Equalizer AIR CART User manual

0

OPERATOR MANUAL

AIR CART

1

CONTENTS

INTRODUCTION .............................................................................................................3

IDENTIFICATION............................................................................................................4

SPECIFICATIONS...........................................................................................................5

SAFETY ..........................................................................................................................6

4.1 SAFETY ALERT SYMBOLS......................................................................................6

4.2 GENERAL OPERATIONS.........................................................................................8

4.3 TRACTOR OPERATIONS ........................................................................................8

4.4 CHEMICAL OPERATIONS.......................................................................................8

4.5 TRANSPORT OPERATIONS....................................................................................8

4.6 HYDRAULIC OPERATIONS.....................................................................................9

4.7 MAINTENANCE OPERATIONS................................................................................9

4.8 STORAGE OPERATIONS........................................................................................9

QUICK GUIDE...............................................................................................................10

5.1 CONNECTING THE AIR CART...............................................................................10

5.2 FILLING THE BINS.................................................................................................10

5.3 CHECKING THE BIN WEIGHT ON THE DIGISTAR SYSTEM.................................11

5.4 CONNECT THE AIR HOSES TO THE SEEDING IMPLEMENT...............................11

5.5 CALIBRATE THE METERING UNIT .......................................................................11

5.6 SET THE FAN SPEED............................................................................................11

5.7 CHECK THEAIR DELIVERY SYSTEM SETUP ......................................................13

FRAME.........................................................................................................................14

6.1 DESIGN OVERVIEW..............................................................................................14

TOW BETWEEN SPECIFICS..............................................................................15

TOW BEHIND SPECIFICS..................................................................................15

6.2 TELESCOPIC LADDER..........................................................................................16

6.3 HYDRAULIC SYSTEM............................................................................................17

OIL FLOW REQUIREMENTS FOR EACH FUNCTION.......................................17

AUGER/HYDRAULIC DRIVE SELECTION.........................................................17

HYDRAULIC REMOTE POINTS (TOW-BETWEEN ONLY).................................18

TRACTOR HOSE IDENTIFICATION...................................................................18

6.4 OPERATING PROCEDURES.................................................................................21

CONNECTING AIR CART...................................................................................21

HITCHING TO THE TRACTOR...........................................................................21

HITCHING TO THE SEEDING IMPLEMENT ......................................................22

AUGER..........................................................................................................................23

7.1 DESIGN OVERVIEW..............................................................................................23

7.2 COMPONENT DESCRIPTION................................................................................24

LODAR REMOTE CONTROL .............................................................................24

ELECTRONIC INTERLOCKS..............................................................................25

AUGER REVERSE VALVE.................................................................................25

TRANSPORT LATCH..........................................................................................26

INLET CHUTE.....................................................................................................26

7.3 OPERATION PROCEDURES.................................................................................28

POSITIONING THE AUGER AND FILLING THE BINS.......................................28

MOVING THE AUGER BACK INTO TRANSPORT POSITION ...........................28

EMERGENCY OVERRIDE ON SOLENOID VALVES..........................................28

2

AIR DELIVERY SYSTEM ..............................................................................................29

8.1 DESIGN OVERVIEW..............................................................................................29

8.2 AIR DELIVERY OPTIONS.......................................................................................30

SINGLE OR DUAL DELIVERY............................................................................30

SINGLE CHUTE OR DUAL MIXER METERING UNITS......................................30

8.3 COMPONENT DESCRIPTION................................................................................31

FANS ..................................................................................................................31

METERING UNITS..............................................................................................32

HYDRAULIC VARIABLE DRIVE SYSTEM..........................................................35

ELECTRONIC CONTROL SYSTEM ...................................................................36

BIN WEIGHING SYSTEM ...................................................................................36

8.4 OPERATING PROCEDURES.................................................................................37

REGULATING AIR FLOW...................................................................................37

SUFFICIENT AIR FLOW TEST...........................................................................38

EQUAL DISTRIBUTION CHECK ON FAN MANIFOLD.......................................39

CALIBRATING THE METERING UNIT ...............................................................40

CHECKING BIN WEIGHT USING THE DIGISTAR SYSTEM..............................42

MAINTENANCE AND INSPECTIONS...........................................................................43

9.1 GENERAL ..............................................................................................................43

