3 (4)

MULTIPLE INSTALLATIONS OF CIRCULATION UNITS ON THE WALL

If more than one Circulation Unit should be used we recommend the use of Serie

ESBE GMA manifold, with or without hydraulic separator.

When no storage tank or other components performing a hydraulic separation

are used, then manifold series GMA2XX should be installed.

FEED OF OPEN SYSTEMS

When installing in the feed of open systems, the safety supply must branch off

upstream of the circulation unit (EN 12828)

.COMMISSIONING CIRCULATION UNIT

WARNING! Before any intervention disconnect the electric mains through the

external mounted switch and depressurise!

WARNING! Depending on the operating status of the circulation pump or

system (fluid temperature), the entire Circulation Unit can become very hot.

Both primary and secondary loops have to be washed in order to remove any

possible mounting residuals.

Check that all connections are fully tightened: it´s important to check all

connections before filling the system in order to avoid leakages or sprays which

may be dangerous for the electric components. Open all shut-off valves and fill

the primary and secondary loop following the instructions for the tank, boiler etc.

During the filling phase recheck that all connections are tightened.

FILLING AND VENTING

Fill the buffer tank and the primary loop with an appropriated liquid, according

to the system instructions, respecting the limits of the components used. While

filling the device, open any vents situated in the circuit. Watch the system until

it reaches its correct operation condition. If pressure is not enough, adjust the

pressure by repeating the above procedure.

To avoid problems with cavitation, fill up the system to get sufficient pressure

head on the suction side of the circulation pump. The minimum pressure needed

depends on the temperature of the fluid. Recommended min pressure head at

fluid temperatures 50/95/110°C is 0,5/4,5/11 m respectively.

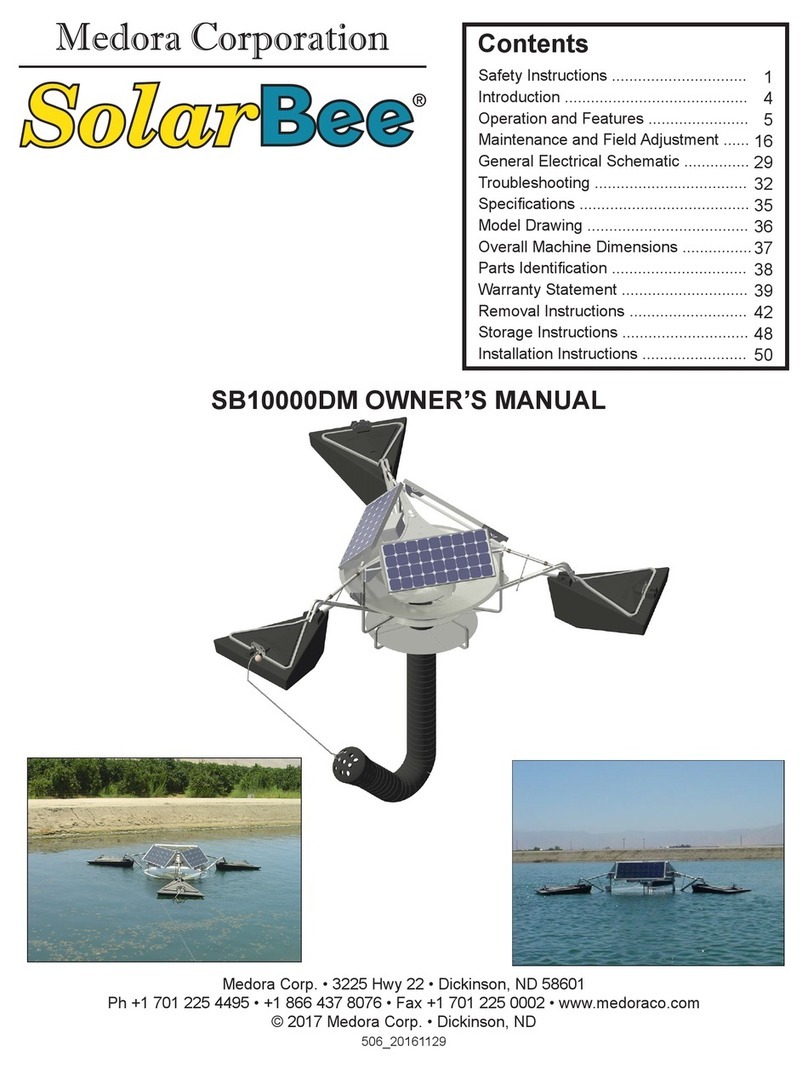

To make the filling and venting of the system easier it´s possible to force the check

valve on the return side of the unit, to an open position (default), see Fig. 1.

