EPPINGER BT Series User manual

Doc. No. : 1002

Version 1 dated 18/10/2018

Page 1/11

Assembly instructions

BT / BM / BF Gearboxes

Assembly instructions (Original)

BT / BM / BF Gearboxes

Doc. No. : 1002

Version 1 dated 18/10/2018

Page 2/11

Table of contents

1Safety instructions ............................................................................. 3

2General.............................................................................................. 3

2.1 Information on the documentation .......................................................... 3

2.2 Target group.............................................................................................. 4

2.3 Scope ......................................................................................................... 4

2.4 Intended use.............................................................................................. 4

2.5 Contact ...................................................................................................... 4

3Handling and Transport...................................................................... 5

4Storage .............................................................................................. 6

5Assembly ........................................................................................... 6

5.1 Mounting of the gearbox .......................................................................... 7

5.2 Assembly of the shafts .............................................................................. 7

5.3Assembly of the motor for the BF series................................................... 7

6Commissioning................................................................................... 8

7Operation .......................................................................................... 8

8Maintenance...................................................................................... 9

9Decommissioning............................................................................. 11

9.1 Dismantling.............................................................................................. 11

9.2 Disposal ................................................................................................... 11

Assembly instructions (Original)

BT / BM / BF Gearboxes

Doc. No. : 1002

Version 1 dated 18/10/2018

Page 3/11

1Safety instructions

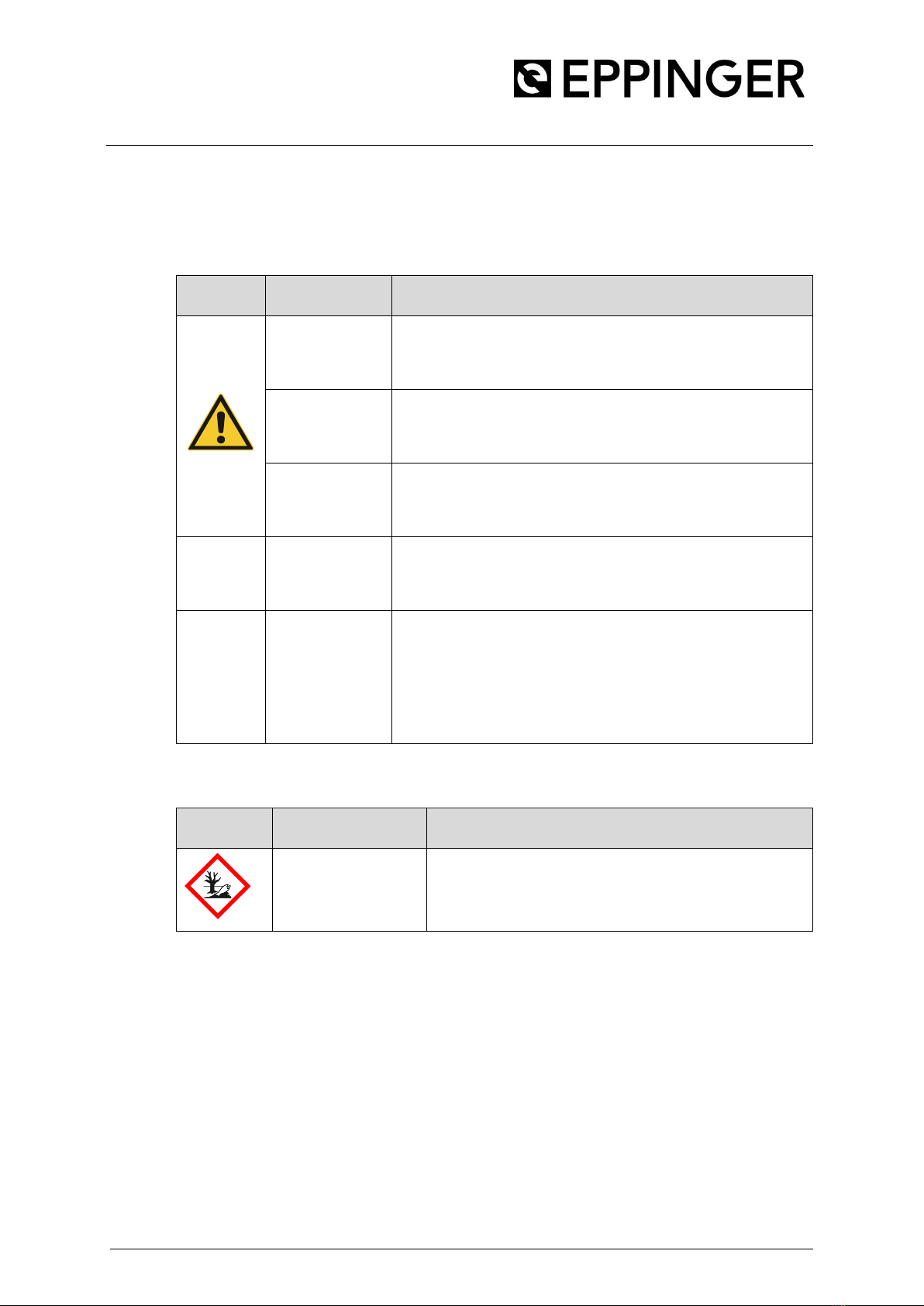

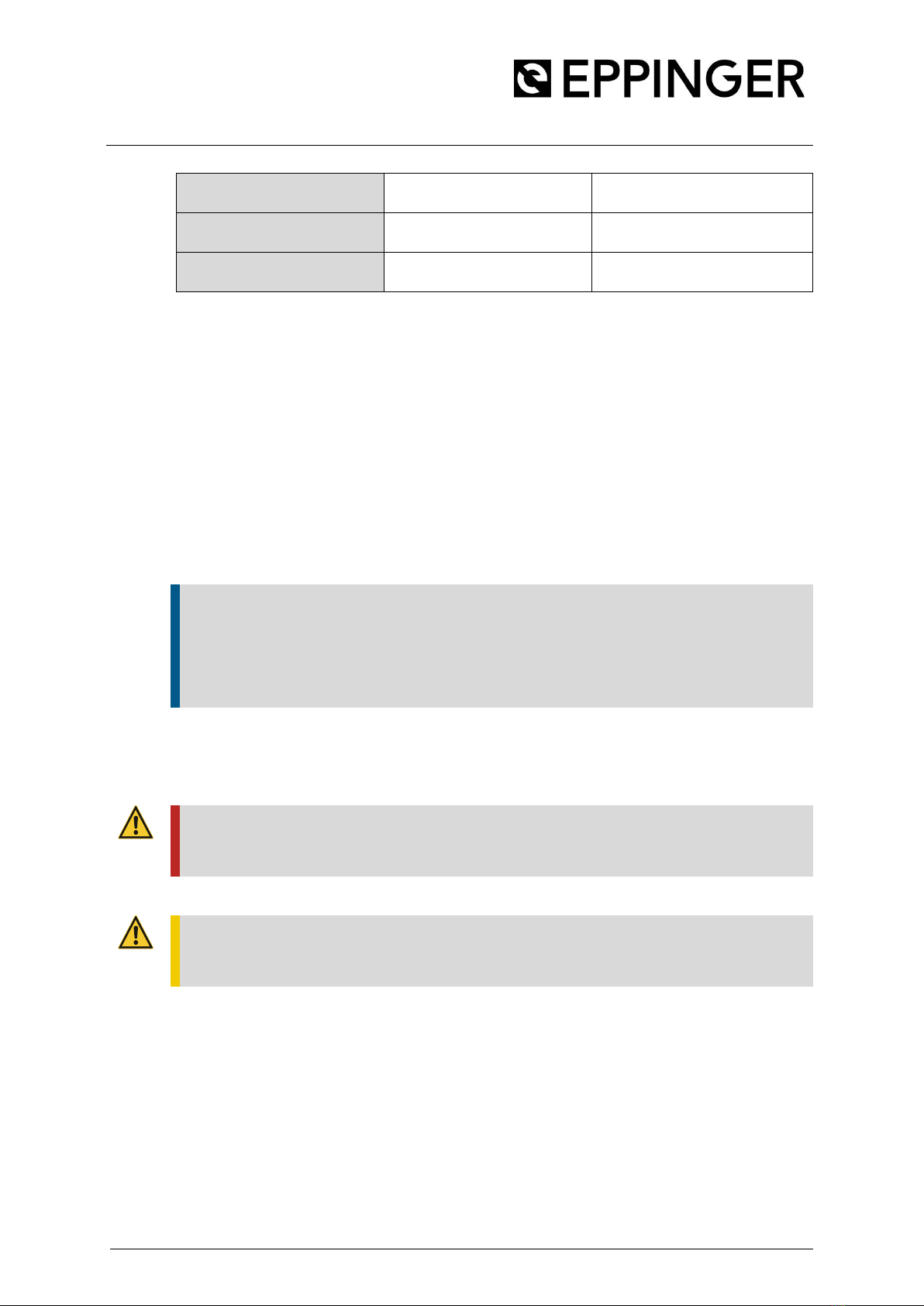

A distinction is made between different levels of safety instructions. Table 1 below

shows the definitions of symbols and signal words.

Symbol

Signal word

Definition

DANGER!

Immediately imminent danger.

Death or extremely serious injury, crippling.

WARNING!

Possibly dangerous situation.

Death or extremely serious injuries may result.

CAUTION!

Less dangerous situation.

Minor or moderate injuries may result.

NOTICE

Potentially damaging situation.

Possible damage to product and/or machine.

INFO

Tips and other useful or important information and

advice.

No dangerous or harmful consequences for persons

or property.

Table 1: Classification of notices

Symbol

Signal word

Definition

Environmental

hazard

Pollution risk for the environment

Table 2: Other symbols

2General

2.1 Information on the documentation

These assembly instructions have to be read carefully before assembling, commis-

sioning and maintaining the product. The document must be kept in a suitable place

for future reference and must be available for any assembly, maintenance or disman-

tling work.

Assembly instructions (Original)

