esera automation 11302-U User manual

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA-Automation or E-Service GmbH. Errors and technical modification subject to change. ESERA-Automation, E-Service GmbH 2019

www.esera.de 11302-U V1.5 R1.2 Manual Page 1 of 6

Art. No. 11302-U

User Guide

1-Wire Bus Coupler USB V3

Galvanic separation of the 1-Wire network and the

computer

LEDs for power and 1-Wire activity

Top-hat rail case for switchboard assembly

Power supply of 9 –30 VDC via external power adapter

(not included in scope of delivery)

Connection via screw terminals

Easy software-based control

Low space requirement in the switchboard

Easy to assemble

1 Introduction

Before you start assembling the 1 Wire Bus Coupler USB

V3 and before you take the device into operation, please

read these assembly and operating instructions carefully to

the end, especially the section referring to the safety notes.

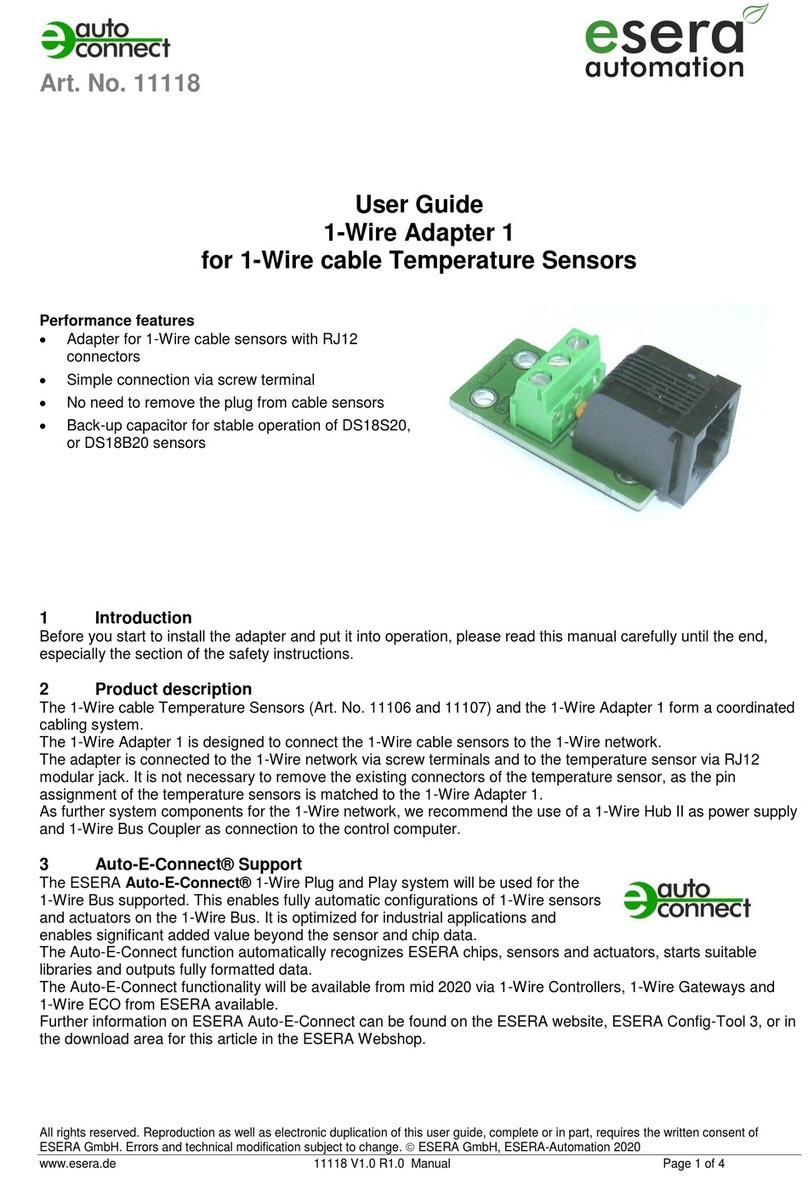

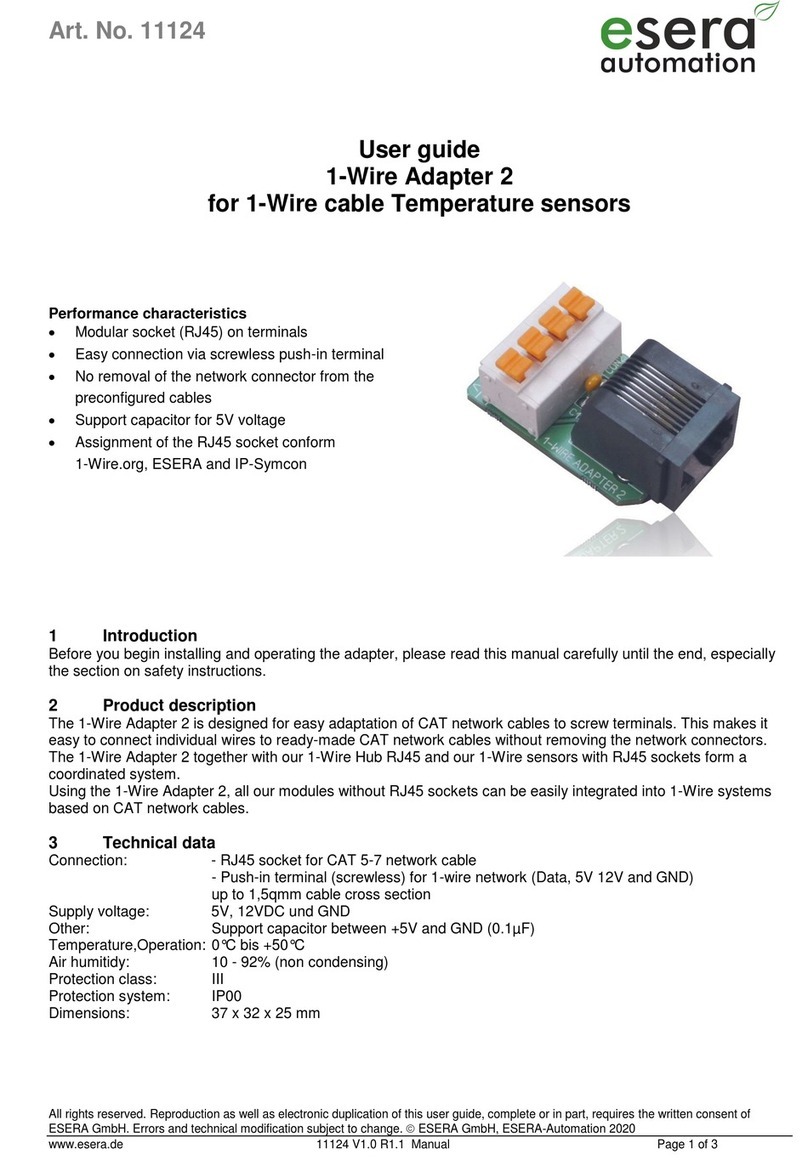

2 Product description

The 1 Wire Serial Bus Coupler USB V3 establishes a stable, electrically isolated connection among a 1-Wire

network and a computer. Special feature of the 1-Wire Bus Coupler USB V3 is an external voltage supply. Thus,

operating safety of the data connection to a computer will significantly be enhanced. Issues caused by unreliable

USB voltage supplies will be avoided. The use of more expensive USB hubs is no longer necessary.

The 1-Wire output of the bus coupler is isolated among the USB data supply and the voltage supply. Thus,

ground loops or EMC emissions and grounding issues from a computer to the 1 Wire network are efficiently

prevented. The isolation significantly reduces stray radiations ("electric smog") in living areas and enhances

electric safety among the systems. For galvanic isolation state-of-the-art high-speed optocouplers and special

