5

• Do not llow lrge cookwre to overhng the

cooktop onto djcent benchtop. This will cuse

scorching to the benchtop surfce.

• Do not llow cooking pots or pns to intrude

into the re which is close to the controls.

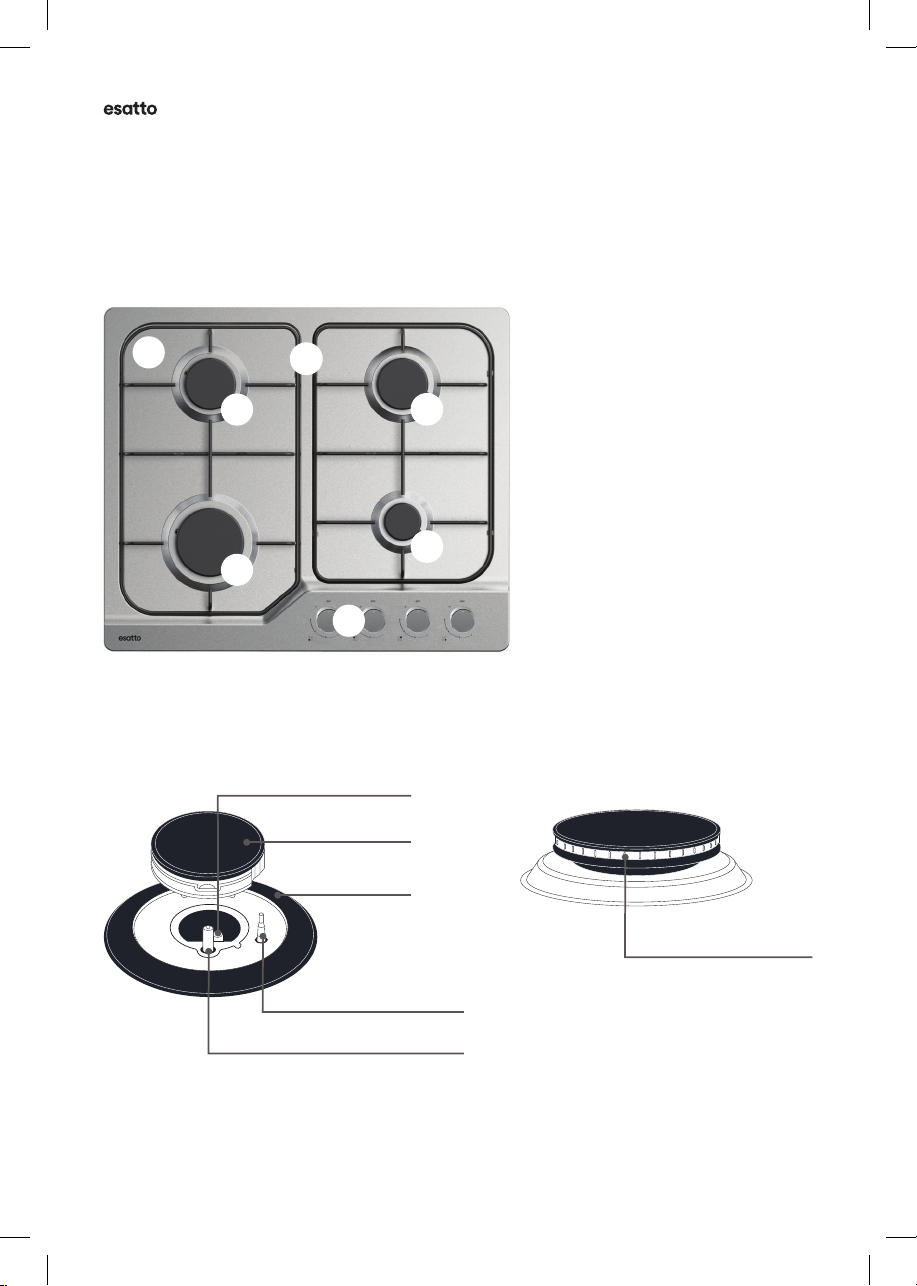

• Ensure burner bodies nd trivets re properly

locted on the cooktop (i.e. correctly ssembled

nd positioned).

CAUTION: Follow these instructions crefully

to void n electric shock or re.

It is importnt to use your cooktop sfely. Check

these sfety points before using your cooktop.

• This pplince is not intended for use by

persons (including children) with reduced

physicl, sensory or mentl cpbilities, or lck

of experience nd knowledge, unless they hve

been given supervision or instruction concerning

use of the pplince by person responsible for

their sfety.

• Children should be supervised to ensure they do

not ply with this pplince.

• During use, this pplince becomes hot.

Cre should be tken to void touching hot

surfces. To void burns, young children should

be kept wy.

• This pplince must not be used s

spce heter.

• Keep vents cler of obstructions.

• In order to void re, this pplince must be

kept clen.

• Do not spry erosols in the vicinity of this

pplince while it is in opertion.

• Do not store mmble mterils on or under

this pplince, e.g. erosols.

• Do not remove the trivet nd enclose the burner

with wok stnd s this will concentrte nd

deect het onto the burner.

