eschmann SES2000 User manual

SES2000

A UT O CLAVE

Service Manual

ST-SM8l

699215

Service Manual

Introduction

Description

Maintenance

Illustrated parts list

Read these Instructions before use

Keep these instructions in a safe convenient place for future reference. Read in conjunction

with the Publications detailed in Section 1.5.

This Service Manual applies to the following Autoclave REF numbers. (Note: In the parts list

section reference is also made to parts required for earlier versions) :-

SES 2000 STANDARD (from Serial Number - SCB8B0000, or SED8B0000 for non-CE)

without printer : 87-028-04 87-028-20 87-028-36 87-029-05 87-029-13 87-029-21

87-029-37 87-029-45 87-029-54 87-029-62 87-029-70 87-029-78

87-029-86 87-030-03 87-030-11 87-030-27 87-030-43 87-030-60

87-031-03 87-031-68

with printer : 87-028-12 87-028-28 87-028-44 87-029-26 87-030-65 87-031-11

87-031-76

SES 2000 LONG (from Serial Number - LSCB8B0000, or LSED8B0000 for non-CE)

without printer : 87-028-53 87-028-69 87-028-85 87-028-90 87-028-97 87-029-29

87-029-94 87-030-70 87-031-19 87-031-84 87-020-05 87-022-01

87-022-17 87-020-21 87-022-49 87-022-66

with printer : 87-028-61 87-028-77 87-030-75 87-031-27 87-031-92 87-020-13

87-022-09 87-022-25 87-020-29 87-022-58 87-022-74

(Note: The alpha parts of the SN are significant.)

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and

assistance during normal office hours.To avoid delays when making enquires, please quote the

Model and Serial Number of your Autoclave. Please ensure you include all alpha and numeric

digits of the Serial Number. (NOTE:The Serial Number Plate is located inside the door in the top

left hand corner).

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing,West Sussex BN15 8TJ, England.

Tel: +44 (0) 1903 765040. Fax: +44 (0) 1903 875711.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents and Trade marks

The ESCHMANN name and logo are trade marks of Eschmann Holdings Limited.

“Eschmann Equipment” is a trading name of Eschmann Holdings Limited.

“SES2000” is a trade mark of Eschmann Holdings Limited.

Patents : Patents Pending plus - Pat. US5090033 and Pat. GB2238407

Copyright © 2008 Eschmann Holdings Limited

All rights reserved. This booklet is protected by copyright. No part of it may be reproduced, stored in a

retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise without written permission from Eschmann Holdings Limited.

The information in this publication was correct at the time of going to print. The Company, however,

reserves the right to modify or improve the equipment referred to.

The CE marking affixed to the product certifies that it complies with the

European Medical Devices Directive 93/42/EEC and related legislation.

