YINGLISOLAR.COM © Yingli Energy Development Company Limited

GB Modules Installation and User Manual Page 2

De-energize PV modules by removing them entirely from light or by covering

their front surface with an opaque material. Regard the safety regulations for

live electrical equipment when working with modules that are exposed to any

light. Use insulated tools and do not wear metallic jewelry while working with

PV modules.

In order to avoid arcing and electrical shock, do not disconnect electrical

connections under load. Faulty connections can also result in arcing and

electrical shock. Keep connectors dry and clean, and ensure that they are in

proper working condition. Never insert metallic objects into the connectors, or

modify them in any way in order to secure an electrical connection.

Do not touch or handle PV modules with broken glass, separated frames or

a damaged backsheet unless the PV modules are first disconnected and you

are wearing proper PPE. Avoid handling PV modules when they are wet unless

cleaning the PV modules as directed in this manual. Never touch electrical

connections that are wet without protecting yourself with insulated gloves.

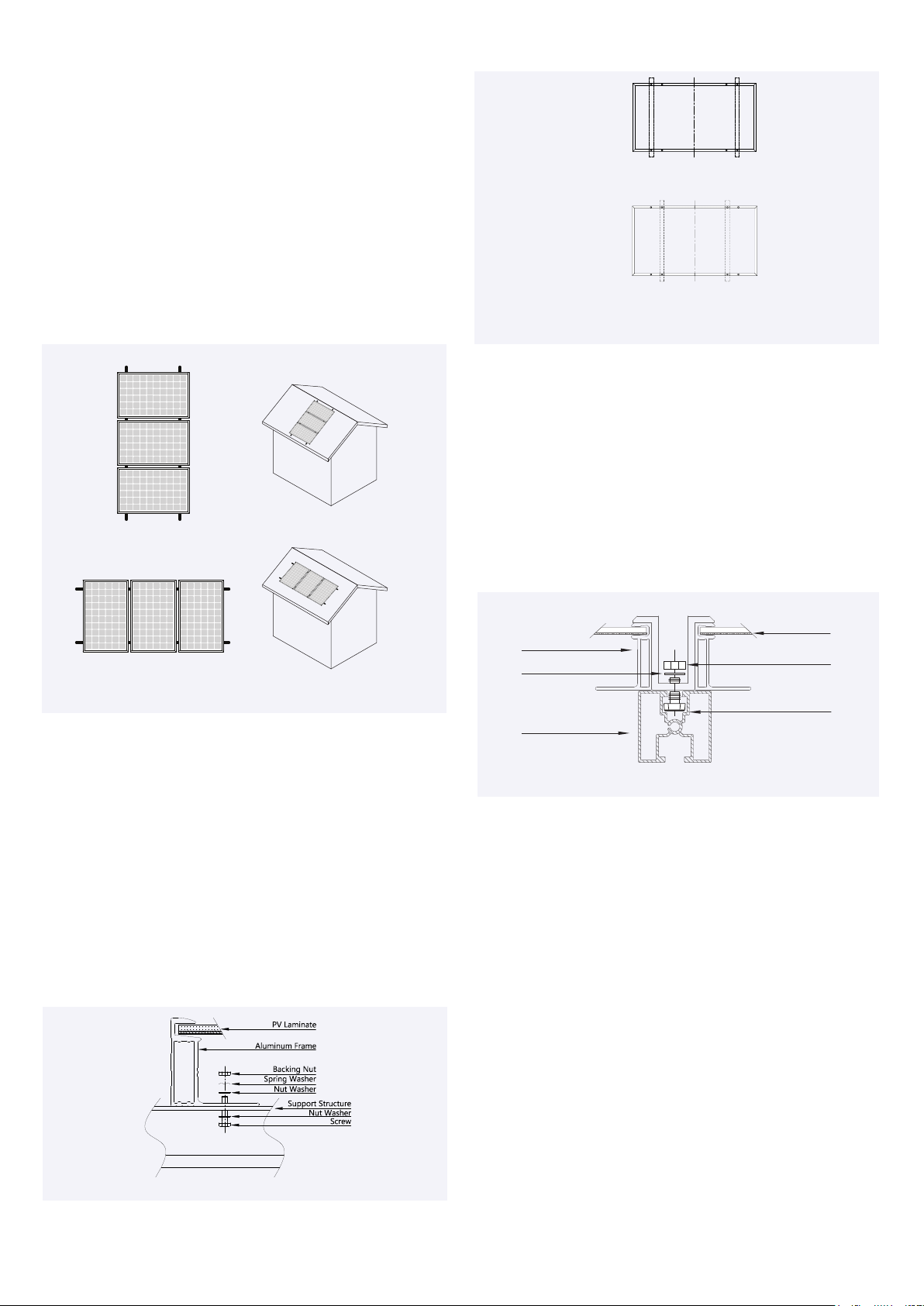

Transport and Handling

Yingli Solar PV modules must be transported in the supplied packaging only and

kept in the packaging until they are ready to be installed. Protect pallets against

movement and exposure to damage during transportation. Secure pallets from

falling over. Do not exceed the maximum height of pallets to be stacked, as

indicated on the pallet packaging. Store pallets in a cool and dry location until

the PV modules are ready to be unpackaged.

Figure 2: Pallet of PV modules

Yingli Solar PV modules are heavy, and should be handled with care. PV modules

shall be handled at the frame; never use the junction box or cables as a grip. Do

not exert mechanical stress on the cables. Never step on PV modules or drop

or place heavy objects on them. Be careful when placing PV modules on hard

surfaces, and secure them from falling. Broken glass can result in personal injury.

PV modules with broken glass cannot be repaired and must not be used. Broken

or damaged PV modules must be handled carefully and disposed of properly.

For unpacking PV modules from the Yingli Solar supplied packaging, first remove

