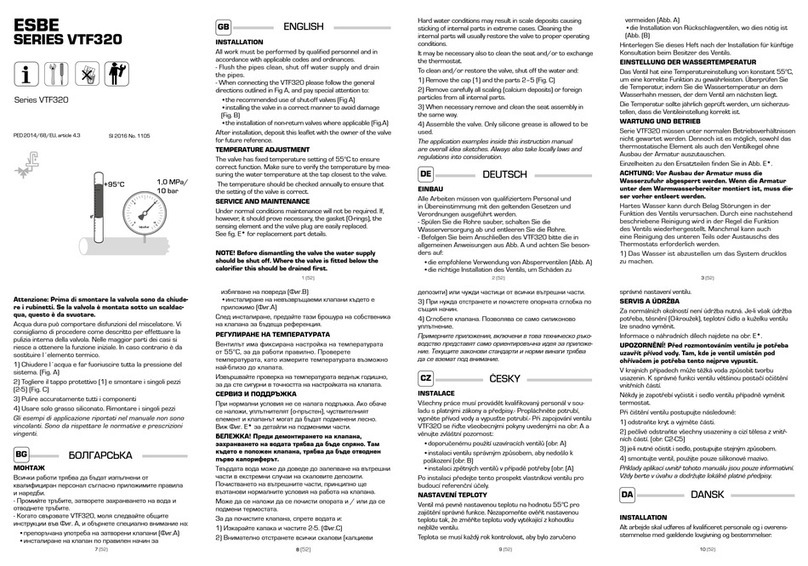

ESBE T4 Guide

For underoor heating with thermostatic

mixing valve.

ESBE T4 Pump Control

Set Installation and

Commissioning

Manual

2

Boxed and pre-assembled ready for

installation, including:

- Esbe Thermostatic mixing valve, adjustable from

20°C to 55°C (BS2164)

- Temperature gauge measuring mixed water

- 'A' rated Stuart Turner 25/6 Pump

- 1" Male swivel joints for fast connection to 1" Female

manifold tappings

- Nickel plated for improved appearance

- In-built non-return valve in ow elbow to enable

simple system lling when commissioning

- 3/4" Female BSP ow and return connections

- Suitable for any manifold with connections on

210mm centres (Also available in 200 and 225mm)

- Fully reversible oering with side or bottom entry

primary connections

2

3

1. General

1.1 Provides control of ow and return water temperature in an underoor heating

system. Pre-assembled and tested to ensure that it can be tted with minimum

on-site labour required and commissioned immediately once tted.

1.2 Designed to connect to the right-hand side of a manifold with 200mm as standard

(210 / 225mm optional) between the centres of the ow and return arms. The control

group can also be altered to t to the left-hand side of a manifold simply by turning the

control group elbows through 180 degrees, using the union ttings at the top and

bottom of the pump. The pump motor may need to be rotated through 180 degrees to

minimise the space occupied by the control group. Primary connections can be applied

from the side or bottom of the control pack.

2. Connections & Dimensions

3. Technical Data

Maximum static pressure 10 Bar

Maximum dierential pressure 3 Bar

Maximum temperature 95°C

Operating temperature range Adjustable between 20°C to 55°C (BS2164)

Inlet connections 2 x 3/4" BSPF

Outlet connections 2 x 1" BSPM swivel joint

Overall dimensions (mm) 290 h x 150 w x 140 h (Excluding item.3)

Kvs 3.4

Material Nickel plated brass

Power 18kW

Item Description Qty

1 Stuart Turner 25/6 Pump 1

2 ESBE Thermostatic Mixing Valve 1

3 Flow / Return Elbow 1

4 2mm Rubber Washer 2

5 1 1/2” Rapid Connection Nut 2

6 Elbow Flanged 1

7 3/4” Female BSP Flow and Return 2

8 3/8” Pocket 1

9 Temperature Gauge 1

10 Manifold Centre Distance Spacer 1

RReturn from Manifold / Flow to Heat

Source NA

H Flow from Heat Source NA

282

70

156

200*

1”M BSP

3/4”F BSP

*STANDARD CENTRE DISTANCE. 210MM & 225MM ALSO AVAILABLE

4

4. Pre-Installation

Prior to installation, manifold conguration must be determined as left or right handed.

5. Installation

5.1 Carefully remove from the packaging and check that all components are in place and that

nothing has been damaged during delivery.

5.2 The pump mixer is supplied for connection to the right-hand side of the manifold but can

be altered very simply for connection to the left-hand side. (See above)

5.3 To change orientation:

a) Remove swivel nut (7) from the TMV and move to opposite connection.

(These joints use o-ring seals and should not be overtightened)

b) Loosen the pump rotating nuts (5) on the elbow (6) and rotate through 180 degrees.

Re-tighten nut (5) after rotation.

5.4 Pipe connection orientation can be altered to suit using ow / return elbow (3) (supplied

loose) tted in either ow or return.