ST-SM8l November 2008

ST-SM8l Page 3 of 43

SES 2000 AUTOCLAVE

CONTENTS

Page

Contents .. .. .. .. .. .. .. .. 3

Technical data .. .. .. .. .. .. .. 4

PART 1 INTRODUCTION

General .. .. .. .. .. .. .. .. 6

Associated publication .. .. .. .. .. 6

Servicing .. .. .. .. .. .. .. .. 6

PART 2 DESCRIPTION

General .. .. .. .. .. .. .. .. 7

Operating features .. .. .. .. .. .. 7

Operation cycle .. .. .. .. .. .. 9

Operation .. .. .. .. .. .. .. 9

Display messages .. .. .. .. .. .. 10

Error indication .. .. .. .. .. .. 11

General .. .. .. .. .. .. .. 11

Overheating .. .. .. .. .. .. 11

PART 3 MAINTENANCE

Fuses .. .. .. .. .. .. .. .. 15

Fault diagnosis and table .. .. .. .. 15

Parts replacement and adjustment .. .. 20

Removing cover .. .. .. .. .. .. 20

Refitting cover .. .. .. .. .. .. 20

Thermal fuse .. .. .. .. .. .. 20

Transformer.. .. .. .. .. .. .. 20

Controller board .. .. .. .. .. .. 20

Pressure door lock .. .. .. .. .. 20

Air valve .. .. .. .. .. .. .. 21

Door interlock switch .. .. .. .. .. 21

Solenoid door lock (CE only) .. .. .. 22

Heater cycling thermostat .. .. .. .. 22

Temperature sensors .. .. .. .. .. 22

Fill and Discharge valves .. .. .. .. 22

Solid state relay (Non-CE) .. .. .. 22

Solid state relay (CE only) .. .. .. 23

Mechanical relay (CE only) .. .. .. 23

Heating element .. .. .. .. .. .. 23

Printer interface board .. .. .. .. 23

Voltage regulators .. .. .. .. .. 23

Door seal .. .. .. .. .. .. .. 23

Pressure gauge .. .. .. .. .. .. 23

Discharge line filter .. .. .. .. .. 24

Printer .. .. .. .. .. .. .. 24

Special operating modes .. .. .. .. 24

Demonstration mode .. .. .. .. .. 24

Engineering mode .. .. .. .. .. 24

Set-up mode .. .. .. .. .. .. 25

Switch identities and function .. .. .. 25

Power-on modes .. .. .. .. .. 25

Page

Set-up procedure .. .. .. .. .. 26

Autoclave without printer .. .. .. 26

Autoclave with printer .. .. .. .. 26

Setting the Autoclave Serial Number 26

Entering the Autoclave Serial Number 27

Entering the date and time.. .. .. 27

Errors and error clearing .. .. .. .. 28

General .. .. .. .. .. .. .. 28

Control sensor selection .. .. .. .. 28

Autocheck .. .. .. .. .. .. .. 28

Routine Autoclave Calibration .. .. .. 28

General .. .. .. .. .. .. .. 28

Calibration procedure .. .. .. .. 29

Safety valve .. .. .. .. .. .. .. 29

Operational test .. .. .. .. .. .. 30

PART 4 ILLUSTRATED PARTS LISTS

Pipes and fittings, latest models .. .. .. 30

Illustrated parts list 1: Pipes and valves .. 31

Illustrated parts list 2: General spares .. 33

Illustrated parts list 3:

Heater and process controls .. .. .. .. 35

ILLUSTRATIONS

Fig. 1 SES 2000 Autoclave .. .. .. .. 6

Fig. 2 Autoclave General Arrangement .. 12

Fig. 3 Autoclave: Pipes and Valves .. .. 13

Fig. 4 Autoclave: Heater & Process Controls 14

Fig. 5 Door interlock microswitch .. .. 21

Fig. 6 Filter unit disassembly .. .. .. 24

Fig. 7 Switch identities and function .. .. 25

Fig. 8 Autoclave Controller boards .. .. 30

Fig. 9 Pipes and valves .. .. .. .. 32

Fig. 10 General spares .. .. .. .. .. 34

Fig. 11 Heater and process controls .. .. 36

Fig. A1-A5 Autoclave printer details .. .. 40

TABLE

Fault Diagnosis table .. .. .. .. .. 15

APPENDIX A

Autoclave printer .. .. .. .. .. .. 39

APPENDIX B

Schematic - Pipes and Valves .. .. .. 41

APPENDIX C

Schematic - Wiring .. .. .. .. .. 42

Page 4 of 43 ST-SM8l

SES 2000 AUTOCLAVE

TECHNICAL DATA

(Standard Version)

Electrical Data

Supply 220/230/240V a.c. at 50/60Hz

110V a.c. at 50/60Hz

Nominal Loading @ 230V - 2kW (8.7A)

@ 110V - 1.4kW (12.7A)

Fuses Chassis

230/240V 10A, Part No.380003, (x2)

400mA, Part No.696181, (x1)

220V 13A, Part No.380002, (x2)

400mA, Part No.696181, (x1)

110V 16A, Part No.111940, (x2)

800mA, Part No.380004, (x1)

Relay board

T2A, 250V (x1)

Safety standards

IEC 1010-1:1990

IEC 601-1:1977

BS5724:Part 1:1979

ESCHLE (Second Edition 1986)

IEC 601-1-2 (1993)

Sterilizing Data

Sterilizing time

At 134/137°C 3 mins 20 sec.

At 121/124°C 15 mins

Typical overall cycle 134°C : 13 minutes

time (D indicates 134°C : 30 minutes (D)

drying included) 121°C : 24 minutes

121°C : 41 minutes (D)

Note: Overall cycle times may vary depending

on machine and loading conditions.

Nominal Operating pressures:

134°C cycle - 3.14 bar abs

121°C cycle - 2.11 bar abs

Water reservoir

capacity 2.0 litres

Dimensions

Autoclave Width 460mm

Length 461mm

Height 360mm

Chamber Diameter 200mm

Length 348mm (max)

Capacity 10.6 litres

Trays Width 183mm

Length 282.6mm

Height l7mm

Tray Loading 1.5 kg per tray

Weight (approx.)

