Epoch WT-PP User manual

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

Weight Transmitter User manual

Contact us :

EPOCH INSTRUMENTS AND CONTROLS PVT LTD

No. 16, Bhadrappa Estate, 54, Magadi Main Road, Kamakshipalya,

Bangalore - 560 079.

Ph : 080-23481364

Email : sales@epochloadcell.com

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

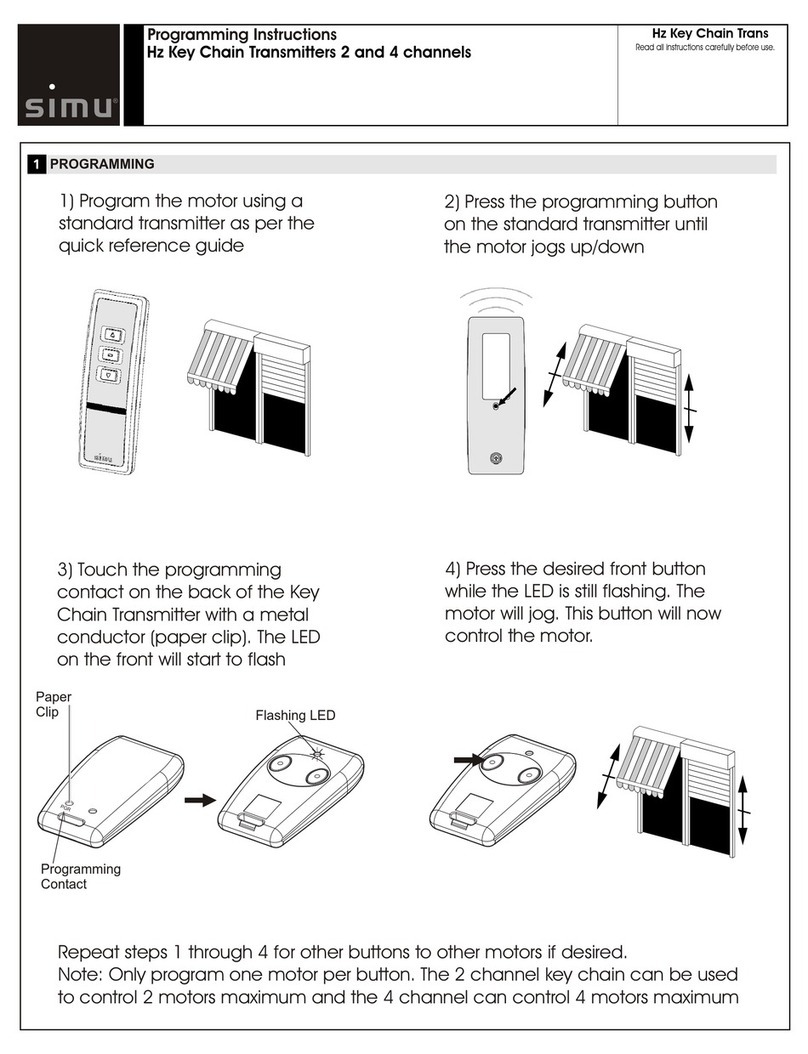

Indicator Front Panel View

Initial Inspection

WEIGHT TRANSMITTER USER MANUAL VERSION-1.3

The front panel of Weighing Transmitter appears similar to one shown below:

1 - LED Display

2 - MENU/ESC key - To enter into Menu from display(Password protected) & to back from menu options

and parameter entries without storing entered values

3 - ENTER/TARE key - To enter into Menu options & Sub menus & to store the parameters values

4 - LEFT key - To select or move to the next cursor position in parameter values entry & to display peak

weight value during the main display

5 - UP key - To select next option and to increase or decrease values & to reset the peak weight during

the main display

6 - Status LED's

7 - Negative indication

STATUS LED’s Description Status

-VE

To indicate the current weight is +ve

weight or –ve weight

ON -ve weight

OFF+ve weight

OPEN

To indicate the Load error(oPEn) (or)

To indicate the display weight is Peak

weight or Current weight

ON(continuous)Load Error

ON(one time)Peak weight

OFF Current weight

PWR To indicate the power is ON or not ON Power ON

OFF Power OFF

The rear panel of Weight Transmitter appears similar to one shown below:

Ensure the following while opening the carton box: a) Weight Transmitter – 1No b)