the pallet lid (after removing securing straps, if provided). Remove PV modules

one at a time by sliding them up the channel in the package (see Figure 3). You

may need to secure the remaining PV modules in the pallet packaging to prevent

them from falling over.

Figure 3: Removing PV modules from a pallet

Check PV modules for damage due to transportation before they are installed;

do not install damaged modules. Contact the company you purchased the Yingli

Solar PV modules from in order to obtain information on making claims for

defective PV modules.

PV module surfaces are susceptible to damage that could aect the performance

or safety of the PV module; do not damage or scratch the PV module surfaces,

and do not apply paint or adhesive to any of the surfaces, including the frame.

For your safety, do not disassemble or modify Yingli Solar PV modules in any

way. Doing so may degrade performance or cause irreparable damage and will

void any applicable warranties.

If it is necessary to store PV modules prior to installation, the PV modules

should remain inside the packaging and protected from exposure that could

compromise the durability of the packaging.

Fire

Yingli Solar PV Modules have a Class C fire resistance rating in accordance with

the IEC 61730-2 certification. When PV modules are mounted on rooftops, the

roof must have a fire resistant covering suitable for this application. PV modules

are electrical generating devices that may aect the fire safety of a building.

The use of improper installation methods and/or defective parts may result

in the unexpected occurrence of an electrical arc during operation. In order to

mitigate the risk of fire in this event, PV modules should not be installed near

flammable liquids, gases, or locations with hazardous materials.

In the event of a fire, PV modules may continue to produce a dangerous voltage,

even if they have been disconnected from the inverter, have been partly or

entirely destroyed, or the system wiring has been compromised or destroyed. In

the event of fire, inform the fire crew about the particular hazards from the PV

system, and stay away from all elements of the PV system during and after a fire

until the necessary steps have been taken to make the PV system safe.

