Eddystone Broadcast S7600 Series Owner's manual

Print Date 21/02/23 Page 1 of 36 S7604-00MA-03a

Eddystone Broadcast

----

S7600 Series

S7604 –S7605C

4kW –5kW

Medium Power

FM Transmitters

----

Installation

and

Operation

----

Issue 3a

S7604-00MA-03a

February 2023

----

Eddystone Broadcast Ltd.

26, Arden Rd.

Arden Forest Industrial Estate

Alcester, Warwickshire

B49 6EP, England

Tel. 44 (0)1789 762278

Fax. 44 (0)1789 766033

www.eddystone-broadcast.com

Print Date 21/02/23 Page 2 of 36 S7604-00MA-03a

Intentional blank page

Print Date 21/02/23 Page 3 of 36 S7604-00MA-03a

Index

SECTION ONE : INTRODUCTION

1.1 : GENERAL DESCRIPTION………………………………………………………………… Page 5

1.1.1 E2021 300W Amplifier Module…….……………………………………………………… Page 5

1.1.2 E2088/E2322 Power Supply Module (single phase variants)…….……………………. Page 6

1.1.3 E2088/E2322 Power Supply Module (three phase variants)……………………..……. Page 6

1.1.4 E2023 Transmitter Controller Unit…………………………..……………………………. Page 7

1.1.5 E2026 Drive Changeover/Output Monitor Unit………………...………………………… Page 7

1.1.6 E2028 16 Way Combiner Unit…………………………………………………………….. Page 8

1.2 : VARIANTS AND OPTIONS………………………………………………………………… Page 9

1.3 : TECHNICAL SPECIFICATIONS…………………………………………………………… Page 10

SECTION TWO : INSTALLATION

2.1 : PHYSICAL DIMENSIONS AND FITTING………………………………………………… Page 13

2.1.1 Installation Items …………………………………………………………………………….Page 13

2.1.2 Rack Mounting………………………………………………………………………………. Page 15

2.2 : EXTERNAL CONECTIONS…………………………………………………………….….. Page 16

2.2.1 Mains Supply Connectors (single phase S7604-01 and S7605-05)………………….. Page 16

2.2.2 Mains Supply Connector (three phase S7604-02 and S7605-07)…………………….. Page 17

2.2.3 RF Output Antenna Connector……………………………………………………………..Page 18

2.2.4 RF Input Exciter/Drive(s) Connectors…………………………………………………….. Page 18

2.2.5 Safety Interlock Connector………………………………………………………………….Page 18

2.2.6 RF Output Monitor Connector……………………………………………………………... Page 18

2.2.7 Drive A/B Monitor and Control Connectors ………………...…………………………….Page 18

2.2.8 Parallel (E2023-01/02) or RS232 Serial Remote Control DTE Con. (E2023-03/04)… Page 19

2.2.9 Second Transmitter Remote Control Connector………………………………………… Page 20

2.2.10 Mains Supply Output Connectors…………………………..……………..…………….. Page 20

2.2.11 RS232 Serial Control and Monitor (COM) Connector ……………………………..…. Page 21

2.2.12 TCP/IP Control and Monitor Connector (/T option only)…………………...…………. Page 21

2.2.13 FWD/REV Output (Analogue Monitor) Connectors………………………….………… Page 21

2.3 : SETTING UP PROCEDURES…………………………………………………………….. Page 22

2.3.1 Fuses…………………………………………………………………………………………. Page 22

2.3.2 Output Power Level and Frequency Adjustment………………………………………… Page 23

2.3.3 Reverse Power Trip Level Adjustment…………………………………………………….Page 24

2.3.4 Serial Remote Control Baud Rate Setting……………………………….…………….… Page 25

2.4 : SERIAL REMOTE CONTROL AND MONITORING…………………….……………….. Page 26

2.4.1 Introduction……………………………………………………………………….…………. Page 26

2.4.2 Control Commands and Status Monitor Requests……………………………………… Page 26

2.4.3 Reverted Status Monitor Information………………………………………………………Page 28

Print Date 21/02/23 Page 4 of 36 S7604-00MA-03a

SECTION THREE : OPERATION

3.1 : CONTROLS AND DISPLAYS…………………..…………………………………..……… Page 31

3.1.1 E2021 Amplifier Module……………………………………………………………………. Page 31

3.1.2 E2088 Power Supply Module……….………..………………………………..………….. Page 31

3.1.3 E2322 Power Supply Module……………………………………………………………... Page 31

3.1.4 E2023 Transmitter Controller Unit…………………………………………..…………….. Page 32

3.1.5 E2026 Drive Changeover/Output Monitor Unit…………………..…………………….… Page 33

3.1.6 Supply Disconnector…………………..……………………………………………………. Page 33

3.2 : MANUAL CONTROL……………………………………………………………………….. Page 34

3.3 : MANUAL MONITORING…………………………………………………………………... Page 34

3.4 : AUTOMATIC CONTROL………………………………………………………………….. Page 35

3.4.1 Exciter/Drive Control and Monitoring…………………………………………………….. Page 35

3.4.2 Muting and Reduced Power Operation…………………………………………………… Page 35

Bound at Rear

Front and Rear Panel Views……………………………………………………………. S7604-00GA

Block Diagram……………………………………………………………………………. S7604-00BK

Interconnections Circuit Diagram …………………………………………………….... S7604-00CT

Print Date 21/02/23 Page 5 of 36 S7604-00MA-03a

SECTION ONE : INTRODUCTION

! CAUTION !

These Transmitters operate at high RF power levels, internal supply energy levels and mains

supply current levels. They also incorporate devices containing toxic BeO. Installation, operation

and maintenance of this unit must therefore, only be carried out by suitably qualified personnel,

familiar with and fully utilising the safety procedures such equipment demands.

NO attempt at installation should be made without full reference to and compliance with SECTION

TWO : INSTALLATION.

NO attempt at internal maintenance should be made without full reference to and compliance with the

appropriate sections (fuse changing which is detailed in INSTALLATION).

1.1 : GENERAL DESCRIPTION

The S7604 Medium Power FM Transmitter provides output powers of up to and including 4kW, or 8kW

using combined pairs, in the standard Band ll frequency range of 87.5-108MHz.The S7605C

‘Compact’ Medium Power FM Transmitter provides increased output powers of up to and including

5kW, or 10kW using combined pairs. They are normally supplied with either one or two Exciters,

capable of generating a standard mono or stereo FM signal from a variety of analogue or digital audio

or data sources (including left/right audio, MPX, RDS, SCA, DARC etc.). It is important to note that the

Exciter(s) supplied will depend on the user’s actual requirements in this regard which, therefore, must

be clearly specified at time of ordering.

The Transmitters are totally self-contained (including forced air-cooling) and can be mounted as a

complete unit (less Exciters) within a standard 19 inch rack with at least 600mm depth and 26U height.

All that is required is a connection to a mains supply (single or three-phase depending on variant

supplied) to an antenna and to the Exciter/Drive(s). When used in pairs, to generate up to 8kW or

10kW, an additional two-way splitter, combiner and approximately 2kW or 2.5kW balance load is also

required. In this situation, additional manual ‘patching’ or manual/automatic switching can be provided,

as an option, to direct all of one Transmitter’s power to the antenna.

The key feature of The S7600 series is its’ ability to remain ‘on-air’. The use of multiple Amplifier and

Power Supplies Modules and dual power supply and control circuitry means that if failures do occur, it

normally only results in a reduction of output power. Furthermore, the lightweight, hot-pluggable

Amplifier and Power Supply Modules can be easily replaced, in seconds, without having to go ‘off-air’.

Provision for dual Exciter/Drive automatic changeover and for connection to a second active/passive

reserve S76XX or S79XX (i.e. 500W to 10kW) Transmitter is also made, further enhancing the ability

to remain ‘on-air’.

Each Transmitter consists of a number of modules described as follows (1.1.1 –6 inc.). Front and rear

views, block and circuit diagrams, showing these modules are bound at the rear of this manual

(S7604-00GA, S7604-00BK and S7604-00CT).

Workshop editions of this manual contain extra information, also bound at the rear, which gives

detailed test procedures, full size circuit diagrams, assembly diagrams, layouts and parts lists

1.1.1 : E2021 300W Amplifier Module

Sixteen of these are provided, each with their own independent control and monitoring circuitry. This

circuitry includes reverse power, supply current and temperature monitoring to shut down and protect

individual modules. Failures in a single Amplifier Module only tend to give a slight reduction in power,

with the Transmitter still operating with several modules having failed.

