ERMCO 11-16-21 User manual

1

INSTRUCTION

MANUAL #105

THREE PHASE POLE MOUNTED DISTRIBUTION TRANSFORMER

ERMCO | 2225 Industrial Road | Dyersburg, TN 38024 | (800)238‐5587

INTRODUCTION

This instrucon manual provides general informaon for the

installaon, operaon, and maintenance of ERMCO three‐phase, pole

mounted transformers. These transformers are to be applied and used

per the “usual service condions” describes in IEEE C57.12.00 (General

Requirements for Liquid‐Immersed Distribuon, Power and Regulaon

Transformers).

RECEIVING AND INSPECTION

ERMCO pole transformers are shipped filled with insulang

transformer oil. Immediately upon receipt, and before being put in

service, transformers should be inspected for any external damage or

loose parts caused by shipping and handling. Damage presumed to

have occurred during shipment should be noted, and your ERMCO

sales representave contacted.

Extreme care is taken at the factory in the processing and sealing of

the transformer to insure that it is clean and dry, and of adequate

dielectric strength. Normally, therefore, it is not recommended that

the transformer seals be broken for internal inspecon. If it is decided,

nevertheless, that the transformer be opened, adequate precauons

should be taken as outlined elsewhere in these instrucons.

HANDLING AND INSTALLATION

Transformers should be lied by the liing lugs only. The transformer

bushings should not be used for liing or moving the transformer into

posion. The transformer should be kept upright at all mes and not

pped over on its side for any reason. This will prevent air bubbles

from entering the coil which could degrade the dielectric strength.

Support lugs for direct pole mounng are provided in accordance with

IEEE standards. Hangers and kickers for cross arm mounng is to be

provided by the user. When installed, transformers should be

protected from dangerous overloads, over voltages and lightning by

suitable, approved devices.

OIL

Transformers are thoroughly dried at the factory and filled with

ERMCO inhibited mineral oil having a minimum dielectric strength of

30 kV at 60 Hz when tested per ASTM D‐877. ERMCO inhibited mineral

oil contains less than 1 ppm of PCB's at me of manufacture. The

transformer should never be energized unless it is filled with oil.

If it should be found necessary to add to or replace the oil in the

transformer, only clean dry oil having the minimum dielectric strength

of 30 kV and less than 1 ppm PCB's should be used. Before opening

the transformer, sufficient me should be allowed for the transformer

to come to temperature equilibrium with the air in the room to

eliminate the possibility of moisture condensaon from the air.

A recommended procedure for opening the transformer is to first

bring the interior of the transformer to atmospheric pressure by

venng the automac pressure relief valve furnished on all ERMCO

transformers. The cover may then be removed. Natural rubber hose

should not be used in the transfer of oil. The correct oil level at 25°C is

marked on the inside of the tank.

Care should be taken to re‐seal the transformer so that moisture is

permanently excluded from the interior. A pressure test using dry air

or nitrogen, may conveniently be made through the pressure‐vacuum

fing, aer removing the pressure relief valve, to be sure all seals are

ght. Pressurize the transformer to 5 psig and hold for 30 minutes. A

drop in pressure during this me would indicate the transformer is not

properly sealed and the tank and fings should be checked and the

leak repaired. Finally, the pressure relief valve should be installed and

carefully ghtened.

CONNECTIONS

Refer to the transformer nameplate for the kVA rang and the

permissible connecons. No connecons other than those shown on

the nameplate should be made; and none of the connecons should

be changed while voltage is applied to the transformer. Provision is

made for grounding the tank by means of a tapped pad or ground

connector.

OVERLOAD AND OVERVOLTAGE PROTECTION

Transformer protecon against overloads and over voltages may be

obtained by suitable devices applied in the field to convenonal

transformers, or by use of protected transformers (ERMCO CSP or CP

types) as supplied from the factory.

1. Fuses: High voltage fused cutouts are recommended for

protecon of convenonal transformers against overloads and to

protect the line against outages. On ERMCO CSP and CP

transformers, a fusible protecve link, mounted inside the tank,

is provided in series with each HV terminal. In case of internal

failure of the transformer, the protecve link disconnects the

transformer from the line without affecng line fuses or breakers.

When the available fault current exceeds the maximum

interrupng rang of the protecve link, a current liming fuse

should be used in series with the protecve link.

2

THREE PHASE POLE MOUNTED DISTRIBUTION TRANSFORMER INSTRUCTION

MANUAL #105

2. Lightning Arresters: Convenonal transformers should be

protected by properly rated lightning arresters. Ground

connecons on the arresters should be made before connecon

to the high voltage line is made.

