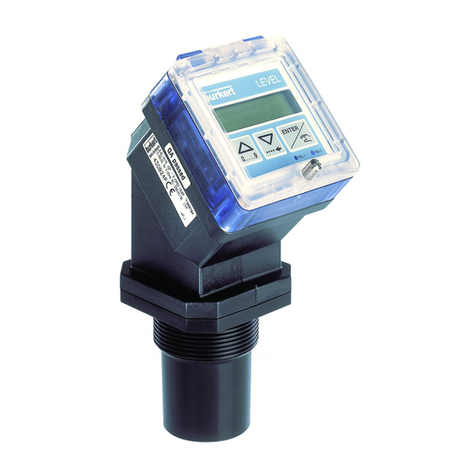

Burkert 8137 User manual

Other Burkert Transmitter manuals

Burkert

Burkert 8222 ELEMENT NEUTRINO User manual

Burkert

Burkert 8026 User manual

Burkert

Burkert 8022 Series User manual

Burkert

Burkert 8022 Series User manual

Burkert

Burkert SE58 S User manual

Burkert

Burkert 8045 User manual

Burkert

Burkert 8176 Installation instructions

Burkert

Burkert 8022 Series User manual

Burkert

Burkert SE58 L User manual

Burkert

Burkert 8138 User manual

Burkert

Burkert 8225 User manual

Burkert

Burkert 8619 multiCELL WM AC User manual

Burkert

Burkert 8025 Series User manual

Burkert

Burkert 8325 User manual

Burkert

Burkert 8177 User manual

Burkert

Burkert 8025 Series User manual

Burkert

Burkert SE56 Specification sheet

Burkert

Burkert 8316 User manual

Burkert

Burkert 8175 User manual

Burkert

Burkert 8225 User manual

Popular Transmitter manuals by other brands

Dejero

Dejero EnGo 3x manual

Rosemount

Rosemount 4600 Reference manual

Speaka Professional

Speaka Professional 2342740 operating instructions

trubomat

trubomat GAB 1000 instruction manual

Teledyne Analytical Instruments

Teledyne Analytical Instruments LXT-380 instructions

Rondish

Rondish UT-11 quick start guide