Each Amplifier Module can be removed or replaced whilst the Transmitter is operating (‘hot-

pluggable’). This feature means that if failures do occur, modules can be replaced within seconds,

without having to go ‘off-air’. Red/green fault displays on the front of each module help indicate the

faulty module to be replaced, this normally restoring the Transmitter’s full output without any further

Print Date 21/02/23 Page 6 of 36 S7604-00MA-03a

immediate technical investigation being required. The relatively low weight and small size of each

module assist their actual transport to site.

Each Amplifier also has its own front panel ‘mute’ switch which is mechanically interlocked so that it

has to be operated before the module can be removed. All other signal, 50V dc supply and control

connectors are at the rear of the unit. The control connectors go to one of two independent internal

Transmitter control buses.

Each control bus has its own RS485 data bus which is used to carry the monitored serial information

from the amplifier to the E2023 Controller. Each bus also has its own power level control line, derived

from the E2026 Drive Changeover/Output Monitor, to set the power level of each amplifier module and

thus the final transmitter output power.

Various versions of the 300W Amplifier Module may be supplied. These versions have slightly

different internal circuitry. They are however interchangeable, but to maximise output power, all

modules should ideally be of the same version.

1.1.2 : E2088/E2322 Power Supply Module (single phase variants)

Any given Transmitter can only accept either E2088 or E2322 modules, not both

Eight of these are provided (twelve on the /P option) with two independent mains supply connectors to

enable operation from dual, single phase, mains supplies. The modules are equally grouped into four

supplies ‘A’, ‘B’, ‘C’, and ‘D’. The two (three on the /P option) E2088/E2322 modules in each group are

current OR’d together. Thus, on the /P option, where the extra third module is fitted, the current lost

when any single module in the group fails, can still be supplied by the remaining two modules in the

group.

The ‘A’ supply provides a supply bus to the four E2021 Amplifier Modules on the bottom right hand ‘A’

side of the transmitter. The ‘B’ supply provides a separate bus to the four Amplifier Modules on the

bottom left hand ‘B’ side. Single units requiring power (E2023 and E2026) and all cooling fans are

supplied from both supply buses.

The ‘C’ supply provides a supply bus to the four E2021 Amplifier Modules on the top right hand ‘A’

side of the transmitter and the ‘D’ supply provides a supply bus to the four E2021 Amplifier Modules

on the top left hand ‘B’ side of the transmitter.

All supplies are switched via a single front panel safety switch and associated relays. The switch can

be padlocked in the ‘off’ position to ensure that the Transmitter remains off whilst work is being carried

out at the antenna etc.

Each E2088/E2322 Power Supply Module has its own forced air cooling, output control and monitoring

circuitry and generates a regulated 50V to 53V dc supply. As with the Amplifier Modules, each

E2088/E2322 Power Supply module can be removed or replaced, within seconds, whilst the

Transmitter is operating (as long as either the ‘A’ or ‘B’ supply has two E2088/E2322 modules

remaining). Red/green fault displays, low module weight and small size again feature.

50-53Vdc outputs for each Amplifier, for all the low power single units and mains supplies for each

Exciter are provided via separate fuses at the rear of the Transmitter. The Power Supply monitor

connectors go to one of two independent internal Transmitter control buses and hence to the E2023

Controller.

1.1.3 : E2088/E2322 Power Supply Module (three phase variants)

Any given Transmitter can only accept either E2088 or E2322 modules, not both

Nine of these are always provided with a single three-phase mains supply connector. The modules are

equally grouped into three supplies ‘A’, ‘B’ and ‘C’. The three E2088/E2322 modules in each group are

current OR’d together.

The ‘A’ supply provides a supply bus to the four E2021 Amplifier Modules on the bottom right hand ‘A’

side of the transmitter and to the top right outer amplifier. The ‘B’ supply provides a separate bus to

Print Date 21/02/23 Page 7 of 36 S7604-00MA-03a

the four Amplifier Modules on the bottom left hand ‘B’ side and to the top left outer amplifier. Single

units requiring power (E2023 and E2026) and all cooling fans are supplied from both supply buses.

The ‘C’ supply provides a supply bus to the two central E2021 Amplifier Modules on the top row and

all four E2021 Amplifier Modules on the row below.

All supplies are switched via a single front panel safety switch. The switch can be padlocked in the ‘off’

position to ensure that the Transmitter remains off whilst work is being carried out at the antenna etc.

Each E2088/E2322 Power Supply Module has its own forced air cooling, output control and monitoring

circuitry and generates a regulated 50V to 53V dc supply. As with the Amplifier Modules, each

E2088/E2322 Power Supply module can be removed or replaced, within seconds, whilst the

Transmitter is operating (as long as either the ‘A’ or ‘B’ supply has three E2088/E2322 modules

remaining). Red/green fault displays, low module weight and small size again feature.

50-53Vdc outputs for each Amplifier, for all the low power single units and mains supplies for each

Exciter are provided via separate fuses at the rear of the Transmitter. The Power Supply monitor

connectors go to one of two independent internal Transmitter control buses and hence to the E2023

Controller.

1.1.4 : E2023 Transmitter Controller Unit

This single unit provides comprehensive monitoring of the forward power, current and temperature of

each E2021 Amplifier Module and of the final output forward power, reverse power and temperature

via the E2026 Drive Changeover/Output Monitor. It also monitors the E2088/E2322 Power Supply

Modules. In the situation where dual drive automatic changeover or automatic power level control is

used, this unit provides the necessary control. Remote control and monitoring of the Transmitter can

also be provided via this unit using parallel or serial data.

The Control Unit is microprocessor based with a back illuminated, high contrast 4 line by 20 character

display and separate red/green ‘System Normal’ indicator. A robust, sealed membrane keypad is

provided with a sounder to indicate correct key entry. The rear of the unit has separate connectors for

the two independent internal Transmitter control buses, connectors to monitor and control one or two

Exciters, a connector for power level control and a connector for parallel monitoring. An RS232

monitor/control port is provided on the front panel (E2023-01/02) with an additional TCP/IP

monitor/control port on the rear (E2023-02 only). An RS232 monitor/control port is provided on the

rear panel (E2023-03/04) with an additional TCP/IP monitor/control port on the rear (E2023-04 only).

When the RS232 port is provided on the rear panel, no parallel monitoring is available.

If a fault should occur within the E2023, manually operated switches on the E2026 Drive

Changeover/Output Monitor Unit can be used for basic control of the Transmitter. This enables it to be

kept ‘on-air’ whilst the E2023 is replaced.

1.1.5 : E2026 Drive Changeover/Output Monitor (and Splitter) Unit

This single unit interfaces between the Exciter(s) and the multiple E2021 Amplifier Module inputs. The

splitter section within the unit is a four way Wilkinson power utilising standard coaxial cable and is thus

easily repaired if any become damaged. All outputs are brought to TNC connectors at the rear of the

unit. Phase length matched, 50coax leads then connect these outputs to the E2021 inputs via four

off four way matching units mounted separately behind the lowest row of E2021s.

This unit also contains circuitry to measure the Transmitter’s final output forward and reverse powers,

via a coupler in the E2028, and the temperature of the E2028 Combiner’s dumping load heatsink (see

1.1.6). Front panel red/green displays indicate any fault condition. Two multi-turn preset High or Low

Power potentiometers are accessible via the front panel to enable independent setting of two

Transmitter output powers. They are selected using various forms of local, external or remote control

or via a link on the Fan connector Board (see section 3.4.2). A front panel connector is provided to

give a test sample of the Transmitter’s output forward power.

As with the E2023, the rear of the E2026 has separate connectors for the two independent internal

Transmitter control buses. As previously detailed, each control bus has its own RS485 data bus, one

of which is used to carry the monitored serial information from the E2026 to the E2023 Control Unit.

Print Date 21/02/23 Page 8 of 36 S7604-00MA-03a

For these two buses, the E2026 also provides two equal but independent power level control voltages

(derived from either the front panel High or Low Power potentiometers) to set the power level of the

E2021 Amplifier Modules and thus the final Transmitter output power. One control voltage is used for

the Amplifier Modules on the right hand A side of the transmitter and the other for the Amplifier

Modules on the left hand B side.