Connectors for

ports (RS485, load cell) – 2Nos c) Side clamps – 2Nos d) User Manual – 1No

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

Technical Specification

Specification

Description

Indicator Power

Power Supply

24V DC Supply

Controller

High speed microcontroller

A/

D Converter

Type

24

-

bit Delta Sigma

Analogue Input Range

0.2mV to 25 mv

Linearity

<0.02% FS

Gain Drifting

2PPM/

◦C

Conversion Rate

12.5 SPS

Display Accuracy

1/30,000

Display & Keypads

LED Display

5 digits 7 Segment LED Display

Keypads

4 Keys, Menu/Esc Key, Enter Key, Up Key and Left Key.

Load cells

Excitation

5 V DC

Mechanical Data

Cabinet Size

129mm (

L)*48mm (H)*96mm (W)

Panel Cutout Details

45mm (H)*92mm (W)

Net Weight

200 gm

Environmental

Operating Temperature

-

10

◦C to 40◦C

Storage Temperature

-

25

◦C to 70◦C

Relative Humidity

90% R.H without dew

IP Level

Front panel IP 55

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

Menu Flow Diagram

Menu can be accessed by using the MENU key by pressing the key continuously for 2 sec.

Calibration accesses through hardware lock protection. Please connect and short pin no. 2

and 3 in rear panel to enable calibration.

Two different Load calibrations available “AUTO” & “MANUAL”. Difference, in manual

calibration User need to enter Known weight count (without zero count) as span

count.

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

LOAD CALIBRATION

Calibration accesses through hardware lock protection. Please short pin no. 7

and 8 in rear panel to enable calibration .

Accessing menus requires entering the default factory set valid 3-digit password i.e. ‘000’. It

is suggested that you change the password.

This menu will help you to calibrate load.To access load calibration menu.

S.No Instruction Display

1. Press MENU/ESCand enter the default factory

set password ‘000’ and press ENTER/TARE.

2. Navigate to “AUto” or “nAnUL” and press

ENTER/TARE.

Two different Load calibrations available

“AUTO” & “MANUAL”. Difference, in manual

calibration we have to enter the span count

(Known weight count).

3. Navigate to Maximum Capacity (n-CAP) and

press ENTER/TARE.

Enter the max capacity of load cell within the

range (0.01-999.99). E.g., ‘020.00’

4. Navigate to Decimal Point (d-Pt) and press

ENTER/TARE.

Set the decimal value with the possible values

of (0, 1, 2, 3).

You can enter the values by pressing “UP” or “SHIFT” keys.

Press ENTER/TARE key to store the current value.

Press MENU/ESC key to either return to previous menu or cancel the entered

values.

000

CALIb

n-CAP

020.00

d

-

Pt

2

AUto

NAnUL

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

5. Navigate to Resolution (rSoL) and press

ENTER/TARE.

Set the resolution value with the possible

values (1, 2, 5, 10, 20, 50 and 100). E.g., ‘2’.

6. Navigate to Cal. Zero (CAL-0) and press

ENTER/TARE.

Remove any load on load cell. LED displays

ADC counts corresponding to the cal. Zero

value.

Press ENTER/TARE to set Cal. Zero.

When you calibrate Cal. Zero and Cal.

Span, wait for LED to display stable

raw ADC counts.

7.

Navigate to Cal. Span (LoAd) and press

ENTER/TARE.

AUTO

Place a reference weight on the load cell, the LED

displays ADC count corresponding to the weight.

E.g., ‘6081’.

MANUAL:

User need to enter Known weight count

(without zero count) as span count.

Press ENTER/TARE to set Cal. Span.

Cal. Span counts should be greater than

Cal. Zero + 50.

8. Navigate to load Capacity (L-CAP) and press

ENTER/TARE.

Enter the reference weight that is used while

calibrating Cal Span using up and left key. The

range should be (0.01 to Max Capacity). E.g.,

‘001.00’

System asks to take calibration backup

(ConF?). If you want take backup then press

ENTER/TARE otherwise press MENU/ESC

thencome out from menu.

rSoL

2

CAL

-

0

1617

LoAd

6017

L

-

CAP

001.00

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

ANALOG SETUP

A

-

Lo

01092

This menu will help you to calibrate Analog output.To access Analog setup menu, navigate

to menu using up key and select A-Set and press ENTER/TARE.

S.No. Instruction Display

1. Navigate to Analog output check (A-CHC) and

press ENTER/TARE.

Here enter the weight value, and then it gives

the corresponding output.

2. Navigate to Analog High (A-HI) and press

ENTER/TARE.

The value which is going to send to DAC for

20mA has to be entered here.

Range is (0 to 6553).

3. Navigate to Analog Low (A-Lo) and press

ENTER/TARE.