BT / BM / BF Gearboxes

Doc. No. : 1002

Version 1 dated 18/10/2018

Page 4/11

2.2 Target group

This documentation is intended for qualified trained personnel who are familiar with

mechanical assembly work. Assembly, commissioning and maintenance may only be

carried out by accordingly qualified personnel. Technical training or safety instruction

is required.

2.3 Scope

The scope of these instructions covers the following products of the company EGT

Eppinger Getriebe Technologie GmbH:

•BT Bevel gearboxes

•BM Bevel gearboxes

•BF Bevel gearboxes with motor flange

All mounting parts necessary for the assembly, installation, operation and mainte-

nance, which are included in the scope of supply of these gearboxes, are also within

the scope of this document.

2.4 Intended use

Eppinger gearboxes are machine elements for converting or diverting torques and

rotational speeds within the respectively specified performance range. Any operation

outside the specified performance characteristics or other than the specified use is

not permitted. The permissible torques and rotational speeds of the gearboxes must

not be exceeded. The forces affecting on the gearbox shafts have to be limited to the

maximum permissible values.

Unauthorised modifications or alterations to the product are not permitted.

According to the EC Machinery Directive 2006/42/EC, gearboxes are referred to as

machine components and are therefore assemblies that do not fall within the scope

of the Machinery Directive 2006/42/EC. Therefore, gearboxes are components to be

installed in machines. The commissioning is forbidden until by or after the integration

into the end product, the requirements of the machine directives are met.

2.5 Contact

EGT EPPINGER Getriebe Technologie GmbH

Breitwiesenweg 2-8

Assembly instructions (Original)

