esera automation ECO 208 PRO User manual

Art.No.11603-48

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 1 of 18

User Guide

ECO 208 PRO

Professional 1-Wire Controller

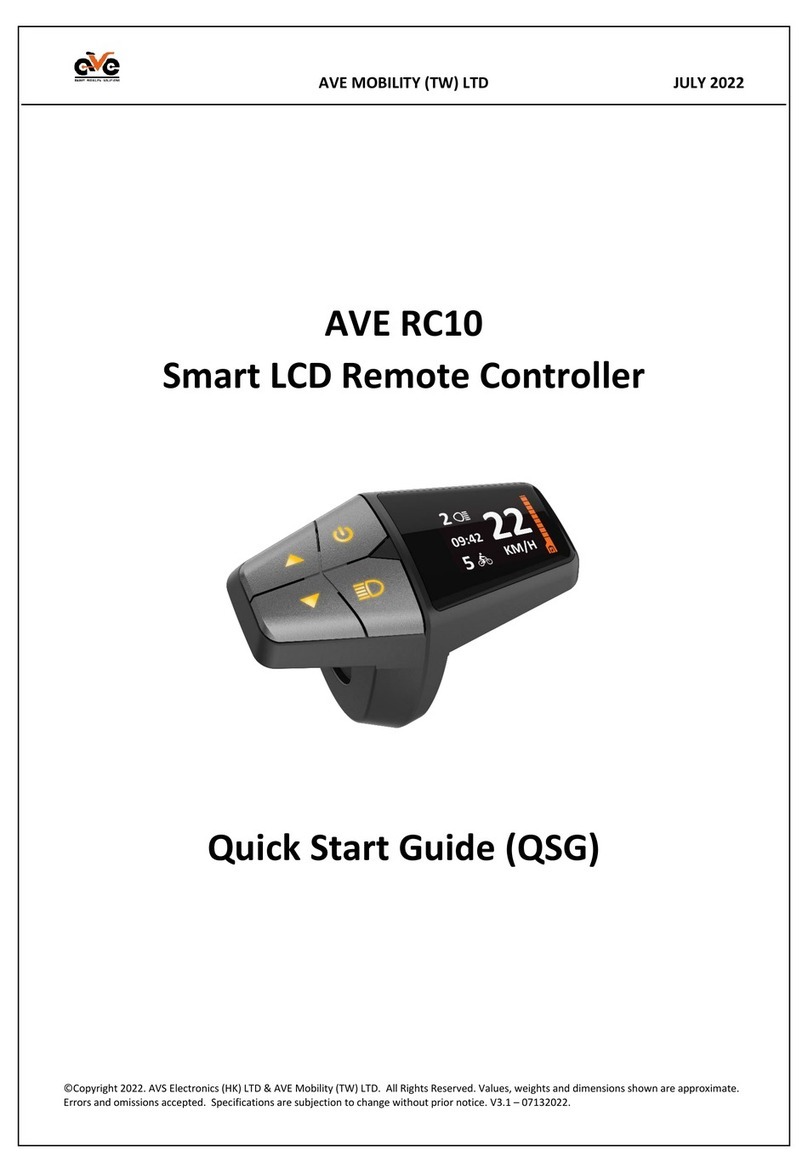

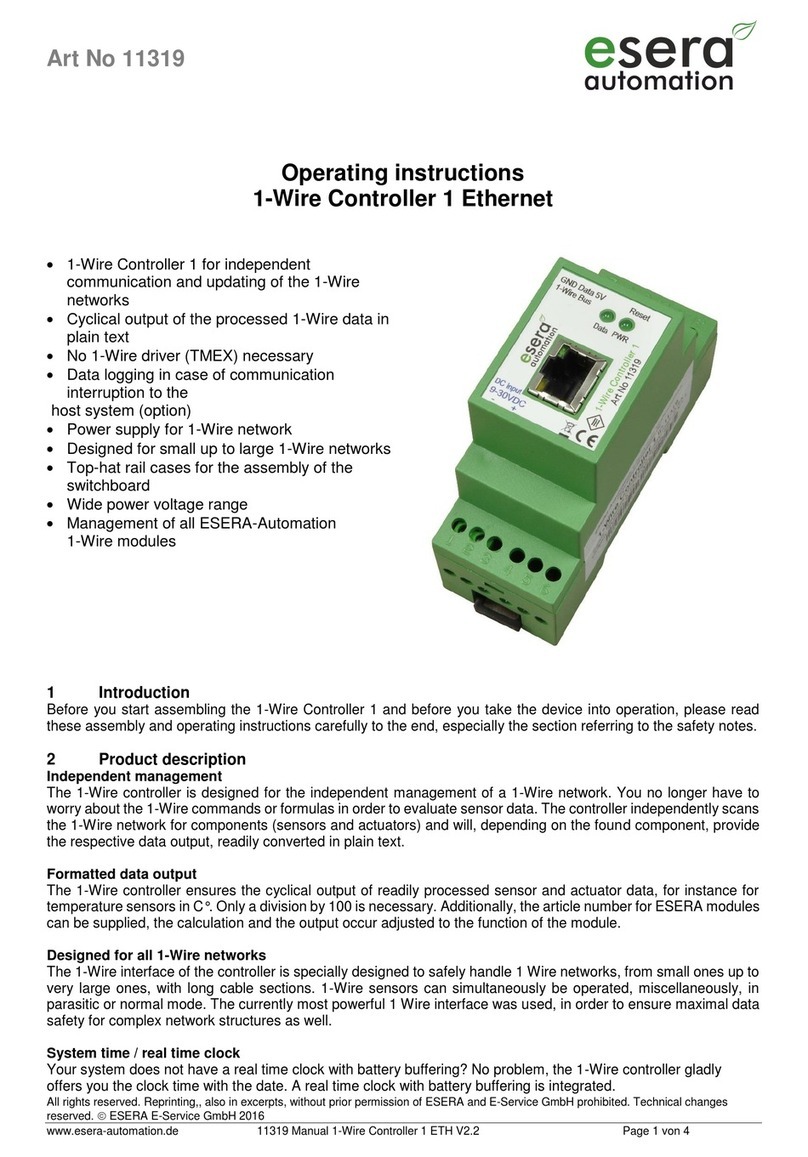

The ECO 208 PRO controller is a high-

performance 1-Wire interface of the 3rd generation

for sensors and actuators in the industrial and

telecommunication sector.

fully automatic integration of sensors* and

actuators*

WLAN and LAN Modbus TCP data interface

max. 20 Modbus data connections

OLED display

8x digital inputs

1 x relay output / alarm output

Plug and Play interface for up to 30 sensors (e.g.

temperature, humidity, air quality, gas sensors)

Web server for configuration, Debug and Firmware

updates

robust industrial design

extensive software support

power supply -48VDC

Auto-E-Connect Support Level I to III

Fast readout of all 1-Wire Devices in a

1-2 seconds cycle

Basic unit for many industrial and telecommunication solutions

Designed for small to large 1-Wire Networks

Management of all ESERA and many standard

1-Wire Modules and Chips

Note

Before starting the installation of the ECO 208 PRO and putting the unit into operation, read this

operating manual carefully to the end, especially the section on safety instructions.

All settings and configurations of the ECO 208 PRO are carried out with the software Config Tool 3.

You can find this software on the ESERA website. Please refer to the operating instructions for

Config Tool 3, which can be found within the Config Tool 3 software under the

"HELP/SUPPORT" tab.

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 2 of 18

1 Product description

Sensors and Actuators

