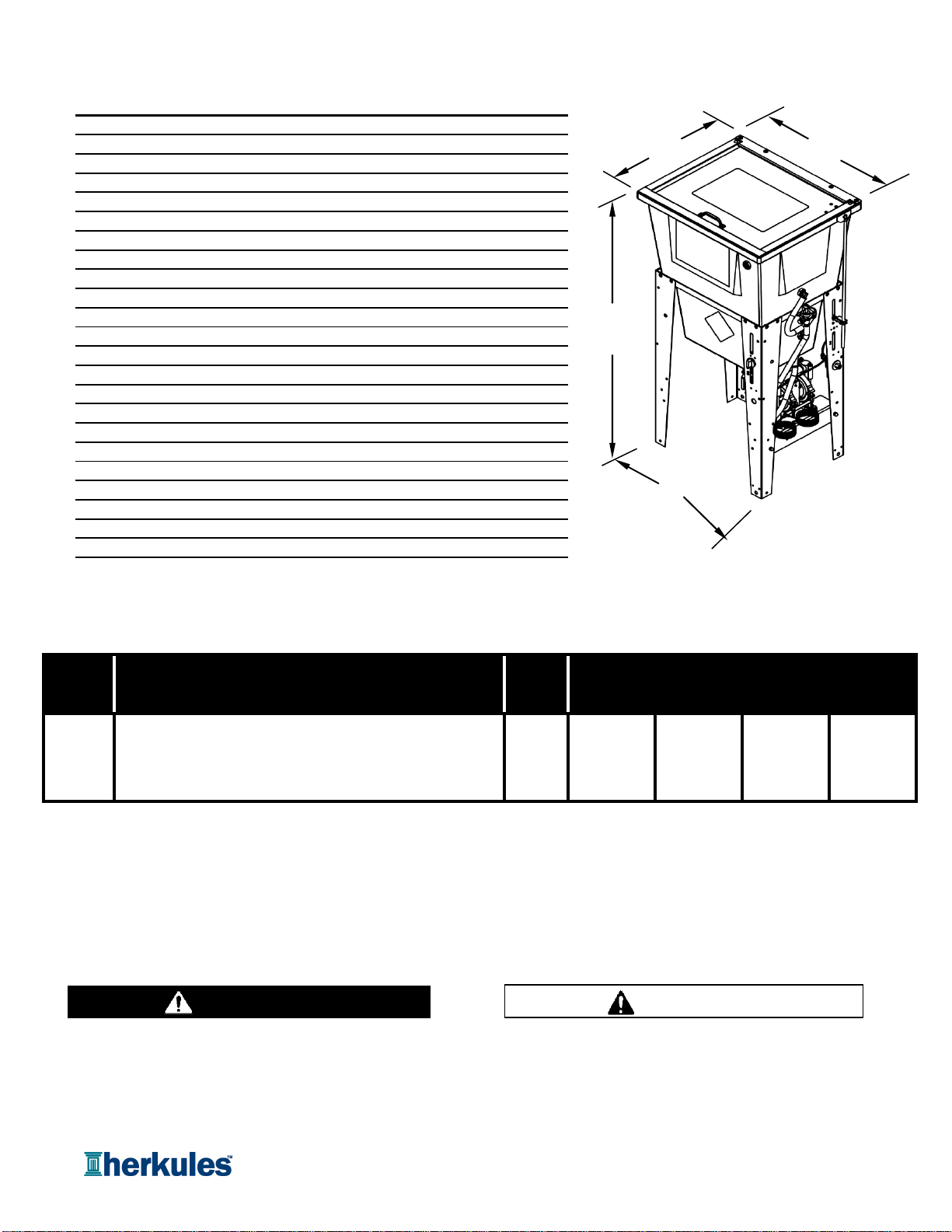

Connecting fluid and air hoses

Insert the nipple and bushing end of the 3-way valve

assembly into the upper bulkhead in the tub. Use sealant

to avoid leaking and orient as shown [see fig.4].

Connect the 13" long fluid outlet tube between the fluid

outlet port of the pump and the straight barb on the valve.

DO NOT HEAT HOSE [see fig.4].

Connect the 16" long fluid inlet tube between the fluid

inlet port of the pump and the lower bulkhead on the tub.

DO NOT HEAT HOSE [see fig.4].

Connect the 20" long fluid tube between the elbow barb on

the valve and the elbow barb on the tub above the valve.

