: TI 279P/24/ae

PMP 135 operation/installation manual: KA 198P/00/a6

UnitedStates

Endress+Hauser, Inc.

2350 Endress Place

Greenwood,IN46143

Phone:(317)535-7138

888-ENDRESS

FAX:(317)535-8498

TI372P/24/ae/03.03

© 2002 Endress+Hauser, Inc.

Canada

Endress+Hauser

CanadaLtd.

1440Graham’sLane

Unit 1, Burlington

ON,L7S 1W3

Phone:(905)681-9292

800-668-3199

FAX:(905)681-9444

Mexico

Endress+Hauser

Paseodel Pedregal No. 610

Col.Jardines del Pedregal

01900, Mexico D.F.

Mexico

Phone:(525)568-2405

FAX:(525)568-7459

For application and selection assistance,

in the U.S. call 888-ENDRESS

For total support of your installed base, 24 hours

a day, in the U.S. call 800-642-8737

Visit us on our web site, www.us.endress.com

Endress+Hauser

The Power of Know How

Table of contents

Popular Transmitter manuals by other brands

HBC-Radiomatic

HBC-Radiomatic spectrum 1 M operating instructions

BEKA

BEKA BA474ND Installation & maintenance instructions

Nice

Nice DTX600 Instructions and warnings for installation and use

PCS Electronics

PCS Electronics TVMAX 8000U+ manual

XtremeMac

XtremeMac Airplay Boost user manual

Eddystone Broadcast

Eddystone Broadcast S7600 Series Installation and operations