The ECO 208 PRO 1-Wire Controller supports up to 30 sensors, actuators, iButton keys or memory devices

(referred to collectively as Devices in the following). Up to 5 data values can be output per 1-Wire device. This

means that the ECO 208 PRO can provide up to 150 data values, which is a very large number and a very good

price per data value ratio.

Data interface

The ECO 208 PRO 1-Wire Controller has a Modbus TCP and ASCII data interface.

You can communicate with your industrial control system, e.g. PLC, monitoring control and data acquisition

systems (SCADA) via the standard Modbus TCP protocol with the ECO 208 PRO Controller.

Thus, the ESERA ECO 208 PRO equiments provide an optimal interface between modern digital

1-Wire devices and your monitoring system.

Modbus Protocol

The Modbus TCP addressing is clearly structured, comparable to many other Modbus systems.

Addresses are available for system and device data.

An address overview with all available data points is available in the download area of our website and within

the configuration software ESERA Config Tool 3.

Autonomous management

The ECO 208 PRO is intended for the autonomous management of a 1-Wire Network. You no longer need to

worry about 1-Wire commands or formulas for evaluating the 1-Wire devices. The ECO 208 PRO

independently scans the 1-Wire Network for new 1-Wire devices, reads their Auto-E-Connect data,

automatically adapts* the device libraries and outputs the adapted data in plain text, adapted to the scanned

1-Wire devices.

Designed for all 1-Wire Networks

The 1-Wire interface of the ECO 208 PRO is specially designed to safely operate small up to very large

1-Wire Networks with long cable distances.

1-Wire devices can be operated simultaneously in mixed parasitic or normal mode.

