r

●Always observe the following items.

1. When using this product in fluid control systems, always use

genuine KOGANEI parts or compatible parts (recommended

parts).

When conducting maintenance and repairs, always use

genuine KOGANEI parts or compatible parts (recommended

parts). Always observe the required methods and procedure.

2. Do not attempt inappropriate disassembly or assembly of the

product relating to basic construction, or its performance or

functions.

Koganei cannot be responsible if these items are not properly

observed.

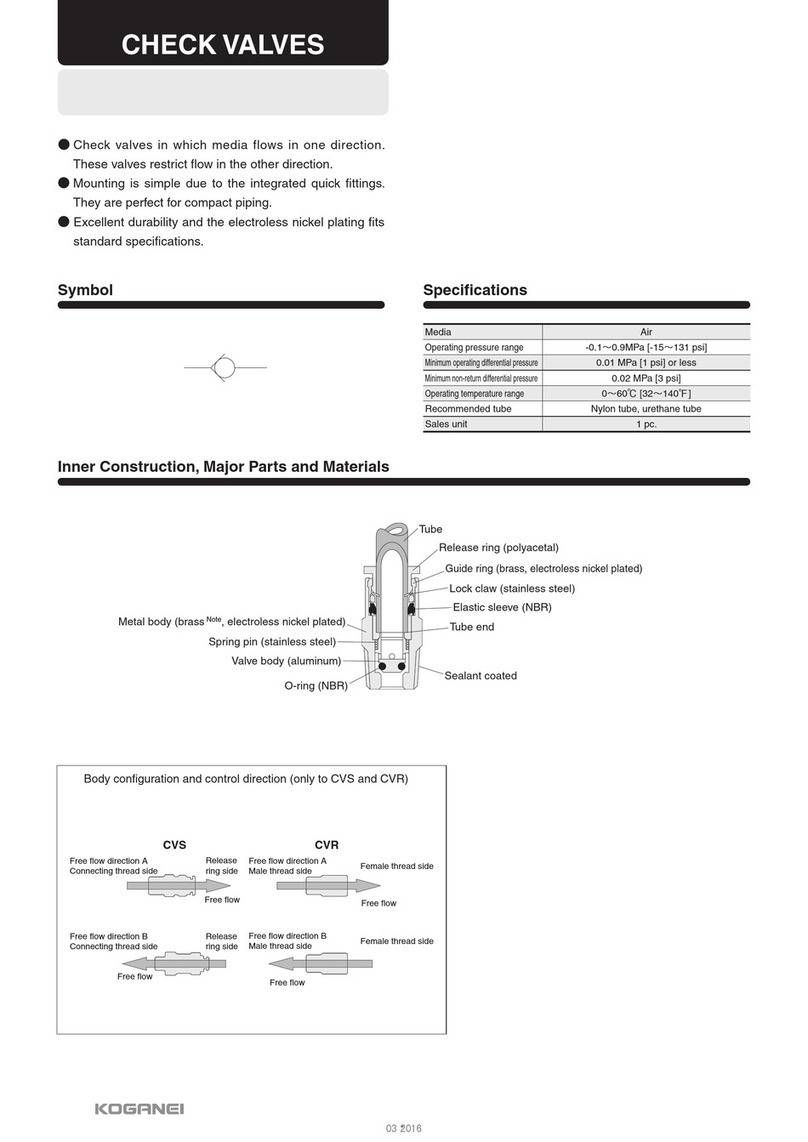

●Do not use the product in locations that are subject to direct

sunlight (ultraviolet), dust, salt, iron powder, humidity and high

temperature, or with the media and/or in the ambient atmosphere

that include organic solvents, phosphoric ester type hydraulic oil,

sulfur dioxide, chlorine gas, or acids, etc. It could lead to early

shutdown of function or a sudden degradation of performance,

and result in a reduced operating life. For the materials used, see

Major Parts and Materials.

●When mounting the product, leave room for adequate working

space around it. Failure to ensure adequate working space will

make it more difficult to conduct daily inspections or maintenance,

which could eventually lead to system shutdown or damage to the

product.

●For mounting or transport of heavy products, use a lift, supporting

tool, or several people, to provide firm support, and proceed with

due caution to ensure personal safety.

●Do not bring floppy disks or magnetic media, etc., within one

meter [3.28ft.] of the energized proportional control valve. There is

a possibility that the data on the floppy disks will be destroyed due

to the magnetism of the magnet.

●Do not use the proportional control valve in locations subject to

large electrical currents or strong magnetic fields. It could result in

erratic operation.

●Oil material from the compressor (excluding the oil-free compres-

sor) can cause drastic deterioration in product performance that

may lead to a functional shutdown. Always install a mist filter

before pneumatic equipment to remove the oil material.