A front panel lockable toggle switch is provided to manually mute or start (i.e. demute) the Transmitter

or can be set to enable the E2023 Control Unit to select high/low power or to mute/demute the

Transmitter as part of an automatic control sequence. An interlock switch connector is also provided

on the rear to enable the open-circuiting of external switches placed at safety points (e.g. at Antenna

access gates) to automatically mute the Transmitter. The state of this circuit is displayed on a front

panel indicator.

The E2026 can also provide manual or automatic dual drive changeover in conjunction with the E2023

Control Unit. A second front panel lockable toggle switch is provided on the E2026 to manually select

which Exciter (i.e. ‘Drive’) is to be used, or to enable the E2023 to automatically select the second

Exciter should the first one fail. Switching is performed by two coaxial RF relays within the E2026.

These direct one of two Exciter’s outputs to the internal splitter and the other to a dumping load. This

dumping load has to be provided (externally to the E2026) whenever two Exciters are supplied and the

Exciter not in use is required to remain ‘active’ or be tested. Three TNC connectors are provided at the

rear of the unit to connect to Exciter(s) and dumping load. Front panel indicators show which Drive is

selected.

1.1.6 : E2028 16 Way Combiner Unit

This single unit interfaces between the multiple E2021 Amplifier Module outputs and the antenna.

Phase length matched, 50coax leads connect the E2021 outputs to the TNC connectors at the

bottom rear of this unit. The combiner section within the unit is a sixteen way Wilkinson power

combiner, followed by a matching section, utilising standard handformable and flexible coaxial cable.

The combiner section is followed by an integral low pass filter, this removing harmonics of the wanted

frequency. An output directional coupler is then provided with an EIA 7/8 (S7604) or EIA 1 5/8

(S7605C) output socket for connection to the antenna. This coupler provides output forward and

reverse power samples, via coax connections, to the E2026 Drive Changeover/Output Monitor (see

1.1.5).