BT / BM / BF Gearboxes

Doc. No. : 1002

Version 1 dated 18/10/2018

Page 5/11

73770 Denkendorf/Germany

+49 (0) 711 / 934 934-626

http://www.eppinger-gears.com

3Handling and Transport

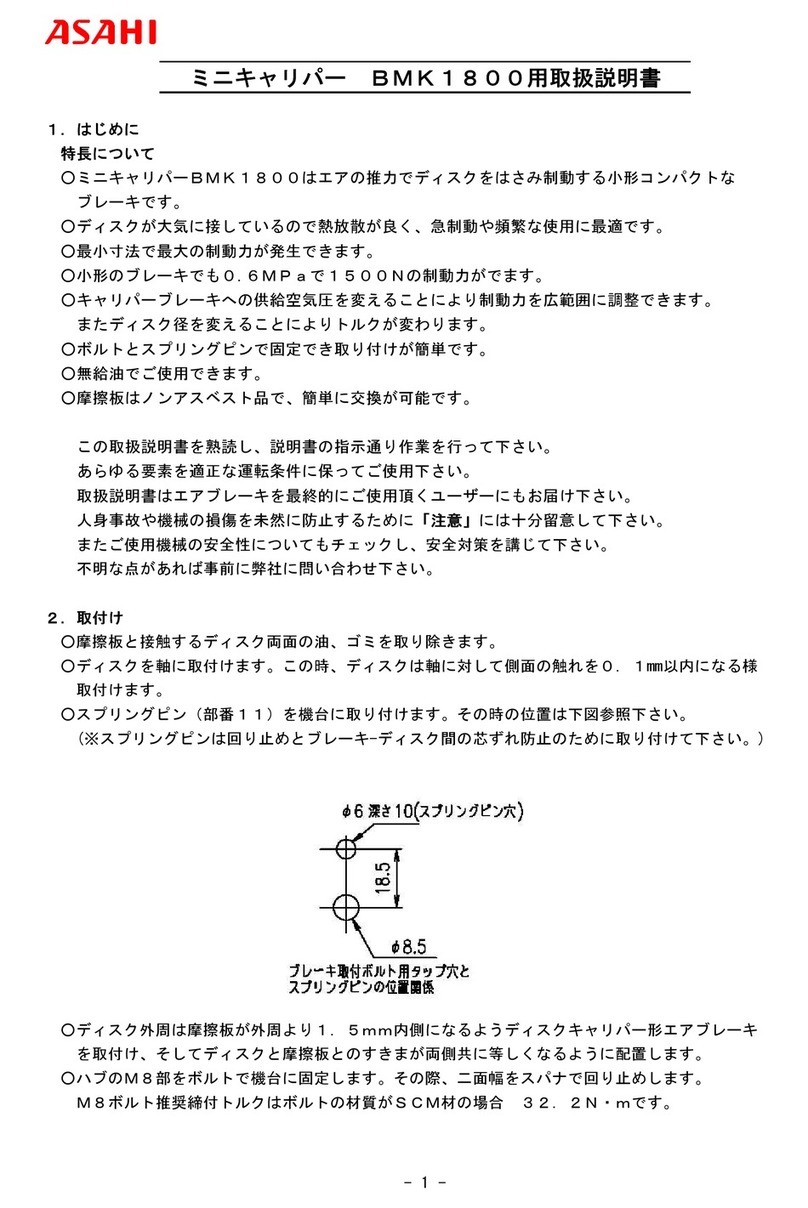

During handling and transport, suitable lifting equip-

ment must be used depending on the weight of the

gearbox. The permissible lifting capacities and other

specifications of the hoist manufacturer must be ob-

served.

Suitable suspension points have to be gathered from

Figure 1. All BT, BM and BF series gearboxes are

equipped with metric threads in the housing at these

points. The thread sizes can be gathered from the re-

spective data sheets. If ring bolts are used, a suitable

spreader beam may have to be used.

DANGER!

Death or extremely serious injury / crippling caused by falling loads. During

transport, never stay under suspended loads.