●If the media is a liquid, install a relief valve on the circuit to

prevent it from being a liquid-closed circuit. There is a possibility

that the valve may eventually fail to open.

●When considering the possibility of using this product in situations

or environments not specifically noted in the Catalog or User’s

Manual, or in applications where safety is an important require-

ment such as in an airplane facility, combustion equipment,

leisure equipment, safety equipment and other places where

human life or assets may be greatly affected, take adequate

safety precautions such as an application with enough margins for

ratings and performance or fail-safe measures. Be sure to consult

us with such applications.

●Always check the Catalog and other reference materials for

product wiring and piping.

●When handling the product, wear protective gloves and a mask,

safety glasses, safety boots, etc. to keep safety.

●When the product can no longer be used, or is no longer

necessary, dispose of it appropriately as industrial waste.

●Proportional control valves can exhibit degraded performance and

function over its operating life. Always conduct daily inspections of

the equipment, and confirm that all requisite system functions are

satisfied, to prevent accidents from happening.

●

Leaks from the

proportional control valve

are not zero. For

application of requiring holding pressure inside the pressure vessel,

consider adequate margin of capacity and holding time in design of

the system.

●

For inquiries about the product, consult your nearest Koganei sales

office or Koganei overseas department. The address and telephone

number is shown on the back cover of this catalog.

CAUTION

ATTENTION

electromagnetic waves when the device is turned off, affecting the

operations of surrounding equipment. Use solenoids with surge

suppression, or take countermeasures in the electrical circuits for

surges and electromagnetic waves.

●Do not use the product where ozone may be generated, such as

near ocean beaches or other places subject to direct sunlight or

mercury lamps. Ozone can cause rubber parts to deteriorate,

which can lead to degraded performance and functions, or to

equipment stoppages and functional shutdown.

●Do not throw the product into fire. The product could explode

and/or release toxic gases.

●Do not sit on the product, place your foot on it, or place other

objects on it. Accidents such as falling and tripping over could

result in injury. Dropping the product may result in injury, or also

damage or break the product resulting in abnormal or erratic

operation, or runaway etc.

●Repair work and maintenance, piping removal and installation,

other parts replacement, and any other kind of work operation

relating to the product, should be performed by a person or

persons with adequate knowledge and experience with the

product, media, fluid control systems, etc. Moreover, always

completely shut off the supply of media, and observe the

precautions listed below when performing these operations.

1. For gases, check that the pressure in the product and in the

piping connected to the product is down to zero prior to work

operations. In particular, be aware of the possibility of residual

air in the air compressor and air storage tank. Residual

pressure in the piping could cause the actuator to suddenly

move, resulting in injury.

2. For liquids, drain all liquids from the product and piping. With

corrosive fluids, in particular, there is a possibility of chemical

burns or contamination of surrounding areas.

3. For high-temperature media, in addition to the above

precautions, also check that the valve temperature has

dropped sufficiently. Accidentally touching the hot surface

could result in burn injuries.

●When it is necessary to keep the heat of the proportional control

valve using an antifreezing heater or thermal insulation material,

provide thermal insulation for pipes and the valve body only, and

do not attempt to insulate the solenoid area. That could lead to

coil burnout resulting in electric shocks, fire, or erratic operation.

●Use of the product under the conditions described below is

subject to regulation under the Japanese High Pressure Gas

Control Law. Be aware that violation of this law can result in

penalties to individuals or corporations:

Pressurized gases used at room temperature with gauge pres-

sures of 1MPa [145psi.] or more, or pressurized gases capable of

reaching pressures of 1MPa [145psi.] or more converted at a

temperature of 35°C [95°F]. (Acetylene gas and liquefied gas are

subject to even stricter standards.)

For details, see the Japanese High Pressure Gas Control Law.

●When the proportional control valve is mounted inside a control

panel or is continuously energized for long periods, take heat

radiation measures to ensure that the ambient temperature of the

proportional control valve always remains within the specified

temperature range. In particular, caution should be exercised

regarding the continuous energizing of a fully opened proportional

control valve, because that could result in operational failure of

the temperature compensation circuit used to stabilize the

electrical current value against increased resistance when the

solenoid temperature rises.

●When energized for long periods, the coil will become quite hot.

Accidentally touching it could result in burn injuries.

●After finishing wiring operations, always check to ensure no wiring

connection error before turning on the power.

●Design equipment systems so as to avoid equipment damage or

personal injury, even in the event of operational failure of fluid

control equipment due to an emergency stop, power outages, or

other system abnormalities, such as an unintentional return to

non-energized status.

OTHERS