Equilibar EPR Series User manual

EPR Series

Electronic Pressure Regulator

2

Page 2 of 24 www.equilibar.com

828.650.6590

This product is warranted to the original purchaser for a period of one year from the date of

purchase to be free of defects in material or workmanship. Under this warranty the product will be

is carried or shipped prepaid to the factory together with proof of purchase. This warranty does

injury damages.

an EPR Series Electronic Pressure Regulator for non-ATEX Use.

training.

limited to:

• Serious personal injury or death

•

• Permanent damage to the pressure regulator and/or permanent

The manufacturer reserves the right to make any changes and improvements to the products

The manufacturer does not warrant or assume responsibility for the use of its products in life

!

CONTACT EQUILIBAR FOR INFORMATION ABOUT HAZARDOUS AREA OPTIONS

Page 3 of 24

www.equilibar.com

11/3/20 R2

•

•

•

listed on the product label match what you

ordered.

•

•

notes.

•

pressure may cause permanent damage to the

•

be mounted in any plane and maintain good

pressure control.

•

•

port threads.

•

•

and in accordance with applicable laws in your

•

maintained.

•

•

safety relief valves or rupture discs to protect

•

worked with you to provide a product rated

•

any service work.

for in the design of the system which interacts with and connects to the EPR Series Electronic Pres-

sure Regulator for non-ATEX Use.

ards.

!

Page 4 of 24 www.equilibar.com

828.650.6590

2

3

7

11

14

22

23

Page 5 of 24

www.equilibar.com

11/3/20 R2

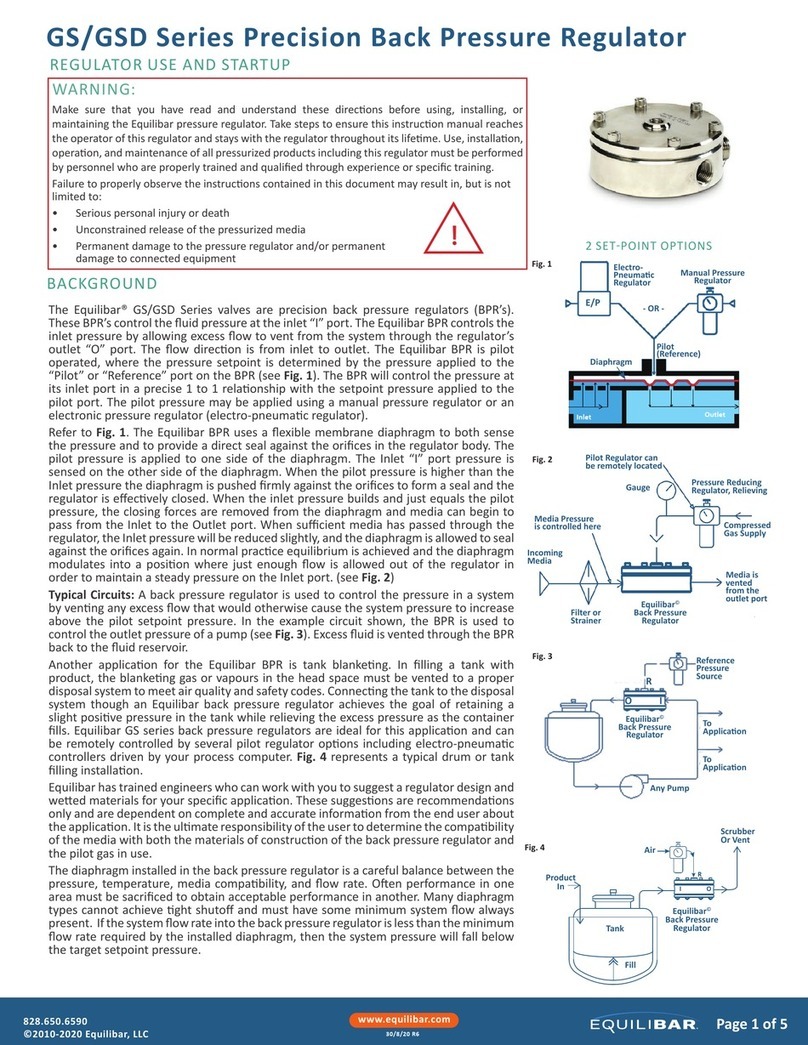

command signal input.

internal pressure sensor. Pressure is controlled

allow supply media into the system to increase

the controlled pressure. The other solenoid

The regulated pressure output is measured by

a solid state pressure transducer internal to

circuit. The control circuit compares the internal

sensor feedback signal to the command signal

pressure is maintained by controlling these two

valves.

pilot pressure signal to the dome of either

control back pressure or vacuum pressure in

An electronic monitor output signal from the

valves come standard with an analog voltage

the analog input.

