esera automation 1-Wire Gateway 20 Modbus TCP User manual

Art. No. 11337

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11337 V2.0 R1.0 Manual Page 1 of 10

User Guide

1-Wire Gateway 20 Modbus TCP

1-Wire Gateway for self-communication

between PLC and a 1-Wire sensor and

actuator Network

Data evaluation of all 1-Wire modules in 1 - 2

seconds increments

Modbus data output as TCP protocol

Edited sensor- and actuator data

Status updates for all sensors and actuators

Easy configuration

No extra drivers needed

Data storage in case of loss of communication

to the host system (optional)

Power supply for 1-Wire network

Designed for all dimensions of 1-Wire

networks

DIN rail housing for switchboard assembly

Wide range of power voltage

Management of all ESERA-Automation 1-Wire

modules and many of standard 1-Wire

sensors and actuators (e.g. switch-modules)

1 Introduction

Before you start assembling the 1-Wire Gateway 20 Modbus TCP and before you take the device into

operation, please read this assembly and operating instruction carefully to the end, especially the section

referring to the safety notes.

We recommend to use Config-Tool 3 for all kind of setup and configuration tasks. Please find the latest

release on our website at, www.esera.de. Please also refer to the Help/Support section to find the user guide

for Config-Tool 3.

2 Product description

Standard Modbus TCP protocol

You can use your industrial controller, e.g. PLC and standard TCP protocol to connect to the 1-Wire

Gateway 20. Addressing is similar to other Modbus systems and easy to handle. You can use addresses

for system data, sensor data and actuator devices. A complete address list including all available data

points is available for download on our webpage. These addresses are also available within the

ESERA configuration software Config-Tool 3.

Standalone controller

The 1-Wire Gateway 20 Modbus is designed to control 1-Wire Networks. You no longer have to worry

about 1-Wire commands or algorithms to analyze sensor data. 1-Wire Gateway 20 Modbus scans 1-Wire

Networks by itself in order to identify new sensors or actuator devices. All data found were automatically

provided in a ready to use Modbus protocol format.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11337 V2.0 R1.0 Manual Page 2 of 10

Formatted data output

1-Wire Gateway 20 Modbus provides plausibility checked sensor and actuator data in a ready to use format.

E.g. temperature sensor provides values in Celsius degrees with 2 decimal places. You only need to divide

this number by 100. Within the 1-Wire Gateway a product specific transformation table is available for most of

our selling 1-Wire sensor and actuator products.

Designed for all 1-Wire Networks

The 1-Wire interface of the 1-Wire Gateway 20 Modbus is specially designed to securely support all sizes

of 1-Wire networks. 1-Wire sensor devices can be operated in parasitic or normal mode at the same time.

The latest available most powerful 1-Wire interface for a maximum level of data security has been used.

This includes complex network structures as well.

1-Wire Gateway 20 Modbus configuration

Free configuration software (Config-Tool 3) is provided. When using Config-Tool 3, the latest

documentation is available at any time hence it automatically updates via internet. This software is

available for download on our webpage. Communication to Modbus TCP is parallel with no switching.

System time / real time clock

No real time clock with battery buffering available in your system? No problem at all. Our 1-Wire Gateway

20 Modbus is providing time and date as real time clock including an integrated backup battery. Data

plausibility check is possible at any time.

Power supply

Input voltage for 1-Wire Gateway 20 Modbus is 9 –30 VDC. Therefore it can be used for 12 V as well as

24 VDC (industrial applications). Appropriate hat-rail mounted power supplies or power plugs can be

found in our webshop.

3 Auto-E-Connect® Support

The ESERA Auto-E-Connect® 1-Wire Plug and Play system will be used for the

1-Wire Bus supported. This enables fully automatic configurations of 1-Wire sensors

and actuators on the 1-Wire bus. It is optimized for industrial applications and

enables significant added value beyond the sensor and chip data.

The Auto-E-Connect function automatically recognizes ESERA chips, sensors and actuators, starts suitable

libraries and outputs fully formatted data.

The Auto-E-Connect functionality will be available from mid-2020 via 1-Wire Controllers, 1-Wire Gateways and

1-Wire ECO from ESERA available.

Further information on ESERA Auto-E-Connect can be found on the ESERA website, ESERA Config-Tool 3,

or in the download area for this article in the ESERA Webshop.