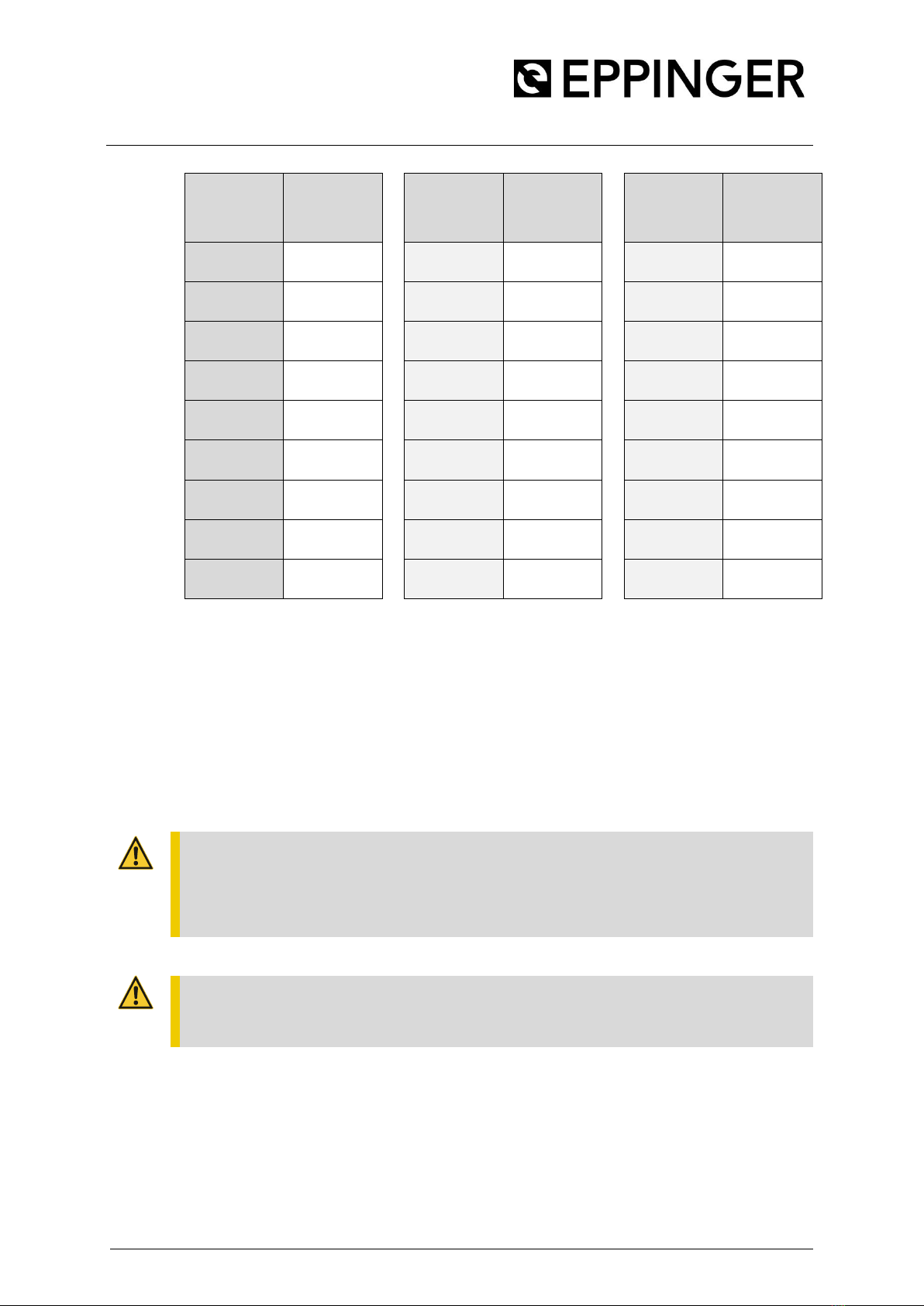

The weights given in Table 3 apply to gearboxes with solid output shafts on both

sides.

Figure 1: Suspension points

Assembly instructions (Original)

BT / BM / BF Gearboxes

Doc. No. : 1002

Version 1 dated 18/10/2018

Page 6/11

Gearbox

Weight

about

Gearbox

Weight

about

Gearbox

Weight

about

BT50

1.5 kg

-

-

BF50

2.0 kg

BT75

5.2 kg

BM75

5.5 kg

BF75

6.0 kg

BT90

8.5 kg

BM90

9 kg

BF90

10 kg

BT110

14 kg

BM110

16 kg

BF110

16 kg

BT140

26 kg

BM140

32 kg

BF140

32 kg

BT170

42 kg

BM170

48 kg

BF170

47 kg

BT210

72 kg

-

-

-

-

BT240

105 kg

-

-

-

-

BT280

160 kg

-

-

-

-

Table 3: Weights

4Storage

The gearboxes have to be stored protected from dust, dirt and moisture. The tem-

perature has to be between -5°C and +40°C.

5Assembly

CAUTION!

Assembly work may only be carried out by accordingly qualified trained person-

nel.First of all, check the gearbox for external damage.

CAUTION!

A damaged gearbox must not be operated.

Before installing the gearbox, always switch off the machine and secure it against a

restart. In addition is has to be ensured that the machine cannot move.

Assembly instructions (Original)

BT / BM / BF Gearboxes

Doc. No. : 1002

Version 1 dated 18/10/2018

Page 7/11

DANGER!