Page 6 of 24 www.equilibar.com

828.650.6590

being controlled and the feed pressure.

extremely sensive to dirt and debris

the controller.

port. This allows the controllers to raise and

lower the pressure of a closed system within

ready to install the device. The inlet port has a

Do not remove

supply port.

right side of the device can vent to atmosphere

network if necessary.

should be at atmospheric pressure or below to

allow the controller to be used over its full scale

range.

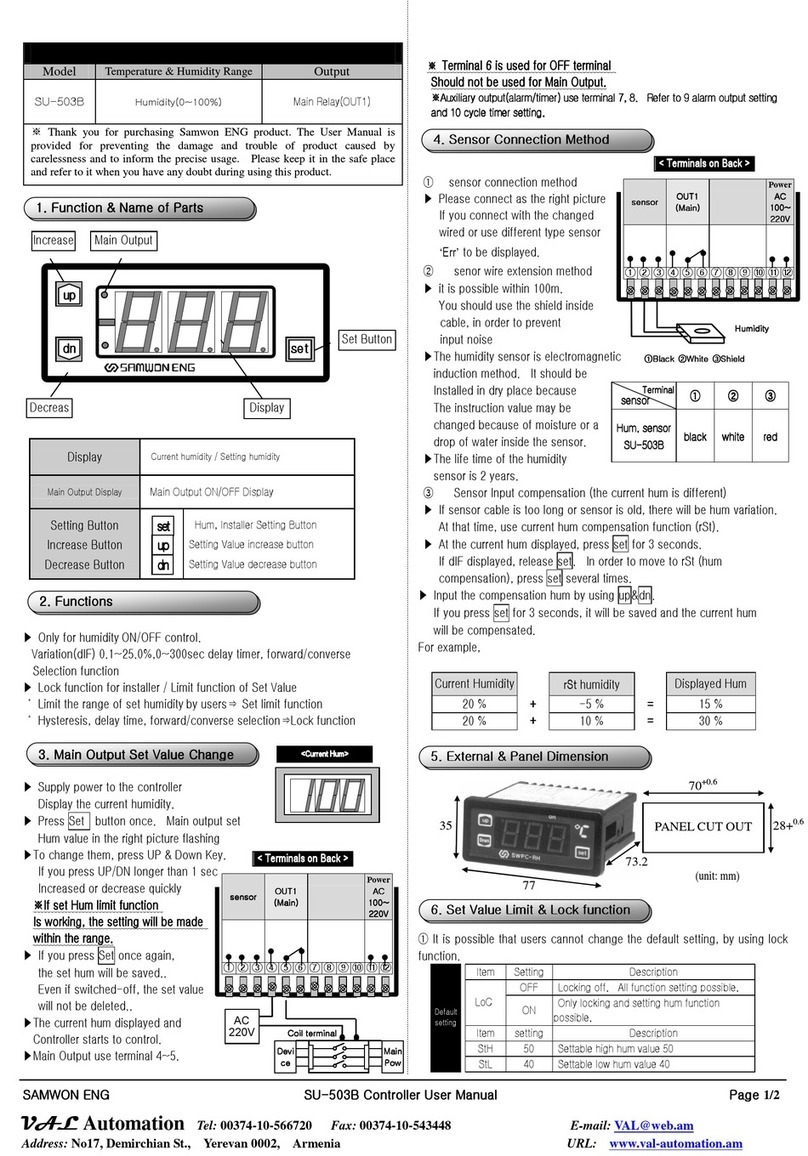

Fig. 2

inlet port

process port

Page 7 of 24

www.equilibar.com

11/3/20 R2

connector.

Pin

cable color

2

3

7

Purple

CAUTION! Do not connect power to pins 1 through 6 as permanent damage can occur!CAUTION! Do not connect power to pins 1 through 6 as permanent damage can occur!

the system bus voltage and can be used as a source for the setpoint signal.

!

www.equilibar.com

828.650.6590

•

•

ground.

CAUTION! Do not connect this device to “loop powered’” systems, as this will destroy

porons of the circuitry and void the warranty. If you must interface with exisng loop

powered systems, always use a signal isolator and a separate power supply.

!

: A simple method for providing setpoint to controllers

Page 9 of 24

www.equilibar.com

11/3/20 R2

Pin Pin

3 Transmit 3

2 Transmit

Page 10 of 24 www.equilibar.com

828.650.6590

Pin

2

3

7

Do not connect RS-485 to RS-232 units or cables. Damage will occur!

Check part number or contact factory to verify RS-485 funconality.

!!

arrangement.

