ERIKS ECON Series User manual

Installation & Operation Manual

Proven Quality since 1892

ECON check valves Fig. 2630-2631 www.eriks.com

Rev. 0

Content

1. ERIKS operating companies

2. Product description

3. Requirements for maintenance staff

4. Transport and storage

5. Function

6. Application

7. Installation

8. Maintenance

9. Service and repair

10. Troubleshooting

11. Removal

1. ERIKS operating companies

ECON ball check valves are being delivered by several ERIKS operating companies on a

worldwide basis. In this manual these will be referred to as ‘ERIKS’, the individual terms of

delivery of the ERIKS operating company having executed the order are applicable.

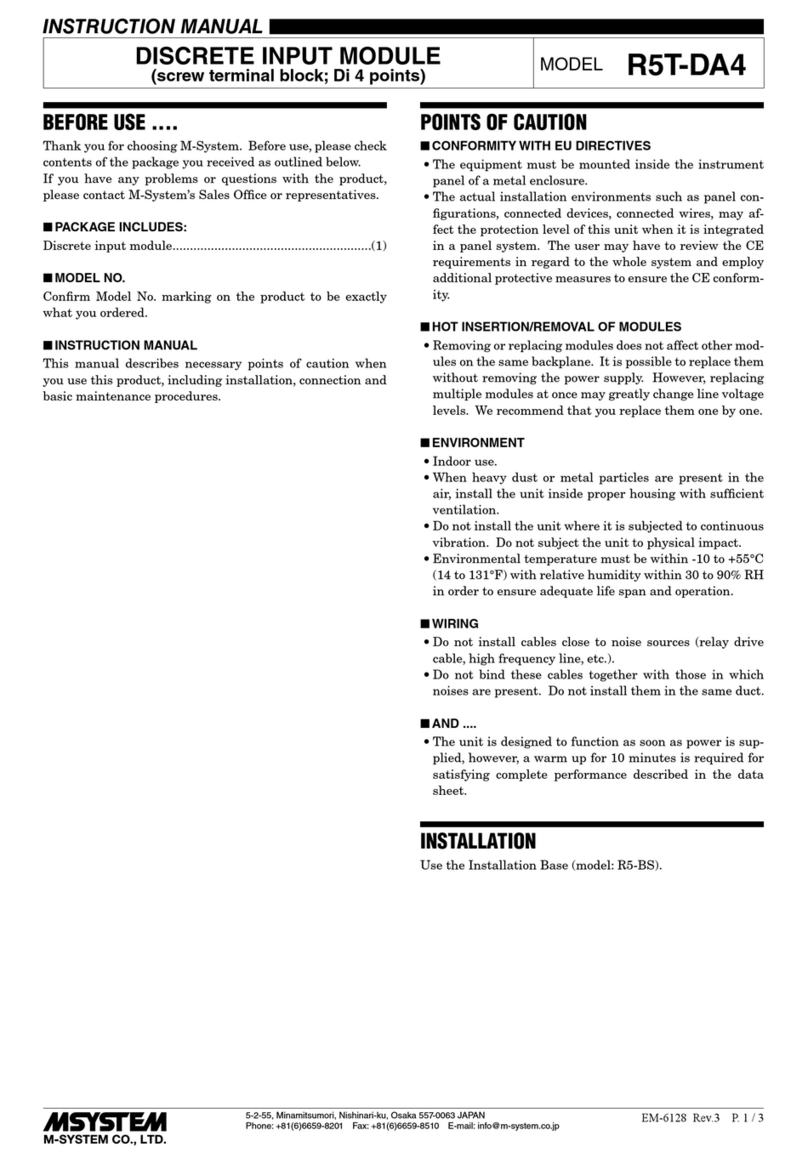

2. Product description

The ECON ball check valves are designed according to the information in our latest catalogue or

see our website www.eriks.com and should be used in accordance with the applicable pressure-

temperature rating as stated on this website. ECON ball check valves are provided with casted

markings according to EN 19. The marking makes the identification of the valve easier and

contains:

- size (DN)

- pressure rating class

- body material marking

- arrow, indicating the medium flow direction

- ECON logo

3. Requirements for maintenance staff

The staff assigned to assembly, operating and maintenance tasks should be qualified to carry out

such jobs and in any circumstance, ensure personal safety

4. Transport and storage

Transport and storage should always the valve should be protected against external forces,

influence and destruction of the painting layer as well. The purpose of the painting layer is to

protect the valve against rust, during transport and storage. The valves should be stored in an

unpolluted space and should also be protected against all atmospheric circumstances. There

should be taken care of the temperature and humidity in the room, in order to prevent condensate

formation.