After a complete filling and venting, turn the screw on the check valve back to it´s

normal operating position, picture 2 and set the circulation pump operation to

recommended position.

COMMISSIONING IF USING LARGER SYSTEMS/CENTRAL REGULATING

Please read each product´s instruction manual.

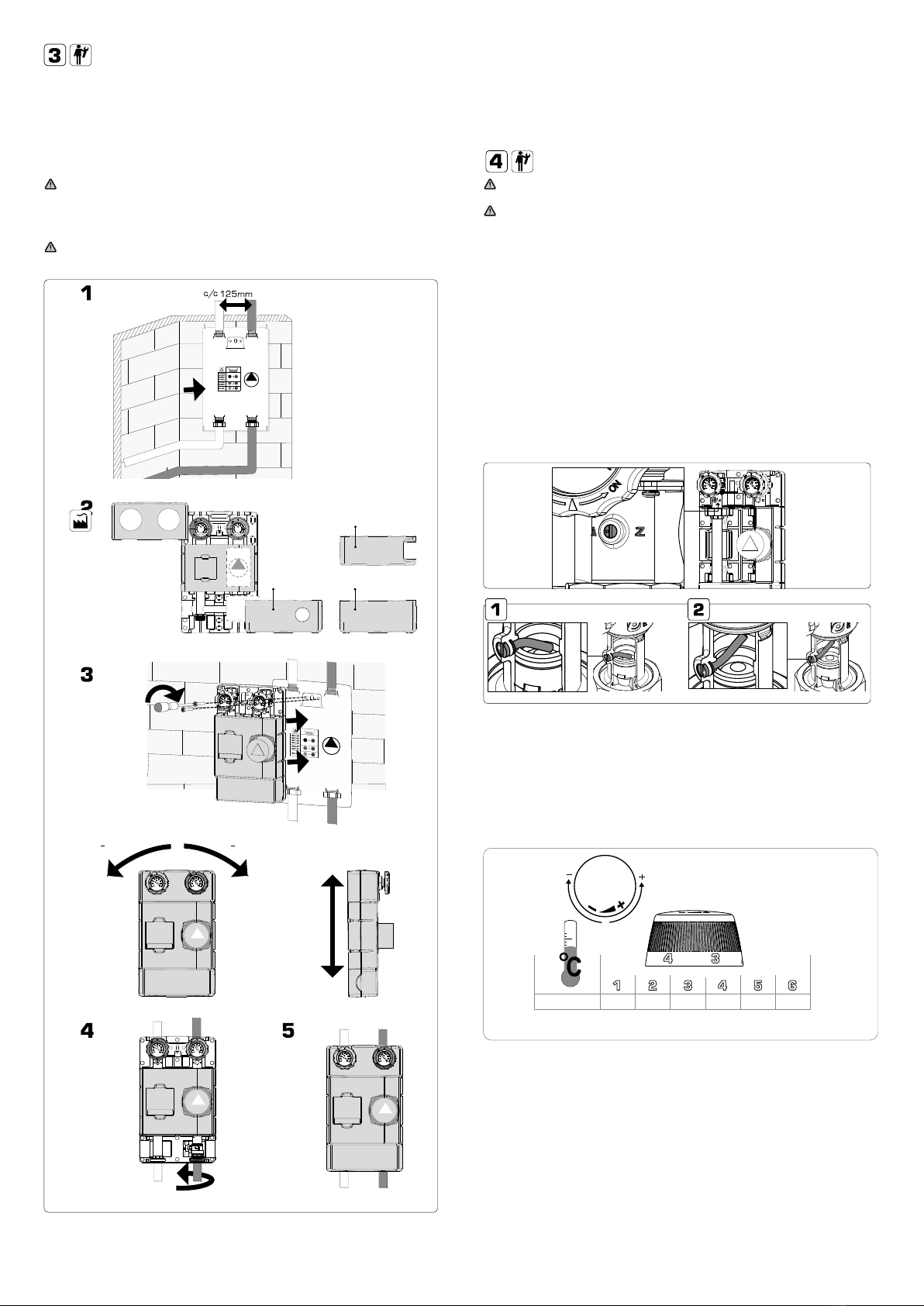

COMMISSIONING FIXED TEMPERATURE OPERATION

To set the mixed water temperature, see recommendations in the table below.

All temperature settings must be measured at suitable location with a

thermometer to have the correct mixing temperature of the valve.

20 - 60°C 25°C 35°C 40°C 46°C 52°C 58°C

The temperatures are only a reference and might be different under certain conditions.

However the range will be kept.