Print Date 21/02/23 Page 9 of 36 S7604-00MA-03a

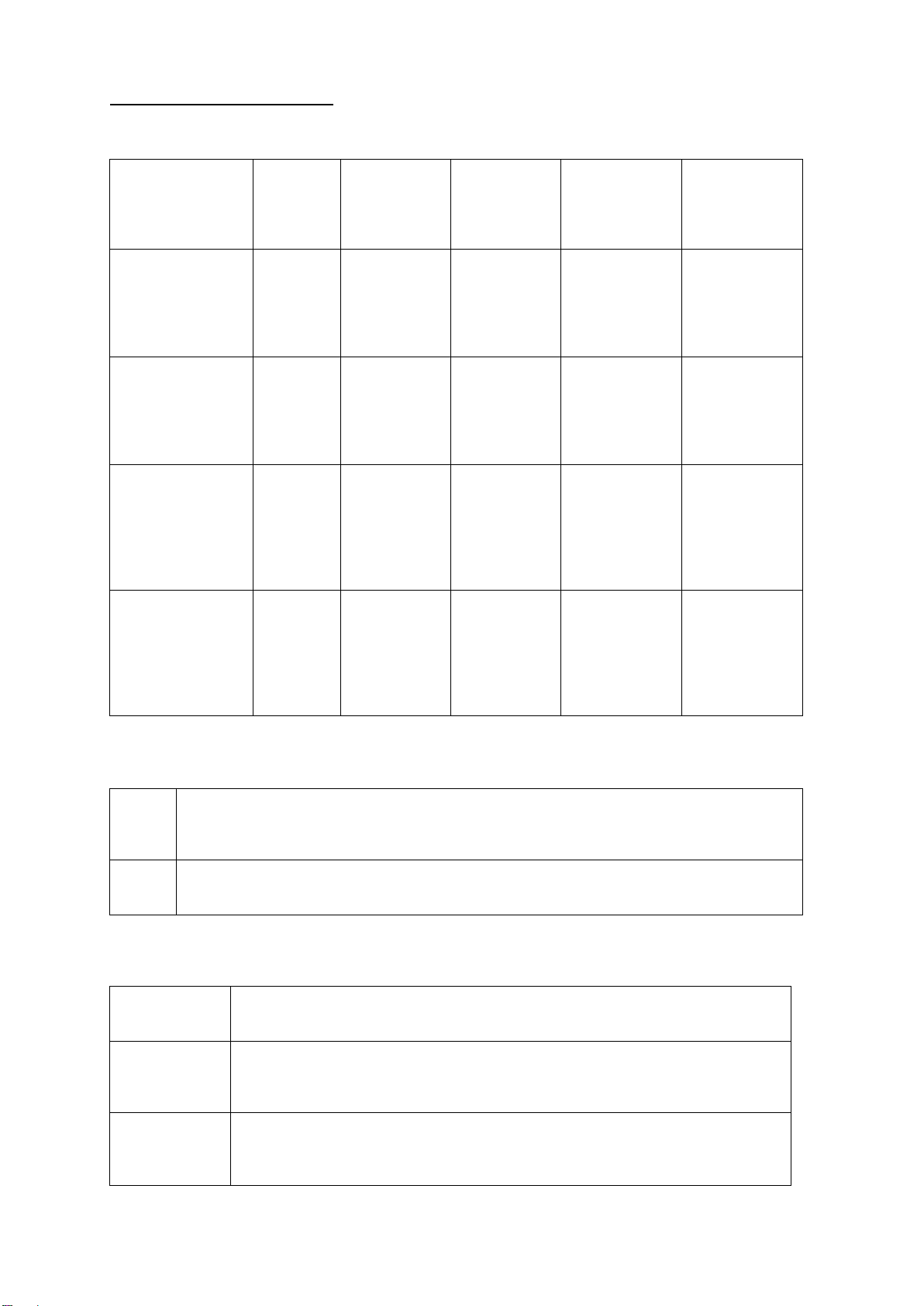

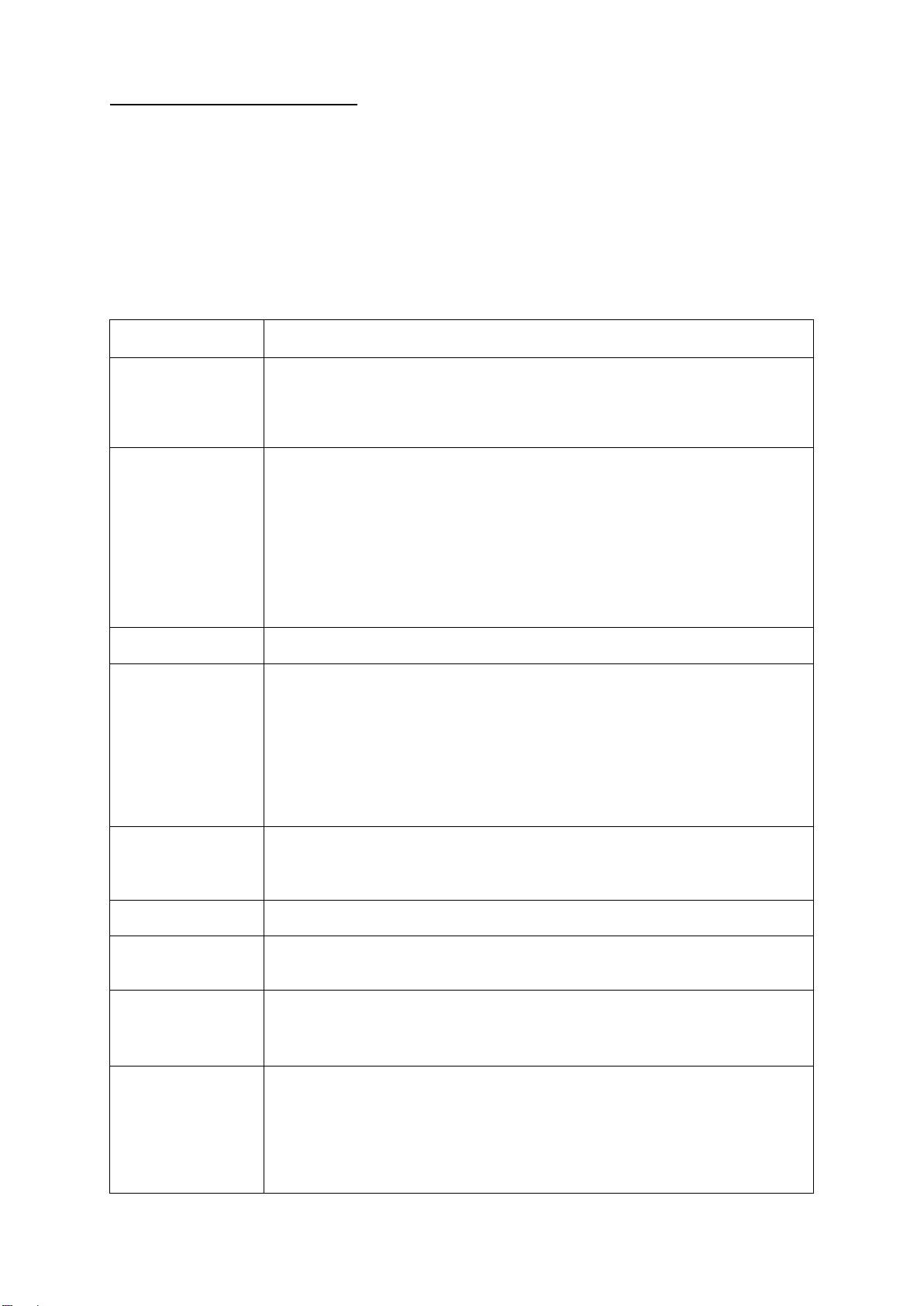

1.2 : VARIANTS AND OPTIONS

The main variants and their constituent modules and units are as follows :-

Amplifier

Modules

Power

Supplies

Transmitter

Auto. Cont.

Output

Monitor and

Drive C/O

Combiner

Unit

S7604-01

4kW Max.

Single Phase

230V Supply

16 off

E2021-XX

8 or 12 off

E2088-01

or E2322-01

Single

E2023-XX

Single

E2026-02

Single

E2028-01

S7604-02

4kW Max.

Three Phase

230/400V Supply

16 off

E2021-XX

9 off

E2088-01

or E2322-01

Single

E2023-XX

Single

E2026-02

Single

E2028-01

S7605-05

5kW Max.

Single Phase

230V Supply

(S7605C)

16 off

E2021-XX

8 or 12 off

E2088-01

or E2322-01

Single

E2023-XX

Single

E2026-02

Single

E2028-02

S7605-07

5kW Max.

Three Phase

230/400V Supply

(S7605C)

16 off

E2021-XX

9 off

E2088-01

or E2322-01

Single

E2023-XX

Single

E2026-02

Single

E2028-02

The options (identified by a letter suffix) are as follows :-

/P

Fitted with four additional E2088/E2322 Power Supply Modules

(S7604-01 and S7605-05 only)

/T

Fitted with TCP/IP Remote Control (E2023-02 or E2023-04 Controller)

Examples are as follows :-

S7604-01

Standard 4kW Transmitter (single phase, 230V supply)

S7605-05/P

Compact S7605C 5kW Transmitter, with four additional E2088/E2322 PSUs

giving twelve total (single phase, 230V supply)

S7605-07/T

Compact 5kW Transmitter, with TCP/IP remote control)

(three phase, 230/400V supply)

Print Date 21/02/23 Page 10 of 36 S7604-00MA-03a

1.3 TECHNICAL SPECIFICATIONS

The S7600 range of FM Transmitters is designed to meet or exceed ETSI Standards:-

EN 301 489-01 : ERM/EMC for Radio Equipment, Part 1, Common Technical Requirements.

EN 301 489-11 : ERM/EMC for Radio Equipment, Part 11, Specific Conditions for FM Transmitters.

EN 302 018-02 : ERM (Spectral Occupancy) for the FM Radio Broadcast Services.

EN 60215:1989 : Safety Requirements for Radio Transmitting Equipment

Note that the following figures do not include any which principally depend on the Exciter/Drive being

used (e.g. frequency stability). The figures given below may also be affected by the Exciter/Drive’s

performance. In both cases the Exciter/Drive’s own manual should be consulted.

.

RF Interface Ports

50nominal

Input Drive Power

RF Input from Exciter/Drive supplied :-

70-80W for S7604 (100W absolute maximum)

85-100W for S7605C (125W absolute maximum)

Output Power Level

With any load with a return loss 14dB (1.5:1 VSWR) any angle.

(though see note below in ‘Output Power shutdown’ section)

Note two independent settings available for selection.

Adjustable at least 1.6kW to 4kW for S7604 (Power Low setting)

Adjustable at least 2.4kW to 4kW for S7604 (Power High setting)

Adjustable at least 2kW to 5kW for S7605C (Power Low setting)

Adjustable at least 3kW to 5kW for S7605C (Power High setting)

Output Power

Variation

Not more than 1dB under all specified operating conditions.

Output Power

Shutdown

Output power is automatically reduced or shutdown to ensure that any load

with return loss 10dB including open and short circuits, does not cause any

damage to the transmitter.

The return loss level at which shutdown starts can be increased by an

internal adjustment (see section 2.3.3). This level is normally set at the

factory to be 16dB, the level at which excess reverse power first produces a

warning indication.

Output Reverse

Intermodulation

Reverse intermodulation products will be better than or equal to –10dB,

relative to the interfering incident signal, this being offset over the range

300kHz to 20MHz (but remaining within 87.5MHz to 108MHz).

Frequency Range

87.5 -108MHz

Spurious Emissions

In the range 9kHz to 1000MHz : -

Better than or equal to –82dBc (S7604) or –83dBc (S7605C)

Out of Band

(Adjacent Channel)

Emissions

Better than or equal to –110dBc/Hz, at 200kHz offsets, and 145dBc/Hz at

2MHz. When measured in a 1kHz bandwidth, the limit figures become –

80dBc at 200kHz offsets and –115dBc at 2MHz.

Incidental

Amplitude

Modulation

Synchronous (AM due to FM) :-

Not greater than 2% with a peak deviation of 40kHz at a modulation

frequency of 500Hz.

Asynchronous (residual AM due to hum and noise with no FM modulation) :-

Not greater than 1% when measured unweighted in a 20Hz to 20kHz

bandwidth.

Print Date 21/02/23 Page 11 of 36 S7604-00MA-03a

Status Indications

Output forward and reverse power and combiner temperature.

Output forward power, temperature and current of any selected Amplifier

module.

Power Supplies, Cooling fans and (when connected) Drives status.

Red/green pass/fail led indicators on all modules.

Dimensions

Height :- 26U

Width :- to fit standard 19in rack.

Depth :- to fit standard 600mm deep rack.

Environmental

Ambient Temperature (operating) : -5 to +50 deg.C

Ambient Temperature (storage) : -20 to +70 deg.C

Relative Humidity (operating) : Less than or equal to 95%, non condensing

with the transmitter at a higher temperature than the ambient.

Altitude (operating) : Up to 3000 metres a.s.l.

Power Supply

S7604-01 and

S7605-05

Four independent single phase inputs.

195 to 255V AC, 50- 60Hz. (note that earlier versions included mains input

relays)

Apparent power factor 98%

Efficiency 88% (Power Supply units only)

S7605C Supply currents (at 5kW RF output) typically :-

8.5A at 230V AC at each of the four inputs.

Typical overall efficiency 55% at above power levels (AC in to RF out). See

note below.

Note - At the required output frequency, overall efficiency of typically 64% can

be achieved by optimising power supply voltage. This will be at the expense

of the performance at other frequencies but can be reversed in the field.

Tests carried out under factory conditions.

Power Supply

S7604-02 and

S7605-07

Single three phase plus neutral (plus protective earth) input.

305 to 455V AC phase to phase (176 to 264V phase to neutral) 47- 63Hz.

Apparent power factor 98%.

Efficiency 88% (Power Supply units only)

S7605C Supply current (at 5kW RF output) typically :-

34A total at 230V AC (phase to neutral)

Typical overall efficiency 55% at above power levels (AC in to RF out). See

note below.

Note - At the required output frequency, overall efficiency of typically 64% can

be achieved by optimising power supply voltage. This will be at the expense

of the performance at other frequencies but can be reversed in the field.

Tests carried out under factory conditions.

Print Date 21/02/23 Page 12 of 36 S7604-00MA-03a

Intentional Blank Page

Print Date 21/02/23 Page 13 of 36 S7604-00MA-03a

SECTION TWO : INSTALLATION

! CAUTION !