4 Technical data

Data Interface: Modbus TCP and ESERA ASCII text protocol

Ethernet Interface: TCP/IP or UDP

- 10/100 MBit Ethernet Interface (RJ45)

- Auto Negotiation (Full-duplex and Half-duplex)

- Auto MDI/MDIX

- Support for DHCP and fix IP-address

- DNS support

- DYN-DNS server sSupport

Firmware Update: via ESERA Config-Tool 3

Power supply: 15 –30 VDC

Power consumption: maximum 1 A

1-Wire interface: 1-Wire bus (12 V, 5 V, GND and data)

Protective circuits: ESD protection and polarity protection

Connection: Screw terminals (up to 2,5 qmm wire cross section)

Output voltage: 12 V maximum 250 mA (+/- 10 %), 5 V maximum 200 mA (+/- 10 %)

overload-proof and short-circuit-proof

Isolation: Galvanic separation among data and 1-Wire interface

Art. No. 11337

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11337 V2.0 R1.0 Manual Page 3 of 10

5 Ambient conditions

Temperature, operation -10 °C up to +55 °C (extended temperature range available upon request)

Air humidity: 10 –92 % (non-condensing)

Protection system: IP20

Protection class: III

Dimensions: 35 x 90 x 70mm (WxHxD)

6 Conformity

EN 50090-2-2

EN 61000-4-2, ESD

EN 61000-4-3, HF

EN 61000-4-4, Burst

EN 61000-4-5, Surge

EN 61000-6-1, Fault-free operation

EN 61000-6-3, Stray radiation

RoHS

7 LED indicators

The module status will be displayed by various LEDs. Please refer to the following table for their functions:

LED status

Description

Function

LED Green

PWR

power indicator

LED Green

DATA

LED flashes 3 times after power on

Flashes at 1-Wire activity

Flashes while transferring data by the data interface

Flashes rapidly if "KAL Receive" has been activated and no

“KAL messages" received.

LED Green

Data Interface

Network Link LED

Is lit when connected

LED Yellow

Data interface

Network activity LED

Is lit while data submission by data interface

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11337 V2.0 R1.0 Manual Page 4 of 10

8 Connection

www.esera.de

Art. No. 11337

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11337 V2.0 R1.0 Manual Page 5 of 10

Module bottom side (power supply, digital input and analog output)

1 = GND/negative digital input isolated to negative supply

2 = digital input 1 10 –30 VDC

3 = digital input 2 10 –30 VDC

4 = digital input 3 10 –30 VDC

5 = digital input 4 10 –30 VDC

6 = GND/ negative analog output isolated to negative supply

7 = analog output 0 –10 VDC

8 - 15 = not assigned

16 = GND/ negative supply voltage

17 = Positive supply voltage

Module top side (Digital Output and 1-Wire Bus)

18 = main supply for digital output 1+2

19 = digital output 1, max. 8 A

20 = digital output 2, max. 8 A

21 = main supply for digital output 3+4

22 = digital output 3, max. 8 A

23 = digital output 4, max. 8 A

24 = digital output 5 break contact, max. 5A

25 = main supply for digital output 5

26 = digital output 5 make contact, max. 5A

30 = Reset Button inside

32 = GND/ negative 1-Wire Bus

33 = 1-Wire Data

34 = 5 V voltage supply for 1-Wire Bus, max. 200 mA

35 = 12 V voltage supply for 1-Wire Bus, max. 250 mA

Basics and tips for 1-Wire Bus systems can be found in our webshop (https://www.esera.de/1-wire-rundlagen/)

or in our e-book which is also available in our webshop (https://www.esera.de/service-

support/dokumentation/352/grundlagen-1-wire-bus-ebook?number=11901).

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11337 V2.0 R1.0 Manual Page 6 of 10

9 Connection - Example 1-Wire Gateway, sensors and actuators

www.esera.de

Art. No. 11337

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11337 V2.0 R1.0 Manual Page 7 of 10

10 Data interface Modbus TCP and ESERA ASCII text protocol

The Ethernet interface is configured using the Windows ESERA program "Config-Tool 3".

You can find this program in the download area of the ESERA online shop.

11 Integration in IP-Symcon / ESERA-Station

ESERA IP-Symcon software modules are provided at our webpage for easy integration of the 4-fold analog

input in IP-Symcon by using a 1-Wire Controller / 1-Wire Gateway. Using software scripts are no longer

necessary. Further details can be found on our webpage: https://www.esera.de/kompatible-steuerungen-

zentralen/ip-symcon-integration/.