CSP transformers are lightning protected by gapped or direct

connected lightning arresters bolted to mounng pads welded to

the tank wall. Gapped arresters have an adjustable electrode on

the top terminal of the arrester to obtain the proper gap seng

to the bushing electrode.

Before the transformer is put into service, the gap type arrester

electrode should be checked for proper gap alignment and

spacing. Adjustments should be made as necessary.

3. Secondary Breakers: ERMCO CSP and CP transformers are

protected against secondary overloads and short circuits by an

internally mounted circuit breaker. The funcon of the breaker is

to open the low voltage circuit and protect the transformer from

faults or severe overloads.

The breaker operang mechanism is designed to be operated by

a lineman's hot sck. Transformers are shipped with the circuit

breakers closed.

To open the low voltage manually, move the handle fully

counterclockwise so that the pointer moves from the "C" (closed)

to "O" (open), at which point the circuit is open. Verify that the

circuit breaker is latched in the "open" posion. To ensure the

discharge of the stac charge which is somemes present in the

low voltage winding due to capacitance, it is recommended that

the low voltage be grounded aer opening the circuit breaker

unl aer the high voltage is disconnected.

To close the breaker, rotate the handle fully counterclockwise to

"R" (reset), which engages the latch mechanism, and then

clockwise to "C" (closed). If a fault exists or an excessive load

exists at the me the breaker is closed, the breaker will reopen

even though the handle is held in the "C" (closed) posion.

Some breakers are provided with a red signal light which gives

warning that the load has reached a value near the tripping point

of the breaker. The signal light remains lighted unl reset (turned

off) by means of the breaker operang handle. Transformers

should not be operated under load condions that will cause the

red light to appear frequently, since it indicates an overload on

the transformer. When such a condion exists, it is

recommended that a larger transformer be substuted to avoid

impairing the life of the smaller unit.

To reset the signal light without disconnecng the load, rotate

the handle to "L" (light), and then return to "C" (closed). If the

light fails to go out, the transformer is sll overheated. To check

the signal light bulb when the transformer is in service, rotate the

handle to "L" (light). The light should turn on. If it does not, the

bulb should be replaced.

Some circuit breakers are equipped with an emergency overload

device which can be used to restore service following a circuit

breaker operaon due to overload. The emergency overload

lever is located immediately above the breaker operang handle.

With the emergency lever in the normal posion, the breaker will

trip at its normal seng as calibrated at the factory. Moving the

lever in a clockwise direcon increases the seng so a higher

temperature is required to trip the breaker. The emergency

seng may be adjusted to an intermediate or extreme value.

This emergency seng provides extra load capacity and sll

permits manual breaker operaon, and also retains short circuit

protecon of the transformer. It is important that the emergency

seng be used only when, and as long as, absolutely necessary

because its use will result in a reducon of transformer life.

A meter seal is provided on the emergency lever to prevent

tampering. It is recommended that a new seal be applied to the

lever when it is returned to the normal posion aer emergency

operaon.

The breaker is a thermal and short circuit protecve device for

the transformer. It is not recommended that the breaker be used

for roune disconnect operaons.

GASKETS

Cover and bushing gaskets are all made of Buna‐N Nitrile rubber.

Gaskets may be reused if not damaged. Round covers must seat

evenly on the gaskets so that pressure is distributed evenly. The cover

must be ghtened firmly to insure an effecve seal.

DUAL VOLTAGE AND TAPS

ERMCO transformers rated for more than one primary voltage are

equipped with a dual voltage switch or tap changer. These switches

are externally operated, but should never be operated while the

transformer is energized. When switching from one voltage to

another, make sure the switch is in the proper posion before re‐

energizing the transformer. Aer turning the switch, ghten the

locking device to minimize the possibility of unintenonal

movement.

STORAGE

Transformers should be stored filled with oil and in a clean dry place,

if possible where there will be no extreme temperature changes.

Before the transformer is put in service, it should be checked in the

same manner as when received.

ERMCO | 2225 Industrial Road | Dyersburg, TN 38024 | (800)238‐5587

3

THREE PHASE POLE MOUNTED DISTRIBUTION TRANSFORMER INSTRUCTION

MANUAL #105

MAINTENANCE

A periodic visual inspecon of the transformer is recommended. At

such mes, the general condion of the following should be noted:

1. High voltage bushings

2. Low voltage bushings

3. Arresters (if provided)

4. Evidence of oil leakage

5. Ground connecons

6. Accessories

7. Safety labels.

Where tanks show evidence of rusng or deterioraon of the finish,

they may be cleaned and then retouched with paint. It is necessary to

remove all loose paint and rust by wire brushing, scraping, or sanding,

and clean with a good solvent. Apply an acrylic lacquer, alkyd enamel,

two part urethane or silicone alkyd primer, allow to dry, and then

apply a color matched compable top coat and allow to dry.