These Transmitters operate at high RF power levels, internal supply energy levels and mains

supply current levels. They also incorporate devices containing toxic BeO. Before commencing

installation, it is recommended that the complete INSTALLATION section is read and understood. The

instructions should then be strictly followed, by suitably qualified personnel, otherwise sub-

standard or even dangerous operation may result.

It is also strongly recommended that a mechanical check is made of the Transmitter, before it is

installed and switched on. This is to ensure that no loosening of connectors or damage has occurred,

during transit, which may lead to further damage being caused at switch-on. The principal items to

check are : -

No obvious physical damage has occurred to the Transmitter frame, modules or internal wiring.

All removable, internal RF coaxial connectors (SMA/B/C, BNC, TNC, N etc) are in place and tight.

All internal multi-way connectors (Ribbon, D Type, Molex etc) are in place and secure.

Each E2021 Amplifier Module is pushed fully into the Transmitter with its lock switch fully pushed

down –do not try to force these modules home –if they appear difficult to insert fully, check that

the locating ‘harpoons’ at the rear of each module (either side of its D connector) are not bent.

Each E2088/E2322 Power Supply Module is pushed fully into the Transmitter with its locking lever

engaged –do not try to force these modules home –if they appear difficult to insert fully, check the

connectors at the rear of the module.

2.1 : PHYSICAL DIMENSIONS AND FITTING

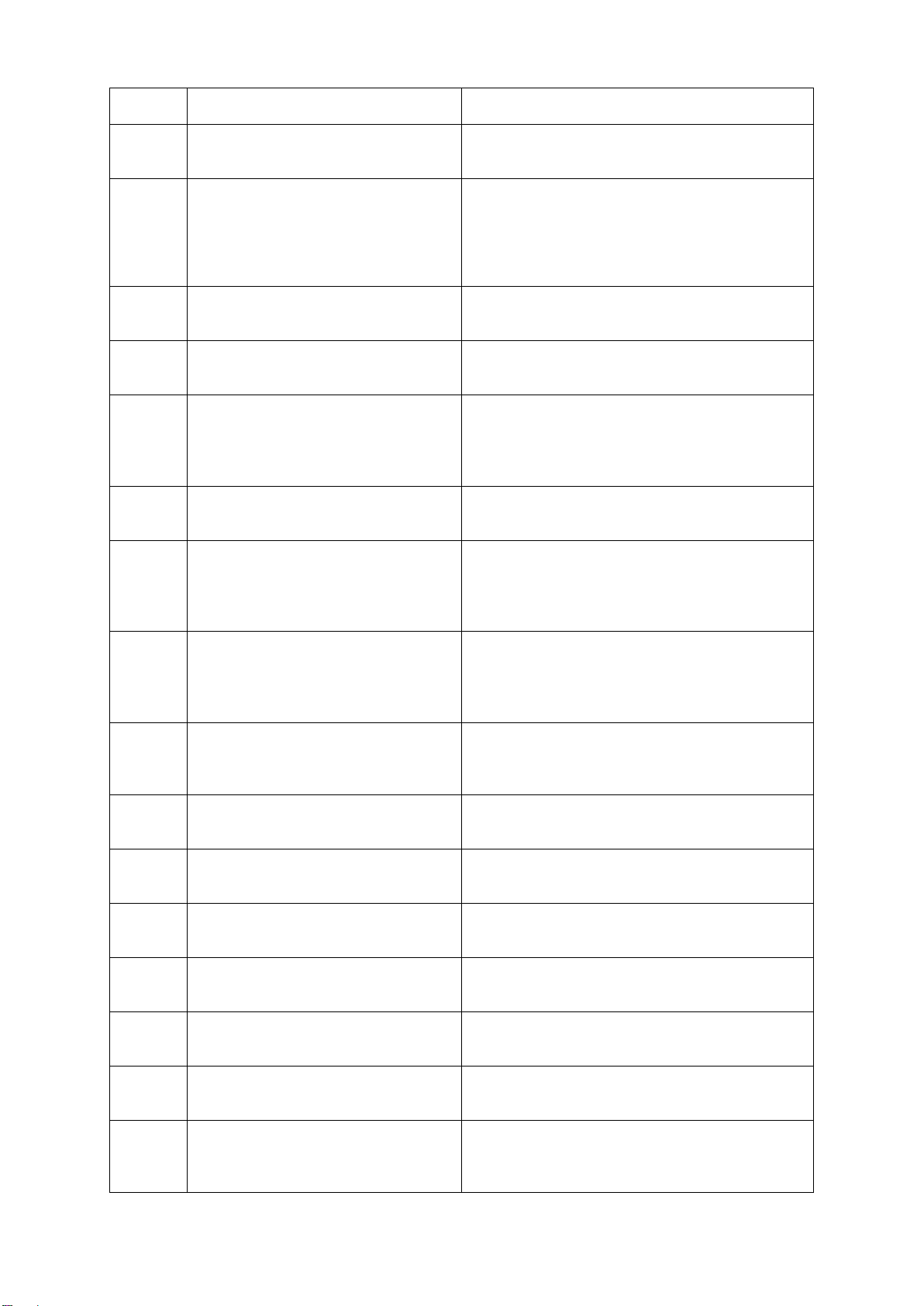

2.1.1 Installation Items

Various installation items are required. A list of these (including spare fuses) is given below. Actual

requirements depend on the configuration of the equipment supplied (e.g. with or without

Exciter/Drive(s), separate to or already fitted into a 19 inch rack, whether or not leads are supplied

ready made etc.). Note that extra, unlisted parts may be required for connections to any

Exciter/Drive(s) that are supplied (see manuals supplied with them).

Typical

Quantity

Description

Function

2

6 Way, 16A/440V, free sockets with

top entry hoods

(e.g. ‘Contact Connectors’ H-BE

part numbers 10-1910 for insert

and 10.0110+12.9543 for hood)

For connection to leads from mains supply

distribution point

(single phase S7604-01 and S7605-05)

4

Length

as req’d

3 core, 2.5mm2 per core, type SY,

flexible steel armoured cable.

Mains supply leads

(single phase S7604-01 and S7605-05).

4

16A ‘C’ rated 2 pole miniature circuit

breakers (MCBs).

Fitted at mains supply distribution point to

protect supply leads and mains input

components in the Transmitter.

(single phase S7604-01 and S7605-05)

1

6 Way, 35A/440V, free socket with

side entry hood

(e.g. ‘Contact Connectors’ H-BS

part numbers 10.1710 for insert

and 10.0820+12.9546 for hood)

For connection to lead from mains supply

distribution point

(three phase S7604-02 and S7605-07)

Print Date 21/02/23 Page 14 of 36 S7604-00MA-03a

Typical

Quantity

Description

Function

1

Length

as req’d

5 core, 6mm2 per core, type SY,

flexible steel armoured cable.

Mains supply lead.

(three phase S7604-02 and S7605-07)

1

3

32A ‘C’ rated four pole miniature

circuit breakers (MCB).

OR

32A ‘C’ rated single pole miniature

circuit breakers (MCBs)

Fitted at mains supply distribution point to

protect supply lead and mains input components

in the Transmitter.

(three phase S7604-02 and S7605-07)

1

EIA 7/8 free connector/bullet.

For connection to lead from Antenna or RF

output load (S7604).

1

EIA 1 5/8 free connector/bullet.

For connection to lead from Antenna or RF

output load (S7605C).

Length

as req’d

Low loss 50RF coaxial cable, rated

in excess of Transmitter output

power at maximum ambient

temperature.

RF output lead.

1 - 3

TNC 50RF coaxial free plug(s).

For connection to leads from Exciter/Drive(s)

and their dummy load.

Length

as req’d

Low loss 50RF coaxial cable, rated

in excess of Exciter/Drive output

power at maximum ambient

temperature.

RF input and dummy load leads.

1

Coaxial, 87.5 –108MHz, 50load

with suitable free connector, rated in

excess of Exciter/Drive output power

at maximum ambient temperature.

Exciter/Drives’ dummy load.

1

2 Way, 10A, 5.08mm pitch screw

terminal block (c/w wire shorting link).

(e.g. Weidmuller BL5.08/2)

External safety interlock connector (wire shorting

link is removed when connector is wired to

external safety circuits).

1 - 2

9 Way D plugs c/w covers.

For connection to leads from control/monitor

inputs of Exciter/Drive(s).