A script for regular connections by 1-Wire Bus Coupler is also available for download on our webpage.

Further details can be found in the sample script.

12 Integration in Loxone

We provide a sample project e.g. for read out analog voltages by 4-fold analog input via

1-Wire Controller 1 in our webshop.

Further details can be found here: https://www.esera.de/kompatible-steuerungen-zentralen/loxone-

integration/demo-1-wire-controller-1-loxone-integration/

13 Integration in FHEM

We provide a software module for easy integration in the Open Source automation software FHEM of the

4-fold analog input into FHEM by 1-Wire Controller / 1-Wire Gateway. Using this software scripts are no

longer necessary. Further details can be found on our webpage: https://www.esera.de/kompatible-

steuerungen-zentralen/fhem-integration/

14 Configuration and communication with 1-Wire Gateway 20

1-Wire Gateway 20 offers various configuration and formatting options. All options can be read out and

controlled by the ESERA Config-Tool 3. 1-Wire Gateway and Config-Tool 3 communication is based on

an open ESERA ASCII text protocol. Therefore configuration and data transfer with any terminal program

(such as Hercules or Putty) by UDP/TCPIP and 1-Wire Gateway 20 is possible at any time. For detailed

communication commands please refer to the “Programming Manual” which is available for download in

our webshop.

15 Firmware-Update

Firmware will be updated by using a Config-Tool

3 software which can be found at the

“DEBUG/DATA” tab. By clicking the button

“DOWNLOAD FIRMWARE” a new window

opens to download new software (firmware) for

the 1-Wire Controller / 1-Wire Gateway.

This firmware is compatible with all releases of

the 1-Wire Controller and 1-Wire Gateways. The

features are individually unlocked at the installed

device. Starting with firmware version V1.18_38

the reset button of the 1-Wire Controller / 1-Wire

Gateway does not need to be pressed for

updates anymore.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11337 V2.0 R1.0 Manual Page 8 of 10

Recovery function Firmware-update

Should an error occur during the firmware update e.g. losing power while updating the

firmware, a recovery function can be started. Press and hold the reset button (the reset

button is located beneath hole no. 30 at module top side). Then start the update in Config-

Tool 3 and release the reset button after 1 second after the update has been started. The

update should start now.

When the updated is completed we recommend to disconnect the 1-Wire Controller /

1-Wire Gateway for approx. 30 seconds, then restart again. If any issues should occur

when installing the update, please contact the ESERA support team: E-Mail:

16 Communication

16.1 ESERA ASCII text protocol / programming manual

The 1-Wire Gateway 20 Modbus provides two types of protocols. The ESERA text protocol in ASCII format

easily supports configuration and analysis whereas the ESERA text protocol runs on “GET” and “SET”

commands. The ESERA text protocol is totally open and documented. The latest version of the ESERA

protocol description is available for download in our webshop

(https://www.esera.de/produkte/software/downloads-firmware-1-wire-controller-1-wire-gateway/) as well as in

the ESERA Config-Tool 3 download area.