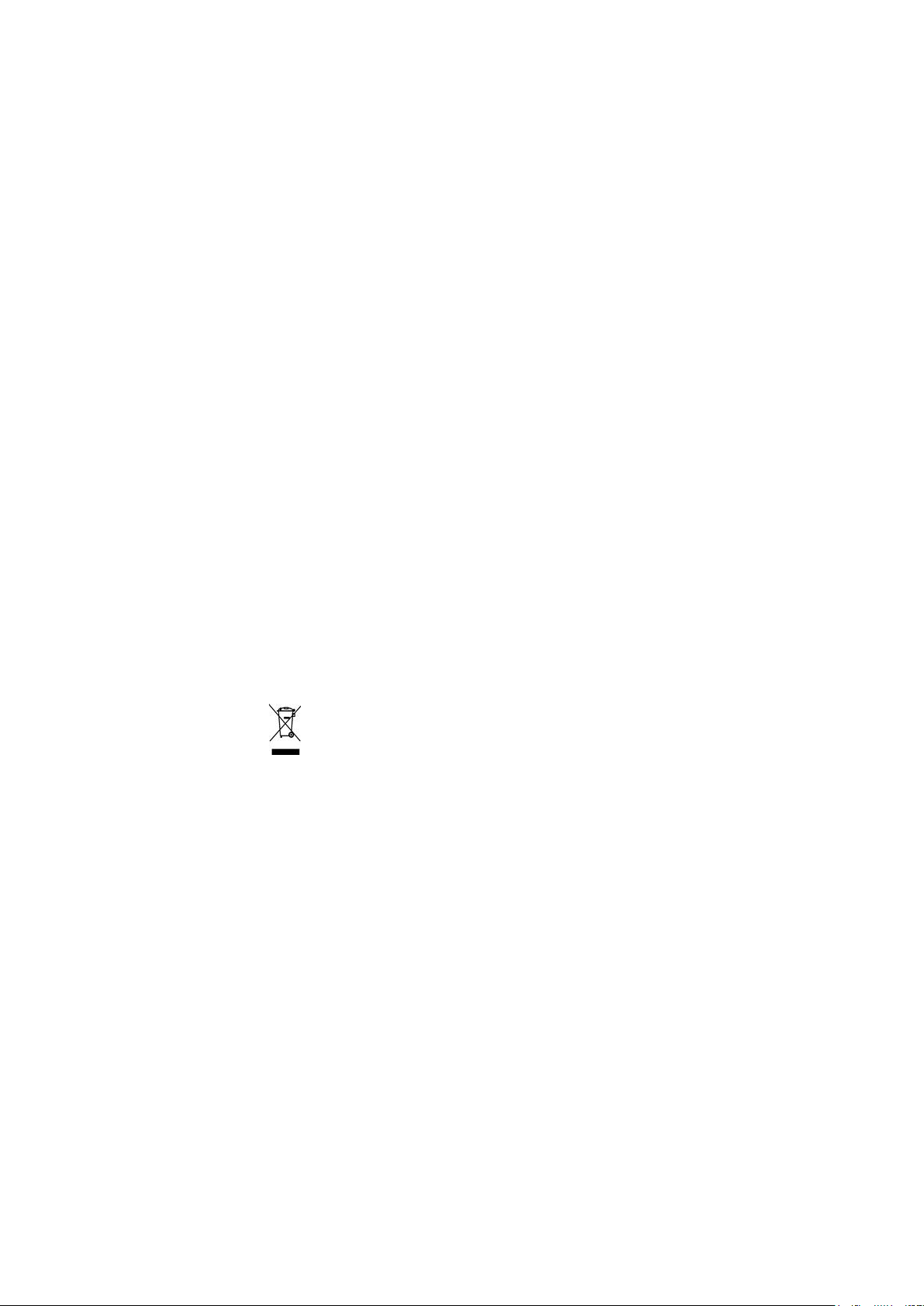

APPLICATION INFORMATION

Application Restrictions

Yingli Solar PV modules must be mounted on appropriate installation structures

positioned on suitable buildings, the ground, or other structures suitable for PV

modules (e.g. carports, building facades or PV trackers). PV modules must not

be mounted on moving vehicles of any kind. Yingli Solar PV modules must not

be installed in locations where they could be submerged in water.

Yingli Solar PV modules must not be sited in locations where aggressive

substances such as salt or salt-water, or any other type of corrosive agent, could

aect the safety and/or performance of the PV modules. Although some types

of Yingli Solar PV modules have passed the IEC 61701 salt-mist corrosion test

with a salt concentration of 5% by weight, galvanic corrosion can occur between

the aluminum frame of the PV module and installation or grounding hardware if

such hardware is comprised of dissimilar metals. Yingli Solar recommends that

only stainless steel and aluminum metal directly contact PV modules in seaside

installations to limit corrosion.

Artificially concentrated light must not be directed on Yingli Solar PV modules.