5. Function

ECON ball check valves are designed for the prevention of flow reversal. The operation of the

valve is fully automatic allowing liquid to flow in one direction only. The flowing medium presses

against the ball, thereby push them open. The ball check valve can be installed horizontal and

vertical (upward flow).

6. Application

ECON ball check valves use primarily in water purification stations, sewage treatment

installations, water supply facilities, pumping stations, etc. Application: for clean, waste and

sewage water and viscous media. The operation of the valve is fully automatic allowing liquid to

flow in one direction only. The installation designer is responsible for the check valve selection,

suitable for the working conditions. The valves are unsuitable, without written permission of an

ERIKS company, to apply for hazardous media as referred into Regulation (EC) No 1272/2008.

Installation & Operation Manual

Proven Quality since 1892

ECON check valves Fig. 2630-2631 www.eriks.com

Rev. 0

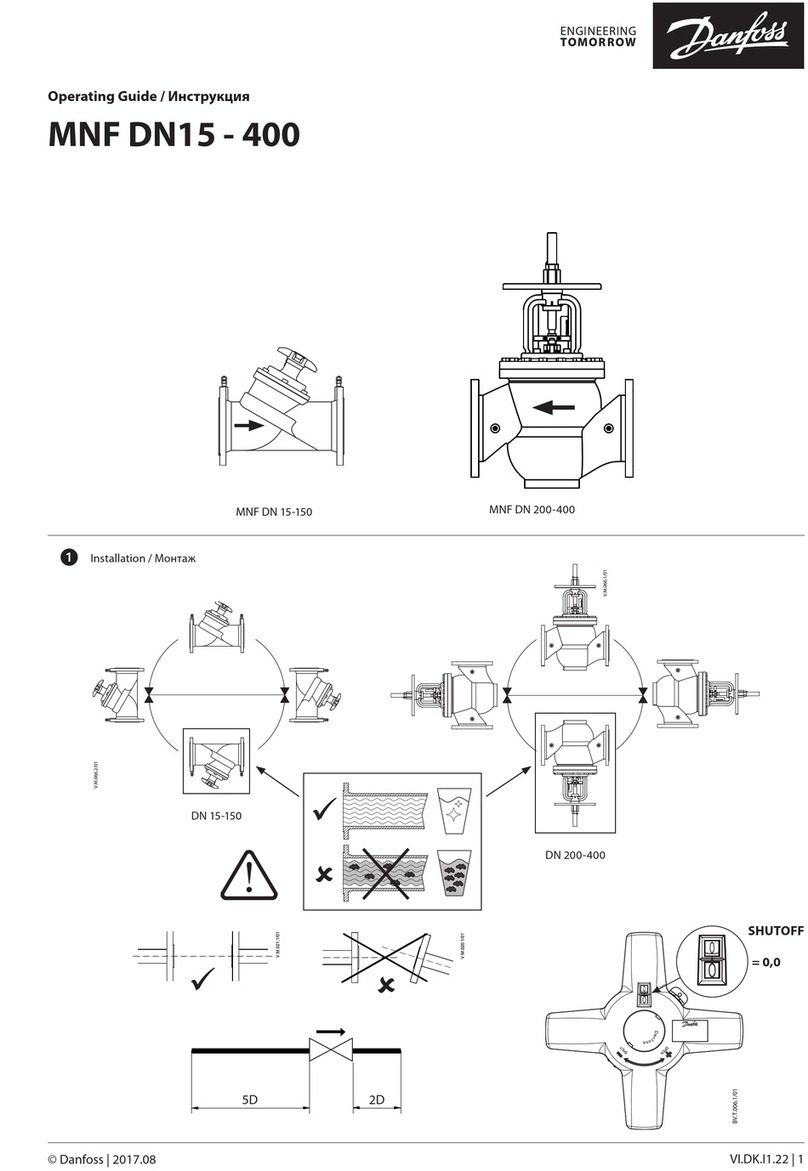

7. Installation

During the assembly of the ECON ball check valves, the following rules should be observed:

Make sure before an assembly that the valves were not damaged during the transport or

storage.

Make sure that the applied valves are suitable for the working conditions, medium used in

the plant and the right system connections, according to pressure and temperature limits.

When installing the ball check valves, ensure that the seat and the flange faces are

clean.

When valves are provided with lifting lugs, plates or eye nuts, these must be used to lift

the valve.

All special packaging material must be removed.

To ensure you use the correct sealing it is important to select the correct type of gasket

for the medium concerned, gaskets with the correct flange size must be used.