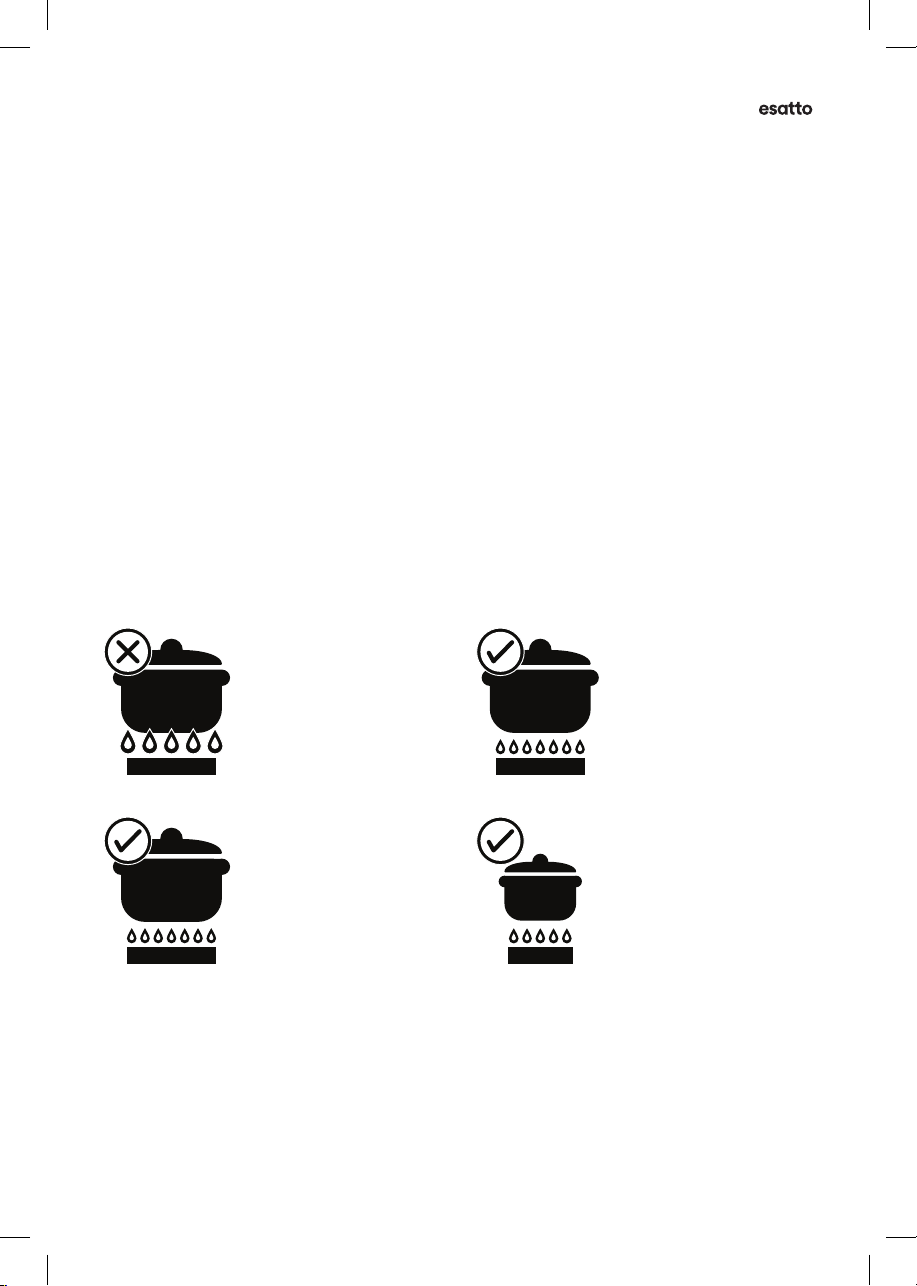

• Do not use lrge pots or hevy weights

which cn bend the trivet or deect me onto

the burner.

• Do not plce nything, e.g. sbestos mt

between pn nd trivet s serious dmge to

the cooktop my occur.

• For mximum stbility, ensure pots nd pns re

centrlly locted on the trivets.

• Hndles should be turned wy from the front

of the bench to void ccidents.

• Do not modify this pplince.

• Only models tted with me sfegurd

cn be used in mrine crft, crvns

or mobile homes.

CAUTION: In the event of gs lek, tke the

following ctions:

• Do not turn on the room light.

• Do not switch on/o ny electricl pplinces

nd do not touch ny electric plugs.

• Do not use telephone.

1. Stop using the product nd close the

middle vlve.

2. Open the window to ventilte.

3. Contct our service centre by using mobile

phone outside.

NOTE: The fuel gs contins mercptn. In the

event of gs lek, it will smell like rotten eggs or

grlic—even if there is only 1/1000th of the gs is

in the ir.

UNPACKING

During trnsporttion, protective pckging ws

used to protect the pplince ginst ny dmge.

After unpcking, plese dispose of ll elements of

pckging in wy tht will not cuse dmge to

the environment.

All mterils used for pckging the pplince re

environmentlly friendly; they re 100% recyclble

nd re mrked with the pproprite symbol.

CAUTION: During unpcking, the pckging

mterils (polythene bgs, polystyrene pieces,

etc.) should be kept out of rech of children.

DISPOSAL OF THE APPLIANCE

Old pplinces should not simply be disposed

of with norml household wste nd should be

delivered to collection nd recycling centre for

electric nd electronic equipment. A symbol shown

on the product, the instruction mnul or the

pckging shows tht it is suitble for recycling.

Mterils used inside the pplince

re recyclble nd re lbelled with

informtion concerning this.

By recycling mterils or other prts

from used devices you re mking

signicnt contribution to the

protection of our environment.

Informtion on pproprite disposl

centres for used devices cn be

provided by your locl uthority.