Design Recommendations

Yingli Solar recommends that PV modules be mounted at a minimum tilt angle

of 10 degrees to allow for proper self-cleaning from normal rain showers.

Partial or complete shading of a PV module or modules can significantly reduce

system performance. Yingli Solar recommends minimizing the amount of shade

throughout the year to increase the amount of energy produced by the PV

modules.

Lightning protection is recommended for PV systems that are to be installed in

locations with high probability of lightning strikes.

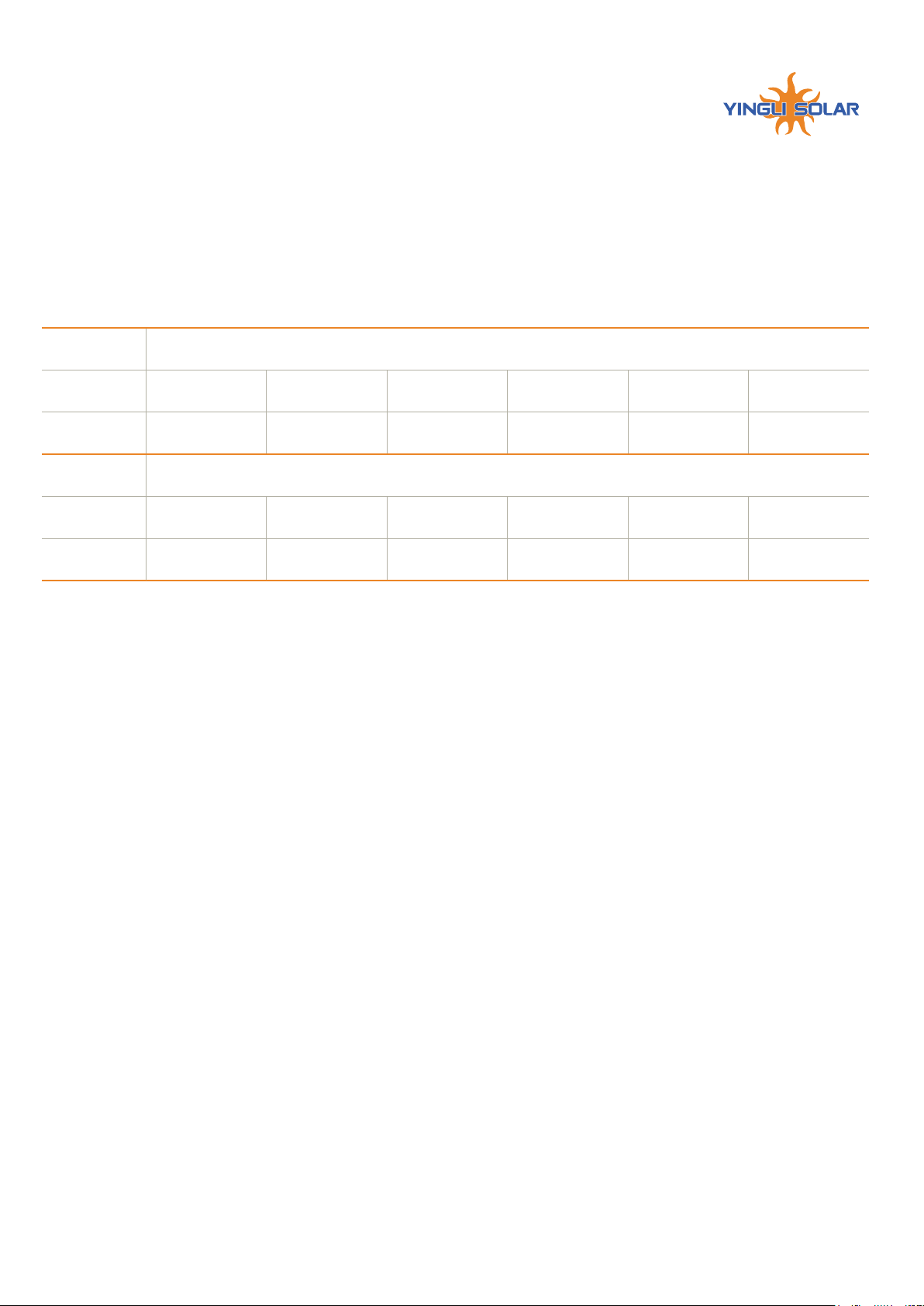

High system voltages could be induced in the event of an indirect lightning

strike, which could cause damage to PV system components. The open area of

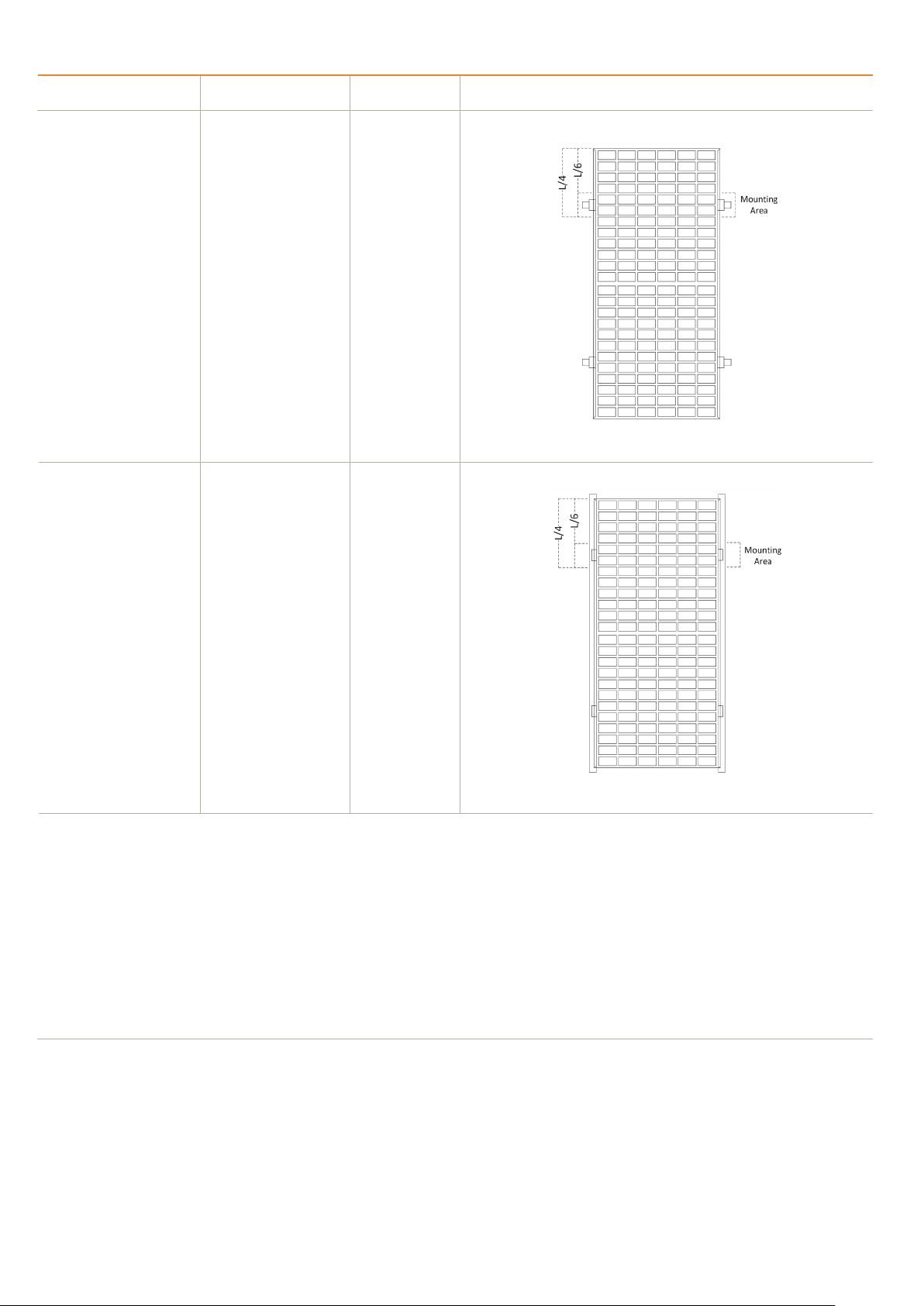

wire loops should be minimized, as shown in Figure 4, in order to reduce the risk