In horizontal pipelines the valve must be installed so that the bolted cover is facing

upward. (for version with sinking ball)

The valve must be installed with the direction arrow on the body coincident with the

direction of flow in the pipeline. For vertical pipelines the flow direction should only be

upwards.

Immediately prior to valve installation, the pipeline should be checked for cleanliness and

free of debris.

Valve end protectors should only be permanently removed prior to installation.

Place valve between pipe flanges, and insert the bolts.

Tighten bolts loosely.

Tighten bolts in a diagonal sequence to ensure flanges are pulled up parallel.

Finally tighten bolts to correct torque levels

Before plant startup, especially after repairs carried out, flash out the pipeline.

After installation it is necessary to check the valve operation and tightness of all

connections. A tightness test should be carried out.

Install pipelines so that damaging transverse, excessive vibrations, bending and tensional

forces are avoided.

Installation & Operation Manual

Proven Quality since 1892

ECON check valves Fig. 2630-2631 www.eriks.com

Rev. 0

Valves with air release plug.

The ball check valves DN400 and above are foreseen of an air release plug for elimination of the

accumulated air in order to avoid damage during start up. This plug must always be located on

the highest part of the valve. See figures below depending on vertical or horizontal installation. If

not specified by the customer, the plug is installed standard for horizontal pipeline installation. If

valves are installed in vertical pipeline (and not specified in the PO), the bonnet must be turned

180°.

To eliminate the air proceed by unscrewing the plug in order to release the accumulated air until

the fluid is coming out. The plug is auto blocked and cannot be unscrewed totally. If the plug is

damaged or blocked, proceed disassembly of the bonnet as indicated in previous content. It is

recommended to clean the plug when bonnet is disassembled for maintenance.

8. Maintenance

Before starting any service jobs, make sure that the medium supply to the pipeline is cut off,

pressure was decreased to ambient pressure, the pipeline is completely cleaned and ventilated

and the plant is cooled down. Always keep safety instructions in mind and take all personal safety

precautions.

ECON ball check valves do not require any special maintenance. In certain cases it might be

possible to replace or clean the internals (ball , O-ring), caused by natural wear of the components

or the accelerated wear as cause of the non-appropriate installation in the pipeline (such like not

respecting the precautions for assembly in pipeline or the application with very corrosive or

aggressive fluids).

During maintenance, the following rules should be observed:

- always keep personal safety precautions in mind and always use appropriate protection

e.g. clothing, masks, gloves etc.

- be alert that the temperature still can be very high or low and can cause burns.

- check the valve on all possible leaking possibilities.

- check if all bolts and nuts, are still fastened.

- check if the ball still functions in a proper manner.

- the thickness of the body must be checked to ensure safety operation at an interval of at

least three months.

Installation & Operation Manual

Proven Quality since 1892

ECON check valves Fig. 2630-2631 www.eriks.com

Rev. 0

9. Service and repair

All service and repair jobs should be carried out by authorized staff, using suitable tools and user

shall use valve ball, O-ring, bolt and nut of the same size and material as the original one.

- weld repair and drilling of the valve is forbidden.

- it is forbidden to replace the bolt, nut or packing when the valve is under pressure.

- tighten the hexagon nuts evenly crosswise in the therefor standard order.

- after replacement of the ball, O-ring, bolts or nuts, it is necessary to check the valve

operation and tightness of all connections. A tightness test should be carried out.

- after installation, the valve should be checked and maintained periodically at least every

3 months, depending on the medium.