1 - 2

9 Way D sockets c/w covers.

For connection to parallel and serial RS232

remote control/monitor links.

1

15 Way D plug c/w cover.

For connection to additional control/monitor

input links.

Length

as req’d

Multi-core screened cable (number of

cores as required).

Control/monitor leads.

2

SMC right angle free plugs fitted with

cable as required

For FWD/REV power monitor analogue outputs.

Length

as req’d

Heavy gauge grounding wire/strap.

For safety earth lead.

1-2

IEC 6A free plug to free socket mains

leads (1 metre, 3 core each

0.75mm2, EPR insulated, HOFR

sheathed for high temperatures)

For fused and switched mains supply

connections to Exciter/Drive(s).

Print Date 21/02/23 Page 15 of 36 S7604-00MA-03a

Typical

Quantity

Description

Function

12

Screws c/w plastic cup washers and

rack caged nuts.

For fixing S7604 or S7605C into 19 inch rack.

2

Side support ‘L’ brackets c/w fixing

screws and washers.

For extra support to carry the Transmitter’s

weight in the rack.

17

500mA (F) Fuses (for smd holders,

‘Littelfuse’ R451.500)

For protection of control circuits within E2021

Amplifiers and E2026 Drive C/O/Output Monitor.

16

16A (T) HBC 5x32mm (¼ x1¼ in)

Fuses

For protection of internal dc supply leads to and

high current circuitry within E2021 Amplifiers.

4

6.3A (T) HBC 5x20mm Fuses

For protection of internal low current dc supply

leads and of mains supply leads and circuitry

intended for connection to Exciter/Drives(s).

2.1.2 Rack Mounting

If the Transmitter is not supplied ready mounted in a 19 inch rack, this will be required to be done at

time of installation.

! CAUTION !

The S7604 and S7605C (i.e. the assembly carrying the Amplifiers, Power Supplies, Controller, Drive

Changeover/Output Monitor and Combiner) are heavy. Before installation in a rack, the Amplifier

Modules and Power Supplies should be removed to reduce the overall weight and ease the process.

These units are removed from the front of the Transmitter, taking care to release the mechanical

securing locks first. The Fan Assembly may also be opened, unplugged and then removed from the

rear of the Transmitter.

The 19 inch rack should be of standard 600mm depth and at least 26U height. Additional height will be

required if Exciter/Drive(s) are to be fitted into the same rack (recommended). These should be fitted

below the actual Transmitter section for ease of inter-wiring.

Additional bottom support ‘L’ brackets are also be required at each side, below the Transmitter, to

help carry its’ weight. The Transmitter is then fixed to the front of the racking using twelve screws,

plastic cup washers and caged nuts. The Amplifier modules, Power Supplies and Fan Assembly can

then be refitted and external connections made.

Print Date 21/02/23 Page 16 of 36 S7604-00MA-03a

2.2 EXTERNAL CONECTIONS

2.2.1 Mains Supply Connectors (single phase S7604-01 and S7605-05)

These are two independent 6 Way plugs at the rear of the Supply Disconnector section, CON02 and

CON03. Having two enables use of independent ‘A/B’ power sources with the same or different

phases. Each supply must be single phase, 195V to 255V AC, 50- 60Hz.

One supply (normally ‘A’) is always directed to the ‘A’ and ‘C’ groups’ Power Supply Modules and the

other ‘B’ supply is always directed to the ‘B’ and ‘D’ groups’ Power Supply Modules. The maximum

total current drawn from the ‘A’ supply is in the order of 16A (S7604) or 20A (S7605C) and the same

from the ‘B’ supply (at 230V AC with 4kW or 5kW RF output respectively).

! CAUTION !

The S7604 and S7605C MUST NOT be operated at voltages significantly below 195V, as the

supply current may exceed the rating of the two 2x16A mains supply connectors and

associated wiring and components. Fitting of the specified MCB (see next paragraph) will ensure

this cannot occur.

! CAUTION !

The mains supply leads (four total) to the Transmitter must each consist of three core (P+N+protective

earth) insulated cable. Each core must be at least 2.5mm2and the overall cable armoured (type SY

flexible steel armoured cable preferred) and not mounted in a conduit with other supply cables.

Four double pole, 16A (C rated) MCBs must be provided at the supply distribution board(s) to

protect both leads and Transmitter supply input circuitry. Also, since the supply input circuitry

contains filters, which pass current to the Transmitter chassis, the Transmitter chassis must be

connected to a safety ground.

Also ensure whilst making any connections to the mains supply, that the Transmitter’s front

panel Supply Disconnector is switched to ‘off’ (i.e. at O) and is preferably padlocked in that

position to prevent inadvertent operation of the Transmitter.

Each lead terminates in a separate 6 Way 16A/440V free socket at the Transmitter end, which are

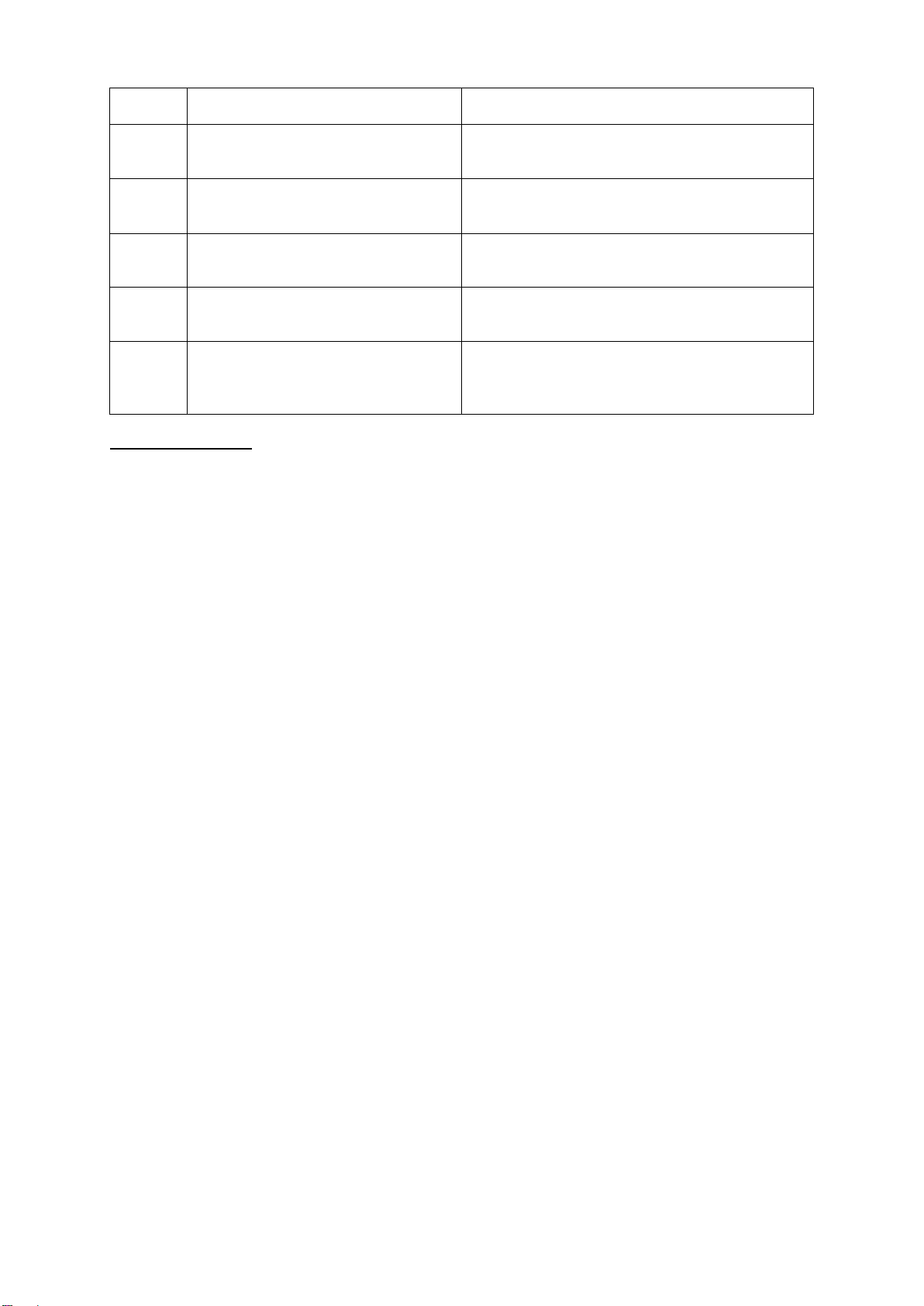

wired as follows :-

Pin 1

Line #1

Pin 2

Neutral #1

Pin 3

Prot. Earth #1

Pin 4

Line #2

Pin 5

Neutral #2

Pin 6

Prot. Earth #2

Earthing Pin

Prot. Earth

The two leads from a connector must both go the same supply via separate MCBs.