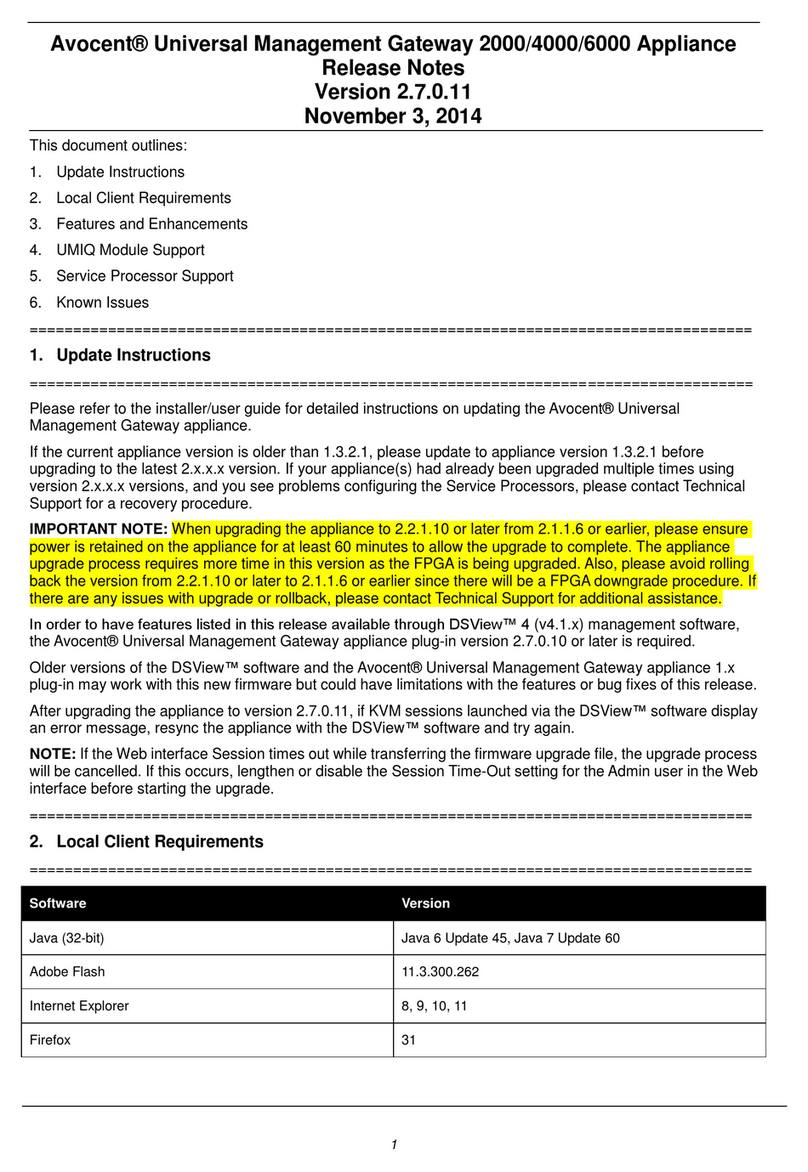

16.2 Modbus TCP protocol

1-Wire Gateway 20 Modbus communication to ESERA text protocol or Modbus TCP protocol is parallel with

no switching. For communication any IP address and any port can be chosen. Default is set to port 5000 and

CHCP mode.

The Modbus protocol is standardized configured. Please refer to the following table for a partial address-

overview. A complete address overview is available for download in EXCEL format at the download area of

the 1-Wire Gateway 20 Modbus.

Partial Modbus address specification

Specification

Reading address

number of words

(16Bit)

type of data

Gateway No.

60000

1

word

Article-No.

60001

1

word

Firmware Version

61000

4

string

Hardware

61010

3

string

Serial number

61020

9

string

Time

61030

4

string

Date

61035

4

string

…

1-Wire bus sensors

and actuators

OWD 1/1-Wire module

40100

1

Integer

40101, 40102

2

DWord1

40103, 40104

2

DWord2

40105, 40106

2

DWord3

40107, 40108

2

DWord4

40109, 40110

2

DWord5

40111, 40112

2

DWord6

40113, 40114

2

DWord7

40115, 40116

2

DWord8

OWD 2/1-Wire module

40200

1

Integer

40201, 40202

2

DWord1

40203, 40204

2

DWord2

…

1-Wire Controller 1

Art. No. 11337

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11337 V2.0 R1.0 Manual Page 9 of 10

17 Operating conditions

The operation of the assembly group can take place only on condition of observing the required voltage

and the ambient conditions. The operating position of the device is irrelevant. The device is meant to be

used in dry and dust-free areas.

Should condensed water build up, an acclimatization period of at least 2 hours must pass.

Assembly groups and components do not belong into the hands of children!

The building group can be operated only under the supervision of an electrically skilled person.

In industrial facilities, the accident prevention regulations of the federation of industrial professional

associations for electrical installations and equipments must be observed.

Do not operate the assembly group in an environment with inflammable gases, vapours or dusts or in an

environment where such gases, vapours or dusts may be found.

18 Assembly

The location of the assembly must be protected against humidity. The device may be used only in dry

inside spaces and protected outside areas. The device is designed to be assembled as a fixed device

within a switchboard.

19 Disposal note

Do not dispose of the device within the household waste!

According to the directive concerning old electrical and electronic appliances,

electronic devices must be disposed of via the collecting points for old electronic

appliances!

20 Safety instructions

When using products that come into contact with electrical voltage, the valid VDE regulations must be observed,

especially VDE 0100, VDE 0550/0551, VDE 0700, VDE 0711 and VDE 0860

All final or wiring work must be carried out with the power turned off.

Before opening the device, always unplug or make sure that the unit is disconnected from the mains.