The value which is going to sent to DAC for 0

mA (or) 4 mA has to be entered here.

If Analog selection is 0-20 (or) 0-10 then

The range is (0 to 6553).

If Analog selection is 4-20 (or) 2-10 then

The range is (0 to 6553).

A

-

CHC

000.00

A

-

HI

05491

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

A

-

dEF

Lo

A

-

oFF

001.00

A

-

SPn

010.00

4. Navigate to Analog Default Value (A-dEF) and

press ENTER/TARE.

This provides safety to Analog Output during

error conditions. The user can select what

value of Analog Output should be during error

conditions.

The available modes are,

Low Value (4 mA / 0 mA) -> ‘Lo’.

High Value (above 20 mA i.e.,22.05 mA)

-> ‘HI9H’.

Value at Previous stage -> ‘LASt’.

5. Navigate to Analog Offset (A-oFF) and press

ENTER/TARE.

This provides the Analog Output starts range.

Here, user can set the positive or negative

offset.

Before entering into “A-oFF” press left key to

Select positive (“pos”) or negative (“nEg”)

analog offset. “nEg”means –ve LED will be On.

The available modes are,

If the offset is “pos” means then analog

output range starts from positive 001.00

kg to analog span value.

If the offset is “nEg” means then analog

output range starts from negative 001.00

kg to analog span value.

6. Navigate to Analog Span (A-Spn) and press

ENTER/TARE.

This provides the Analog Output end range.

Here, user can set the weight at which can get

the max analog output.

This menu is restricted to the max

capacity value under calibration.

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

SETUP

Adc

-

f

1

N

-

aUg

10

PASS

000

AUt

-

0

5

t

-

Ed

Enb

To access General setup menu, navigate to menu ->SETUP and press ENTER/TARE.

S.No Instruction Display

1. Navigate to ADC Filter (adc-f) and press

ENTER/TARE.

User can enter the filter value here with range of

(1-9). It is used to reduce fluctuations due to

sudden load impacts.

2. Navigate to moving Average (m-avg) and press

ENTER/TARE.

User can enter the Moving average value here

with range of (1-100).

3. Navigate to Password (PASS) and press

ENTER/TARE.

Enter the password you want to use, using UP and

LEFT keys and press ENTER key to store &

activate it. This is three-digit password.

Default password is ‘000’.

4. Navigate to Auto zero (Aut-0) and press

ENTER/TARE.

The available Auto Zero value in engineering

count value is from 0 to 9.

If we enter 5, when weight is Zero, if the current

weight deviation from 0 value in either positive or

negative is less than or equal to (5 * Resolution),

then the system will take the Current weight value

as 0. The 0 value disables the Auto Zero. Auto

Zero Function is used to avoid drift error.

5. Navigate to Tare Enable/Disable (t-Ed) and press

ENTER/TARE.

This is to enable or disable the tare when normal

process.

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

COMMUNICATION SETUP

d

-

Id

01

bAUd

9600

C

-

nod

n

-

bUS

OFFSE

00000

To access Serial communication setup menu, navigate to menu ->S-Conand press

ENTER/TARE.

S.No. Instruction Display

1. Navigate to Device ID (d-Id) and press ENTER/TARE.

Enter the Device ID (1-99). It is required to identify the

system, in case of multiple systems are deployed.

2. Navigate to Baud Rate (bAUd) and press

ENTER/TARE.

It is used to set the communication between unit and

host device. It is settable between 2400, 4800, 9600,

19200, 38400, 57600, 115200bps.

3. Navigate to Communication mode (C-nod) and press

ENTER/TARE.

Available modes are,

o Request mode

o Dump mode

o ModBusRTU mode

o ModBus ASCII mode

Refer Serial Communication protocol section.

4. Navigate to OFFSET(OFFSE) and press

ENTER/TARE.

User can enter the OFFSET value here with range of

(00000-49999).

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

SYSTEM CHECK (TEST)

r

-

AdC

1716

rECAL

ConF

?

L

-

dF

000

dIo

t

-

dIp

dis

-

c

88888

To access System check menu, navigate to menu -> tESt and press ENTER/TARE.

S.No. Instruction Display

1. Navigate toRaw ADC (r-AdC) and press ENTER/TARE.

Raw ADC counts corresponding to load cell is

displayed.

2. Navigate to Restore Calibration (rECAL) and press

ENTER/TARE.

On pressing ‘ENTER/TARE’ Key, system asks

confirmation. If ENTER key is pressed, Original

Calibration values are restored.