The armouring of the cable should also be taken to ground at the supply distribution board.

The free connectors should be fitted with top entry hoods.

An earthing bolt is provided adjacent to the mains supply input connector to allow the Transmitter

chassis to be permanently bonded to nearby safety ground directly or via rack metalwork.

Print Date 21/02/23 Page 17 of 36 S7604-00MA-03a

2.2.2 Mains Supply Connector (three phase S7604-02 and S7605-07)

This is a 6 way plug, CON02, at the rear of the Supply Disconnector section. The supply must be three

phase plus neutral, 176-264V AC phase to neutral, 305-455V AC phase to phase and 47-63Hz.

Provision is made for a protective earth. The maximum current drawn from each phase (at 230/400V

AC) is in the order of 10.5A (S7604-02) or 13.5A (S7605-07).

! CAUTION !

The S7604 and S7605C MUST NOT be operated at voltages significantly below 176V AC phase

to neutral, 305V AC phase to phase, as the supply current may exceed the rating of the 35A

mains supply connector and associated wiring and components. Fitting of the specified MCB

(see next paragraph) will ensure this cannot occur.

! CAUTION !

The mains supply lead to the Transmitter must consist of five core (3P+N+protective earth) insulated

cable. Each core must be at least 6mm2and the overall cable armoured (type SY flexible steel wire

armoured cable preferred) and not mounted in a conduit with other supply cables.

A four pole, 32A (C rated) MCB must be provided at the supply distribution board to protect

both lead and Transmitter supply input circuitry.

Alternatively (to give supply breaker redundancy) three separate single pole 32A (C rated)

MCBs may be used, one in each phase line at the supply distribution board.

Also, since the supply circuitry contains filters, which pass current to the Transmitter chassis, the

Transmitter chassis must be connected to a safety ground.

Also ensure whilst making any connections to the mains supply, that the Transmitter’s front

panel Supply Disconnector is switched to ‘off’ (i.e. at O) and is preferably padlocked in that

position to prevent inadvertent operation of the Transmitter.

The supply lead terminates in a 6 Way 35A/440V free socket at the Transmitter end, which is wired as

follows :-

Pin 1

Phase #1

Pin 2

Phase #2

Pin 3

Phase #3

Pin 4

Neutral.

Pin 5

Prot Earth #1

Pin 6

Prot Earth #2

Earthing Pin

Prot. Earth

The armouring of the cable should also be taken to ground at the supply distribution board.

The free connector should be fitted with a side entry hood.

An earthing bolt is provided adjacent to the mains supply input connector to allow the Transmitter

chassis to be permanently bonded to nearby safety ground directly or via rack metalwork.

Note that the individual three phase input leads MUST NOT be connected, in parallel, to a

single phase supply.

.

Print Date 21/02/23 Page 18 of 36 S7604-00MA-03a

2.2.3 RF Output Antenna Connector

! CAUTION !

When operating, high RF Voltages are present on this connector. Always ensure when making

connections here, or working on any load connected, that the Transmitter’s front panel Supply

Disconnector is switched to ‘off’ (i.e. at O) and is preferably padlocked in that position.

This is a 50EIA 7/8 (S7604) or 1 5/8 (S7605C) coaxial socket on the E2028 Combiner Unit’s output

directional coupler (at the top rear of the Transmitter). Care must be taken to use adequately rated (at

maximum ambient temperature) low loss cable for the lead to the antenna or load

2.2.4 RF Input Exciter/Drive(s) Connectors

! CAUTION !

When operating, high RF Voltages may be present on these connectors. Always ensure when

making connections here, or working on any load connected, that the drive source(s) to the

Transmitter are switched off or safely muted.

These are three 50TNC coaxial sockets at the centre rear of the E2026 Drive C/O /Output Monitor

Unit. Socket SK09 (Drive A) is for connection a single Exciter/Drive’s RF Output. When dual drive

changeover is supplied, socket SK07 (Drive B) is used for connection to the second Exciter/Drive’s RF

Output. In this case, socket SK08 (Load) is used for connection a 50Exciter/Drive dummy load,

normally situated in the section of the rack where the Exciter/Drives are fitted.

2.2.5 Safety Interlock Connector

This is a removable, 2 Way, 5.08mm screw terminal block, PL11, at the rear of the E2026 Drive C/O

/Output Monitor Unit. A shorting link has to be made between the terminals to de-mute the Transmitter

(the front panel INTERLOCK EXT. MUTE display goes from red to green when the terminals are

linked). If there are no external safety interlock switches, a short direct link is made, this being the

state in which the connector is normally supplied. If connections need to be made to external safety

switches, this link is removed and the switches are wired in a series loop to the connector so that if

any switch opens, the link is broken.

! CAUTION !

For the safety interlocks to work correctly, the external switches and link wiring must ‘float’

(i.e. must not be grounded at any point). The total loop resistance should not exceed approximately

100. The external wiring may also be ferrite loaded for emc requirements. No external voltages

should be applied to this connector.

2.2.6 RF Output Monitor Connector

This is a 50BNC coaxial socket SK01 on the left-hand side of the E2026 Drive C/O /Output Monitor

Unit front panel. This provides an filtered sample of the Transmitter’s forward output power at a level,

into 50, approximately 60dB below the power being delivered into the load (e.g. approximately 4-

5mW for 4-5kW being delivered). This connector is for test purpose only with the test equipment and

lead being disconnected when not in use. NOTE that the levels of any harmonics present are not

necessarily equal to those at the antenna.

2.2.7 Drive A/B Monitor and Control Connectors

These are two identical 9 Way D sockets SK03 and SK06 at the rear of the E2023 Controller unit.

These are used to enable one or two Exciter/Drive(s) to be monitored and controlled by the E2023

(with two Exciter/Drives this enables automatic dual Exciter/Drive changeover). Multi-core screened

cable, not exceeding 3 metres in length, should be used for the interconnecting leads.