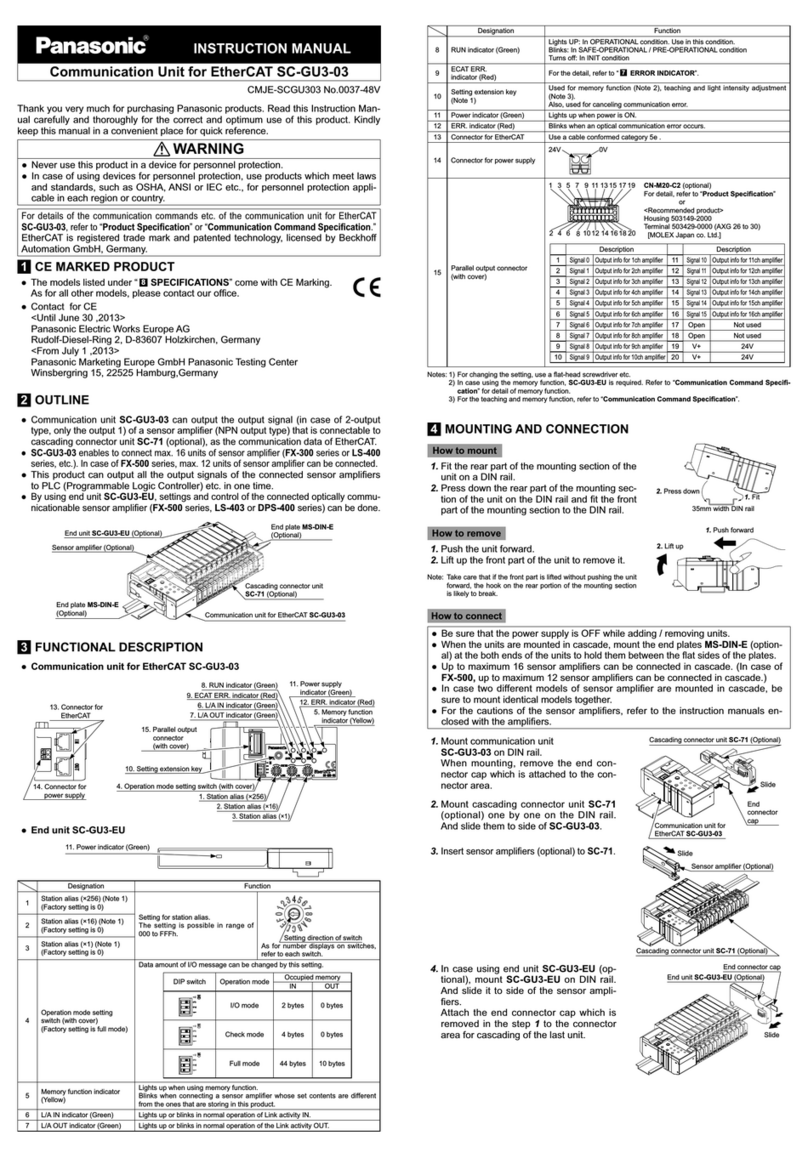

Replacement and/or cleaning of ball check valve components.

- Loosen the bolts of the bonnet (5) in a cross sequence and with correct tools in order to

avoid damage to the components

- Proceed by lifting the bonnet. For big sizes it is recommended to use elevation equipment.

If the bonnet contains a lifting or is foreseen of a threaded hole to fix a lifting lug, than this

must be used to lift the bonnet. If the bonnet is not foreseen of lifting lugs it is

recommended to use straps passing the holes of the bolting

- Take out the O-ring (4) for sealing the bonnet and proceed with cleaning or replacement.

In order to assure the tightness after assembly, we recommend to replace the O-ring

every time the bonnet is being disassembled.

Installation & Operation Manual

Proven Quality since 1892

ECON check valves Fig. 2630-2631 www.eriks.com

Rev. 0

- Take out the ball (3) to proceed cleaning or replacement. Be careful not damaging the ball

or coating during replacement or cleaning when using non compatible products. For the

bigger sized valves it is recommended to use elevation equipment and straps like shown

in below figures. Verify if the ball is not damaged at any point. In case of any damage, we

recommend to replace the ball.

- Clean the area where the ball is located when closed and also the valve passage must be

clean

- Proceed assembly of the valve, introduce the ball, place the O-ring (4) for tightness and

the bonnet (2) centered correctly in the opening of the body (1), take special care that the

O-ring is placed in correct position in order to avoid damage when fixing the bolts. Finally

start fixing the bolts (5) in a cross sequenced order.

10. Troubleshooting

It is essential that the safety regulations are observed when identifying the fault.

Problem

Possible cause

Corrective measures

No flow

Valve is installed in the wrong

way

Arrow of flow direction has to

run in the same direction as the

flow itself

Little flow

Piping system clogged

Check piping system

Leakage across valve seat

Seat or ball is damaged

Replace the seat or ball

Foreign matter is in the valve

Clean the valve.

11. Removal

All dismantled and rejected valves cannot be disposed with household waste. The valves are

made of materials which can be re-used and should be delivered to designated recycling centers.

Installation & Operation Manual

Proven Quality since 1892

ECON check valves Fig. 2630-2631 www.eriks.com

Rev. 0

General warning:

General note for products which may be used for seawater:

Although our products can be used in seawater systems it should always be noted that, in case of

installation in a piping system made of materials which are frequently used because of their excellent

seawater resistance (e.g. Cunifer), large potential differences may occur possibly causing corrosion

which could permanently damage the proper functioning and integrity of our product.

A combination of different materials should always be mentioned prior to the purchase of our products

in order for us to give the best possible advise on a safe functioning.

General note for cast iron products:

Cast iron can be used for various applications, such as listed in our catalogue. It should however

always be observed, that frost (in combination with non-drained products) may permanently damage

the proper functioning and integrity of our product.

Table of contents