The currently strongest 1-Wire interface was developed for maximum data security even for complex network

structures.

Formatted data output

The ECO 208 PRO outputs the sensor and actuator data ready-prepared, e.g. for temperature sensors

cyclically in C°. It is only necessary to divide by 100.

In addition, the article number for ESERA-Modules can be entered, the calculation and output is adapted to

the function of the module.

System time / real-time clock

You do not have a real-time clock with battery buffering in your system? No problem, the ECO 208 PRO will

gladly provide the time with date. The real-time clock (RTC) is supplied by a maintenance-free goldcap

(super capacitor) for approx. 2 days in the event of a power failure.

What is a gold cap (super capacitor)? You can find an explanation here:

https://de.wikipedia.org/wiki/Superkondensator

Power supply

For power supply, the ECO 208 PRO has a wide range input from -38VDC to -72VDC and is thus intended

for telecommunication typical -48V system supplies.

Suitable DIN rail or plug-in power supply units can be found in our webshop.

Commissioning

Support videos for commissioning and configuration can be found on our website www.esera.de under

"Service and Support", Support Videos.

Note

Basics and Tips on the 1-Wire Bus system can be found in the ESERA Online Shop under

1-Wire Basics or please refer to our eBook in the shop under Training/Documentation.

Art.No.11603-48

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 3 of 18

2 Auto-E-Connect Support

The ECO 208 PRO 1-Wire Controller supports Auto-E-Connect Level I, II and III.

3 Auto-E-Connect System

With the launch of the ECO Controller, the ESERA Auto-E-Connect® 1-Wire Plug and Play system for the

1-Wire Bus is now introduced and supported.

This means that fully automatic configurations of the 1-Wire devices* (sensors and actuators) are now

possible on the 1-Wire Bus. It is optimised for commercial and industrial applications and enables significant

added value beyond sensor and chip data.

The Auto-E-Connect function is built up in three levels. Currently there are Level I, Level II and Level III

available.

With Auto-E-Connect Level III, fully automatic configurations of the 1-Wire devices on the

1-Wire Bus are possible. It is optimised for industrial and IoT applications and enables significant added

value beyond sensor and chip data.

With the Auto-E-Connect function, ESERA devices are recognised fully automatically, suitable libraries are

started and ready-formatted data is output.

The Auto-E-Connect functionality will be available for the ECO Controller and ESERA-Station 200 Pro from

2021.

Auto-E-Connect Level I

OWD Detect: Detection of new sensors* and actuators* and automatic start of adapted libraries

Auto-E-Connect Level II

Visualise product data: Readout and visualisation of Auto-E-Connect and manufacturer data of sensors* and

actuators*, such as article number, date of manufacture, firmware and hardware version.

Auto-E-Connect Level III

Extended Plug and Play System for 1-Wire Bus

oPre Configuration: The OWD number for the next installation can be written into the 1-Wire device*.

oAutomatic Positioning: The device* logs on to each ECO controller with Auto-E-Connect III with the new

desired OWD number. This automatic registration works up to the maximum possible OWD number of the

ECO Controller.

oSensorfinder Function: The ECO 208 PRO can activate a status LED within the ESERA 1-Wire Pro

sensors*. The status LED flashes or lights up permanently for a certain time. This makes the detection of a

device in a 1-Wire Network much easier. Faster detection saves a lot of time and therefore money when

searching for a 1-Wire device.

oClasses Assignment: ESERA 1-Wire devices are assigned to OWD classes with the same properties. This

assignment enables fully automatic visualisation and data evaluation in control systems. A class list is

available from ESERA.

For further information on the ESERA Auto-E-Connect system, please refer to the ESERA website and the

ESERA Config Tool 3.

Auto-E-Connect is registered by ESERA GmbH as a German and European Patent.

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 4 of 18

4 Technical data

Ethernet interface: - TCP/IP, Socket Server

- 10/100 MBit/s Ethernet Interface, WLAN: 802.11 b/g, LAN 10/100MBit/s

- up to 20 data connections for ModbusTCP

- Auto Negotiation (Full-duplex and Half-duplex)

- Auto MDI/MDIX

- Support for DHCP and fixed IP-Adress

Auto-E-Connect: Level I to III supported

Data, Firmware Update

and Configuration ESERA Config Tool 3

Software Support: ECO Dashboard 100

Supply voltage: -38VDC to -72VDC

Current consumption max. 100mA

Power supply RTC: Goldcap, buffering of the internal clock (RTC) in case of power failure for approx. 2 days.

In the event of a longer failure, the RTC must be reset.