Components, modules or devices may only be put into service if they are mounted in a contact proof housing.

During installation they must not have power applied.

Tools may only be used on devices, components or assemblies when it is certain that the devices are

disconnected from the power supply and electrical charges stored in the components inside the device have

been discharged.

Live cables or wires to which the device or an assembly is connected, must always be tested for insulation faults

or breaks.

If an error is detected in the supply line, the device must be immediately taken out of operation until the faulty

cable has been replaced.

When using components or modules it is absolutely necessary to comply with the requirements set out in the

accompanying description specifications for electrical quantities.

If the available description is not clear to the non-commercial end-user what the applicable electrical

characteristics for a part or assembly are, how to connect an external circuit, which external components or

additional devices can be connected or which values these external components may have, a qualified

electrician must be consulted.

It must be examined generally before the commissioning of a device, whether this device or module is basically

suitable for the application in which it is to be used.

In case of doubt, consultation with experts or the manufacturer of the components used is absolutely necessary.

For operational and connection errors outside of our control, we assume no liability of any kind for any resulting

damage.

Kits should be returned without their housing when not functional with an exact error description and the

accompanying instructions. Without an error description it is not possible to repair. For time-consuming assembly

or disassembly of cases charges will be invoiced.

During installation and handling of components which later have mains potential on their parts, the relevant VDE

regulations must be observed.

Devices that are to be operated at a voltage greater than 35 VDC / 12mA, may only be connected by a qualified

electrician and put into operation.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 11337 V2.0 R1.0 Manual Page 10 of 10

Commissioning may only be realized if the circuit is built into a contact proof housing.

If measurements with an open housing are unavoidable, for safety reasons an isolating transformer must be

installed upstream or a suitable power supply can be used.

After installing the required tests according to DGUV / regulation 3 (German statutory accident insurance,

https://en.wikipedia.org/wiki/German_Statutory_Accident_Insurance) must be carried

21 Warranty

ESERA GmbH guarantees that the goods sold at the time of transfer of risk to be free from material and workmanship

defects and have the contractually assured characteristics. The statutory warranty period of two years begins from date

of invoice. The warranty does not extend to the normal operational wear and normal wear and tear. Customer claims

for damages, for example, for non-performance, fault in contracting, breach of secondary contractual obligations,

consequential damages, damages resulting from unauthorized usage and other legal grounds are excluded. Excepting

to this, ESERA GmbH accepts liability for the absence of a guaranteed quality resulting from intent or gross negligence.

Claims made under the Product Liability Act are not affected.

If defects occur for which the ESERA GmbH is responsible, and in the case of replacement goods, the replacement is

faulty, the buyer has the right to have the original purchase price refunded or a reduction of the purchase price.

ESERA GmbH accepts liability neither for the constant and uninterrupted availability of the ESERA GmbH or for

technical or electronic errors in the online offer.

We develop our products further and we reserve the right to make changes and improvements to any of the products

described in this documentation without prior notice. If you need documentation or information about older product

22 Trademarks

All mentioned designations, logos, names and trademarks (including those which are not explicitly marked) are

trademarks, registered trademarks or other copyright or trademarks or titles or legally protected designations of their

respective owners and are hereby expressly recognized as such by us. The mention of these designations, logos,

names and trademarks is made for identification purposes only and does not represent a claim of any kind on the part

of ESERA GmbH on these designations, logos, names and trademarks. Moreover, from their appearance on

ESERA GmbH webpages it cannot be concluded that designations, logos, names and trademarks are free of

commercial property rights.

ESERA and Auto-E-Connect are registered trademarks of ESERA GmbH.

23 Contact

ESERA GmbH

Adelindastrasse 20

87600 Kaufbeuren

GERMANY

Tel.: +49 8341 999 80-0

Fax: +49 8341 999 80-10

www.esera.de

WEEE-Number: DE30249510

This manual suits for next models

1

Table of contents

Other esera automation Gateway manuals

Popular Gateway manuals by other brands

SmartSavy

SmartSavy Serial GSM Gateway Software configuration guide

D-Link

D-Link DVG-3104MS - VoiceCenter PSTN Gateway user manual

Ericsson

Ericsson EDACS Jessica Operator's manual

Lütze

Lütze LOCC-Box-GWPN 0-6457 operating instructions

Sygonix

Sygonix 1898921 operating instructions

RTA

RTA 460ETCMC-N700 Product user guide