HYDRAULIC INSTALLATION

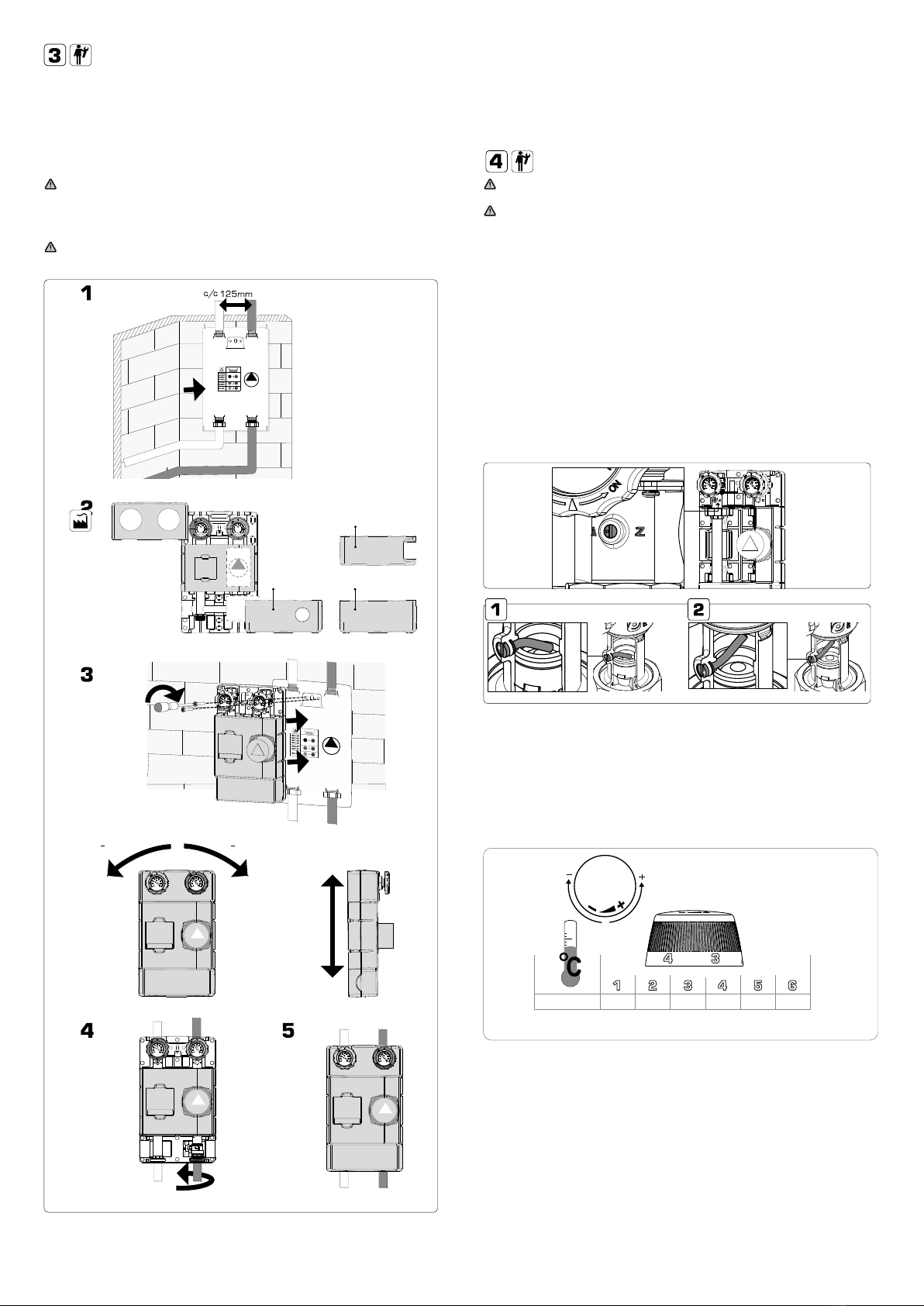

SINGULAR INSTALLATION ON THE WALL

Install the appliance on a solid wall.

1. Choose the correct position for the piping and drilling by usage of the Mounting

template supplied with the package. Drill the holes in the wall for your installation

purposes. Take care not to damage any electrical wiring or existing piping.

2. Detach parts of the Circulation Unit's insulation shell.

3. Mount the Circulation Unit on the wall with the supplied screws and plugs.

Ensure that the pipes are completely in line and lock them firmly. *Please note

that to achive best performance there should be no tilt at all.

WARNING! For all installations, verify that the plugs are suitable for the kind of

wall chosen. Otherwise replace them with a special model. To value the suitability of

the plugs please consider the structure of the wall, all the units connected and the

weight of the water.

4. Connect the pipings.

WARNING! Equipment might be damaged when incorrect usage of tools.

5. Remount the insulation shell parts (and actuator/controller).

GDA100

180˚

>

180˚

>

40 - 50 Nm

GRF100

GFA100

0º

*