Net 27.5kg

Shipping 32.0kg

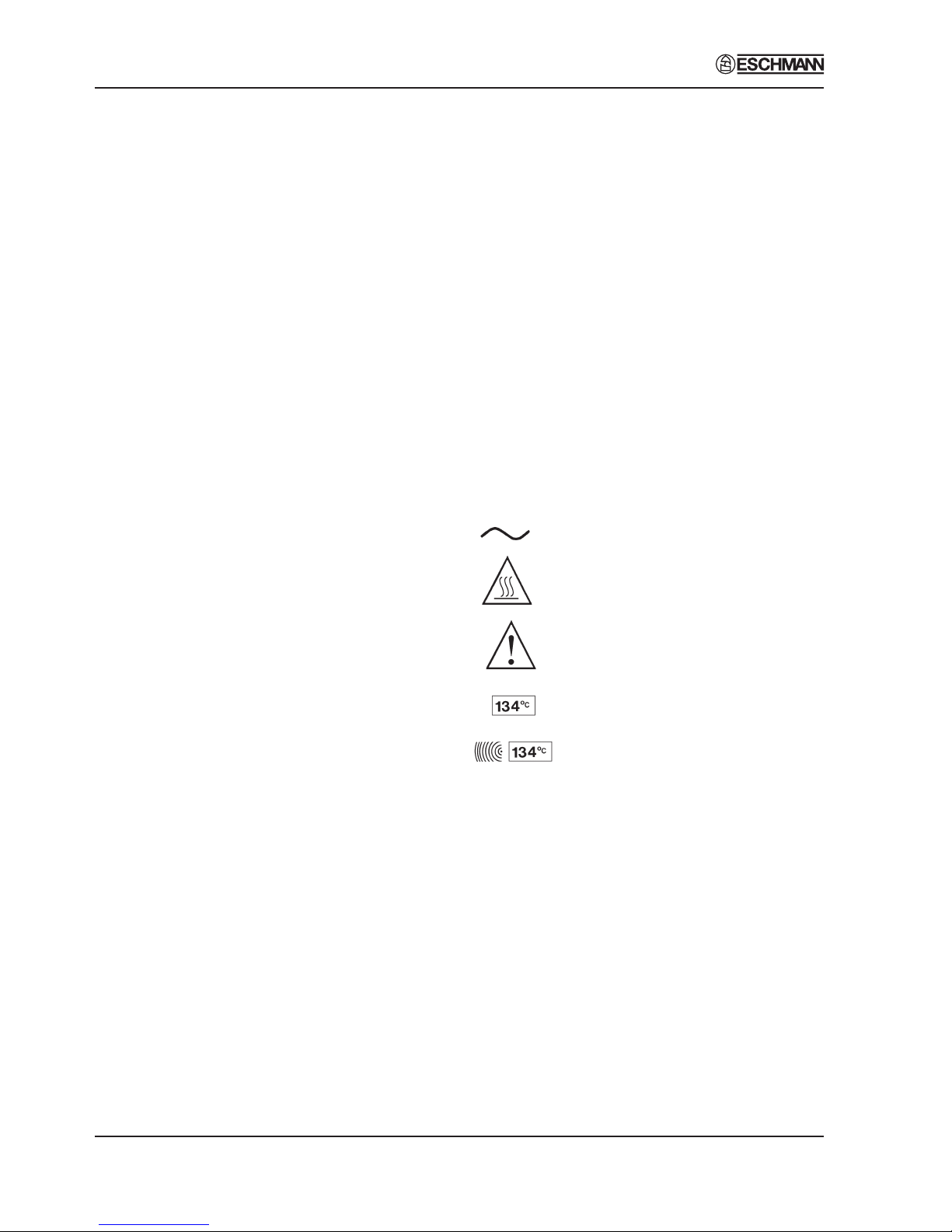

Symbols

For use with alternating current

Caution Hot Surface

Caution refer to accompanying

documents

Sterilising cycle without drying phase

(NB. temperature = cycle temperature)

Sterilising cycle with drying phase

(NB. temperature = cycle temperature)

ST-SM8l Page 5 of 43

SES 2000 AUTOCLAVE

Electrical Data

Supply 230Vac at 50/60Hz

Nominal Loading @ 230V - 2.75kW (12A)

Fuses Chassis

15A, 250V, (x2) Part No. 301871

400mA, Part No. 696181

Relay board

T2A, 250V (x1)

Safety standards

IEC1010-1 (1990)

IEC 601-1-2 (1993)

Sterilizing Data

Sterilizing time

At 134/137°C 3 mins 20 sec.

At 121/124°C 15 mins

Typical overall cycle 134°C : 13 minutes

time (D indicates 134°C : 30 minutes (D)

drying included) 121°C : 24 minutes

121°C : 41 minutes (D)

Note: Overall cycle times may vary depending

on machine and loading conditions.

Nominal Operating pressures:

134°C cycle - 3.14 bar abs

121°C cycle - 2.11 bar abs

Water reservoir

capacity 2.0 litres

Dimensions

Autoclave Width 460mm

Length 650mm*

Height 360mm

* Feet spaced to fit 600mm worktop

Chamber Diameter 200mm

Length 500mm (max)

Capacity 15.6 litres

Trays Width 180mm

Length 457mm

Height 24mm

Tray Loading 3.0 kg per tray

Weight (approx.)

Net 35.5kg

Shipping 40kg

Symbols

For use with alternating current

Caution Hot Surface

Caution refer to accompanying

documents

Sterilising cycle without drying phase

(NB.temperature = cycle temperature)

Sterilising cycle with drying phase

(NB.temperature = cycle temperature)

TECHNICAL DATA

(Long Version)

Other manuals for SES2000

1

Table of contents