Death or extremely serious injury / crippling caused by moving machine elements

when accidentally switched on or by accidentally releasing stressed components

during assembly.

Before installation, check the direction of rotation of the gearbox. The direction of

rotation of the gearbox can be gathered from the data sheet.

5.1 Mounting of the gearbox

The gearbox has to be securely screwed to the application. Special attention has to

be paid to a flat support.

All existing mounting holes must always be used on the selected screw-on side. At

this, the screw tightening torque depends on the strength class of the screw as well

as the material of the bearing face respectively the internal thread.

5.2 Assembly of the shafts

The torque transmission takes place via a key. The shaft is suitable for mounting cou-

plings or for a direct mounting of transmission elements such as gearwheels or belt

wheels onto the shaft.

The gear shaft must be clean and free of grease or oil.

For the chosen transmission principle, the existing specification of the manufacturer

of the coupling or the clamping device must be observed.

NOTICE

Damages of the gearbox caused by large axial loads during the assembly.

When pressing components onto the shaft, do not support the force via the gear-

box housing.

The supporting length of the key must be suitable for the torque to be transmitted.

5.3 Assembly of the motor for the BF series

The torque transmission of the motor also takes place via a key. The hollow input

shaft of the gearbox as well as the solid shaft of the motor must be clean and free of

grease or oil.

Assembly instructions (Original)