DO NOT HEAT HOSE [see fig.4].

Connect the black 5/32" air hose between the regulator

and the air in port of the limit valve located on the rear leg

of the gun washer [see fig.4].

Note: Air in port of limit valve is the port opposite the roller.

For all air hose, press tubing in through collar until seated.

Pull firmly on hose to test for a tight connection.

Connect the blue 5/32" air hose between the air in port of

limit valve located on the front leg and the air out port of the

limit valve located on the rear leg of the gun washer [see fig.4].

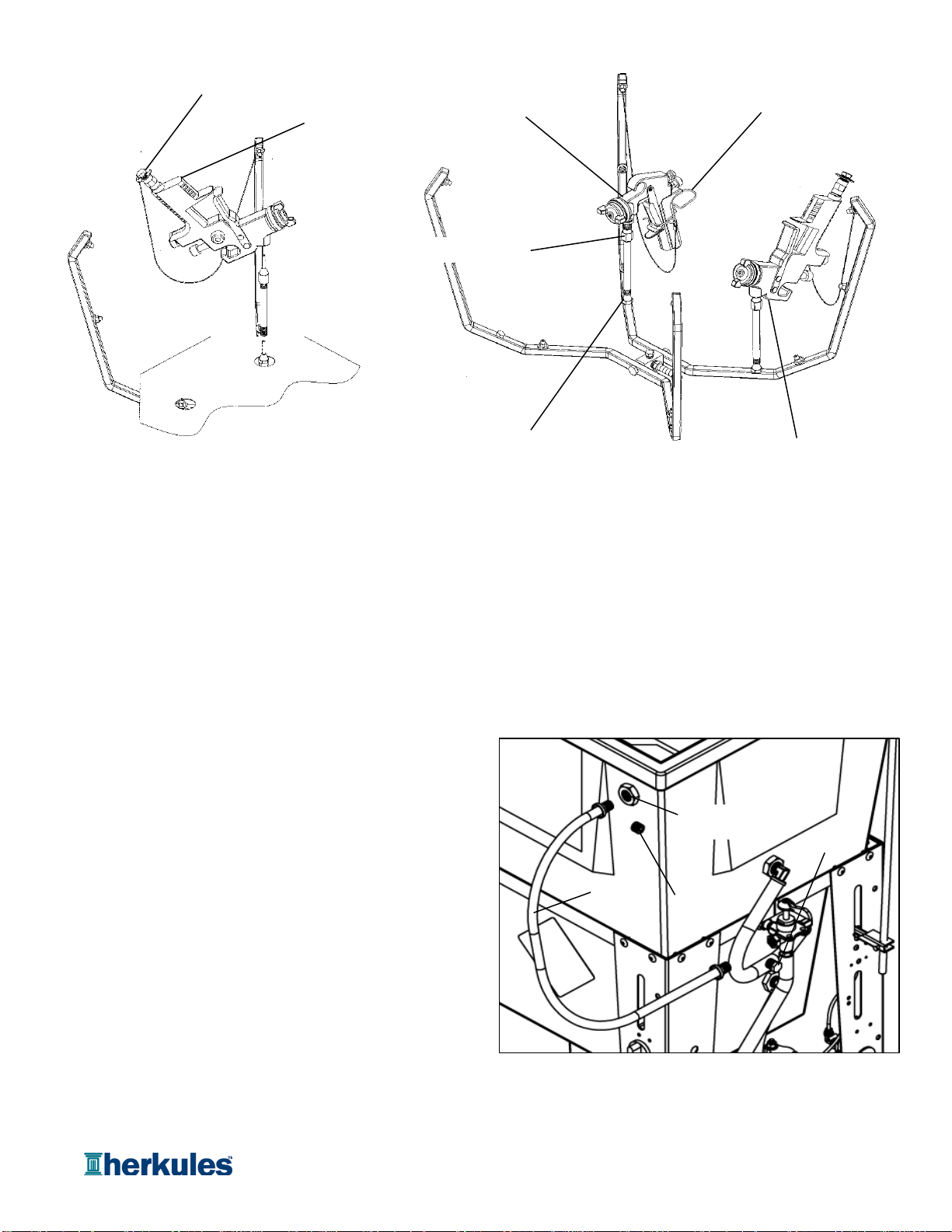

Connect the clear 5/32" air hose between the pump and

the air out port of the limit valve located on the front leg

of the gun washer [see fig.4].