isolated power adapters are being used. Even the 1-Wire „data“ LED is isolated controlled by optical coupler

The 1-Wire component DS2480 from Dallas/Maxim is used within the 1-Wire Bus Coupler. This component,

combined with the complex internal voltage supply, is the basis for a very stable 1-Wire network. The DS2480

component supports the „Strong Pull Up“ function and is thus predestined for the use in large 1 Wire networks as

well.

For the voltage supply, the 1-Wire Bus Coupler has a wide-range input of 9-32VDC and is thus equally suitable

for 12V systems and typically industrial 24VDC supplies. You can find compatible top-hat rail power adapters or

socket power adapters in our webshop.

Individual 1-Wire sensors can be connected directly. For major 1-Wire networks it is recommended to use a

1-Wire Hub III.

Please refer to the connection plan for further details in regards to the electric connection.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA-Automation or E-Service GmbH. Errors and technical modification subject to change. ESERA-Automation, E-Service GmbH 2019

www.esera.de 11302-U V1.5 R1.2 Manual Page 2 of 6

3 Technical data

1-Wire Bus

Interface: 1-Wire Bus with DS2480 bus master component (5 V, load und data)

Protection circuits: ESD- and reverse polarity protection

Connection: Screw terminals (up to 2,5qmm cross wire section)

Output voltage: 5 V (+/-10 %), maximum 500 mA

Isolation: Galvanic separation between data input, voltage supply

and 1-Wire interface

Isolation: minimally 500VDC between PC interface and 1-Wire bus

Voltage supply: 9-30VDC

Power consumption: maximally 500mA

USB Interface

Connection: USB type B connection jack

Interface: USB 1.1, FTDI 232RL Chip

4 Ambient Conditions

Temperature, operation: 0 °C up to +60 °C

Air humidity: 10 –92 % (non-condensing)

