Honeywell HC900 Use and care manual

Other Honeywell Controllers manuals

Honeywell

Honeywell DBC2000 Series User manual

Honeywell

Honeywell M7061 User manual

Honeywell

Honeywell LKS 131 User manual

Honeywell

Honeywell LKS 310 Manual

Honeywell

Honeywell MP909E Datasheet

Honeywell

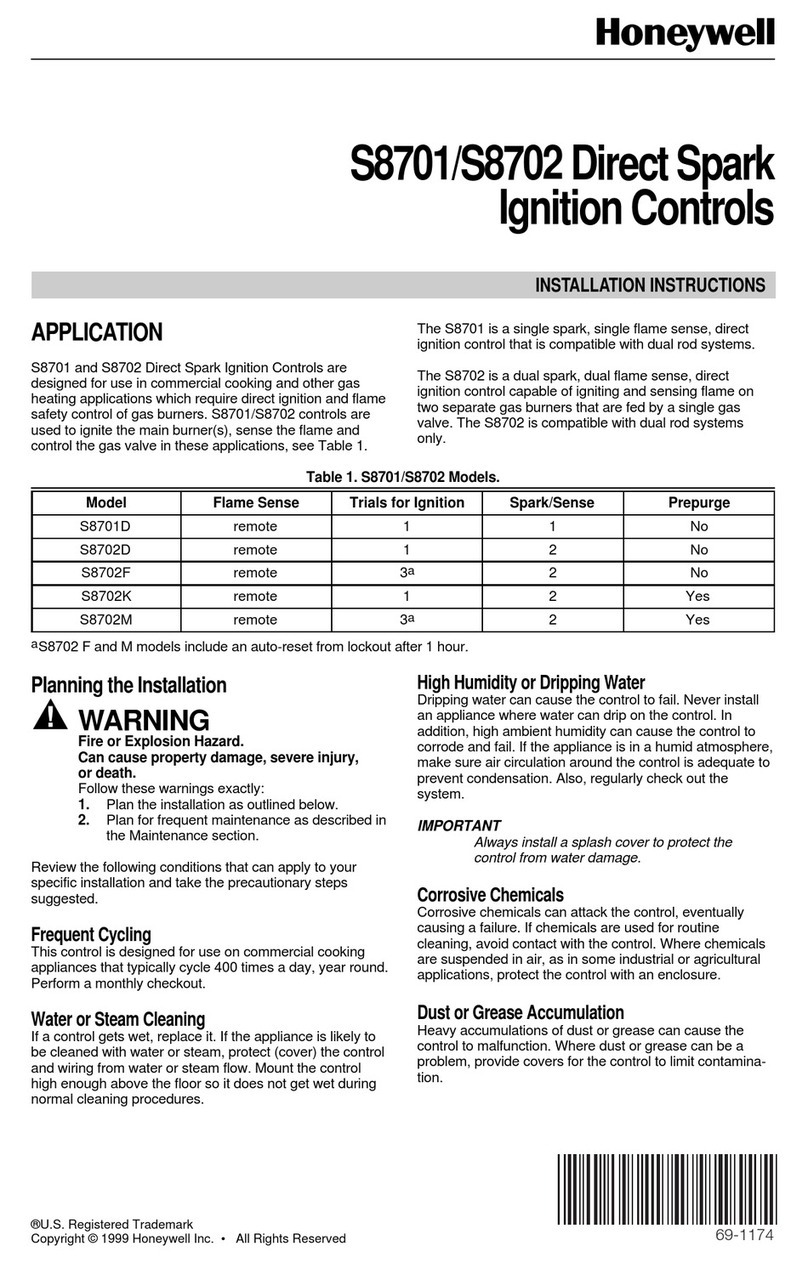

Honeywell S8701 User manual

Honeywell

Honeywell PCR-310 User manual

Honeywell

Honeywell N05010 Operation manual

Honeywell

Honeywell VaporStat L408J User manual

Honeywell

Honeywell Lyric LCP300-LC Product information sheet

Honeywell

Honeywell 900U02-0100 Operating manual

Honeywell

Honeywell Pneumatic Controls User manual

Honeywell

Honeywell CUL6438SR-CV1 User manual

Honeywell

Honeywell T2798I2000 User manual

Honeywell

Honeywell MSR PolyGard 2 MGC2-K User manual

Honeywell

Honeywell HA71 User manual

Honeywell

Honeywell M847D User manual

Honeywell

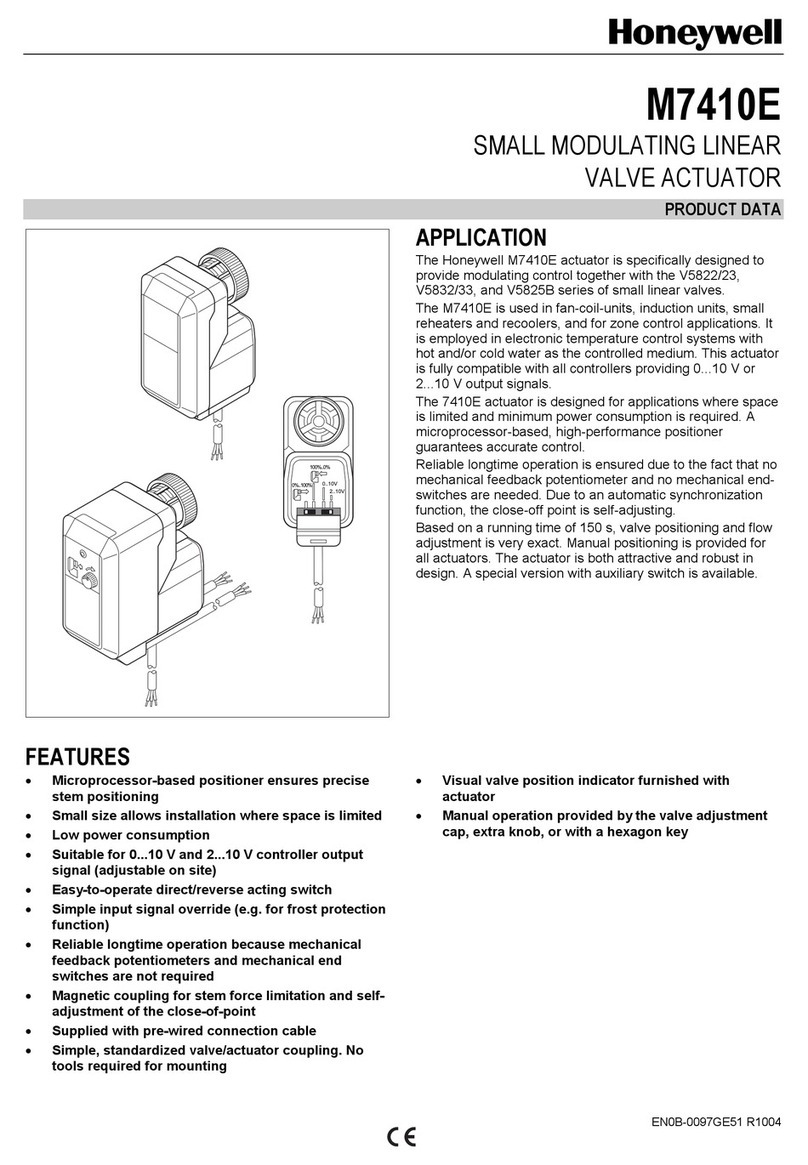

Honeywell M7410E Operation manual

Honeywell

Honeywell 40014 User manual

Honeywell

Honeywell HON 670 Guide

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions