NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product. WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

Declaration of Conformity We, the sole importer into the UK, declare that the product listed below is in conformity with the following

standards and directives.

The construction file for this product is held by the Manufacturer and may be

inspected, by a national authority, upon request to Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Professional Tools.

21st October 2008

Signed by Tim Thompson

Paint Can Crusher

Model No. HCC08

93/68/EEC CE Marking Directive

2006/42/EC Machinery Directive

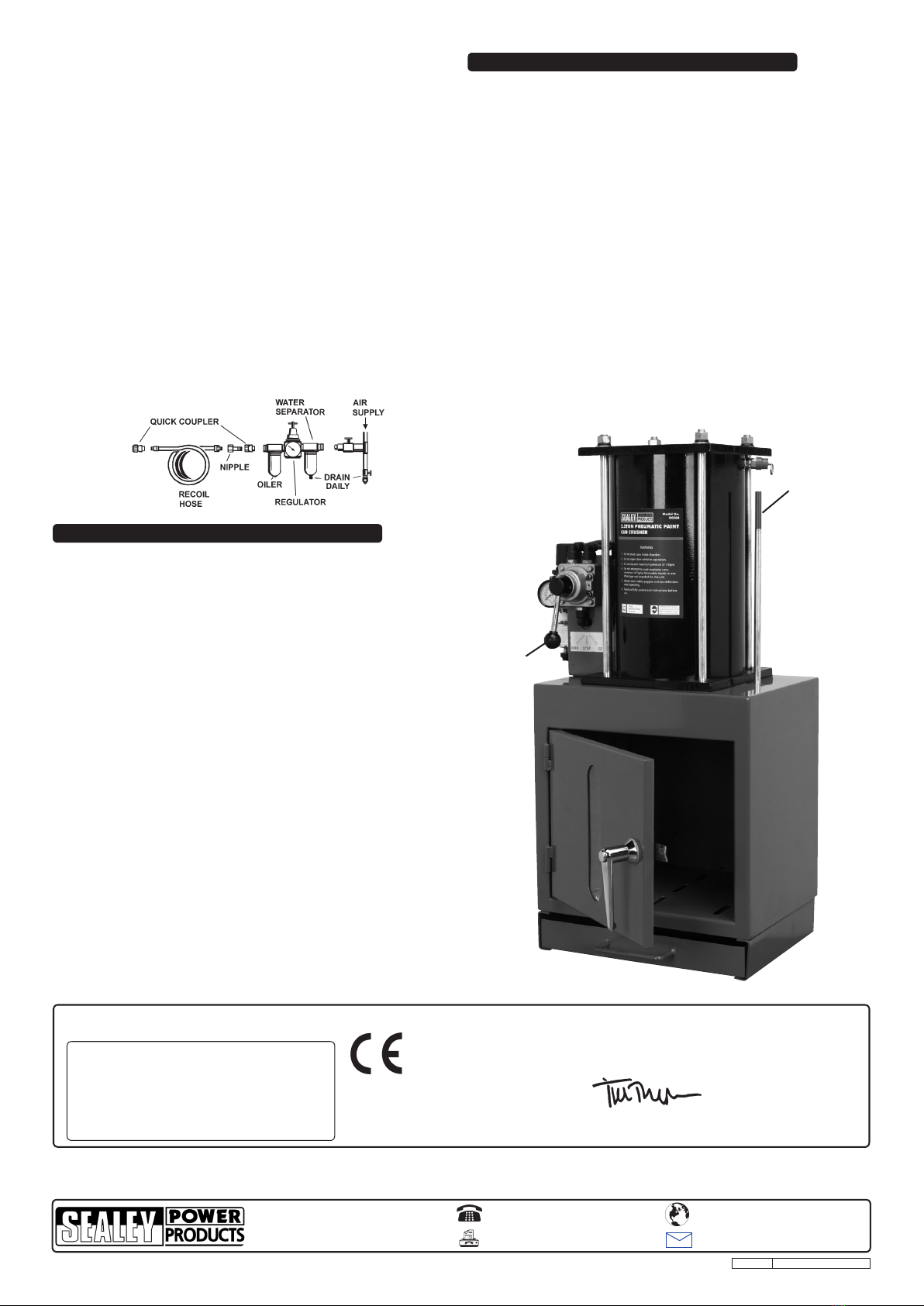

4.1 Place the empty paint can with its lid removed, open end

downwards in the centre of the crushing chamber.

4.2 Close the door ensuring the lock is full engaged. (The

crusher will not function until the door is firmly closed).

4.3 Turn the control lever (Fig.3) to the 'DOWN' position and

the piston will descend.

4.4 When the red line on the indicating rod (Fig.3) is level

with the main body the can is crushed. You can also

listen for the air to stop flowing (approx 20 seconds).