Print Date 21/02/23 Page 19 of 36 S7604-00MA-03a

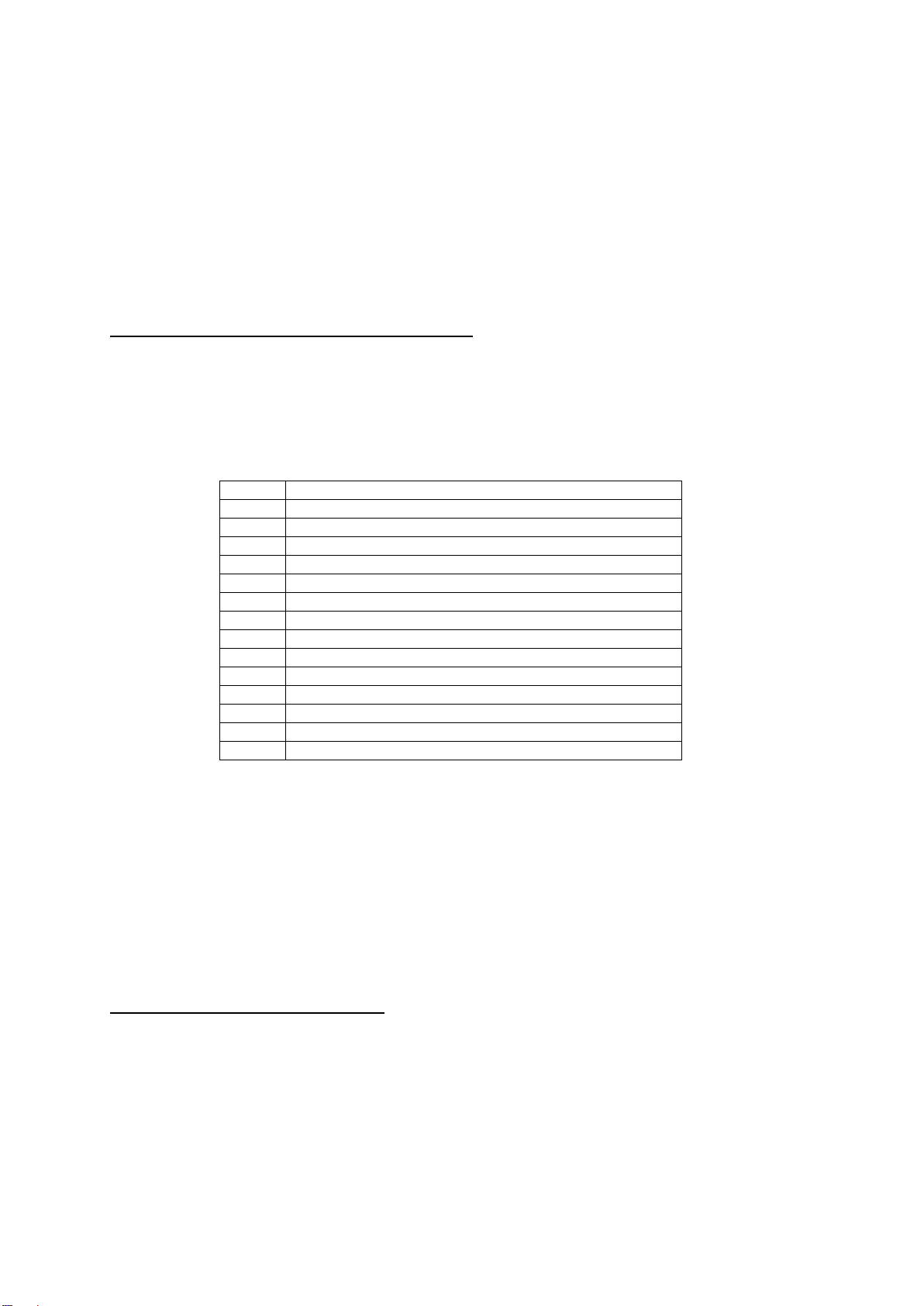

Each lead terminates in a separate 9 Way free D plug at the E2023 end which is wired as follows :-

Pin 1

RS232 Data from Drive (not enabled)

Pin 2

Ground

Pin 3

Prefer Drive from Rem. Control

Momentary low > approx. 1sec

Pin 4

Slow Status Monitor from Drive

Continuous low >2secs registers ‘good’

Continuous high >10secs registers ‘fail’

Pin 5

Fast Status Monitor from Drive

Continuous low >2secs registers ‘good’

Continuous high >2secs registers ‘fail’

Pin 6

RS232 Data to Drive (not enabled)

Pin 7

Ground

Pin 8

Ground

Pin 9

Mute/demute to Drive

Continuous low to mute

Each input (pins 3, 4, 5) is internally ‘pulled up’ to +5V through 12kand must be fed from a voltage

free source of less than 1kto ground for a low state (open-circuit for a high state). These inputs are

protected against constant application of up to 12V dc directly applied.

The mute/demute output (pin 9) is an ‘open collector’ NPN, silicon low saturation switching transistor

suitable for driving loads from +5V to +24V dc with maximum currents of 10mA. The low state output

impedance is approximately 10.

These connections are wired in accordance with the monitor and control requirements of the type of

Exciter/Drive(s) supplied and normally, not all the pins will need to be connected. Pin 3, if used, is for

connection to a remote control and monitoring system. This enables selection of a particular drive to

be preferred (forced) remotely by momentarily pulling this line to ground.

If automatic dual Exciter/Drive changeover only requires one of the two status monitor inputs for

operation, the other must be connected to ground.

2.2.8 Parallel (E2023-01/02) or RS232 Serial Remote Control DTE Connector (E2023-03/04)

This is a 9 Way D plug PL04 at the rear of the E2023 Controller unit. It is used to enable various forms

of remote control and monitoring, possibly requiring additional external units. Multi-core screened

cable, not exceeding 3 metres (parallel) or 30 metres (serial) in length, should be used for the

interconnecting lead.

The lead terminates in a 9 Way free D socket at the E2023 end which is wired as follows :-

Parallel

Serial RS232

Pin 1

Power Output Low (app.–2dB rel. set output)

Not connected

Pin 2

Power Output Fail (app. –12dB rel. max o/p)

Received Data (to E2023)

Pin 3

Reverse Power High (app. 100W or 125W)

Transmit Data (from E2023)

Pin 4

Combiner Temp. High (app. +100deg.C)

Not Connected

Pin 5

Ground

Ground

Pin 6

Fan/Cooling System Fail

Not Connected

Pin 7

System Normal

Not Connected

Pin 8

Drive A/B Selected

Not Connected

Pin 9

Drive Changeover on Auto

Not Connected

The parallel outputs are ‘open collector’ NPN, silicon low saturation switching transistors suitable for

driving loads from +5V to +24V dc with maximum currents of 10mA. The low state output impedance

is approximately 100. Each output is protected against constant application of up to 5V dc directly

applied. A normal (non-faulty) condition is indicated by the output pin being pulled to ground (i.e. low

state) by the switching transistor. Drive A selected and Drive C/O on Auto are similarly indicated.

Print Date 21/02/23 Page 20 of 36 S7604-00MA-03a

The serial RS232 outputs are used to enable down loading of status and to enable simple control

using a personal computer (PC) directly connected to this rear panel COM/DTE port.

Note that the assigned pin numbers and their functions are for a standard 9 pin plug on ‘Data Terminal

Equipment’ (DTE) such as computers. Standard crossover or ‘null modem’ leads may thus be used for

connection to a personal computer or PC. The length of the interconnecting lead may be extended by

use of compatible RS422/485 or fibre-optic line drivers.

Note also that the serial option requires an additional internal link lead, which re-directs the serial

remote control from the front panel COM port to the rear panel DTE connector.

Full details of serial remote control procedures via this connector are given in Section 2.4

2.2.9 Second Transmitter Remote Control Connector

This is a 15 Way D socket SK05 at the rear of the E2023 Control Unit. It is used to enable externally

derived automatic control of Transmitter muting and high/low power level setting. Multi-core screened

cable, not exceeding 3 metres in length, should be used for the interconnecting lead.

The lead terminates in a 15 Way free D plug at the E2023 end which is wired as follows :-

Pin 1

Select Low Power Input (continuous low to select)

Pin 2

Mute Transmitter Input (continuous low to mute)

Pin 3

Output Status A (continuous low state –not used)

Pin 4

Output Status B (continuous low state –not used)

Pin 5

RS485 Data (+) In (not used)

Pin 6

RS485 Data (-) In (not used)

Pin 7

RS485 Data (+) Out (not used)

Pin 8

RS485 Data (-) Out (not used)

Pin 9

Not Connected

Pin 10

Ground

Pin 11

Ground

Pin 12

Ground

Pin 13

Ground

Pin 14

Not Connected

Pin 15

Not Connected

Each input (pins 1, 2) is internally ‘pulled up’ to +5V through 12kand must be fed from a voltage free

source of less than 1kto ground for a low state (open-circuit for a high state). These inputs are

protected against constant application of up to 12V dc directly applied. Note that they are only active

when the associated E2026 Auto-Mute-Start switch is in the Auto position and have delays in the

order of 200mS. Thus, they should not be used as part of a safety interlock system (see 2.2.5).

Each output (pins 3, 4) is a relay contact to ground for a low state (open-circuit for a high state). The

contacts are rated at 1mA (minimum at 5V dc) to 1A maximum switching current. The maximum

voltage (including switching surges) must be limited to 24V dc. These outputs (and pins 5-8 inc.) are

not used and thus should not be externally connected.

2.2.10 Mains Supply Output Connectors

These are two standard IEC three pin (L+N+PE) sockets CON01 and CON04 either side of the mains

supply input connectors. Each one is connected, via the front panel SUPPLY DISCONNECTOR

switch to the mains supply input which is adjacent to it (single phase variants) or to different phases

(three phase variants). Thus equipment connected to these supplies can be arranged in two

independent groups, both groups being switched off when the Transmitter itself is switched off using

the front panel switch.

The continuous total load on output each should not exceed approximately three amps. Each output is

protected by a 6.3A (T) HBC fuse, FS19 and FS20, to allow for current surges at ‘switch-on’.

This manual suits for next models

8

Table of contents

Other Eddystone Broadcast Transmitter manuals