Page 4 of 34

LISTofFIGURES

PAGE

Figure 1: Temporary set up in shipping crate ....................................................................................................12

Figure 2: Connect Power Supply to SuiteSentry Single Screener in Shipping Crate .....................................12

Figure 3: SuiteSentry Single Screener standing – Ready to TEST Location....................................................12

Figure 4: Drill Locations for Mounting Brackets ...............................................................................................14

Figure 5: Typical Installation ...............................................................................................................................14

Figure 6.1, 6.2, 6.3, 6.4 Fastening Wall Toggler to Wall ...................................................................................15

Figure 7: Fastening Wall Toggler through Mounting Block and into wall. ...................................................... 16

Figure 8: Exploded view of Mounting Block, toggle, screw and washer into wall...........................................16

Figure 9: a, b, c, d, Exploded views of Mounting Block+Mtg Block Extension over Rub Rail. ......................16

Figure 10: Fastening Mounting Block to SuiteSentry Single Screener ...........................................................17

Figure 11: Completed Installation.......................................................................................................................17

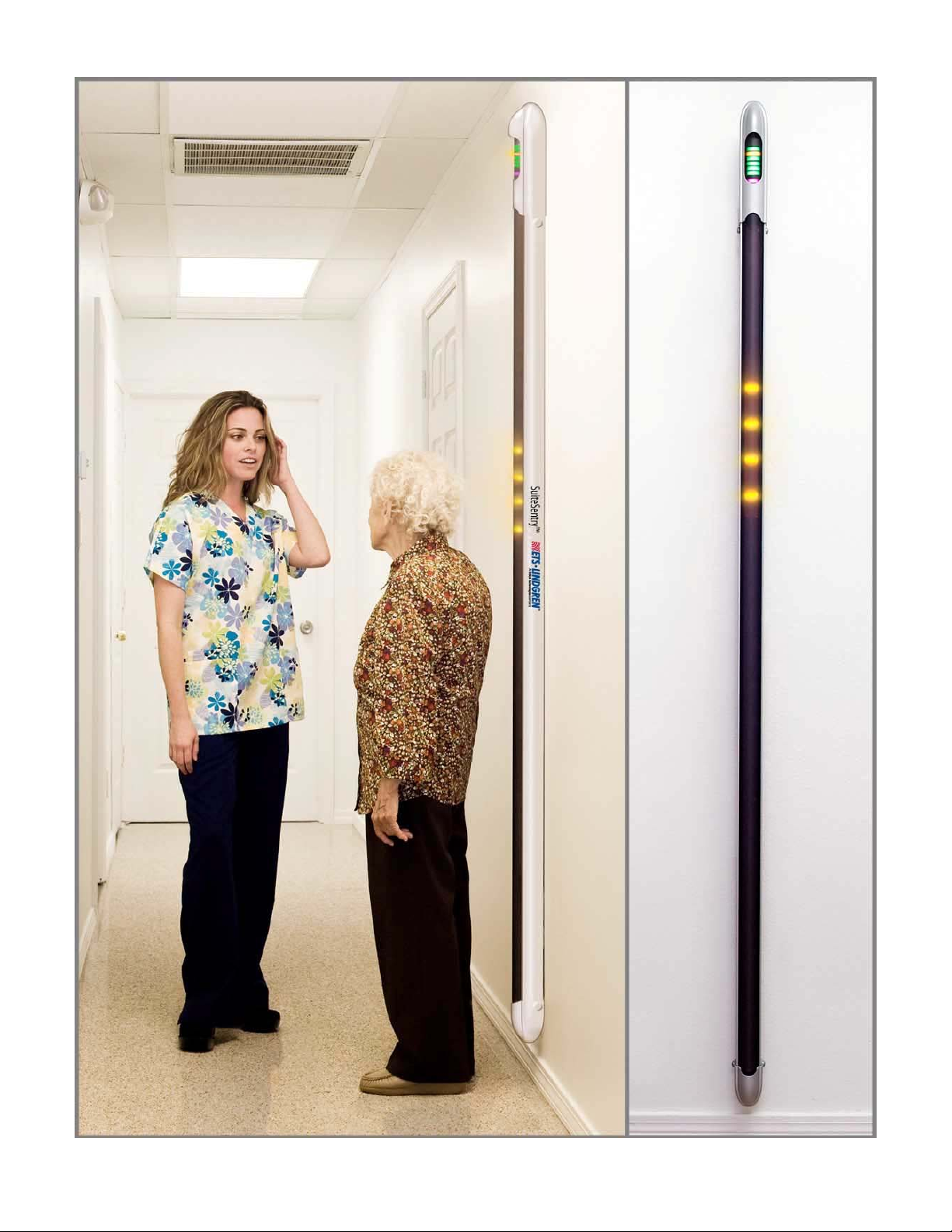

Figure 12: SuiteSentry Single Screener - 3 Modes of Operation......................................................................20

Figure 13: a., b., c. - SuiteSentry Single Screener Operation and Usage .......................................................22

Figure 14: SuiteSentry Single Screener Controls.............................................................................................23

Figure 15: SuiteSentry Single Screener top cap and PIR access/adjustment.................................................25

Figure 16: Typical Installation .............................................................................................................................28

Acronyms used in this manual

ACR: .........American College of Radiology

TJC: ..........The Joint Commission

Zone II: .....ACR definition of area immediately outside the MRI control room

Zone III: ....ACR definition of area immediately outside the MRI magnet room

Zone IV: ....ACR definition of area inside the MRI magnet room

FMD: .........Ferromagnetic Detector

LED: ..........Light Emitting Diode; electronic replacement for lamp

PIR: ...........Passive Infra-Red-Detects body heat and motion and

...................enables SuiteSentry Single Screener to go into Active Mode

Symbols and Terms

NOTE: The following Symbols and Terms may be used in this manual:

Damage in Transportation

All packages should be closely examined at time of delivery. If damage to outer package is visible,

make certain the notation “damaged in shipment” was written on all copies of the freight or express

bill when delivery is accepted by your receiving agent. Whether noted or concealed, damage must

be reported to the carrier immediately upon discovery, or in any event, within 14 days after

receipt, and the contents and containers held for inspection by the carrier. Transportation

company will not pay a claim for damage if an inspection is not requested within this 14 day

period. Transport this product for a period not to exceed 4 weeks. The following environmental

conditions must be adhered to in order to avoid damage to the product.

Ambient Temperature: -34°C (-11°F) to +60°C (+140°F)

Relative Humidity: 15% TO 95% (Non-Condensing)

Atmospheric Pressure: 50 kPa (0.5 atm) to 127 kPa (1.25 atm)

WARNING!

Warning statements identify conditions or practices that could result in injury or death.

CAUTION!

Caution statements identify conditions or practices that could result in damage to the product or

other

ro

ert

.

TIP or HINT:

The following is a recommendation and may help simplfy efforts during the installation.