LUBRICATION....................................................................................................43

BOLT TORQUE VALUES....................................................................................43

TYRE PRESSURES............................................................................................44

CLEANING PROCEDURE ..................................................................................44

9.2 MAINTENANCE SCHEDULE..................................................................................45

9.3 LOCATION OFGREASE POINTS..........................................................................46

TROUBLESHOOTING...................................................................................................49

10.1 AUGER...................................................................................................................49

10.2 AIR DELIVERY SYSTEM........................................................................................50

SCHEMATICS...............................................................................................................52

INTRODUCTION

3

INTRODUCTION

This document describes the operation and maintenance of both the tow-between and tow-

behind Equalizer Air Cart. Tow-between refers to a setup where the Air Cart is hitched to the

tractor with the seeding implement running behind the cart. Tow-behind refers to a setup where

the Aircart is hitched behind the seeding implement. For illustration purposes the tow-between

configuration will be shown. Special reference will be made when there are differences between

the tow-between and tow-behind carts.

Read and understand this manual carefully before attempting to operate this machine. Failure

to do so could result in personal injury or equipment damage. Equalizer will not accept any

responsibility for any damage or malfunctions resulting from failure to comply with the safe

operating instructions outlined in this manual. This manual should be considered a permanent

part of your planter and should remain with the planter even if you no longer own it.

RIGHT-HAND and LEFT-HAND sides are determined by facing the direction of forward travel

of the machine.

The manufacturer reserves the right to introduce design changes, revisions and upgrades to

machines without making minor amendments to this manual.

Write the product identification numbers in the identification section of this manual. Your dealer

will need these numbers for product support and ordering of parts.

IDENTIFICATION

4

IDENTIFICATION

Record the Air Cart’s data on the name tag below:

SPECIFICATION

5

SPECIFICATIONS

AIR CART MODEL

12000M2

12000M3

16000M3

16000M4

20000M4

22000M3

Number of bins

2

3

3

4

4

3

Bin capacity (Litres)

12000

12000

16000

16000

20000

22000

Bin configuration

(Litres)

6000|6000

4000|4000|4000

6000|4000|6000

4000|4000|4000|

4000

6000|4000|4000|

6000

8000|6000|8000

Main wheel track

width (m)

3

3

3

3

3

3

Frame style

Tow-between

Hitch style

Drawbar with hardened insert for CAT3 (1.5”) or CAT4 (2”) or CAT5 (2.75”) Pin

Transport width (m)

3.85 Main wheel option dependent

4.15

Transport height (m)

4.2

4.2

4.2

4.2

4.2

4.2

AIR CART MODEL

8000R2

12000R2

12000R3

16000R3

20000R4

28000R4

Number of bins

2

2

3

3

4

4

Bin capacity (Litres)

8000

12000

12000

16000

20000

28000

Bin configuration

(Litres)

4000|4000

6000|6000

4000|4000|4000

6000|4000|6000

6000|4000|4000|

6000

8000|6000|6000|

8000

Main wheel track

width (m)

3

3

3

3

3

3

Frame style

Tow-behind

Hitch style

Drawbar with hardened insert for CAT3 (1.5”) or CAT4 (2”) or CAT5 (2.75”) Pin

Transport width (m)

3.85 Main wheel option dependent

4.15

Transport height (m)

4.2

4.2

4.2

4.2

4.2

4.2

SAFETY

6

SAFETY

Follow the safety signs below to ensure a safe operating environment. Take note of these signs

and lurking danger in its vicinity.

4.1 SAFETY ALERT SYMBOLS

SIGN

DESCRIPTION

COMMENT

Do not step on this section of

the machine.

Stand clear if wings are

folded/unfolded.

Be aware that the machine

can touch overheadlines and

result in serious injury.