3. Navigate to Load default (L-dF) and press

ENTER/TARE.

It will ask the password to conform to load default. On

entering the correct password, system asks

confirmation. If ENTER key is pressed, System loads

the factory set defaults to Calibration, Analog setup,

Serial Communication setup and System check

Parameters and also in to the memory.

4. Navigate to Display check (dis-c) and press

ENTER/TARE.

The all LED will be ON at the same time, for checking

purpose.

5. Navigate toDIO check (dIo) and press ENTER/TARE.

Navigate to “t-doP” to test digital output.

Output can be checked by pressing Up key.

Navigate to “t-dIp” to test digital input.

t

-

dop

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

Serial Communication Protocol

The communication protocols used are a) Request mode b) Dump mode c) Modbus RTU mode d)

Modbus ASCII mode

Note: Modbus RTU mode implemented and tested with Simply modbus Software,

Modscan32,Modbus tester.

Communication settings:

Parity : None ; Data Bits: 8 ; Stop Bits: 1 ; Flow Control: None

Baud rate is settable under setup.

Request Mode:

If the Communication mode (C-nod), under setup is “rE9” then the below protocol will dump one

time based on the request from PC. Baud rate is settable under setup.

For Error condition weight value,

Over Range (OR)Weight value is 99999.

Over Capacity (OC)Weight value is 88888.

Under Range (UR)Weight value is 77777.

Dump Mode:

If the Communication mode (C-nod), under setup is “dUmp” then the below protocol will dump

continuously (Same as request mode response). Baud rate is settable under setup.

%XX[YZWWWWW]$

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

Modbus ASCII Mode:

If the Communication mode (C-nod), under setup is “n-ASC” then the below protocol will receive

based on request. All the parameters in the protocols should be in hex format.

The Modbus ASCII mode having the same address of Modbus RTU.

FOR READ OPERATION:

For ASCII mode read operation protocol, the example format is given below,

Request: Eg - Request for Maximum Capacity: 010300030001F8

Start Char Device

Id

Read

Command Address No. of

Registers LRC Stop Char

1 Byte

(:)

1 Byte

(01)

1 Byte

(03)

2 Bytes

(0003)

2 Bytes

(0001)

1 Byte

(F8)

1 Byte

(CRLF)

Response:

Start Char Device

Id

Read

Command

No. of Bytes to

send Data LRC Stop Char

1 Byte

(:)

1 Byte

(01)

1 Byte

(03)

1 Byte

(04)

2 Bytes

(07d0)

1 Byte

(e3)

1 Byte

(CRLF)

FOR WRITE OPERATION:

For ASCII mode write operation protocol, the example format is given below,

Request:

Start Char Device

Id

Read

Command Address Data LRC Stop Char

1 Byte

(:)

1 Byte

(01)

1 Byte

(06)

2 Byte

(0064)

2 Bytes

(0000)

1 Byte

(95)

1 Byte

(CRLF)

Response:

If the write operation is successfully done then the response will be same as that of request.

Modbus RTU Mode:

If the Communication mode (C-nod), under setup is “n-rtu” then the below protocol will receive

based on request. All the parameters in the protocols should be in hex format. Baud rate is

settable under setup.

Read operation can be performed for all address values and Write operation can be done only

for2,3,5,100,101,102,103,104,105,106,107,108,109,200,201,202,203,204,205,206,207,300,301.

Default the offset value is 00000.

In menu toselect485 setup menu ->to change the offset value.

The offset value 40000 means 40000 is Max Capacity address for read operation,

40000 is Max Capacity address for write operation.

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

S.NO ADDRESSES PARAMETER FUNCTION

1 0 RAW ADC (LSB OF RAW ADC) R

2 1 RAW ADC (MSB OF RAW ADC) R

3 2 PEAK VALUE (LSB OF PEAK VALUE) R

4 3 PEAK VALUE (MSB OF PEAK VALUE) R

5 4 STATUS R

6 5 TARE-CURRENT

WEIGHT

R-W(WRITE ‘0’TO TARE THE

WEIGHT )