4.5 Turn the control lever to the 'UP' position, when the

piston has returned to the start position move the control

lever back to the centre 'STOP' position.

WARNING! Never attempt to open the door until the

piston is fully retracted and the control lever is in

the 'Stop' position.

4.6 Open the door and remove the crushed can.

Note: You may crush several cans at the same time provided

they are all a similar height and providing you have

adequate air pressure.

Note: It is necessary to remove the catch basin and clean it

periodically. Dispose of solid residue according to local

authority guidelines.

Note: Leave the door ajar when not in use.

Tip: Crease the can with your fingers before putting in the

crusher. This will enable faster crushing and place less

strain on the crusher.

5. MAINTENANCE

4. OPERATION

WARNING! All inspection and maintenance

procedures must be with ram retracted.

5.1 Persons using the crusher should be properly trained in

its use including inspection of the unit prior to operation.

If the operator is in any doubt regarding the proper

functioning or structural integrity of the unit it should not

be used. Remove it from service immediately and

contact your local Sealey dealer.

5.2 If the unit is used daily it should be further inspected by

a qualified person on a weekly basis.

5.3 If the unit is used intermittently it should be further

inspected by a qualified person on a monthly basis.

5.4 All warning labels, instruction labels, and specification

labels should be complete and readable.

5.5 External surfaces of the unit can be washed with a mild

soap solution.

5.6 Periodically remove the paint collection tray and

clean/remove paint and other foreign matter.