BT / BM / BF Gearboxes

Doc. No. : 1002

Version 1 dated 18/10/2018

Page 8/11

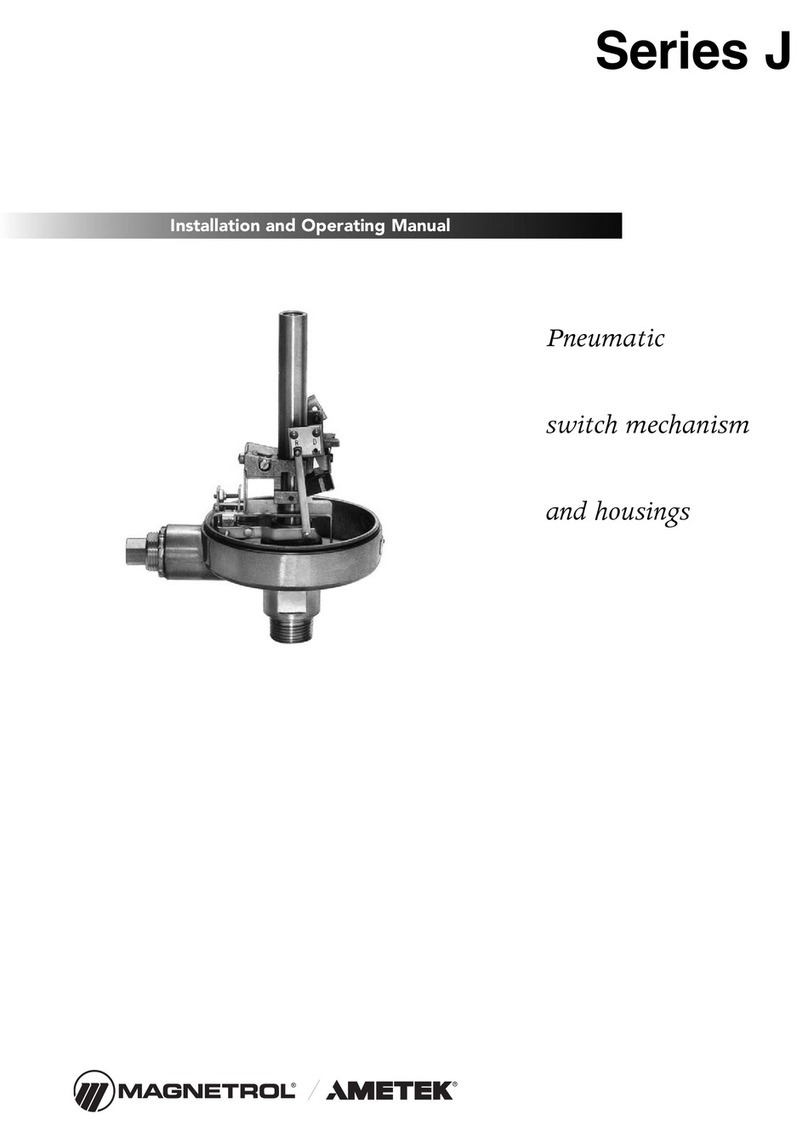

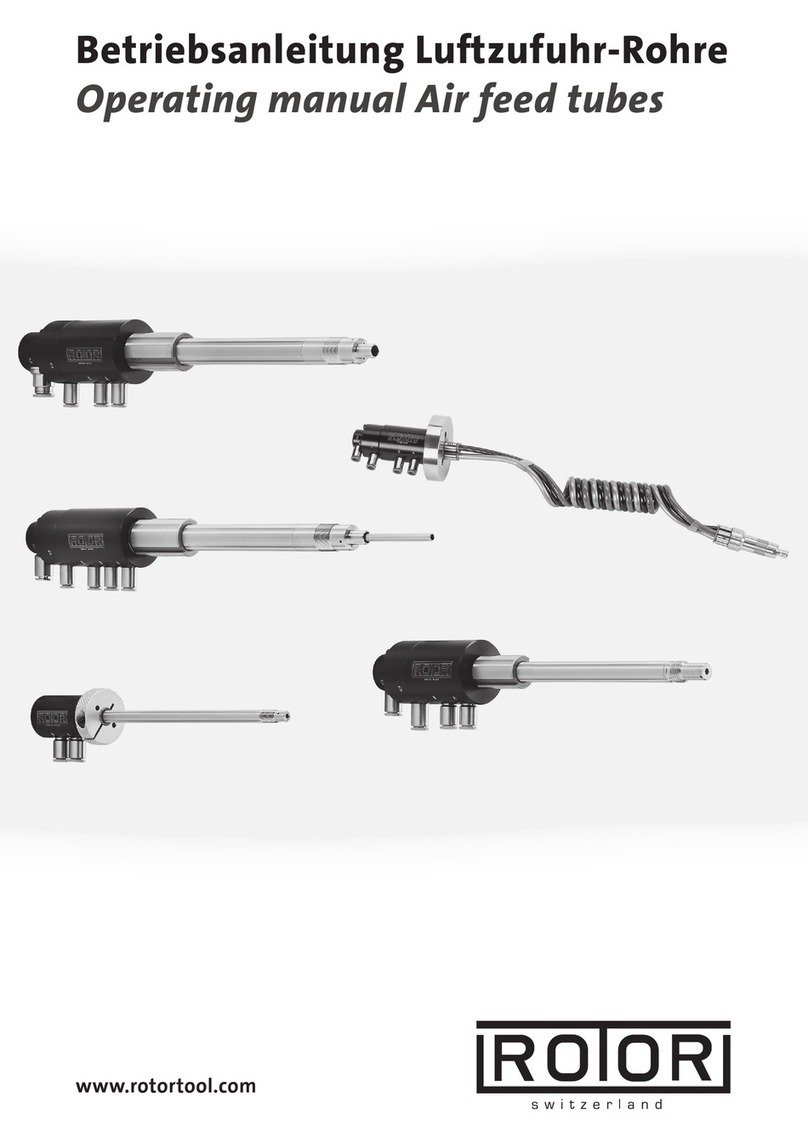

After the motor has been inserted until the motor plate is in

contact with the gearbox flange, screw the motor to the

gearbox flange. Take care of the thread reach of the bolts.

The thread reach of the bolt shall be twice the length of the

nominal diameter of the bolt. (Figure 2)

6Commissioning

CAUTION!

The commissioning may only be carried out by accordingly qualified trained per-

sonnel.

Before commissioning, all mechanical mounting parts and their fastening must be

checked. Check the screw tightening torques. Commissioning may only take place if

the machine complies with the provisions of the EC Machinery Directive. The moni-

toring and protective devices of the machine must not be put out of operation. In

addition to EMERGENCY STOP buttons, EMERGENCY STOP command devices, covers

and hoods, this also includes other protective devices such as sensors, light barriers

and acoustic or optical emergency signals. The security of the gearbox can only be

assured by the end product. Therefore, any commissioning with overridden protec-

tion equipment of the machine is not permitted.

DANGER!

Death or extremely serious injury / crippling caused by equipment in operation

without suitable safety or protective devices by the surrounding end product.

7Operation

CAUTION!