The Goldcap is charged after approx. 2 hours.

1-Wire Interface : 1-Wire Bus (+5V, ground (GND) and data)

Protective circuits: ESD, overvoltage and reverse polarity protection.

Connection: Push In plug-in terminals (up to 2.5qmm cable cross-section)

Output voltage: +5V (+/-10%), max. 300mA, overload, overvoltage and short-circuit proof

Isolation: Galvanic isolation between Ethernet and 1-Wire Interface

Supported DS2401, DS1963, DS1990, DS1820, DS18S20, DS18B20, DS2413, DS2438, DS2450

1-Wire devices: DS2408, DS2405, DS2406 (only input), DS2423, other chips on request.

We will be happy to support other components as an OEM product for you.

5 Ambient conditons

Temperature, operation: -25°C to +60°C

Storage temperature: -20°C to +70°C

Relative air humidity: 10% to 92% (non condensing)

Room classification: operate only in dry rooms

Protection system: IP20

Protection class: III

Dimensions: 106,3 x 90,5 x 62mm (WxHxD)

6 Conformity

EN 50090-2-2

EN 61000-4-2, ESD

EN 61000-4-3, HF

EN 61000-4-4, Burst

EN 61000-4-5, Surge

EN 61000-6-1, interference immunity

EN 61000-6-3, interference radiation

RoHS

7 Display LED

The module has various indicator LEDs. The function of the indicators is as follows

Display

Designation

Function

LED Green

PWR

Display for supply voltage

LED Green

DATA

after switching on the unit, the LED flashes 3x

flashes during 1-Wire activity

flashes when data is sent via the data interface

flashes very quickly if "KAL Receive" has been

activated and the "KAL Messages" of the control

system are missing.

LED Green

LAN

LAN - Network Status LED

lights up when LAN - Network connection is established

flashes when the interface is not activated

Art.No.11603-48

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 5 of 18

LED Green

WLAN

WLAN - Network Status LED

lights up when a WLAN Network connection is established

flashes when the WLAN access point is activated and a direct

connection is possible.

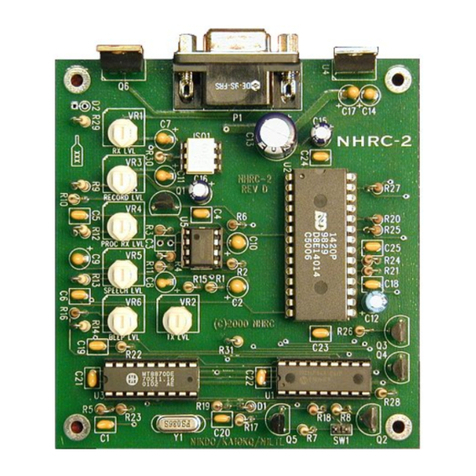

8 Connection plan

Module top side: Digital inputs, normally open contacts

Reset Button: Reset Button for recovery

Note

The normally open contacts must not be connected to external voltages or potentials.

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 6 of 18

Module bottom side: Digital Output (Changeover Contact), Power Supply, Sensor Bus Interface (1-Wire) and

Ethernet Connection.

9 Reset Button

The reset is carried out via the reset button of the system.

When the button is pressed, the unit is restarted. The stored data is retained, but all connections are

Interrupted.

This keystroke does not correspond to an interruption of the power supply.

Note

The module may only be operated at the voltages and under the ambient conditions specified for it. The

operating position of the unit is arbitrary.

The modules may only be put into operation by a qualified electrician.

For further information on the operating conditions, see the following instructions under "Operating

conditions".

Weitergehende Informationen zu den Betriebsbedingungen siehe nachfolgende Anleitung unter

„Betriebsbedingungen“.

Note

The PE connection of the ECO 208 PRO should be connected to earth potential (PE). This establishes a

functional earth

Art.No.11603-48

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 7 of 18

10 Connection example 1-Wire Multisensors

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 8 of 18

11 Software

Data interface ESERA ASCII Text protocol

The Ethernet interface is configured with the help of the Windows ESERA programme Config Tool 3, which

can be found in the download area of the ESERA online shop.

12 Configuration und Communication

The ECO 208 PRO has extensive configuration and formatting options which are read out and operated with

the ESERA Config Tool 3.

Since the communication between ECO 208 PRO and Config Tool 3 takes place via the open ESERA ASCII

text protocol, you can also communicate at any time with any terminal program (e.g. z.B. Hercules oder

Putty) via UDP / TCP/IP. to exchange data with the ECO 208 PRO and to carry out the configuration.

Details on the communication commands can be found in the document "Programming Manual", which you

can find in the download area of the ECO 208 PRO and within the Config Tool 3 software.