5.7 Periodically oil all moving parts.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

www.sealey.co.uk

Web

email

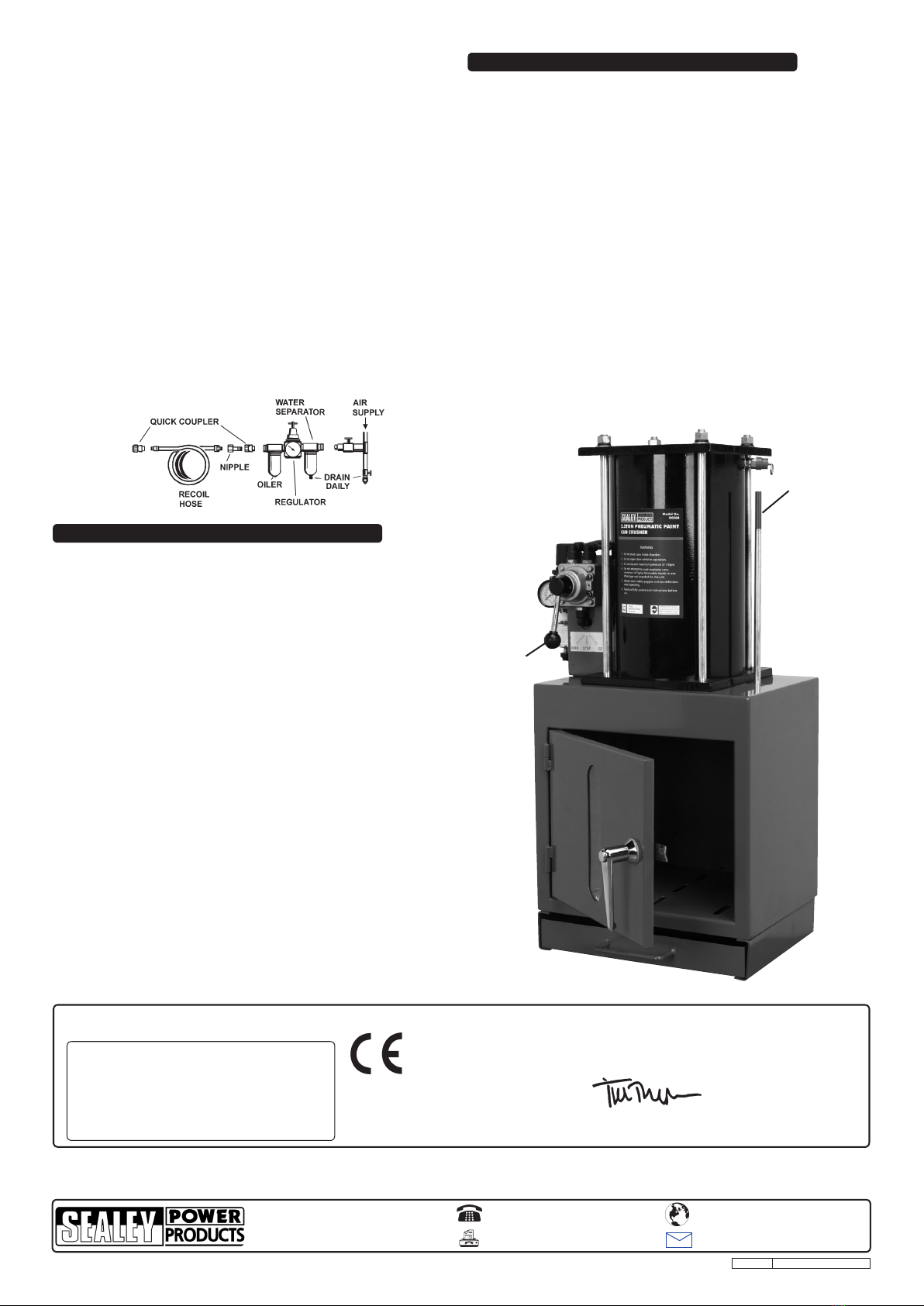

Fig.2

Fig.3

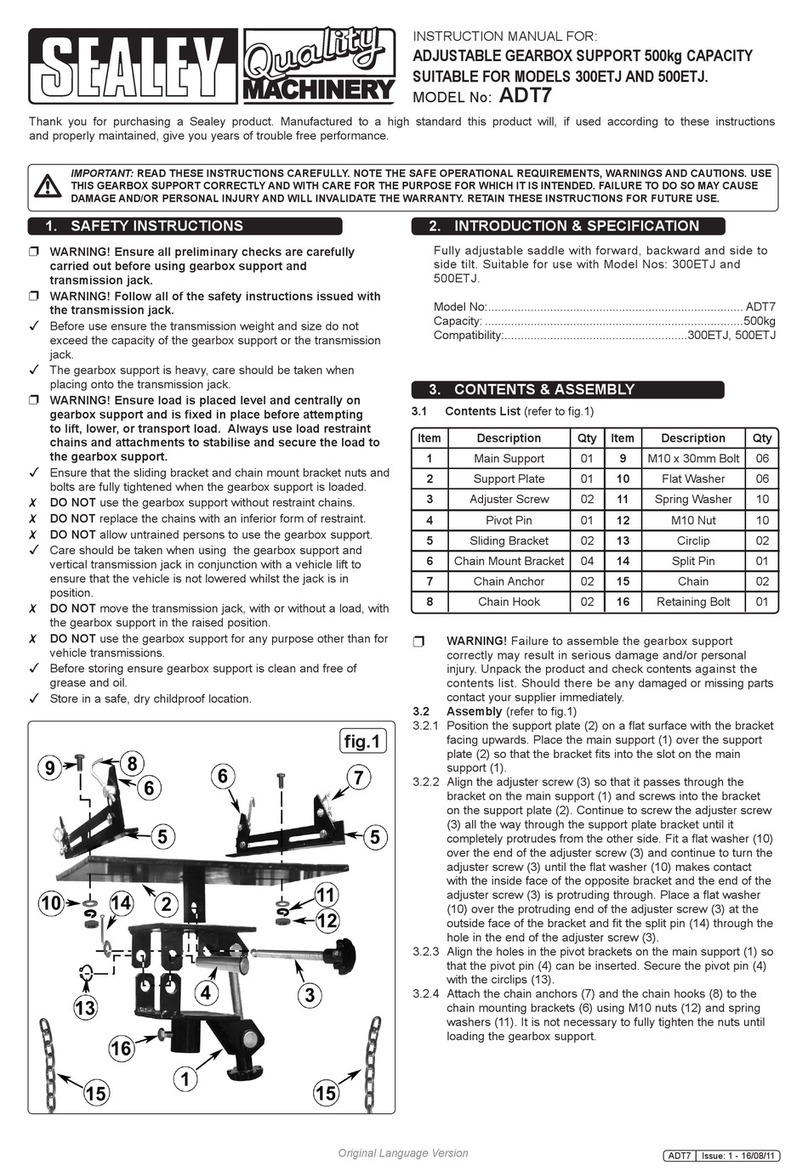

3.6 Air Supply.

Connect the air supply to the air inlet situated on the

regulator. The inlet connection is 1/4”BSP.

The recommended air hook-up procedure is shown in

Fig.2.

3.6.1 You will require a minimum air pressure of 100psi.

3.6.2 WARNING! Ensure the air supply is clean and does not

exceed 130psi whilst operating the paint can crusher.

Too high an air pressure and unclean air will shorten the

product life, and may be dangerous, causing damage

and/or personal injury.

3.6.3 Drain the air tank daily. Water in the air line will damage

the ram.

3.6.4 Clean compressor air inlet weekly.

3.6.5 Line pressure should be increased to compensate for

unusually long air hoses (over 8 metres).

3.6.6 Keep hose away from heat, oil and sharp edges. Check

hose for wear, and make certain that all connections

are secure.

The paint can crusher is now ready for use.

Screw

HCC08 Issue No: 1 23/10/08

Indicating Rod

Control Lever