The gearbox may only be operated by accordingly qualified trained personnel.

The gearbox may only be operated with active protective and monitoring equipment

of the machine.

Figure 2: Length of the

bolt

Assembly instructions (Original)

BT / BM / BF Gearboxes

Doc. No. : 1002

Version 1 dated 18/10/2018

Page 9/11

DANGER!

Death or extremely serious injury / crippling caused by equipment in operation

without suitable safety or protective devices by the surrounding end product.

WARNING!

Burns at hot surfaces.

During operation, the surface of the gearbox can reach high temperatures. It must

be ensured that there is no unintentional contact with the surface of the gearbox.

During the operation, the gearbox should be observed.

Leakage, unusual temperature rises or an increase in the noise respectively vibration

indicate a fault which has to be repaired. If one of these criteria should occur, the

plant has to be shut down immediately. If the fault cannot be eliminated, contact EGT

Eppinger

(chapter 2.5).

8Maintenance

CAUTION!

Maintenance may only be carried out by accordingly qualified trained personnel.

Gearboxes from size 140 are equipped with screw plugs to allow an oil change.

Smaller gearboxes are lubricated for life and they are therefore designed without any

screw plugs.

The quantities of oil and the intervals of the oil changes can be gathered from Table

4. The recommended intervals for a change have to be observed.

For special gearboxes and gearboxes with operating conditions outside the specifica-

tion, any separately communicated maintenance intervals and specifications apply.

Gearbox

Oil quantity

Change interval

BT/BM/BF 140

0.35 L

15 000 h

BT/BM/BF 170

0.8 L

15 000 h

Assembly instructions (Original)

BT / BM / BF Gearboxes

Doc. No. : 1002

Version 1 dated 18/10/2018

Page 10/11

BT210

1.5 L

15 000 h

BT240

2.0 L

15 000 h

BT280

2.8 L

15 000 h

Table 4: Oil quantities and maintenance intervals

Fully synthetic oil Mobil SHC Gear 150 is used as the standard lubricant. During the

oil change, choose either the same lubricant or a lubricant acc. to the following spec-

ification:

•Fully synthetic lubricant

•Viscosity class ISO VG150

•Minimum requirements according to DIN 51517-3:2018-09 respectively

ANSI/AGMA 9005-F16

NOTICE

Damages to the gearbox by a reduced lubricity.

Different lubricants must not be mixed. This may result in a reduced lubrication

effect and a damaging of the gearbox.

To change the oil, open the screw plugs on one side of the gearbox and empty the

gearbox completely. For a complete draining, it might be necessary to move the gear-

box.

DANGER!

Risk of burns during the oil change by hot gearbox oil.

CAUTION!

Skin irritation by intensive contact with synthetic oil.

After the complete draining all but the topmost of screw plugs can be closed again.

The required quantity of oil according to Table 4 can be filled via this opening.

The required quantity of oil must not be exceeded or undercut.

Assembly instructions (Original)

BT / BM / BF Gearboxes

Doc. No. : 1002

Version 1 dated 18/10/2018

Page 11/11

NOTICE

Damages to the gearbox due to the wrong quantity of lubricant.

Insufficient lubricant can result in a damaging of the gearbox.

Too much lubricant can result in an excessive heating.

Fill in each time the specified quantity of lubricant.

After the filling of the lubricant, close the screw plug again.

The drained oil has to be disposed of acc. to chapter 9.2.

9Decommissioning

CAUTION!

Dismantling and disposal may only be carried out by accordingly qualified trained

personnel.

9.1 Dismantling

Before dismantling the gearbox, always switch off the machine and secure it against

a restart. In addition is has to ensured that the machine cannot move.

DANGER!

Death or extremely serious injury / crippling caused by moving machine elements

when accidentally switched on or by accidentally releasing stressed components

during dismantling.

9.2 Disposal

ENVIRONMENTAL HAZARD!

Environmental compatibility, health risks, disposal regulations and the local possi-

bilities of proper disposal must be observed.

Any and all operating materials, in particular oils, fats and lubricants are to be dis-

posed of according to the national and regional applicable regulations.

CAUTION!

Skin irritation by intensive contact with synthetic oil.

This manual suits for next models

22

Table of contents

Other EPPINGER Industrial Equipment manuals