3High Voltage Instrument Transformers | UG

User Manual

TRANSPORT AND HANDLING

STORAGE/

The storage area must maintain the necessary cleanliness and

safety conditions so as to avoid damage to the transformer.

Follow the safety markings on the packaging at all times.

› Storage in vertical position: The transformers can be stored in

an upright position after unpacking and must always be firmly

anchored to the ground without any time restriction.

› Storage in horizontal position: The transformers can be stored

upright in their original packaging, which was designed to

this end, for a of limited period of time. We recommend not

keeping them in this position for more than 6 months if stored

outdoors, or 12 months if sheltered from bad weather. In any

case, they should be placed on firm, horizontal ground.

The final holder will be responsible for delivering the used

packaging or its waste for environmental management according

to the legislation in force in their country.

Unpacking: Remove the top and sides of the box, if any, to allow

free handling of the unit.

Annex I, contains the figures mentioned below.

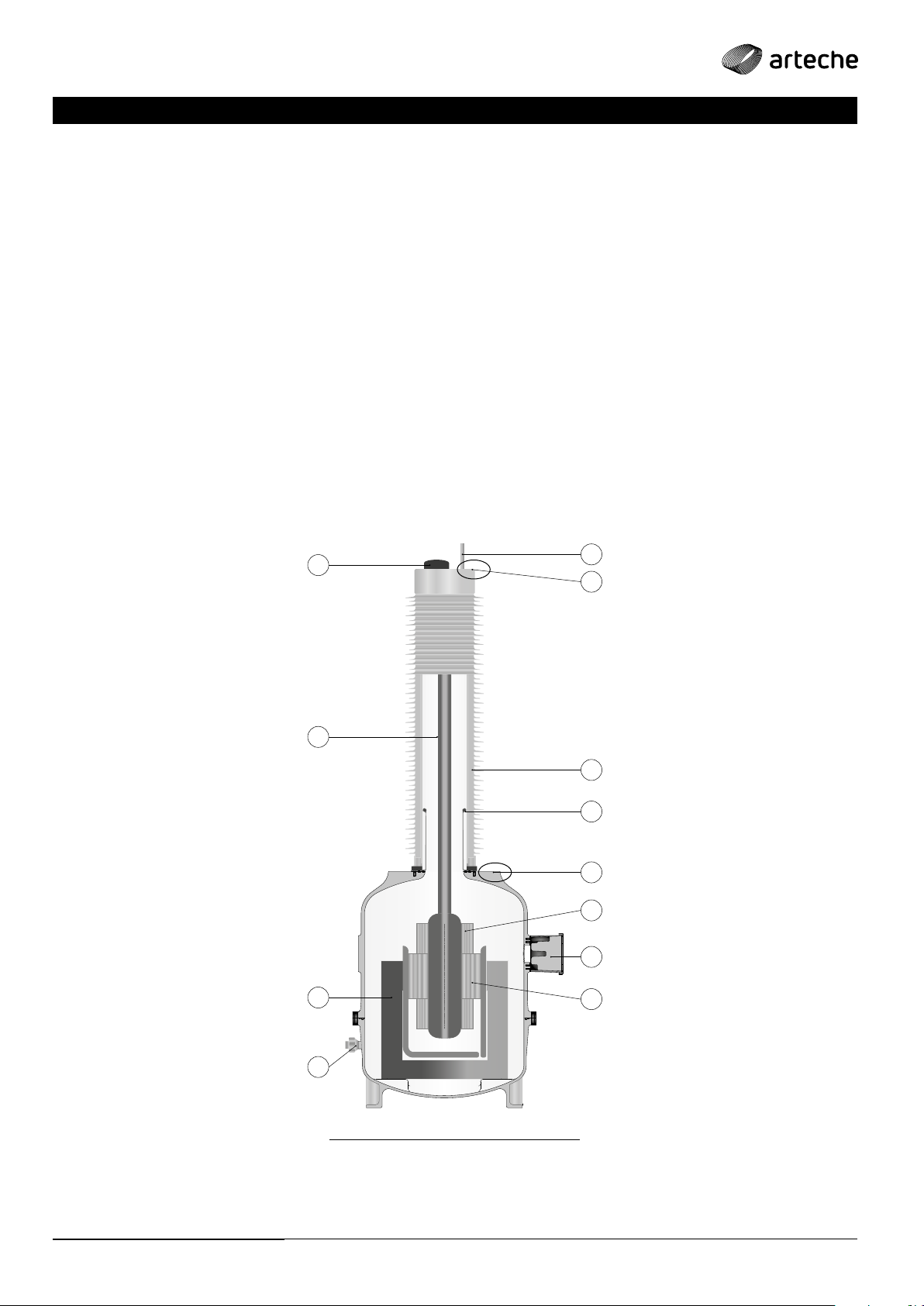

If the transformer is in a horizontal position, to place it in a vertical

position, proceed as indicated in Fig. 1 and Fig. 2. During the lifting

process, the slings must always be kept in an upright position.

When the device is in a vertical position, movements can be

made:

› If the tank is not equipped with lifting eyes, as shown in Fig. 3.

› If the tank is equipped with lifting eyes, as shown in Fig. 4.

Once the equipment has been placed in an upright position, a

visual inspection is suggested so as to detect possible damage.

Precautions will be taken throughout the process to avoid

damaging the sheds of the synthetic insulator.

TRANSPORT/

ARTECHE’s packaging guarantees a correct transport to

destination.

These transformers can be transported both horizontally and

vertically. For transport, the transformer should be properly

attached to the packaging so as to avoid movement.

› Load and unload the transformer slowly and avoid sudden

movements.

› It must be secured to the truck to avoid movement.

› Keep truck acceleration under 5G, and the speed under:

• Unpaved road ___________ Max. 30 km/hour

• Secondary roads ___________ Max. 60 km/hour

• Highway (motorway) ___________ Max. 90 km/hour

DANGER

INJURIES from falls and tipping

› Do not place the equipment upside down or on its side

› Do not transport the equipment in conditions other than those mentioned

RECEIPT/

After receipt, check the packages for signs of shock, tampering,

etc. Any anomaly must be indicated on the transport

company’s receipt sheet and communicated to ARTECHE or

the equipment supplier.

Once the transformer has been unpacked, check that none of

the screws holding the insulator have become loose during

transport. If they have, tighten them according to the torque

indicated in Annex II. If any other type of anomaly appears,

inform ARTECHE or the supplier of the equipment.

Attach photos of the damaged transformers to the report.

› Possible damage to the packaging: Dents on the outside, open

packaging, etc.

› › Possible damage to equipment: Broken or defective insulator,

dented metal parts, damaged secondary terminal box, etc.

The packed units can be moved by forklift or with slings or

chains. Follow the safety markings on the packaging

DANGER INJURIES AND/OR FIRE

› Do not use damaged equipment

HANDLING/

DANGER

INJURIES from falls and tipping

› Do not place the equipment upside down or on its side

› Handle the transformer according to the instructions in this manual

› Never manipulate the transformer with internal pressure

› The slings used must be in good condition and suitable for handling the equipment

according to its weight, which is indicated on the nameplate

Under no circumstances should a transformer be manipulated by pulling on the primary terminals

This may cause damage to the equipment and void its warranty