Dimensions: 35 x 90 x 70mm (WxHxD)

Protection class: III

Protection type: IP20

Insulation: 500 VAC output to 1-Wire Bus, 250 VAC output to output

5 Conformity

EN 50090-2-2

EN 61000-4-2, ESD

EN 61000-4-3, HF

EN 61000-4-4, Burst

EN 61000-4-5, Surge

EN 61000-6-1, Fault-free operation

EN 61000-6-3, Stray radiations

RoHS

6 Connection plan

Connection 1-Wire Bus

(module topside)

7+8 = 1-Wire load

9+10 = 1-Wire data

11+12 = + 5 V output

Voltage supply of 9 –30 VDC

(module bottom side)

1 = Voltage Supply negative

2 = Voltage Supply positive

3-6 = not assigned

Note: Further information and tips for the 1-Wire bus system can be found in our webshop at

https://www.esera.de/1-wire-grundlagen/ or in our eBook at (https://www.esera.de/service-

support/dokumentation/352/grundlagen-1-wire-bus-ebook?number=11901)

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA-Automation or E-Service GmbH. Errors and technical modification subject to change. ESERA-Automation, E-Service GmbH 2019

www.esera.de 11302-U V1.5 R1.2 Manual Page 3 of 6

Art. No. 11302-U

7 Connection - Example

Combination of 1–Wire Bus Coupler, 1-Wire Hub III, top-hat rail case, sensor and bus terminator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA-Automation or E-Service GmbH. Errors and technical modification subject to change. ESERA-Automation, E-Service GmbH 2019

www.esera.de 11302-U V1.5 R1.2 Manual Page 4 of 6

8 LED display

The module has two LED displays. The function of the displays is explained in the following

Display

Label

Function

LED Green

Power

Display for supply voltage via external power adapter

LED Green

Data

Flashes in the case of 1-Wire activity

Permanently flashes in the case of the 1-Wire Data Line short-

circuit

9 Software

We recommend the use of the latest FTDI- and TEMX driver. We do not recommend the use of any driver that

has beta status. Once the FTDI driver is installed, the 1-Wire Bus Coupler with USB interface is available as

software-based serial bus coupler. The 1 Wire Bus Coupler USB can be operated with any software, that is

aligned to operate the COM Port adapter „DS9097“.

The 1-Wire Bus Coupler is being operated with 9600 Baud and settings of 8 data bits, no parity and 1 stop bit. As

1-Wire interface for the 1-Wire Bus Coupler a Maxim Chip DS2480 is used.

The 1-Wire Bus Coupler was tested with the following software:

IP-Symcon, 1-Wire Viewer (Windows), FHEM

Note: The „Strong Pullup“ function must be activated.

10 USB-Connection cable

Please note, that the cable length is limited to 5 m in maximum for the USB data cable among the 1-Wire Bus

Coupler and the PC interface. To bridge USB cable sections of 30 to 50 meters, USB long distance extension

cables are offered in our webshop. These long distance extension cables use a CAT5, CAT6 or CAT7 network

cable for data transfer. This network cable cannot be connected with a TCP/IP network or a hub/switch network.

11 Windows power management for USB ports

As soon as the Virtual Com Port Driver is installed, the 1-Wire Bus Coupler USB may break down after several

hours of operation. This may be caused by the Windows Power Management settings for USB ports. The

energy saving mode is activated in Windows basic settings. To operate the 1-Wire Bus Coupler USB, these

settings must be deactivated.

In Windows7, WHS and Server 2008, the drivers are to be installed with admin rights.

Windows 7 Energy Options You will find the Windows 7 energy options under:

Start / Control Panel / Energy Options

Windows 7 offers two options: Balanced and Energy saving

mode. The recommended mode is Balanced where it

focusses on PC performance (not energy saving). Under

Advanced Settings, you have several setup options.

USB, Setup for selective operation:

Uncheck the box. The port will then be permanently

enabled.

In addition we recommend the use of the „Presenter View“as

the computer will operate with no screensavers. Further

information can be found at:

http://www.thewindowsclub.com/presentation-settings-in-

windows-7

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA-Automation or E-Service GmbH. Errors and technical modification subject to change. ESERA-Automation, E-Service GmbH 2019

www.esera.de 11302-U V1.5 R1.2 Manual Page 5 of 6

Art. No. 11302-U

12 Operating conditions

The operation of the assembly group can take place only on condition of observing the required voltage and the

ambient conditions. The operating position of the device is irrelevant. The device is meant to be used in dry

areas free of dust.

Should condensed water build up within the sensor, an acclimatization period of at least 2 hours must be met.

The components can be operated only under the supervision of an electrically skilled person. Assembly groups

and components do not belong into the hands of children.

In industrial facilities, the accident prevention regulations of the federation of industrial professional associations

for electrical installations and equipment must be observed.