12.1 ESERA ASCII Textprotokoll

The ECO 208 PRO provides two protocols. For configuration and analysis, the ESERA text protocol in ASCII

format can be used very easily. Here, special emphasis was placed on good readability and traceability. The

ESERA text protocol works with "GET" and "SET" commands, which probably every programmer has used in

his own projects.

The ESERA text protocol is disclosed and documented. The latest version of the ESERA protocol description

can be found in the Programming Manual in the download area of the article and in the ESERA Config Tool 3.

By default, port 5000 is preset for the ASCII protocol.

Note

For ASCII protocol only a TCP/IP socket data connection with the ECO 208 PRO is possible.

The IP address is preset to DHCP.

Art.No.11603-48

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 9 of 18

12.2 Modbus TCP Protocol

You can communicate with the ECO 208 PRO simultaneously via several data connections using the Modbus

TCP protocol.

The ports 502, 503, 504, 505 and 506 are preset for the Modbus TCP data connections.

Up to 10 simultaneous data connections are possible per port. In total, the number of data connections must be

limited to 20. The IP address is preset to DHCP operation.

The Modbus protocol has a standardised structure. The following is a small excerpt of the addressing overview.

The complete Modbus addressing overview can be found in the Programming Manual in the download area of the

ECO 208 PRO and within the Config Tool 3 software.

Excerpt Modbus adress description

Description

Read address

Number of words

(16Bit)

Data type

Gateway No.

60000

1

Word

Article No.

60001

1

Word

Firmware Version

61000

4

String

Hardware Version

61010

3

String

Serial number

61020

9

String

Time

61030

4

String

Date

61035

4

String

…

1-Wire Bus Sensors

and Actuators

OWD 1/1-Wire device

40100

1

Integer

40101,40102

2

Dword 1

40103,40104

2

Dword 2

40105,40106

2

Dword 3

40107,40108

2

Dword 4

40109,40110

2

Dword 5

40111,40112

2

Dword 6

40113,40114

2

Dword 7

40115,40116

2

Dword 8

OWD 2/1-Wire device

40200

1

Integer

40201,40202

2

Dword 1

40203,40204

2

Dword 2

…

13 Your desired protocol not included?

The ECO 208 PRO is extremely powerful due to the Maxi data interface used. On request, we can also integrate

other interface protocols. We would be happy to provide you with a quotation for this. Contact us via the technical

Note

Up to 10 connections per port are possible via Modbus TCP, but the total number must be limited to a

maximum of 20 connections.

The IP address is preset to DHCP operation.

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 10 of 18

14 Interface configuration Modbus/TCP, Maxi Interface

Important, at present the configuration of the Ethernet interfaces is only possible via the web interface. The IP

address for starting the web server is shown on the unit display or can be found in the system overview of the

router / DHCP server.

14.1 Maxi Interface, Web server

The ECO controllers with Maxi interface, e.g. ECO 208, have a web server for configuring the Ethernet interfaces

(LAN and WLAN).

The ECO Controller with Maxi interface logs into your network with the identifier "ESERA". The Ethernet interface

is set to "DHCP" in the delivery state.

14.2 Web server, LogIn

Password, LogIn

In order to be able to log into the web server of the

ECO Controller, use the following password for the

initial login: eserapwd

For security reasons, the password is not displayed in

plain text but with dots.

Important: Please change the password after the

first login, otherwise unauthorised persons can

make settings on the ECO Controller.

Please enter a new and secure password via the

main menu, button "Change Password".

You can find information on assigning secure

passwords on the Internet.

After entering the password, click on the "Login" button

to open the main menu (hereinafter referred to as

Main Menu).

Software status Ethernet interface / LogOut

Display of the software version of the Ethernet

interface installed on the unit. You can see the version

of the 1-Wire Firmware via Config Tool 3.

Click on the "LogOut" button to exit the web interface.

Art.No.11603-48

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 11 of 18

14.3 Web server, Home page (Main Page), Maxi Interface

The Main Page provides a selection of options for configuring the Ethernet interface. The various buttons

(selection keys) take you to the corresponding submenus. These are described on the following pages.

Ethernet Interface Setting

This button takes you to the menu for setting the IP

address, SubNet and gateway number.

Protocol Settings

Pressing this button takes you to the menu for

configuring the socket interfaces 2-5.

In this menu you can set the port number of the

Modbus/TCP interfaces, for example.

Disable AP Modus

This button is only visible if the access point is

activated.

To deactivate the WLAN access point, press the

"Disable AP Mode" button or

press the "WLAN Mode" button (at least 3 seconds) on

the front panel of the unit.