If metal is rusted to the point of being weak such that the tank

integrity can be compromised, repair or replace the part rather than

painng it.

REPLACEMENT PARTS

Replacement parts are available from ERMCO. When ordering parts,

give a complete descripon of the part. Also, give the kVA, voltage,

and serial number of the transformer, all of which may be found on

the nameplate.

ADDITIONAL INFORMATION

Complete informaon on details of construcon, installaon,

operaon and maintenance can be obtained from the ERMCO factory

or your nearest ERMCO Sales office.

ERMCO | 2225 Industrial Road | Dyersburg, TN 38024 | (800)238‐5587

Popular Transformer manuals by other brands

Lamarche

Lamarche ITSM Installation and operation manual

Tripp Lite

Tripp Lite IS Medical Grade IS250HG Important safety instructions

BLACK DECKER

BLACK DECKER LEDUC-24WP instruction manual

Siemens

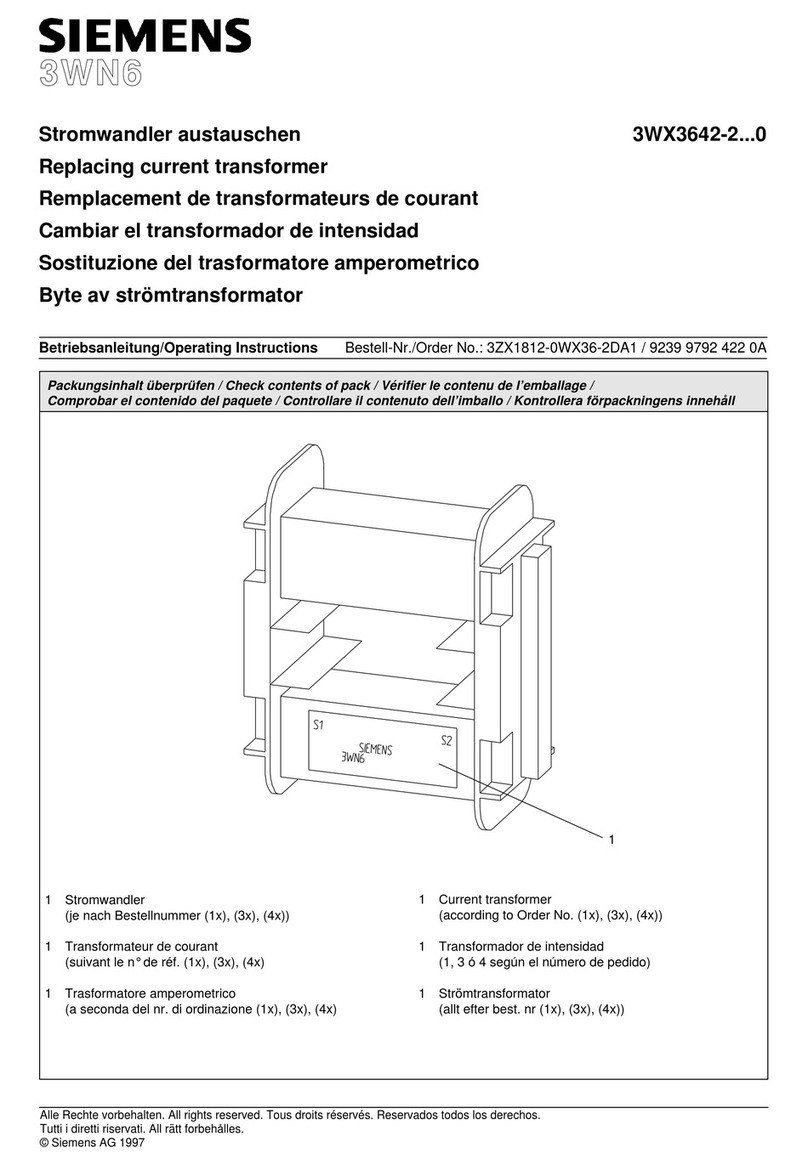

Siemens 3WX3642-2 0 Series operating instructions

Arteche

Arteche UG-72 525 Series user manual

Dehner

Dehner SL60 VF Series User manual and safety information