Do not operate the components in an environment with inflammable gases, vapors or dusts or in an environment

where such gases, vapors or dusts may occur.

13 Assembly

The mounting place must be protected against moisture. The module may only be used in dry indoor rooms or in

protected outside areas. The device is designed for fixed installation within a switching cabinet.

14 Disposal Note

Do not dispose of this device in the household waste. Electronic devices must be disposed

in accordance with directives for disposing of waste electrical and electronic equipment at

local collection points for electronic waste material.

15 Safety Instructions

When using products that come into contact with electrical voltage, the valid VDE regulations must be

observed, especially VDE 0100, VDE 0550/0551, VDE 0700, VDE 0711 and VDE 0860

All final or wiring work must be carried out with the power turned off.

Before opening the device, always unplug or make sure that the unit is disconnected from the mains.

Components, modules or devices may only be put into service if they are mounted in a contact proof housing. During

installation they must not have power applied.

Tools may only be used on devices, components or assemblies when it is certain that the devices are disconnected

from the power supply and electrical charges stored in the components inside the device have been discharged.

Live cables or wires to which the device or an assembly is connected, must always be tested for insulation faults or

breaks.

If an error is detected in the supply line, the device must be immediately taken out of operation until the faulty cable

has been replaced.

When using components or modules it is absolutely necessary to comply with the requirements set out in the

accompanying description specifications for electrical quantities.

If the available description is not clear to the non-commercial end-user what the applicable electrical characteristics

for a part or assembly are, how to connect an external circuit, which external components or additional devices can

be connected or which values these external components may have, a qualified electrician must be consulted.

It must be examined generally before the commissioning of a device, whether this device or module is basically

suitable for the application in which it is to be used.

In case of doubt, consultation with experts or the manufacturer of the components used is absolutely necessary.

For operational and connection errors outside of our control, we assume no liability of any kind for any resulting

damage.

Kits should be returned without their housing when not functional with an exact error description and the

accompanying instructions. Without an error description it is not possible to repair. For time-consuming assembly or

disassembly of cases charges will be invoiced.

During installation and handling of components which later have mains potential on their parts, the relevant VDE

regulations must be observed.

Devices that are to be operated at a voltage greater than 35 VDC / 12mA, may only be connected by a qualified

electrician and put into operation.

Commissioning may only be realized if the circuit is built into a contact proof housing.

If measurements with an open housing are unavoidable, for safety reasons an isolating transformer must be installed

upstream or a suitable power supply can be used.

After installing the required tests according to BGV A3 / Betriebssicherheitsverordnung must be performed.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA-Automation or E-Service GmbH. Errors and technical modification subject to change. ESERA-Automation, E-Service GmbH 2019

www.esera.de 11302-U V1.5 R1.2 Manual Page 6 of 6

16 Warranty

ESERA-Automation (E-SERVICE GmbH) guarantees that the goods sold at the time of transfer of risk to be free from material

and workmanship defects and have the contractually assured characteristics. The statutory warranty period of two years

begins from date of invoice. The warranty does not extend to the normal operational wear and normal wear and tear.

Customer claims for damages, for example, for non-performance, fault in contracting, breach of secondary contractual

obligations, consequential damages, damages resulting from unauthorized usage and other legal grounds are excluded.

Excepting to this, ESERA-Automation accepts liability for the absence of a guaranteed quality resulting from intent or gross

negligence. Claims made under the Product Liability Act are not affected.

If defects occur for which the ESERA-Automation is responsible, and in the case of replacement goods, the replacement is

faulty, the buyer has the right to have the original purchase price refunded or a reduction of the purchase price. ESERA-

Automation accepts liability neither for the constant and uninterrupted availability of the ESERA-Automation or for technical or

electronic errors in the online offer.

We develop our products further and we reserve the right to make changes and improvements to any of the products

described in this documentation without prior notice. If you need documentation or information about older product versions,

17 Trademarks

All mentioned designations, logos, names and trademarks (including those which are not explicitly marked) are trademarks,

registered trademarks or other copyright or trademarks or titles or legally protected designations of their respective owners

and are hereby expressly recognized as such by us. The mention of these designations, logos, names and trademarks is

made for identification purposes only and does not represent a claim of any kind on the part of ESERA-Automation, E-Service

GmbH on these designations, logos, names and trademarks. Moreover, from their appearance on ESERA-Automation

webpages it cannot be concluded that designations, logos, names and trademarks are free of commercial property rights.

ESERA is a registered trademark of E-Service GmbH.

18 Contact

ESERA-Automation, E-Service GmbH

Adelindastrasse 20

87600 Kaufbeuren

GERMANY

Tel.: +49 8341 999 80-0

Fax: +49 8341 999 80-10

www.esera.de

WEEE-Number: DE30249510

Table of contents

Other esera automation Adapter manuals