Read operator’s manual

when required.

Make sure tractor is switched

of before working on the

planter.

Keep all body parts and

clothing clear off any chain

drives or rotating parts.

Warning Sign

Be cautious when working in

this area/section.

Stand away from machine’s

drawbar to avoid injury.

SAFETY

7

Do not stand on the machine

while it is in operation or

moving.

Do not touch pressurized

hydraulic lines to do

inspections or repairs.

Release pressure if it is

required to work on

hydraulic lines.

Do not work under the

machine while the operator is

in the tractor.

Explosive Hazard

This component holds an

explosive hazard; be

cautious when working

around such a component

and do not make any

adjustments to this

component. Only the

authorised dealer will be

allowed to do so.

The words DANGER, WARNING or CAUTION are used with the safety alert symbol.

Recognize and be on the lookout for the safety alert symbols and follow the recommended

precautions and safe practices. The signs and descriptions are used in conjunction with the

DANGER, WARNING or CAUTION where applicable.

WARNING: Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Used with the safety alert symbol to indicate a hazardous situation which, if not

avoided, could result in minor or moderate injury.

DANGER: Indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

The words IMPORTANT and NOTE are not related to personal safety but are used in this

manual to give additional information and tips for operating or servicing this machine.

SAFETY

8

IMPORTANT: Identifies special instructions or procedures which, if not strictly observed could

result in damage to, or destruction of the machine, process or its surroundings.

NOTE: Indicates points of particular interest for more efficient and convenient repair or

operation.

4.2 GENERAL OPERATIONS

•Ensure the safety chain is secure before any of the operations start. Check the safety

chain regularly to see if it is still secure.

•Do not ride on the machine and do not allow anyone on the machine while it is moving or

in operation.

•Do not allow any passengers in the tractor unless an instructor seat and seat belt are

available.

•Check for anyone or anything behind the machine when backing up with the machine.

•Reduce speed when working in fields with steep gradients/hilly terrain.

•Do not allow anyone near the machine while it is moving or in operation.

•Keep all protective shields in place and replace them immediately when it was removed.

•Be familiar with all the machine’s functions for safe operation.

•Only operate the machine from the operator’s seat.

4.3 TRACTOR OPERATIONS

•Be aware of the correct tractor operating procedures when working with the machine.

•Review the tractor operator’s manual.

4.4 CHEMICAL OPERATIONS

•Use extreme care when cleaning, filling or making any adjustment to the chemical system

on the machine.

•Carefully read the manufacturer’s warning labels for granular chemicals, liquid chemicals

or treated seed.

•Wear protective equipment when handling granular chemicals, liquid chemicals or treated

seed, which include safety goggles, breathing apparatus and gloves.

•Do not feed any treated seed to animals.

•Wash exposed skin immediately if chemicals came in contact with skin.

•Store chemicals properly according to the manufacturer’s instructions.

4.5 TRANSPORT OPERATIONS

•Be aware of the machine’s height, length and width when turning and passing overhead

lines or structures.

•Do not exceed 32 km/h (20 mph) during transportation.

•Use an agricultural tractor that is large enough with sufficient braking capacity so that the

weight of the loaded equipment towed does not exceed 1.5 times the weight of the tractor.

•Use flashing amber warning lights, turn signals and ABNORMAL/OVERSIZE emblems

when on public roads.

•Be familiar with and adhere to local laws which is applicable to the transportation of the

planter.

SAFETY

9

4.6 HYDRAULIC OPERATIONS

•Do not search for high pressure hydraulic leaks without the necessary hand and face

protection. Make use of paper, cardboard or wood sticks to detect leaks. A tiny, almost

invisible leak can penetrate skin and thereby requiring immediate medical attention.

•Double check that everything is safe before operating the hydraulics.

•Never remove hydraulic hoses if the machine is elevated. First relief the pressure inside

the system before disconnecting the hydraulic hoses or ends.

•Maintain a proper hydraulic fluid level.

•Keep all hydraulic connectors/fittings clean when they are being connected to the tractor.