If the access point is not activated, this button is not

visible. You can only activate the access point with the

"WLAN Mode" button (at least 3 seconds) on the front

panel.

Change Password

To change the password for the web server, press the

button to enter the password menu.

Factory Reset

You can reset the Ethernet interface to the delivery

status. To do this, switch to the "Factory Reset" menu.

Firmware Update

This button takes you to the update menu. This menu

allows you to update the software for the interface and

the 1-Wire interface.

Softwarestatus Ethernet interface / LogOut

Display of the software version of the Ethernet

interface installed on the unit. You can see the version

of the 1-Wire firmware via Config Tool 3.

Click on the "LogOut" button to exit the web interface.

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 12 of 18

14.4 Web server, Interface Setting, Maxi Interface

Use the "Interface Setting" web page to set the basic settings for the Maxi interface.

In this menu, the operating mode of the Ethernet interface, TCP Server or UDP, of the ECO Controller is

configured.

The IP address, subnet mask and the gateway IP address are set here.

.

TCP Server or UDP operating mode

With this selection, the basic operating mode for the

ECO Controller Maxi Interface is set.

Port

The port address is assigned for socket 1, the

ESERA ASCII protocol.

The port can be selected in the range 1-50000.

The default port is 5000.

DHCP / Manual, Operating mode IP address

assignment

You can choose between automatic (DHCP) and

manual assignment of the IP address.

DHCP is activated in the delivery state.

IP Address

For automatic address assignment (DHCP), the IP

addresses are displayed.

For manual assignment of IP addresses, the

corresponding settings are entered in the fields

IP address, subnet mask and gateway.

Save / Back

Press the "Save" button to permanently save the

current settings.

If you do not want to make any changes, press the

"Back" button.

Click on the "LogOut" button to exit the web interface.

Art.No.11603-48

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 13 of 18

14.5 Web server, Protocol Settings, Maxi Interface

The data protocol settings for the 5 data interfaces can be made on this page.

Currently, 1 x ASCII and 4 x Modbus/TCP are available for the Maxi interface.

On request, further protocols can be integrated here and made selectable. We will be happy to provide you with

an offer for the integration of further protocols.

Protocol and Port for Socket Data connections

Interface 1, ASCII Protocol

Interface 1 is permanently reserved for a TCP/IP or

UDP socket data connection via ESERA ASCII text

protocol.

The port for this interface is set on the "Interface

Settings" page.

Interface 2 to 5, Modbus/TCP

Interfaces 2 to 5 can be set to "None" to deactivate the

interface or the Modbus/TCP protocoll can be

selected.

The ports can be freely selected in each case.

By default, all interface connections are preset to

Modbus/TCP and the various ports..

Save / Back

Press the "Save" button to permanently save the

current settings.

If you do not want to make any changes, press the

"Back" button.

Click on the "LogOut" button to exit the web interface.

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 14 of 18

14.6 Web server, Disable AP Mode, Maxi Interface

In addition to a LAN interface, the ECO Controller with Maxi Interface also has a connectable WLAN access point

that you can use for configuration and data communication. The access point is activated by a button on the unit's

surface. To activate the access point, press the 'WLAN Mode' button for approx. 3 seconds.

Activation is confirmed by the LED and the display. Now you can connect to the ECO Controller using a WLAN-

capable device with a web browser. To do this, select the access point "ESERA". The web server of the ECO

Controller can be reached via the IP address 192.168.4.1.

A data connection via ESERA ASCII and Modbus/TCP can now also be established via the IP address. The

access point is now permanently in operation.

You can deactivate the access point by pressing the "WLAN Mode" button again or by pressing the "Disable AP

Mode" button described below.

It can only be reactivated by pressing the "WLAN Mode" button.

Disable AP Mode

To switch off the WLAN access point, press the "YES"

button.

Press the "No" button to exit the menu without making

any changes.

Click on the "LogOut" button to exit the web interface..

Art.No.11603-48

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 15 of 18

15 1-Wire Network, Cabling

The special feature of the 1-Wire system is the "BUS technology". All devices (sensors and actuators) are

operated in parallel on a three-wire line, which is used for both power supply and data communication. The 1-

Wire bus system joins the list of other successful bus systems such as CAN or Modbus RTU. All of the installation

principles recommended for these are also applicable and appropriate to 1-Wire.

The maximum size of a 1-Wire Network is determined by various factors. These are mainly:

- Total cable length and cable type

- Number of 1-Wire devices

- Type of cable installation (topology)

- Number and design of cable connectors (unnecessary connection transitions should be avoided)

All factors in total are summarised and referred to as 1-Wire Bus load. Each increase of a factor increases the

total 1-Wire Bus load for the 1-Wire controller and thus reduces the maximum network size.