Page 11 of 24

www.equilibar.com

11/3/20 R2

your device to determine which output signals

were ordered.

scale pressure. The output current is linear over

Page 12 of 24 www.equilibar.com

828.650.6590

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

• Maximize signicant digitsMatch older devices

•

•

•

•

•

•

•

•

The following pages describe the controller screens that can be set with user preferences. Upon

!

Page 13 of 24

www.equilibar.com

11/3/20 R2

MAIN MENU

CONTROL

SETPT RAMP SETPT

ADV CONTROL

DELTA

TIME UNITS

TIME

SETPT SOURCE

LOOP SETUP

LOOP VAR

LOOP TYPE

LOOP GAINS

CONTROL OPTS

RAMP ENABLE

DEAD BAND

USER MAX

RAMP UP

RAMP DOWN

MORE OPTS

SETPT LIMITS

USER MIN

REMOVE LIMITS

ABOUT

DEVICE INFO

DEVICE STATE

MFG INFO

TARES

TARE PRESS

AUTO TARE

ADV SETUP

SENSOR SETUP

COMM SETUP

DISP SETUP

DISPLAY AS ZERO

SIG DIGITS

AVERAGING

UNIT

BAUD

CONTRAST

POWER UP

ROTATE

Page 14 of 24 www.equilibar.com

828.650.6590

important to ascertain that the process ports are

open to atmosphere and that there is

If your pressure controller was ordered with

the oponal “TARE PRESS”

F

The controller must be le in the default AUTO

TARE OFF mode except when actually taring the

controller as explained below.

To correctly tare a pressure controller:

2.

3.

results in the closing of the valve and a

7.

If the unit reads signicantly dierent than zero

when removed from the line and open, it is a good

indicaon that it was given a false zero.

allow you to select how the setpoint will be

conveyed to your controller.

that of the selected setpoint source and it will

remember which input is selected even if the

1.

• Serial refers to a setpoint applied via

• Front Panel refers to a setpoint applied

directly at the controller. *Front Panel input

must be selected prior to changing the

setpoint at the device.

2. Analog

• Analog refers to a remote analog setpoint

manual. To determine what type of analog

your controller.

•

setpoint values.

a generic tuning designed to handle most

Do Not Aempt to Tare Absolute Pressure (psia) Instruments! !

MAIN

to change the displayed units and the

units the device sends across the serial port to the computer.

Page 15 of 24

www.equilibar.com

11/3/20 R2

Press

revision.

Press

MFG INFO

Pressure Averaging may be useful to make it

pressures. Pressure averaging can be adjusted

Any Unit ID change will take eect upon exit

of Communicaon Setup menu.

If the symbol @ is selected as the Unit ID,

the device will enter streaming mode when

Communicaon Select menu is exited.

receive data at the same baud rate. The default

Any baud rate change will not take eect unl

power to the unit is cycled.

The display contrast can be adjusted between

POWER UP

upon powering up.

more easily if it is not mounted in an upright

CAUTION! Never leave a Controller with a non-zero setpoint if no pressure is available to make

ow. The controller will apply full power to the valve in an aempt to reach the set-point. When

there is no ow, this can make the valve very HOT!

!

Page 16 of 24 www.equilibar.com

828.650.6590

with the result added to the output drive

register.

The second operates on the present process

value minus the process value during the

the result subtracted from the output drive

register.

output drive register are carried over from

will promote the tendency

will reduce the tendency

of the system to overshoot.

primarily for high performance pressure control

value.

2.

certain amount of ‘look ahead’ capability in

the control loop.

following:

2.

because it relates primarily to the system

3.

jumps to near the setpoint and then takes

a while to converge the rest of the way. Too

Page 17 of 24

www.equilibar.com

11/3/20 R2

2.

3.

protocol.

The recommended default rate of data

to balance streaming speed with number of parameters streamed.

To return to the recommended factory default streaming speed

www.equilibar.com

828.650.6590

Changing from Streaming Mode to Polling Mode

your screen:

2.

3.

can all be put back on the same line and polled individually.

Page 19 of 24

www.equilibar.com

11/3/20 R2

event and all of the data associated with the

as described below.

from the Transfer Menu. Type in the path and

appears.

is pasted it will all be in the selected column.

desired.

page.

The data stream on the screen represents the

pressure parameters of the main mode in the

units shown on the display.

Page 20 of 24 www.equilibar.com

828.650.6590

2. Set the cap lock on so that you are typing in

3.

how many lines you have by the line count at

number of lines of data it will produce.

A

A

A

A

A

like.

7.

with your pressure device as outlined in the

manual.

Set the pressure device to Polling Mode as

data to the screen.

milliseconds. This is where you will tell the

created.

when it receives it.

analysis.

analysis.

Table of contents

Other Equilibar Controllers manuals