•Ensure that all fittings and hoses are in suitable conditions before hydraulic operations

are initiated.

4.7 MAINTENANCE OPERATIONS

•Turn off the tractor engine before any maintenance or adjustments are done on the

machine.

•Understand all the procedures before starting the maintenance task/job.

•Secure the machine properly before any maintenance tasks are done.

•Wear appropriate clothing and protective equipment when completing any maintenance

task.

•Make use of proper tools to do the required maintenance.

•Do not make any modifications to the machine.

•Work in a clean and dry environment.

•Remove build-up of grease, oil and dust regularly.

•Ensure that all the tools and parts are removed from the machine before operation.

•Be careful when inflating the machine’s tyre(s). Do not stand in front of or over the tyre.

Make use of a clip-on chuck and long enough hose to increase the distance between

yourself and the tyre when it is being inflated.

4.8 STORAGE OPERATIONS

•Store the machine away from high activity areas.

•Level the machine and block up securely to relief pressure on the hydraulic parking jack.

•Do not allow children to play on or around the planter.

QUICK GUIDE

10

QUICK GUIDE

The quick guide is intended for knowledgeable/experienced users only and is helpful to refresh

their knowledge regarding the operation of the planter. For first time operators the whole

document MUST be read before starting with any operation.

5.1 CONNECTING THE AIR CART

1. Connect the tractor to the Air Cart; secure the safety chain and connect the necessary

hydraulic hoses.

2. Connect the electronics of the Air Cart to the tractor.

3. When connecting the seeding implement: back the Air Cart into position, aligning the

seeding implement hitch with that of the Air Cart.

4. Attach the implement hitch to the Air Cart using the correct pin.

5. Connect the hydraulics of the seeding implement to the remote hydraulic supply on the

Air Cart.

6. Connect any electrical harnesses from the seeding implement to the Air Cart.

5.2 FILLING THE BINS

1. Ensure the tractor hydraulic supply is in operation and connect the Air Cart hydraulics to

the tractor.

2. Set the selector the valve to auger.

3. Switch the Lodar system ON

4. Unlatch the transport latch.

5. Move the external auger into the filling position and select forward rotation on the auger

rotation valve.

6. Start the auger and fill the bin to the desired capacity.

7. Once finished with filling all the bins, move the auger back to the transport position and

secure the transport latch.

8. Switch the Lodar system OFF

9. Set the selector valve back to drive.

QUICK GUIDE

11

5.3 CHECKING THE BIN WEIGHT ON THE DIGISTAR SYSTEM

1. Switch on the console.

2. Repeatedly press select until the SCALE appears on the display.

3. Press function to increment through the available scales on the system.

5.4 CONNECT THE AIR HOSES TO THE SEEDING IMPLEMENT

1. Connect the seeding implement’s air hoses to the Air Cart’s distribution system.

2. Use hose clamps to secure the hoses.

5.5 CALIBRATE THE METERING UNIT

1. Set the mixer adjustment knob to 100% lower.

2. Remove the calibration lid on the metering unit.

3. Fit the funnel bag and container below the metering unit.

4. Run the calibration program on the ISOBUS control system.

5. Measure the calibration weight and enter the amount into the control system.

6. Repeat the calibration process and check that the calibration is indeed correct.

7. Set the adjustment knob back to the desired position. Ensure that seed metering units

are set to 100% upper.

5.6 SET THE FAN SPEED

1. Connect the case drain of the fan motor(s) to a dump port on the tractor.

2. Connect the 1-inch return line to the relevant return line port (dumping port) for constant

oil flow systems, according to the tractor's manual.

3. Connect the ½ inch pressure line to a standard quick coupler on the tractor.

4. Set the oil flow rate at the chosen connector to ¼ of its capacity before it can be activated

for the first time.

5. Make adjustments to the oil flow rate to change the fan pressure reading. Set the fan

pressure for the desired product application rate.