According to our many years of experience and a lot of feedback from customers, the following conservative

recommendation can be made:

- Maximum cable length 50 -120m

- Number of 1-Wire devices no more than 20 -22 pieces

- As linear a topology as possible without T-junctions

The topology in particular plays a major role. If possible, linear topology should be used. The linear topology can

be compared like pearls on a pearl necklace. The data line should be laid from one device to the next without

T-joints.

Furthermore, the type of cable used can also be mentioned here. We recommend for the cabling

CAT5 or CAT6 network cable. It is also possible to use J-Y(St)Y telephone cables and KNX cables. Longer cable

runs are possible with CAT5 versus CAT7 cables.

With twisted pair cables, a longer connection length can be achieved in an undisturbed environment, as the

capacitive bus load is lower. A total length of 50 m and more can be easily achieved without additional measures.

In disturbed, commercial and industrial environments, the cable should always be shielded in order to increase

the "robustness" or interference sensitivity of the system.

Note

The above statements on 1-Wire are hints and tips and do not describe any product property or represent

any guaranteed product property of the ECO 208 PRO.

Information on the basics and tips on the 1-Wire Bus system can also be found in the ESERA Online Shop

under https://www.esera.de/1-wire-grundlagen/

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 16 of 18

16 Firmware-Update

The latest device software (firmware) can

be found in the download area of the

Config Tool 3. Please check for a new

firmware version when commissioning

the ECO 208 PRO.

Please use the latest version. The

firmware update is carried out via

Config Tool 3.

Please observe the operating instructions

for the Config Tool 3, which you can find

within the Config Tool 3

under the tab "HELP/SUPPORT".

You can find a video about the firmware

update on our website under

"Service and Support, Support Videos".

16.1 Recovery function Firmware-Update

If the update is faulty, e.g. due to a power failure during the update, you can use the

recovery function. To do this, press and hold the reset button (this is located under

hole 5 on the top of the module), start the update in Config Tool 3 and release the

reset button after approx. 1 second after starting in Config Tool 3. The update should

now start.

If you have any problems with the installation, we will be happy to help you. Simply

contact our support team by e-mail at support@esera.de.

17 Example for integration in Codesys

We would be pleased to provide you with a test software for the integration of the ECO 208 PRO into the PLC

18 Example for integration in Siemens SPS

For many years, the Modbus TCP protocol has also been available in the programming environment of Siemens

PLCs. The Modbus addresses of the ECO 208 PRO have been adapted to the requirements of the Siemens

programming environment. Therefore, this combination is also possible and has already been implemented by

many customers.

19 Example for integration in KNX Automation

For integration into a KNX automation system, we offer a software module for the Gira Homeserver together with

Grot compnay. This provides you with a very powerful 1-Wire integration for your KNX system. Details can be

found on the ESERA website under "Compatible controls / Control units / KNX Gira Homeserver“.

https://www.esera.de/cat/index/sCategory/339

Note

Please also note the operating instructions for Config Tool 3, which you can find within Config Tool 3

under the "HELP/SUPPORT" tab.

Furthermore, you will find a video about the firmware update on our website under "Service and

Support, Support Videos".

Note

After performing an update, we recommend disconnecting the ECO 208 PRO from the power supply for

approx. 30 seconds and restarting it.

Pressing the reset button does not correspond to an interruption of the power supply.

Art.No.11603-48

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 17 of 18

20 Your software not listed?

Due to the text protocol used, the ECO 208 PRO can be integrated extremely universally into many devices and

software solutions.

21 Operating conditions

The module may only be operated at the voltages and under the ambient conditions specified for it. The unit may

be operated in any position. The unit is intended for use in dry and dust-free rooms.

Do not operate the assembly in an environment where flammable gases, vapours or dusts are or could

be present.

If condensation forms, wait for an acclimatisation period of at least 2 hours.

The assemblies may only be put into operation by a qualified electrician.

22 Assembly

The mounting location must be protected from moisture. The unit may only be used in dry rooms. The unit is

intended for installation inside a control cabinet as a stationary unit

23 Disposal note

Do not dispose of the device within the household waste!

According to the directive concerning old electrical and electronic appliances,

electronic devices must be disposed of via the collecting points for old electronic

appliances!

24 Safety instructions

When handling products that come into contact with electrical voltage, the applicable VDE regulations must be observed, in

particular VDE 0100, VDE 0550/0551, VDE 0700, VDE 0711 and VDE 0860.