5.5 A swivel joint is tted to each side of the control group for connecting to the 1” F manifold

tappings. Carefully oer up and screw the swivel joint threads evenly into the

manifold using a 37mm A/F spanner: the use of a 31mm A/F spanner will also ensure

that the connection to the pump mixer is kept tight. The joints use o-ring seals and care

should be taken not to over-tighten them.

5.6 Once connected, nish securing the manifold and large area mixer to the wall if not

already completed.

5.7 The primary ow and return pipework can now be connected to the 2 x 3/4” F connections.

The ow connection is at the H and the return connection is at the R. It is recommended

that ball valves are used to isolate this pipework where it is connected to the pump mixer.

5

6. Commissioning

6.1 Filling the UFH system - The inbuilt non-return valve in the ow elbow allows you to ll

the circuits from the upper ow rail drain and ll valve only.

Be aware that you cannot get the benet of this feature when lling via the primary ow and

return connections or the lower manifold rail drain and ll valve.

6.2 The mixer, manifold and underoor circuits can now be lled and commissioned in

accordance with the manifold instructions. Prior to lling, a nal check of all joints should

be made to ensure no connections have loosened during transit.

6.3 The pump is supplied with a pre-connected 1m long 3-core lead assembly ready for

connection to the electrical control system. Ensure that the pump is lled and vented,

operate the control system to call for heat then select the desired pump setting.

The ESBE T4 control pack comes pre-assembled ready for installation, please ensure the

pump connections are tightened before commissioning. These connections are equipped

with EPDM seals.

7. Pump Settings

Buttons

All pump functions can be controlled with two buttons. The button switches the night

reduction function on and o. The button controls the operating modes. The selected

operating mode is shown in the clear eld of the LED indicator.

Temperature Setpoints in °C 20 25 30 35 40 45 50 55

5

Service Mode, setting the capacity range

The capacity range can be changed to 4m or 6m in

service mode.

• Pump must be disconnected from the 230V mains

voltage for at least 15 seconds

• Connect the pump to the 230V mains voltage

• Press the and buttons simultaneously with 3

seconds

• Release both buttons

• Select the capacity range with the button

• - 4 = 4m

• - 6 = 6m

• Pump must be disconnected from the 230V mains

voltage for at least 15 seconds

• Connect the pump to the 230V mains voltage

6

7. Pump Settings (Continued)

Technical data

6

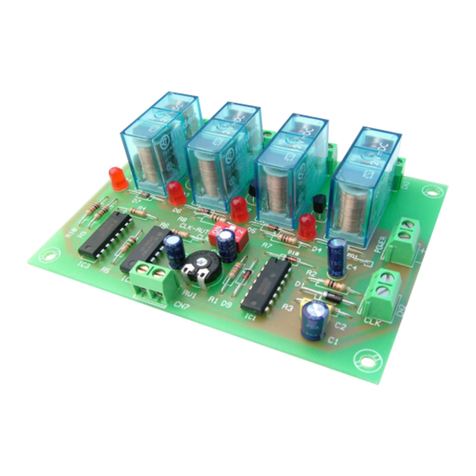

1 2

3

4

5

6

Malfunctions, causes and elimination

Maintenance work or repair attempts may only be performed by qualied personnel. Before

conducting maintenance, cleaning and repair work, disconnect the system from the power

supply and secure it against neing switched on again by unauthorized persons. At high water

temperatures and system pressures, wait for the pump to cool down beforehand. There is

risk of burns!

Control panel and LED display

1. Display of energy consumption in watts

2. Automatic night reduction display

3. Button for activating the automatic night reduction

4. Operating mode selection button

5. Display for activated AUTO Smartadapt mode

6. Display of the nine operating levels (characteristics)

of the pump

7

Our other UFH products:

Single-loop Pump Pack

The single-loop assembly is designed to connect

to new and existing heating systems with 15mm

compression connections for the flow and return.

The temperature switch supplies power to the pump

and will remain open until the existing heating

system water is above 40°c. Following this, the

switch will close activating the 'A' rated pump, which

will allow the TMV to mix flow and return to the

required UFH temperature. Unit is suitable for use

with floor areas of 60–90sqm or max output of 5kW.

Heat Pump Pack

The heat pump model is a pre-assembled unit that

is designed to be connected (via ball valves) to the

manifold. The unit is for use in applications where

water temperature controls are not required.

This is typically seen where heat pumps or low

temperature systems are utilised.

The unit includes an ‘A’ rated energy efficient pump

and is suitable for use with floor areas up to 250sqm

or a maximum output of 20kW. Primary flow and

return connections can be made from the side or

the bottom of the unit. This can also be mounted on

either the left- or right-hand side of the manifold.

7

Table of contents

Other ESBE Control Unit manuals

Popular Control Unit manuals by other brands

Doepke

Doepke DSU 8plus Installation and operating manual

Staubli

Staubli CombiTac direqt CTD-NET Assembly instructions

RF SOLUTIONS

RF SOLUTIONS DS-KAPPA-T868-2 quick start guide

Wilo

Wilo PLR Installation and operating instructions

MacroAir Technologies

MacroAir Technologies AirLynk Operation manual

SMC Networks

SMC Networks JSXFA Series manual