QUICK GUIDE

12

TOTAL APPLICATIONS

QUANTITY KG/HA

STATIC AIR PRESSURE READING

5-8 Km/h planting speed

5-50 kg/ha

2.5 kPa

50-125 kg/ha

2.5 –4.0 kPa

125-200 kg/ha

4.0 –4.8 kPa

200-275 kg/ha

4.8 –5.5 kPa

275-350 kg/ha

5.5 –6.0 kPa

NOTE: During planting the pressure will settle at a higher value, 2-3 kPa higher,

when product is introduced into the air stream. This is normal.

QUICK GUIDE

13

5.7 CHECK THE AIR DELIVERY SYSTEM SETUP

1. Check that the air delivery system is completely air tight. Fix any air leaks before

advancing to the next step.

2. Check that all seed metering units are set to 100% upper air lines.

3. Check that the gear ratio of the metering units is set correctly to high or low range

depending on the product application rate.

4. Check that the fan pressure is correctly set for the desired product application rate.

Ensure the fertilizer fan pressure is set 0.2 to 0.4 kPa above the seed fan

FRAME

14

FRAME

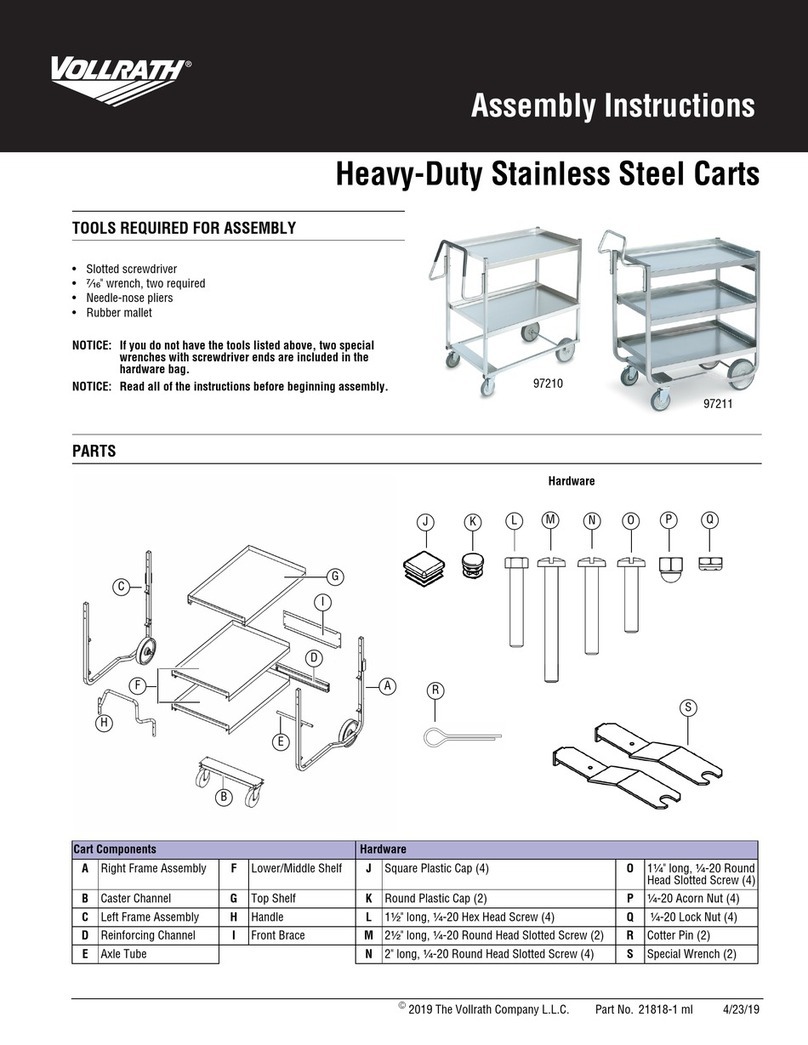

6.1 DESIGN OVERVIEW

1. Tow eye

2. Hydraulic parking jack (tow between only)

3. Gauge stand

4. Hydraulic driven fans

5. Telescopic ladder

6. Top fill auger with hydraulic drive

7. Bins

8. Wheels and wheel axle

9. Bin lids

10. Platform

1

2

3

4

5

6

7

8

9

10

FRAME

15

TOW BETWEEN SPECIFICS

1. Remote hydraulic points.

2. Seed and fertilizer delivery connector profile

3. Tow bar

TOW BEHIND SPECIFICS

1. Drawbar

2. Front axle and steering mechanism

3. Front wheels

1

2

3

1

2

3

FRAME

16

6.2 TELESCOPIC LADDER

The tow-between and tow-behind Air Carts have a telescopic ladder which can be retracted for

transportation. Gas struts mounted to the top of the ladder provide additional pulling force,

making the process of lifting the ladder effortless.

A spring bolt ensures the ladder remains either in the lowered position or transport position.

Spring bolt

Spring bolt latching

position for transport

FRAME

17

6.3 HYDRAULIC SYSTEM

The Air Cart is equipped with a hydraulic system to:

1. Drive the fan motors

2. Drive the motors on the seed and fertilizer metering units

3. Lift and lower the hydraulic parking jack

4. Feed the remote points (only applicable to tow-between models)

5. Position the auger and drive the auger motor.

A detailed schematic depicting the complete hydraulic circuit is provided at the end of this

manual.

OIL FLOW REQUIREMENTS FOR EACH FUNCTION

1. Fan motor = 50 L/min per fan

2. Seed meters = 50 L/min

3. Remote points = dependent on hitched implement’s requirements.

NOTE: The hydraulic parking jack and auger is only used during hitching and during refilling