All final or wiring work must be carried out with the power turned off.

Before opening the device, always unplug or make sure that the unit is disconnected from the mains.

Components, modules or devices may only be put into service if they are mounted in a contact proof housing. During

installation they must not have power applied.

Tools may only be used on devices, components or assemblies when it is certain that the devices are disconnected

from the power supply and electrical charges stored in the components inside the device have been discharged.

Live cables or wires to which the device or an assembly is connected, must always be tested for insulation faults or

breaks.

If an error is detected in the supply line, the device must be immediately taken out of operation until the faulty cable

has been replaced.

When using components or modules it is absolutely necessary to comply with the requirements set out in the

accompanying description specifications for electrical quantities.

If the available description is not clear to the non-commercial end-user what the applicable electrical characteristics for

a part or assembly are, how to connect an external circuit, which external components or additional devices can be

connected or which values these external components may have, a qualified electrician must be consulted.

It must be examined generally before the commissioning of a device, whether this device or module is basically

suitable for the application in which it is to be used.

In case of doubt, consultation with experts or the manufacturer of the components used is absolutely necessary.

For operational and connection errors outside of our control, we assume no liability of any kind for any resulting

damage.

Kits should be returned without their housing when not functional with an exact error description and the

accompanying instructions. Without an error description it is not possible to repair. For time-consuming assembly or

disassembly of cases charges will be invoiced.

During installation and handling of components which later have mains potential on their parts, the relevant VDE

regulations must be observed.

Devices that are to be operated at a voltage greater than 35 VDC / 12mA, may only be connected by a qualified

electrician and put into operation.

Commissioning may only be realized if the circuit is built into a contact proof housing.

If measurements with an open housing are unavoidable, for safety reasons an isolating transformer must be installed

upstream or a suitable power supply can be used.

After installing the required tests according to DGUV / regulation 3 (German statutory accident insurance,

https://en.wikipedia.org/wiki/German_Statutory_Accident_Insurance) must be carried out.

*if the sensor or actuator supports Auto-E-Connect. For details, please refer to the operating instructions of the sensor or actuator.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH 2021

www.esera.de 11603-48 V1.0 R1.1 Manual Page 18 of 18

25 Warranty

ESERA GmbH guarantees that the goods sold at the time of transfer of risk to be free from material and workmanship

defects and have the contractually assured characteristics. The statutory warranty period of two years begins from date of

invoice. The warranty does not extend to the normal operational wear and normal wear and tear. Customer claims for

damages, for example, for non-performance, fault in contracting, breach of secondary contractual obligations,

consequential damages, damages resulting from unauthorized usage and other legal grounds are excluded. Excepting to

this, ESERA GmbH accepts liability for the absence of a guaranteed quality resulting from intent or gross negligence.

Claims made under the Product Liability Act are not affected.

If defects occur for which ESERA GmbH is responsible, and in the case of replacement goods, the replacement is faulty,

the buyer has the right to have the original purchase price refunded or a reduction of the purchase price. ESERA GmbH

accepts liability neither for the constant and uninterrupted availability of the ESERA GmbH or for technical or electronic

errors in the online offer.

We develop our products further and we reserve the right to make changes and improvements to any of the products

described in this documentation without prior notice. If you need documentation or information about older product

26 Trade marks

All mentioned designations, logos, names and trademarks (including those which are not explicitly marked) are

trademarks, registered trademarks or other copyright or trademarks or titles or legally protected designations of their

respective owners and are hereby expressly recognized as such by us. The mention of these designations, logos, names

and trademarks is made for identification purposes only and does not represent a claim of any kind on the part of

ESERA GmbH on these designations, logos, names and trademarks. Moreover, from their appearance on ESERA GmbH

webpages it cannot be concluded that designations, logos, names and trademarks are free of commercial property rights.

ESERA and Auto-E-Connect are registered trademarks of ESERA GmbH.

Auto-E-Connect is registered by ESERA GmbH as a German and European Patent.

27 Contact

ESERA GmbH

Adelindastrasse 20

87600 Kaufbeuren

GERMANY

Tel.: +49 8341 999 80-0

Fax: +49 8341 999 80-10

www.esera.de

WEEE-Number: DE30249510

Table of contents

Other esera automation Controllers manuals

esera automation

esera automation 1-Wire Controller 1 User manual

esera automation

esera automation 11319 User manual

esera automation

esera automation 11320 User manual

esera automation

esera automation 11319 User manual

esera automation

esera automation ECO 10 User manual

esera automation

esera automation Auto-E-Connect 11340 User manual

esera automation

esera automation 11325 User manual