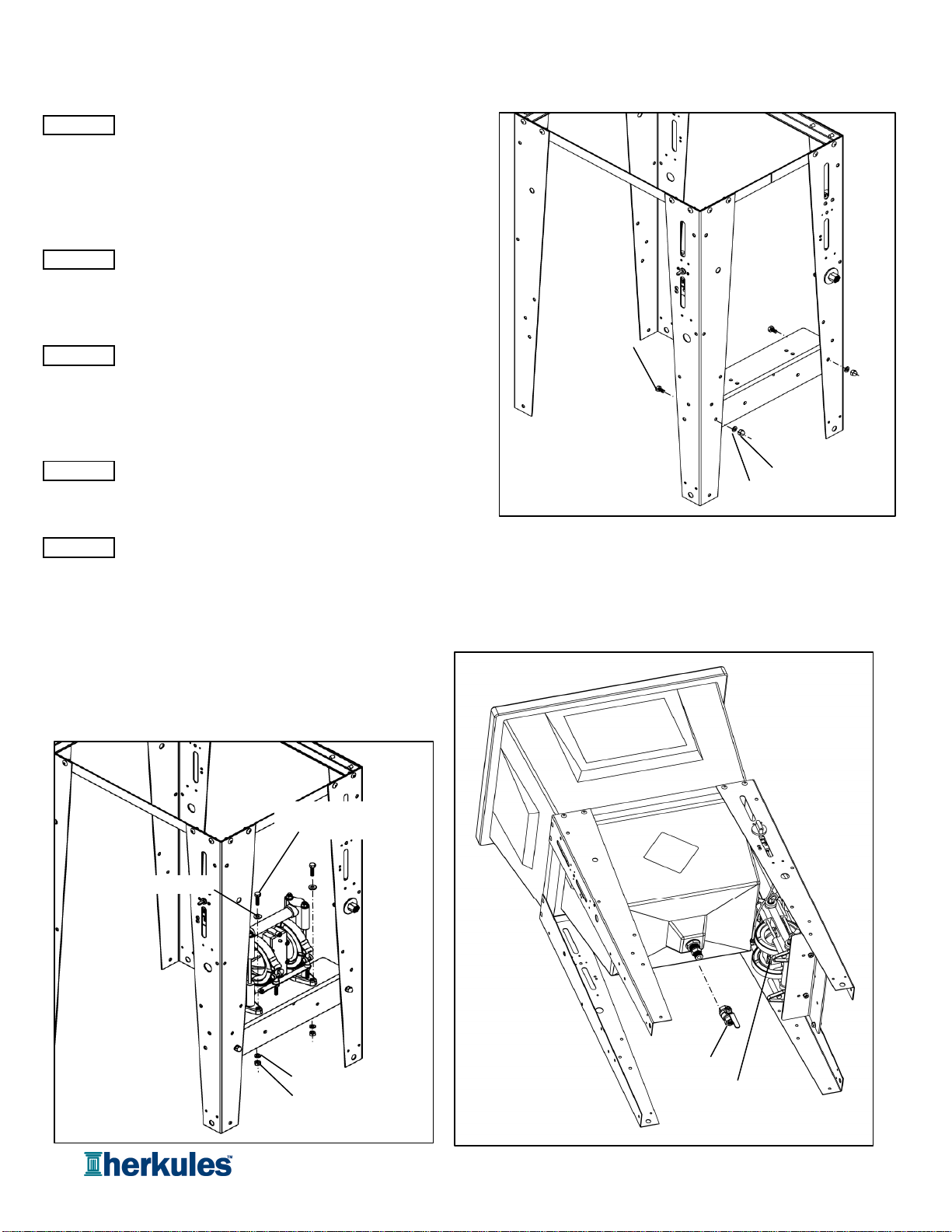

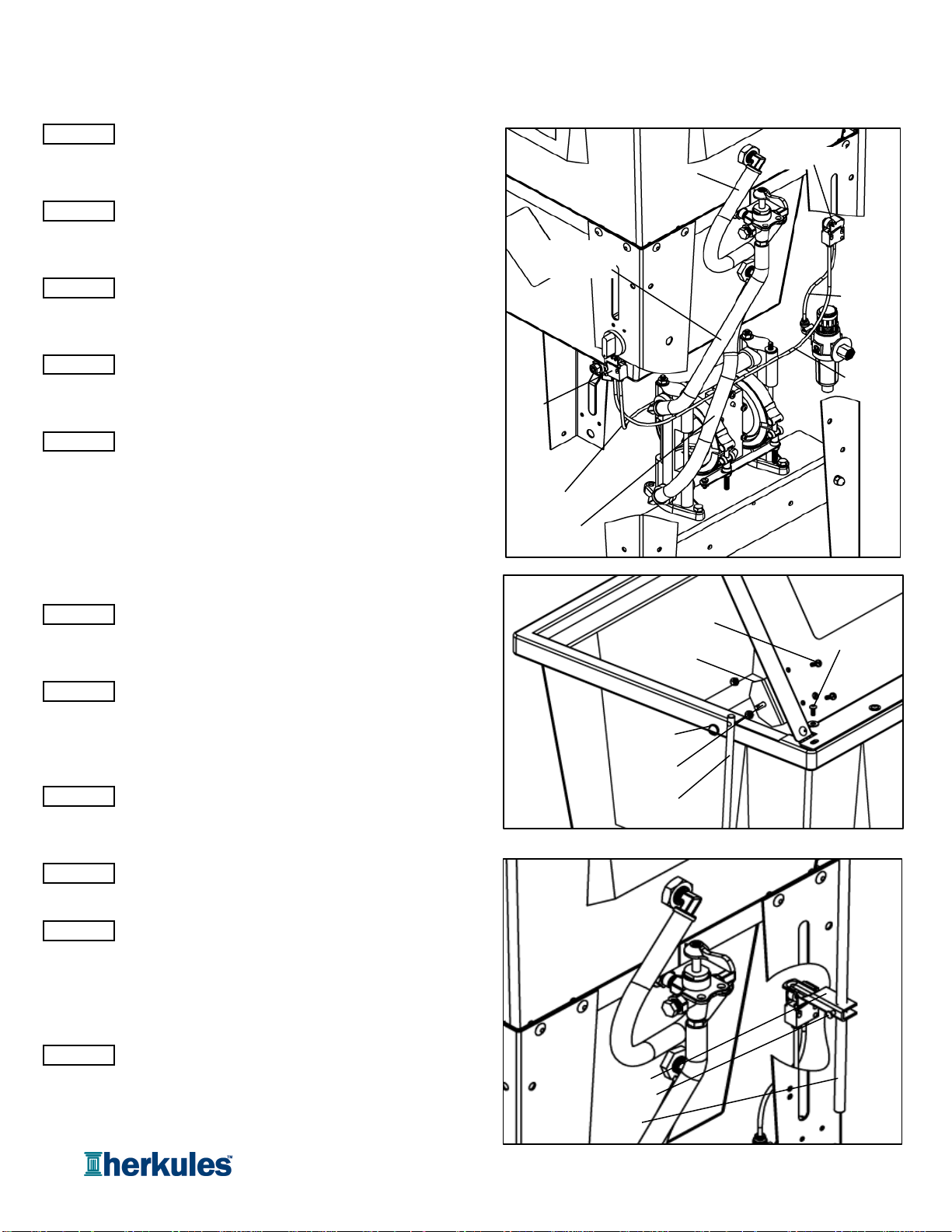

Connecting lid rod and actuator linkage

Slide the actuator over the lid rod opposite the drilled end

and hand tighten approx. 4" from the end of the rod. Insert

the actuator into the large slot in the right rear leg [see fig 6].

Attach the lid rod to the lid bracket using the 1/4" clevis pin

and circular cotter ring supplied [see fig. 5].

To adjust the actuator, close the lid and loosen the set

screw on the actuator. Slide the actuator down until it

completely closes the limit valve and retighten the set

screw [see fig. 6].

Grounding the lid

Using an 1/8" allen wrench, remove the back right lid screw.

Connect the ground wire (with the aluminum terminal

attached) from the pump to the lid screw and reconnect it

to the tub [see fig. 5].

Assembly Instructions

STEP 8

STEP 11

STEP 7

STEP 6

STEP 10

STEP 9

STEP 15

STEP 16

STEP 14

STEP 13

STEP 12

fig.5

Lid screw

Lid rod

Cotter pin

Lid bracket

Clevis pin

Limit valve

Limit

valve

Clear air

hose

13" Fluid

outlet tube

16" Fluid

inlet tube fig.4

Black air

hose

Blue air

hose

fig.6

Lid rod

Actuator

Set screw

20" Fluid

tube

Bracket

screw

Page 8 of 20