7 6 CURRENT WEIGHT (LSB OF CURRENT WEIGHT) R

8 7 CURRENT WEIGHT (MSB OF CURRENT WEIGHT) R

S.NO ADDRESSES PARAMETER FUNCTION

1 100 MAX CAPACITY (LSB OF MAX CAPACITY) R-W

2 101 MAX CAPACITY (MSB OF MAX CAPACITY) R-W

3 102 DECIMAL POINT (0-3)R-W

4 103 RESOLUTION (1,2,5,10,20,50,100)R-W

5 104 CAL ZERO (LSB OF CAL ZERO) R-W

6 105 CAL ZERO (MSB OF CAL ZERO) R-W

7 106 CAL SPAN (LSB OF CAL SPAN) R-W

8 107 CAL SPAN (MSB OF CAL SPAN) R-W

9 108 CAL CAPACITY (LSB OF CAL CAPACITY) R-W

10 109 CAL CAPACITY (MSB OF CAL CAPACITY) R-W

S.NO ADDRESSES PARAMETER FUNCTION

1 200 ANALOG HIGH LSB R/W

2 201 ANALOG HIGH MSB R/W

3 202 ANALOG LOW LSB R/W

4 203 ANALOG LOW MSB R/W

5 204 ANALOG OFFSET LSB R/W

6 205 ANALOG OFFSET MSB R/W

7 206 ANALOG SPAN LSB R/W

8 207 ANALOG SPAN MSB R/W

S.NO ADDRESSES PARAMETER FUNCTION

1 300 ADC-FILTER R-W

2 301 MOV-AVG R-W

3 302 AUTO ZERO R

4 303 TARE EN/DI R

S.NO ADDRESSES PARAMETER FUNCTION

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

1 400 DEVICE ID R

2 401 BAUD RATE R

3 402 COM MODE R

4 403 OFFSET (LSB OF OFFSET) R

5 404 OFFSET (MSB OF OFFSET) R

FOR READ OPERATION:

Request: Example - Request for Resolution is 01 03 9C 41 00 01 D5CA

Device Id Read

Command

Address

No. of

Registers CRC

1 Byte

(01)

1 Byte

(03)

2 Bytes

(9C41)

2 Bytes

(0001)

2 Bytes

(D5CA)

Response: Example - Response for Resolution is 01 03 04 00 02D9 84

Each request and response will end with CRC values.

FOR WRITE OPERATION:

Request: Example - Request for write Cal-Capacity is 01069C 41 00 03 6E51

Response:

Response received is as same as that of request.

Device

Id

Read

Command

No. of Bytes

to send Data CRC

1 Byte

(01)

1 Byte

(03)

1 Byte

(02)

2 Bytes

(0002)

2 Byte

(D984)

Device Id

Write

Command Address Data CRC

1 Byte 1 Byte (06) 2 Bytes 2 Bytes 2 Byte

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

Troubleshooting

S. No

Problem

Reason

Solution

1.

No Display

Power line to the control unit

might be faulty.

Check the power cable

continuity.

2.

Weight

fluctuations

24 D

C.

Voltage

f

luctuations.

Check the Line Input Voltage.

Improper earth.

Check the

earth cable or

earth.

Load cell loose contact.

Check

c

able between

l

oad

cell &main PCB.

Over load

stopper touching

the

Load cell.

Avoid over loading or check

the Load cell.

Improper calibration

Re

–

c

alibration properly.

3.

Weight

Variation

Imp

roper

l

oad cell

connection

.

Check the Load cell

mounting “ALLEN” Screws.

Check whether any other

material is touching the

weigh platform.

Check whether over load

stopper is touching the

Load cell.

4.

Communication

not working

Improper wiring connection

Loose contact

Electrical damage

Check the communication

cable.

Contacts us : email : sales@epochloadcell.com , Ph: 080-23481364

Error Messages

S.No. Error

Code

Description

1. -oC-

If the value of current weight or displacement exceeds the

[Maximum load capacity or Maximum displacement value +

(9 * resolution)], then “OC” is displayed.

2.

oPEn

If the value of load cell exceeds its range or if the load cell

disconnected, “or” is displayed.

Or

If the value of load cell under ranged, “ur” is displayed.

3. PASEr If the entered password was wrong then this error message

will display. Please enter the correct password.

4.

U-Err

If the entered value exceeds the limit then this error

message will display. Please enter the correct value.

5. S-Err If the entered cal span is not more than the cal zero + 50

value then the system will display this error message.

6. C-Err If calibration back not taken then this error message will

display.

7. C-dIS Calibration menu access disabled.

Table of contents

Popular Transmitter manuals by other brands

Avalon RF

Avalon RF OTX627 User's guide & operating manual

RVR Solar

RVR Solar BLUES30NV user manual

Endress+Hauser

Endress+Hauser iTEMP TMT162 Brief operating instructions

Brähler Systems

Brähler Systems INFRACOM ICen IV operating instructions

DME

DME SRB-406 Operation manual

E+E Elektronik

E+E Elektronik EE22 Series manual