respectively and therefore do not require continuous hydraulic flow.

AUGER/HYDRAULIC DRIVE SELECTION

The auger and hydraulic drive (metering units motors) runs on a single pressure line from the

tractor (marked as hydraulic drive) due to the fact that only one of these two functions are in

use at any given moment. A three-way valve, located in the front left section of the Air Cart,

allows for selection between these two functions. A high-pressure filter mounted upstream of

the valve provides filtration.

High-

pressure

filter

Select between auger

and hydraulic drive

FRAME

18

HYDRAULIC REMOTE POINTS (TOW-BETWEEN ONLY)

Hydraulic remote points located at the rear of the tow-between Air Cart allow hydraulic function

on the seeding implement behind the cart to be operated. Remote points 1 and 2 are ¾” hose

and should preferably be connected to the LIFT/LOWER function of the seeding implement.

Remote points 3, 4, 5 and 6 are all ½” hose. An extension of the hydraulic drive for the metering

units with a ½” pressure and ¾” return provides an additional pressure line and a return line

linked to the Air Cart’s main return line.

TRACTOR HOSE IDENTIFICATION

The hoses that run to the tractor are marked with colour coded cable ties. There are three

different types of colour codes:

1. Individual pressure lines: For this type of application an individual pressure hose is

used on a SCV (Selective Control Valve) set on the tractor. Only one coupler on the set

is used, as this application is single directional flow only, for example a hydraulic driven

pump or fan.

2. Tank/Zero pressure lines. For this application, the hoses must be connected to the tank

line of the tractor. This usually include fan return lines or case drains, where pressure

needs to be drained away.

3. Remote point lines. These lines are only applicable to tow-between Air Carts and are

used to supply hydraulic oil, via the Air Cart, to the hitched implement at the rear.

The specific codes for each of the different systems are shown on the next page. These codes

are also displayed on a sticker on left side of the Air Cart frame.

FRAME

19

NOTE: Remote point 1 and 2 have ¾” hoses while remote points 3, 4, 5 and 6 have ½” hoses.

Remote points 1 and 2 therefore have a higher flow capacity. It is recommended to use these

hoses for the planter raise/lower function.

IMPORTANT: Make sure the 1” return hose is connected to allocated dump port on the tractor.

IMPORTANT: Ensure the pressure is drained from the hydraulic hoses before you attempt to

connect or disconnect the hoses from the tractor’s selective control valves (SCVs)

Table of contents